How can I extend the life of my car's hydraulic clutch master cylinder?

2025.09.03

2025.09.03

Industry News

Industry News

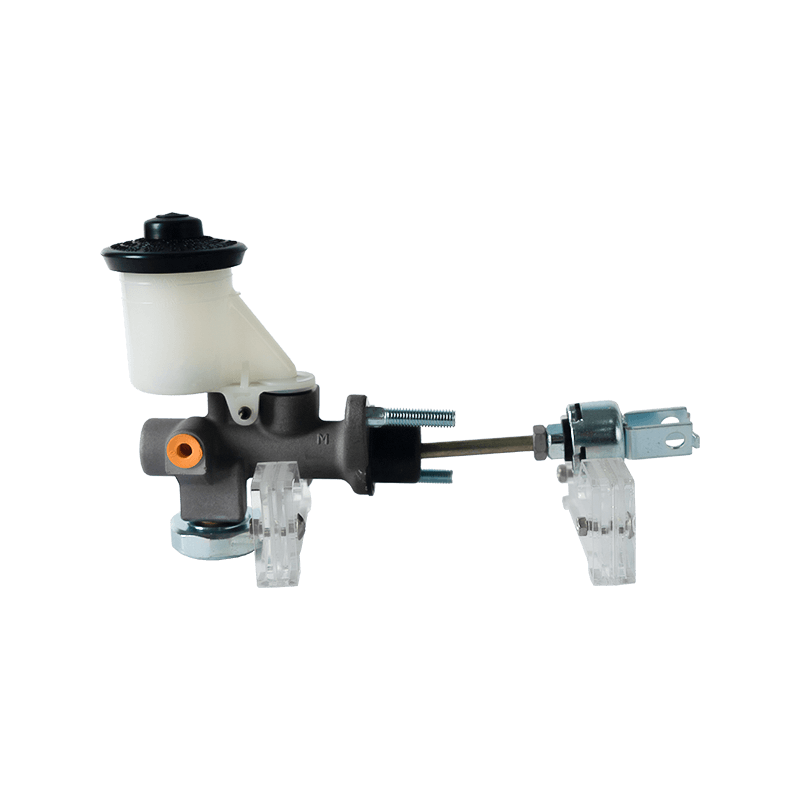

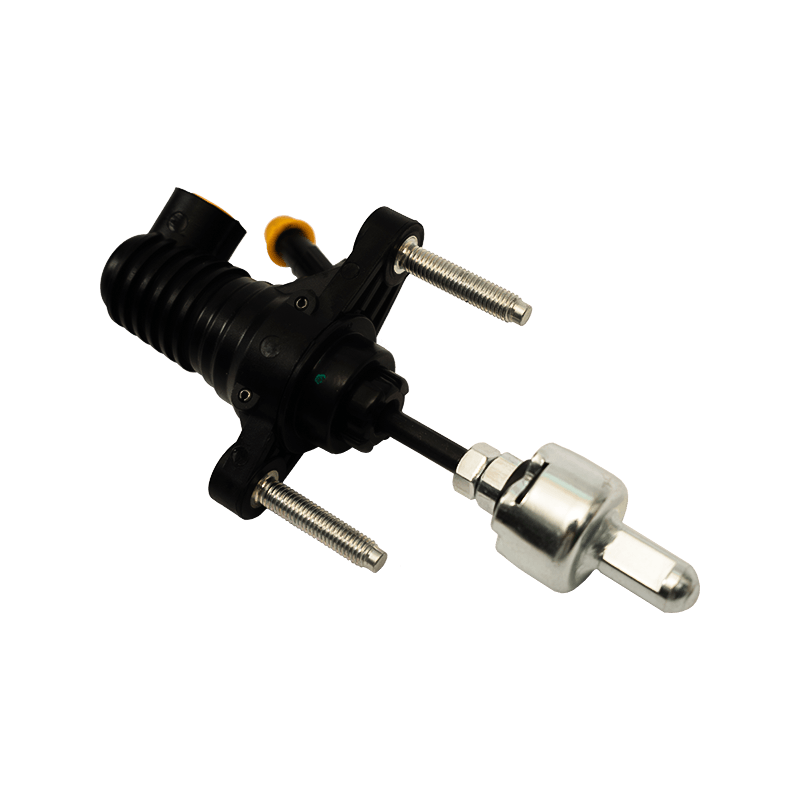

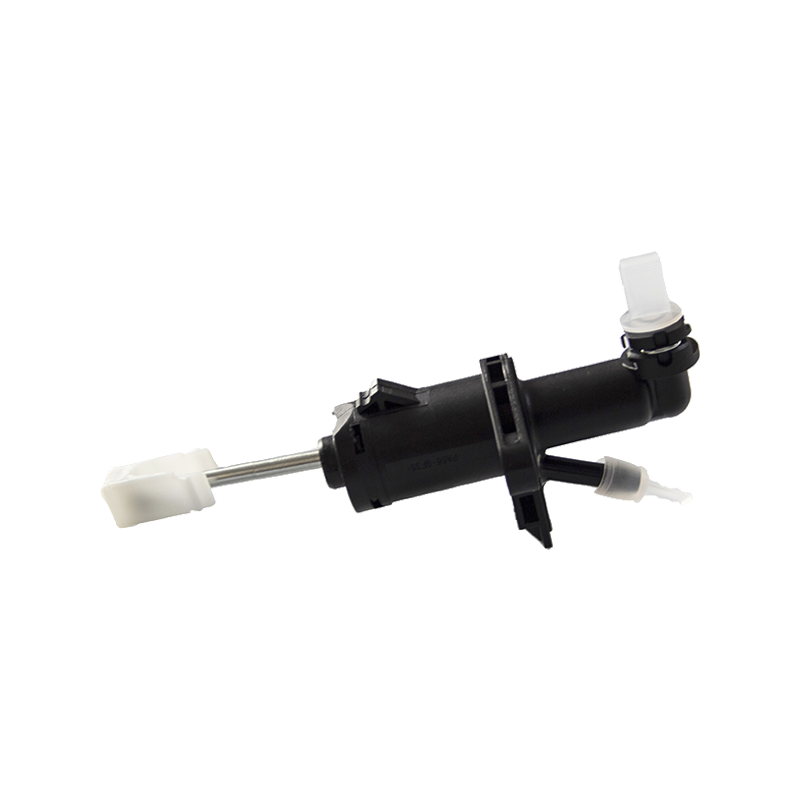

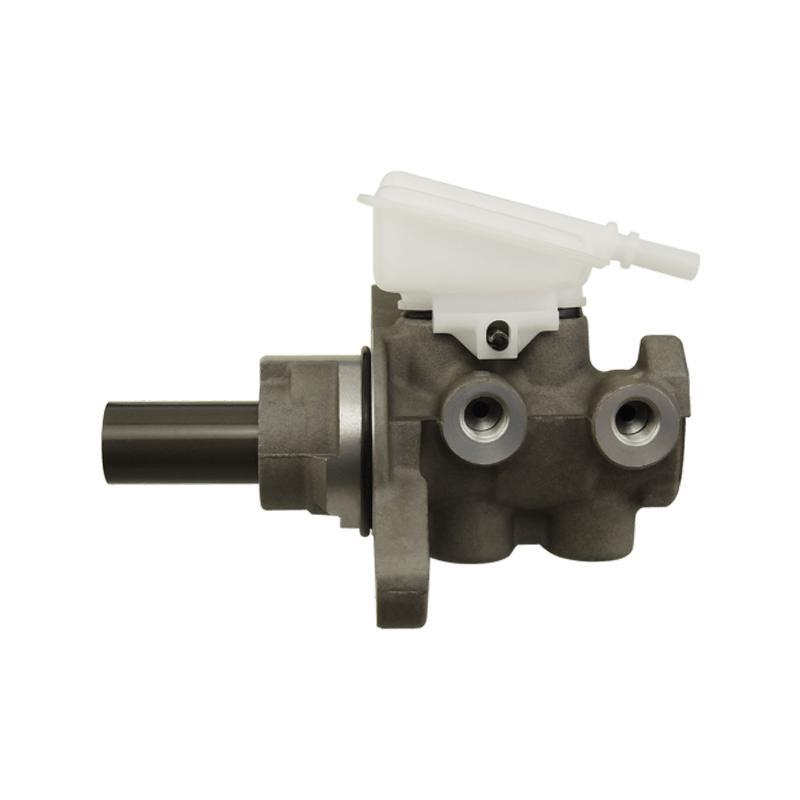

The hydraulic clutch master cylinder is a core component in manual transmission vehicles, and its lifespan directly impacts shifting smoothness and driving safety. Through scientific maintenance and standardized operation, its service life can be significantly extended (up to over 150,000 kilometers under normal operating conditions).

1. Standardize operating habits

Avoid misuse of the clutch pedal.

Control the clutch pedal time to less than 3 seconds (extended clutch operation will cause the master cylinder oil temperature to rise to 120°C+, accelerating seal aging).

When starting on a hill, it is recommended to use the parking brake to reduce the load on the master cylinder.

Optimize clutch pedal operation.

Pedal force ≤ 50N (excessive force can cause piston impact wear).

Replenish fluid after fully releasing the pedal (to prevent residual pressure in the hydraulic system).

