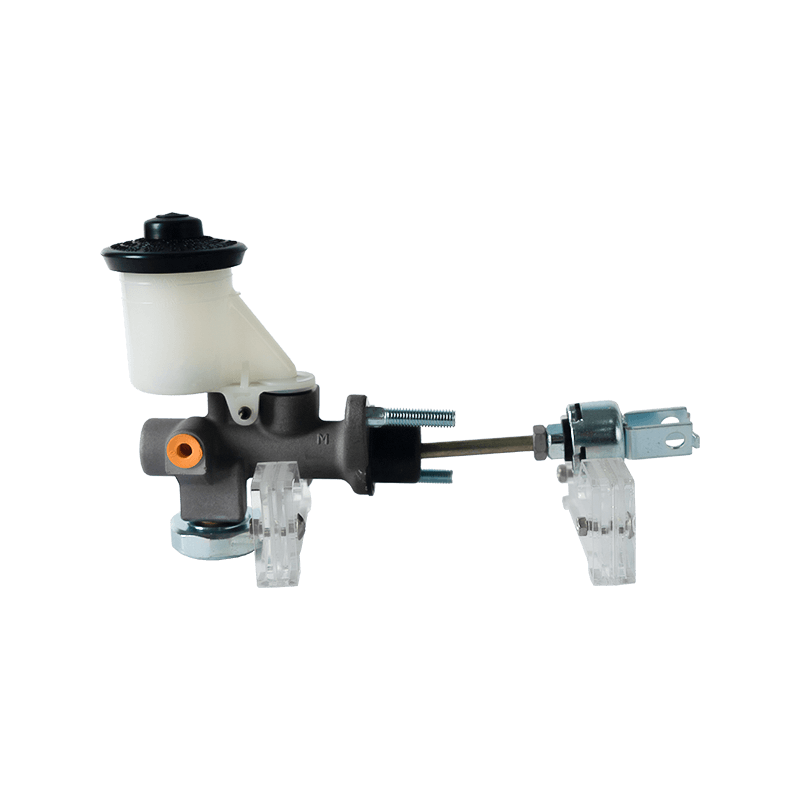

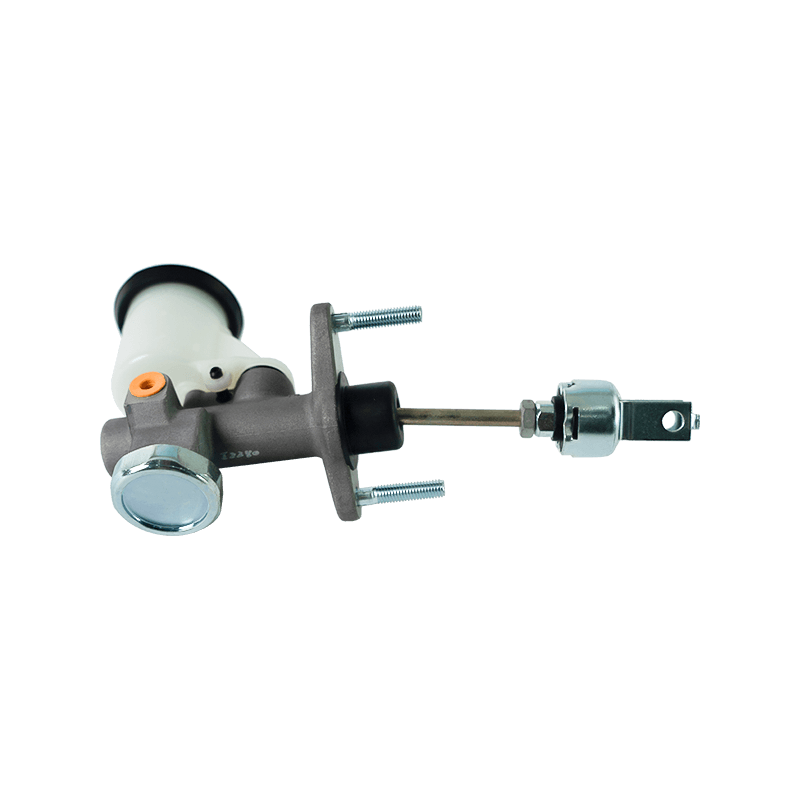

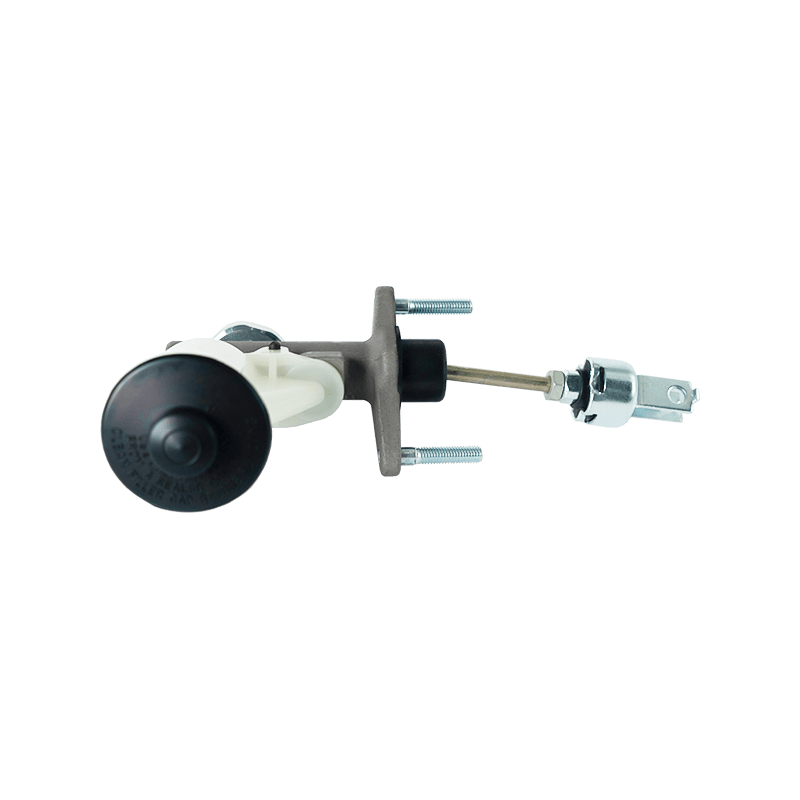

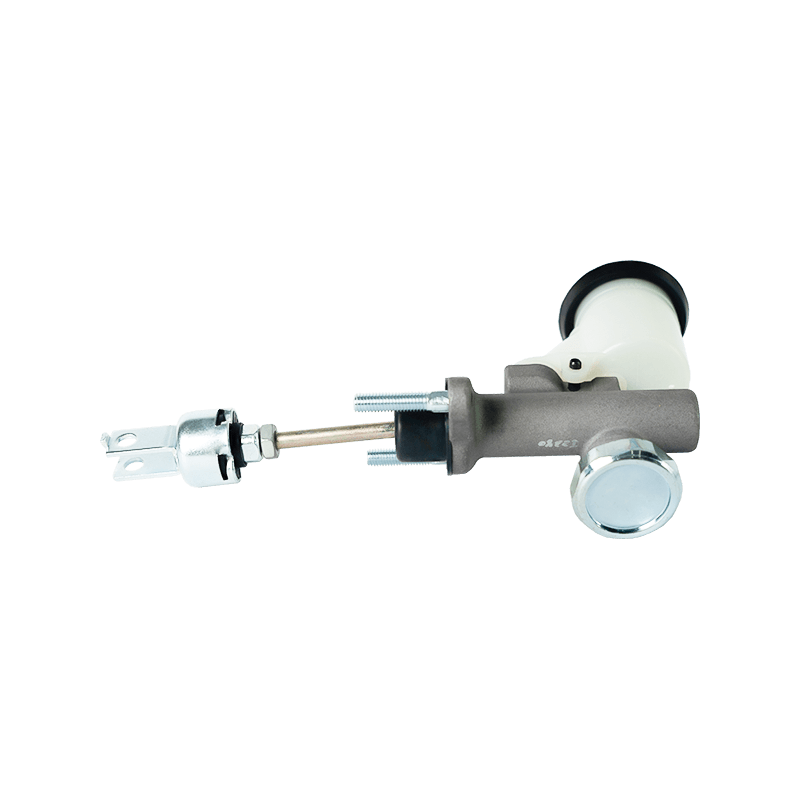

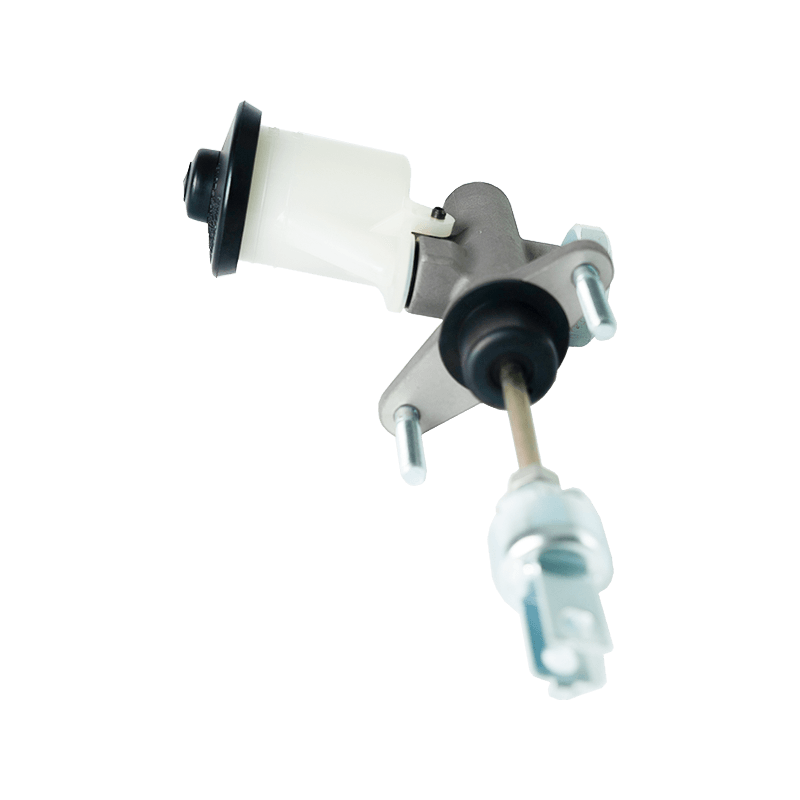

