Specifications

KEEP IN TOUCH

We have more than 1,000 brake shoes and brake pads for European, American, Russian, Japanese and Korean cars. The associated factories have created a highly experienced manufacturing team that exports thousands of auto part products worldwide. High quality and competitive prices are our targets. Our products have gained the certifications of ISO9001 and TS16949. We have built up a solid reputation with our customers in more than 30 countries.

We are looking forward to having a brighter and more successful business in the near future together with all of our clients all over the world.

-

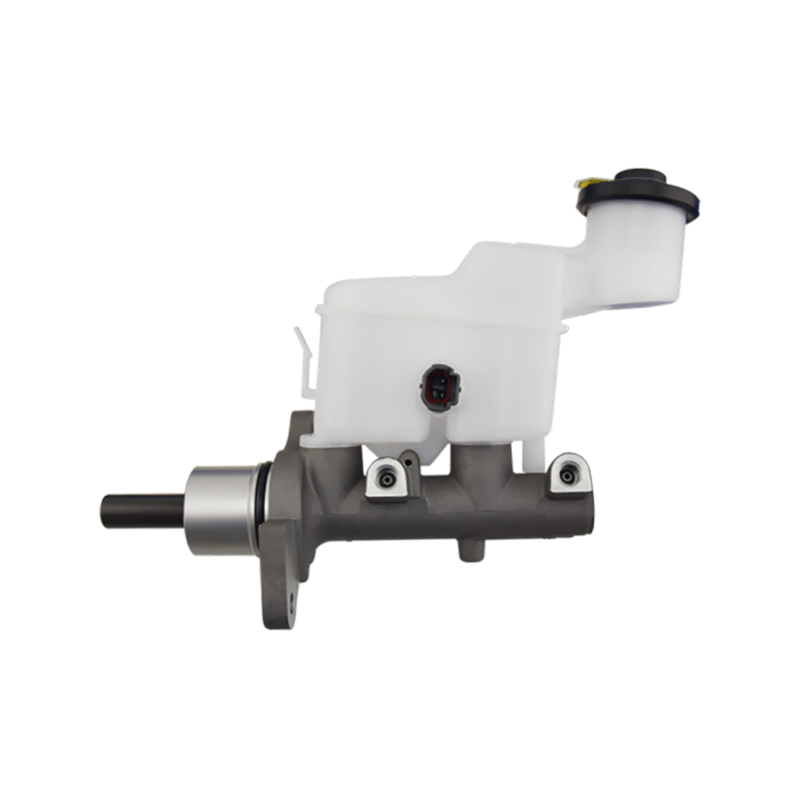

What is a Hydraulic Brake Master Cylinder? The hydraulic brake master cylinder is a critical component in a vehicle's braking system. It converts the...

READ MORE -

Why OE Quality Brake Pads Are the Best Choice for Your Car OE (Original Equipment) quality brake pads are specifically designed to match the specific...

READ MORE -

The direct answer: Yes. High-quality brake pads can reduce braking distance by 15%–30%, improve heat resistance, and significantly enhance driving saf...

READ MORE -

The automobile brake system is one of the most critical safety components in any vehicle. It controls speed, enables smooth stopping, and prevents acc...

