What is a clutch slave cylinder?

2025.08.26

2025.08.26

Industry News

Industry News

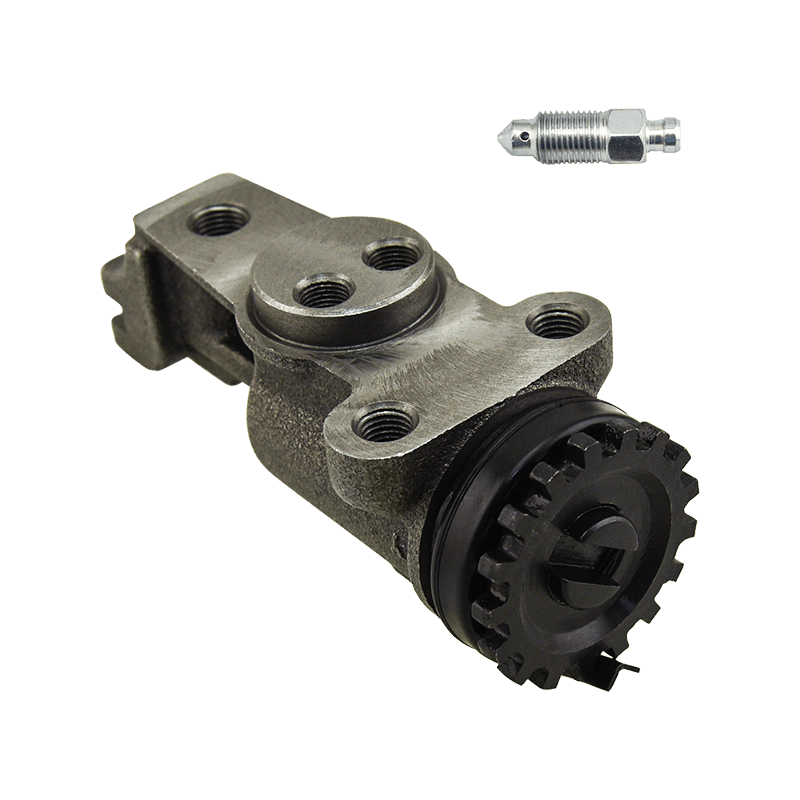

The clutch slave cylinder (also known as the clutch slave cylinder) is the core actuator in the hydraulic clutch system, responsible for converting hydraulic pressure into mechanical action, pushing the clutch release bearing, thereby disengaging and engaging the clutch.