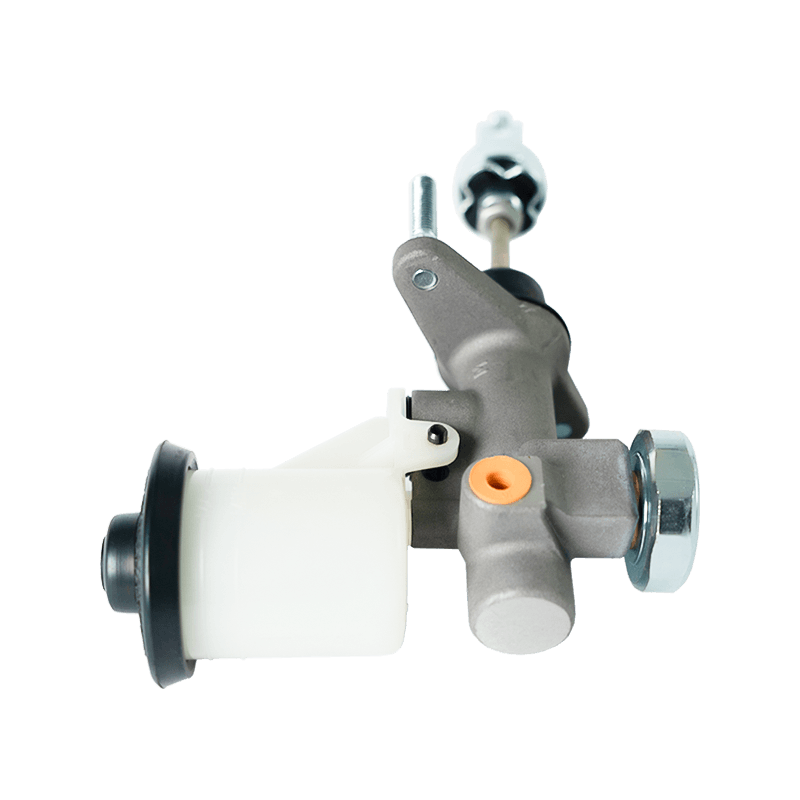

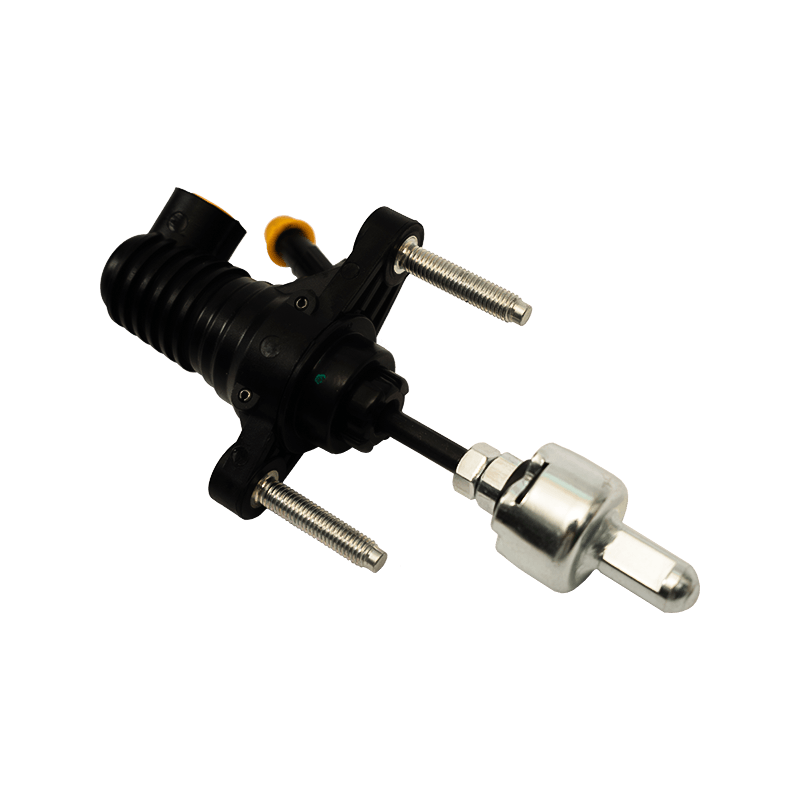

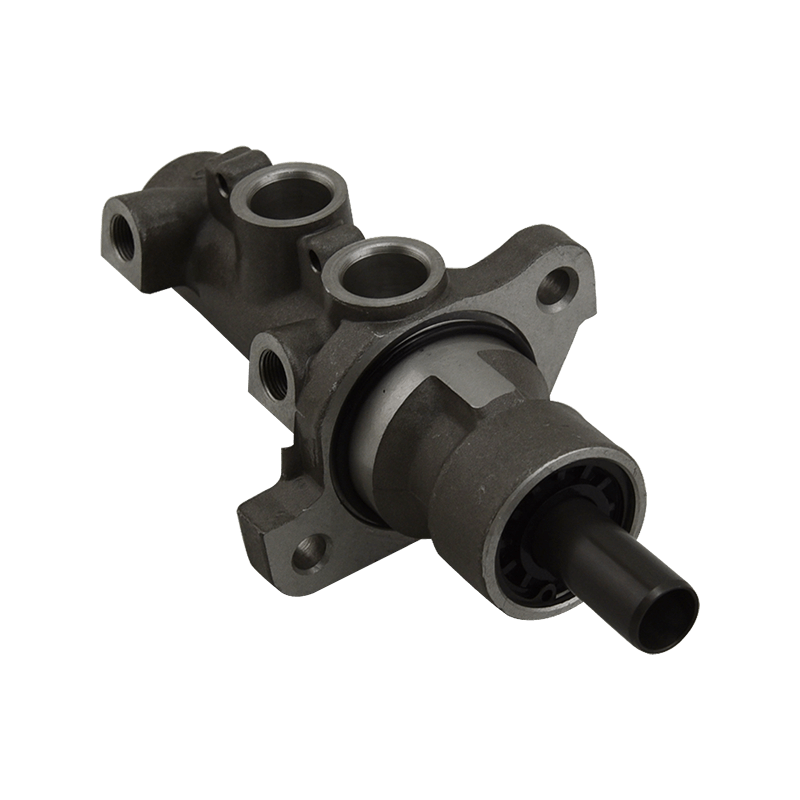

31410-38050 Clutch Master Cylinder for Toyota

CMC is a component of car clutch systems, specifically semi- and