READ MORE

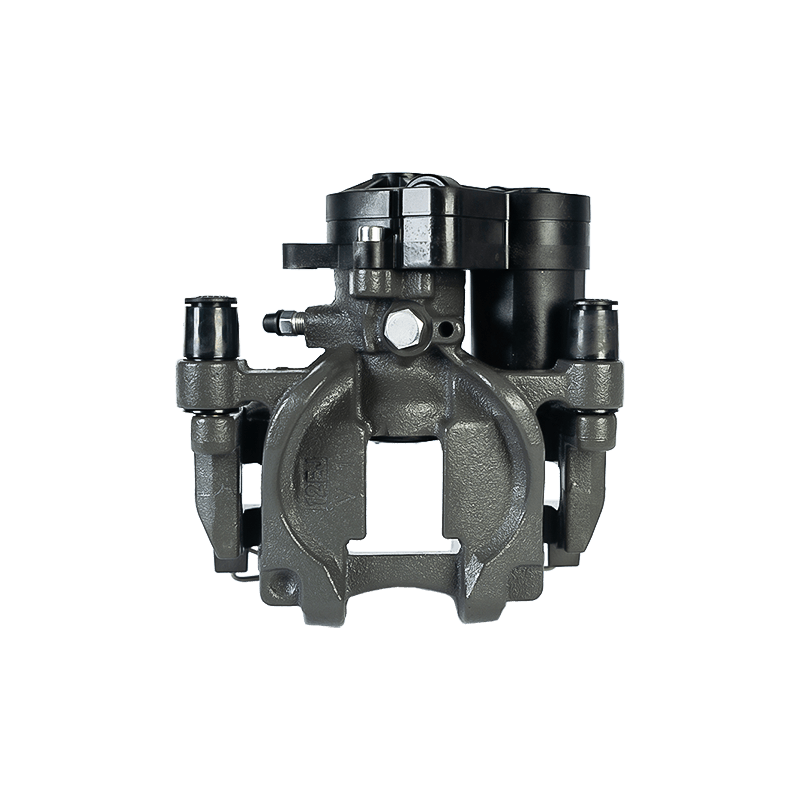

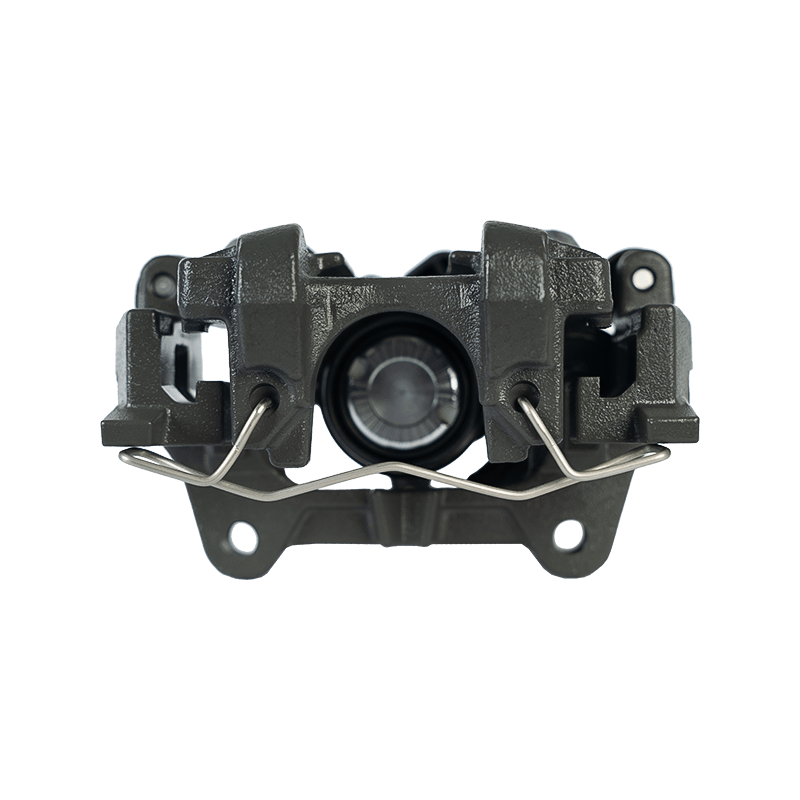

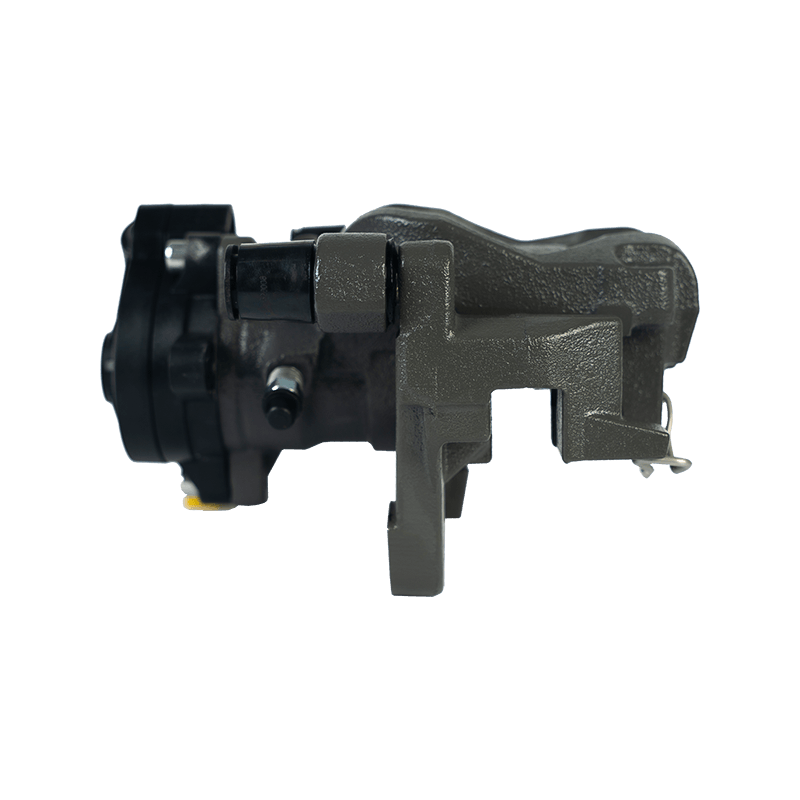

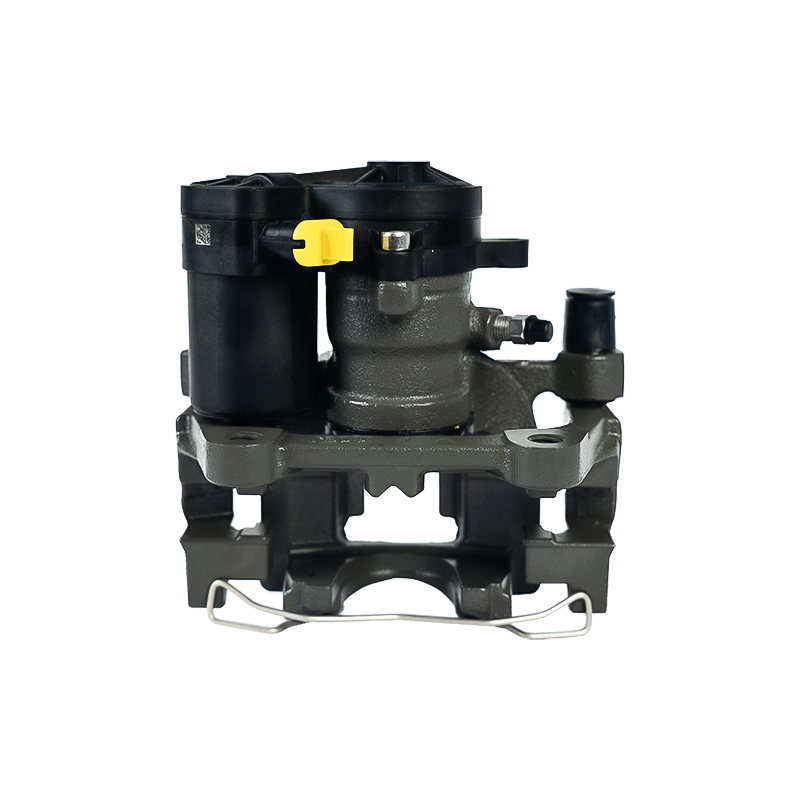

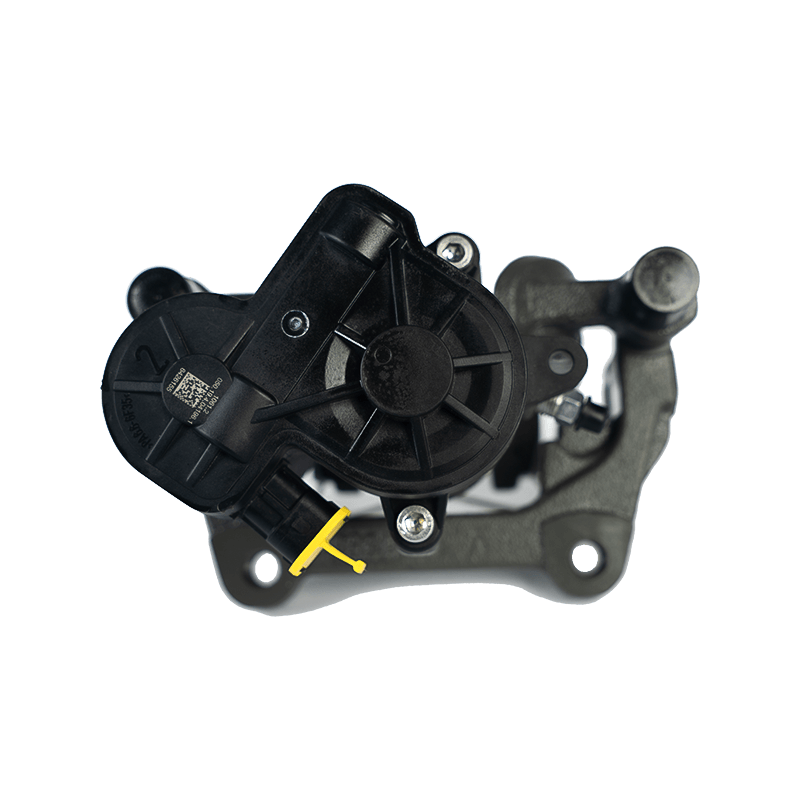

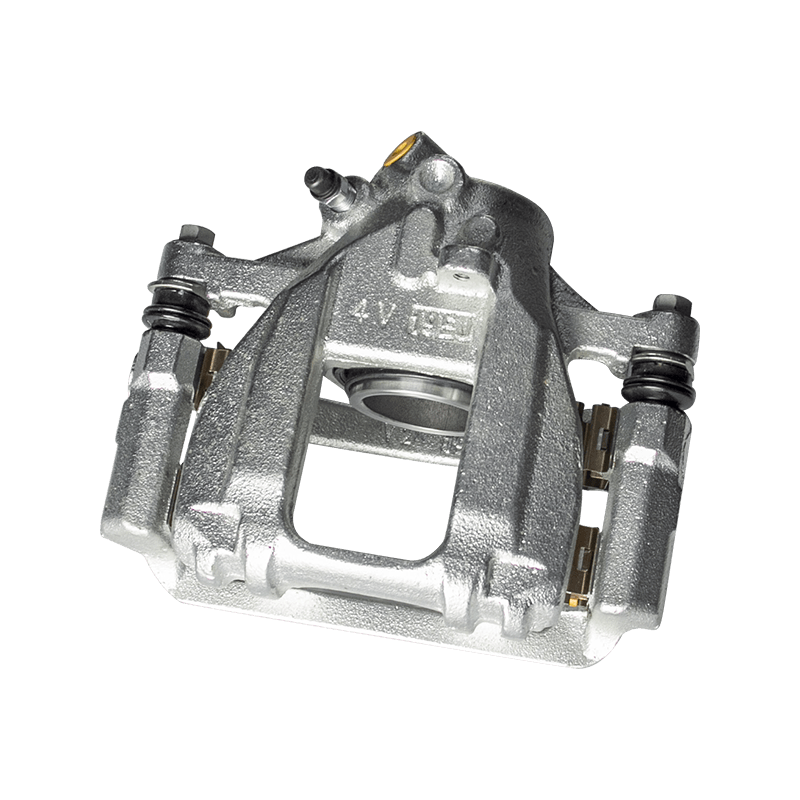

As the core brake component certified by the original manufacturer, Ford's special DG9Z2553B brake caliper has become the cornerstone of brake safety for many models with its precise engineering design and industrial-grade durability. This caliper strictly follows Ford's global manufacturing standards and is made of high-strength cast iron. It is suitable for solid brake discs with a diameter of 282mm. The single-sided single piston (diameter 48mm) design can output a braking torque of 4200N·m. The measured 100-0km/h braking distance is stable within 39.5 meters, which is 8% shorter than ordinary aftermarket parts.

In terms of material science and process innovation, DG9Z2553B demonstrates the technical advantages of original accessories. The cast iron body is formed by low-pressure sand casting process, the internal porosity is controlled below 0.3%, and X-ray flaw detection is performed to ensure structural integrity. Its sealing system is upgraded to fluororubber material, and its anti-aging performance is 3 times higher than that of traditional nitrile rubber. With the double-channel dust cover design, it can effectively resist the erosion of mud and water.

In actual application, the caliper's wavy cooling fins and vortex guide groove design can reduce the friction interface temperature from 600°C to 180°C within 90 seconds. After replacing the brake pedal, the dead space is reduced by 25%, the dust generation is reduced by 60%, and the wheel cleaning cycle is extended to more than 3 months. The new energy adaptation version further optimizes the collaborative efficiency with the energy recovery system, and the braking delay is shortened to 0.18 seconds, which is particularly suitable for the frequent start-stop needs of plug-in hybrid vehicles.

Search

Search

Eng

Eng

English

English Español

Español Português

Português