Content

1. Clutch Slave Cylinder Structure and Operating Principle

Structural Components

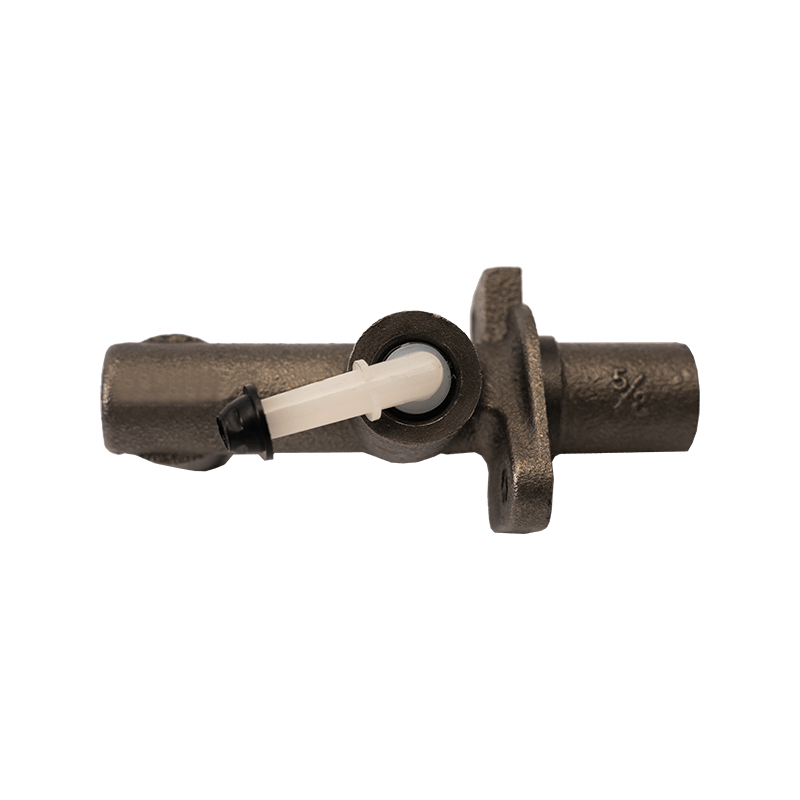

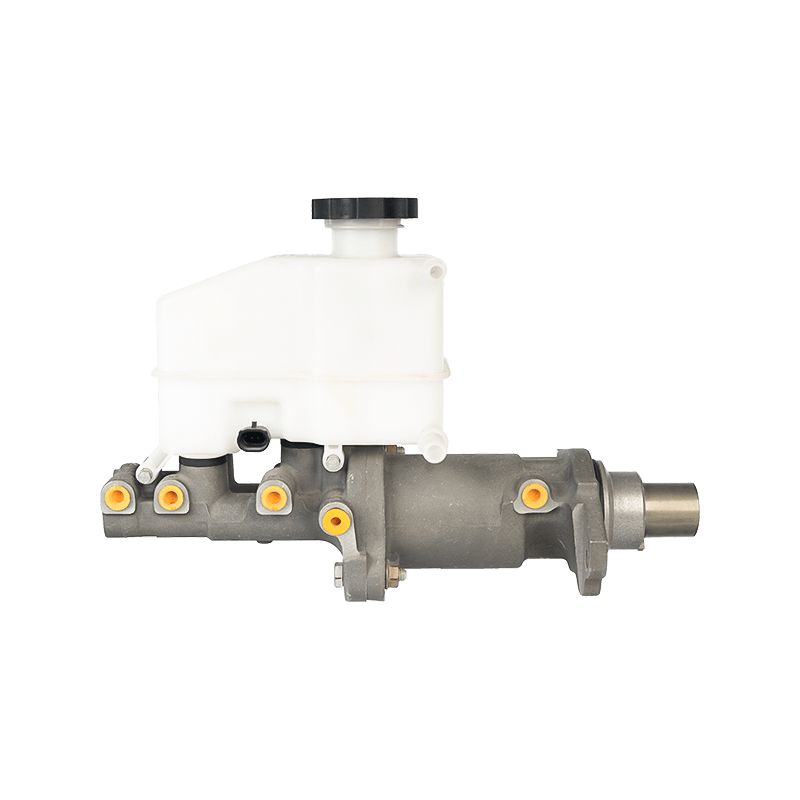

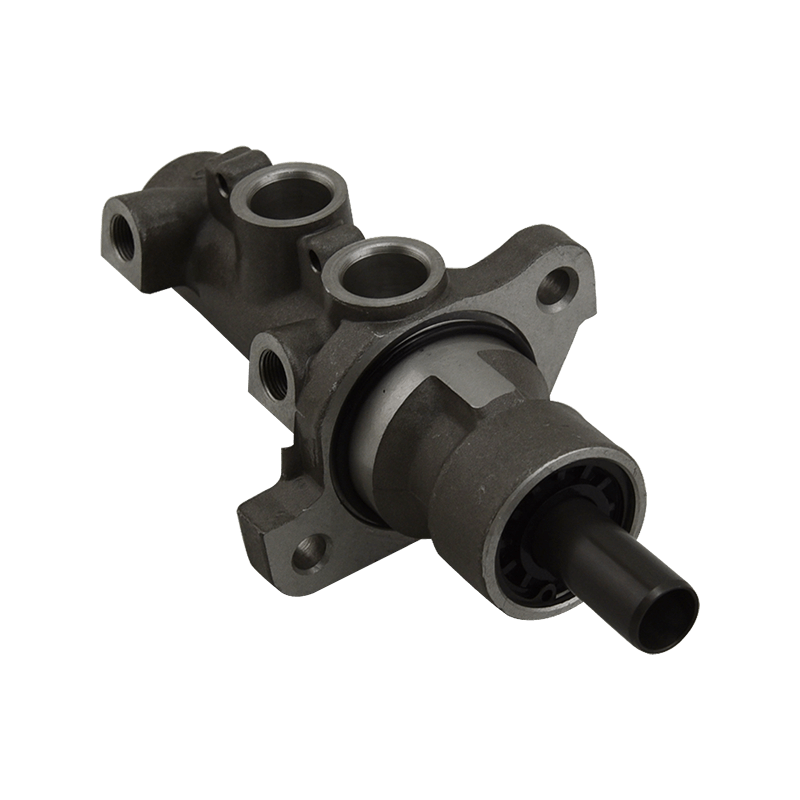

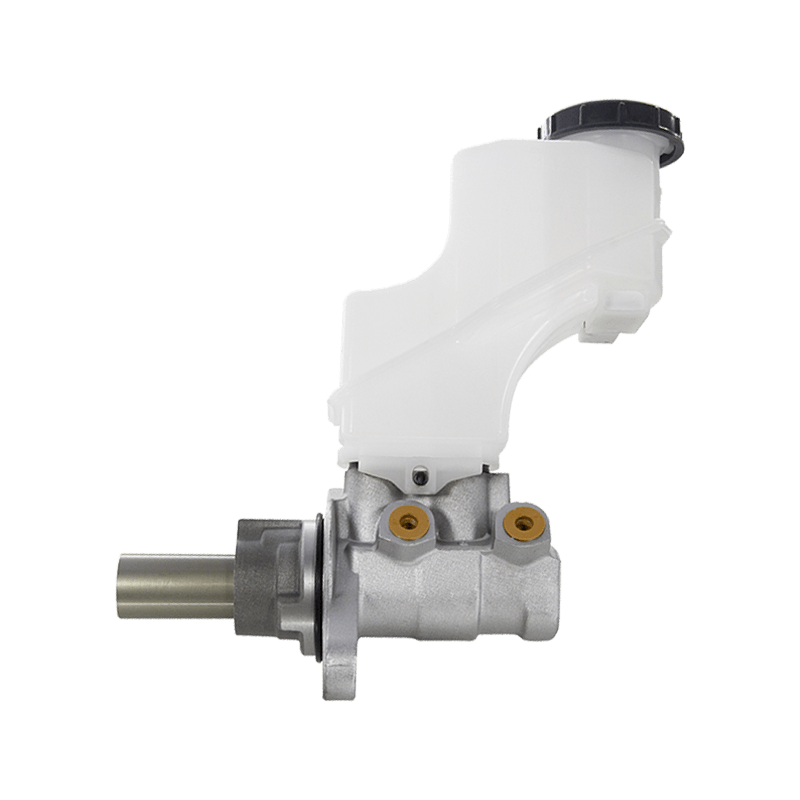

Cylinder body: Typically made of aluminum alloy or cast iron, containing the piston.

Piston and pushrod: The piston is driven by hydraulic pressure and connected to the clutch release bearing via the pushrod.

Dust boot: Prevents dust from entering the cylinder body and protects the piston seal.

Oil inlet: Connects to the hydraulic line and receives hydraulic oil from the clutch master cylinder.

Operating Principle

When the clutch pedal is pressed, hydraulic pressure is generated in the clutch master cylinder (master cylinder), which is transmitted through the oil pipe to the slave cylinder.

Hydraulic pressure pushes the piston: The oil pressure pushes the piston in the slave cylinder, driving the pushrod forward. Release bearing action: The push rod pushes the clutch release bearing against the pressure plate spring, separating the clutch plate from the flywheel and cutting off power transmission.