Do not operate with the clutch held in the air.

Ensure the clutch is fully released when releasing the pedal (partial pressure will cause the compensation hole to remain closed).

2. Precision maintenance of the hydraulic system

Brake fluid management.

Replace DOT4 brake fluid every 2 years or 40,000 kilometers (replacement is mandatory if the water content exceeds 3%).

Use low-viscosity brake fluid (such as DOT4). LV, viscosity ≤750mm²/s at -40°C)

Ensure thorough exhaustion

Use pressure-type exhaust equipment (traditional foot-operated methods have a 25% chance of residual bubbles).

After exhaustion, the liquid level should be 10-15mm above the tank opening (overfilling can cause blockage of the compensation hole).

Pipeline system inspection

Monthly check hose expansion (diameter expansion >5% requires replacement).

Metal pipes must be replaced if rust >30% of the area is covered.

3. Key component maintenance

Master cylinder dust boot maintenance

Clean and apply silicone-based grease every 30,000 km (to prevent dust intrusion and piston wear).

Damaged dust boots should be replaced within 48 hours.

Push rod clearance adjustment

Maintain 0 0.5-1mm free travel (excessive clearance will cause delayed opening of the compensation hole).

Measure with a feeler gauge (error ≤ 0.2mm).

Preventative seal replacement.

Replace the master cylinder repair kit (including the main and auxiliary rubber cups) every 80,000 kilometers.

Preferably use fluororubber (temperature resistant -40°C to 200°C).

4. Environmental Adaptability Protection

Extreme Temperature Protection.

Cold Regions: Install a master cylinder heating jacket (maintains oil temperature > -35°C).

High Temperature Regions: Use a metal oiler with cooling fins.

Corrosion Protection.

In coastal areas, spray the circuit board (master cylinder circuitry) with protective paint every six months.

Apply rust inhibitor to metal surfaces.

5. Fault Warning and Diagnosis

| Symptoms | Potential Problems | Interventions |

| Pedal force increased by 20% | Master cylinder primary seal failure | Replace the repair kit immediately |

| Pedal travel reduced by 1/3 | Compensation hole clogged | Clean the oil passages and change the oil |

| Abnormally low fluid level | Leaking in the slave cylinder or line | Locate the leak with a pressure test |

Search

Search

Eng

Eng

English

English Español

Español Português

Português