Releasing the pedal: Hydraulic pressure is released, the piston returns to its original position under the action of the return spring, and the clutch reengages.

2. Function of the Clutch Slave Cylinder

|

Function |

Description |

|

Power Transmission Control |

Enables quick clutch disengagement and smooth engagement through hydraulic-mechanical linkage. |

|

Force Amplification |

Amplifies the driver's pedal force through the hydraulic system, reducing operating effort (especially suitable for heavy vehicles). |

|

Precise Adjustment |

The hydraulic system's responsiveness allows precise control of clutch travel to prevent slippage or incomplete disengagement. |

3. Common Clutch Slave Cylinder Faults and Symptoms

Hydraulic Leak

Symptom Verification:

After depressing the clutch pedal, observe the ground or transmission case for fluid leakage.

Check the oil tank level to see if it continues to drop.

Emergency Action:

If the leakage is severe, stop driving immediately (the clutch may fail suddenly).

Piston Stuck

Diagnostic Steps:

Depress the pedal and observe whether a strong force is required to operate it.

After releasing the pedal, listen for a continuous grinding noise from the release bearing (the piston has not fully returned).

Root Cause:

A damaged dust boot allows dust and moisture to enter the cylinder, increasing resistance to piston movement.

Push Rod Problem

Quick Inspection:

Remove the slave cylinder dust boot and manually push the push rod. If it is stuck or cannot be moved, replace the slave cylinder.

Consequential Damage:

A broken push rod may also damage the release bearing and should be inspected simultaneously.

Hydraulic System Air Intake

Test Method:

Continuously and rapidly press the pedal. If pedal force gradually recovers, there is air in the system.

Solution:

Re-bleed the air (requires two people to simultaneously loosen the slave cylinder bleed screw while pressing the pedal).

4. Key points for maintaining the clutch slave cylinder

Daily Inspection and Basic Maintenance

- Hydraulic Oil Inspection

Fluid Level: Check the clutch oil reservoir regularly. The fluid level should be between "MIN" and "MAX." If it is too low, refill with the same type of hydraulic oil.

Fluid Condition: If the fluid is cloudy, black, or contains impurities, replace it immediately (recommended every two years or 40,000 kilometers).

- Leak Check

Slave Cylinder Body: Observe the connection between the transmission and the slave cylinder for oil stains (commonly seen with aging seals).

Hydraulic Hoses and Joints: Inspect metal/rubber hoses for cracks and loose joints.

- Pedal Condition Monitoring

Pedal Force: There should be some resistance when depressing the clutch pedal. If it becomes soft or sinks, there may be air ingress or a leak in the hydraulic system.

Rebound Speed: The clutch pedal should return quickly after being released. If it rebounds slowly, there may be a piston sticking or a blockage in the oil line.

Regular Maintenance Items

- Sealing Ring and Dust Boot Maintenance

Dust Boot Inspection: Check the slave cylinder dust boot monthly for damage (damage allows dust and moisture to enter, accelerating piston wear).

Seal Replacement: Replace the piston seal every 50,000 kilometers or if an oil leak is detected (this is a low-cost option and can prevent major failures).

- Hydraulic System Bleeding

When to bleed: After changing the hydraulic oil, or if the pedal becomes soft or travel becomes longer.

Bleeding Procedure:

Fill the oiler with DOT4 oil. One person presses the pedal several times in succession inside the vehicle and then holds it down. Another person loosens the slave cylinder bleed screw (usually located on the back of the slave cylinder), releases the air, and then tightens it. Repeat until the pedal returns to normal force.

- Pushrod and Release Bearing Lubrication

Pushrod Lubrication: Apply a small amount of high-temperature grease (such as lithium-based grease) annually to prevent rust and seizure.

Release Bearing Inspection: When replacing the clutch assembly, inspect the slave cylinder pushrod for wear.

Search

Search

Eng

Eng

English

English Español

Español Português

Português