fully-hydraulic clutch systems. It transmits the pressure from the clutch pedal to the clutch itself, allowing the driver to engage and change gears.

|

OE NO |

31410-38050 |

|

DESCRIP |

CMC |

|

MODEL |

Toyota |

Specifications

KEEP IN TOUCH

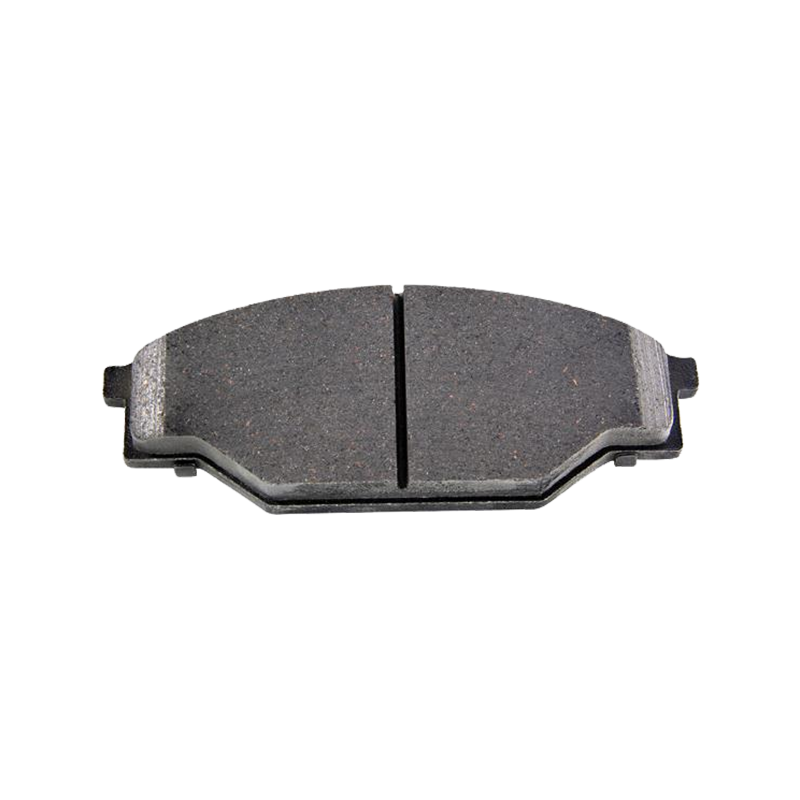

We have more than 1,000 brake shoes and brake pads for European, American, Russian, Japanese and Korean cars. The associated factories have created a highly experienced manufacturing team that exports thousands of auto part products worldwide. High quality and competitive prices are our targets. Our products have gained the certifications of ISO9001 and TS16949. We have built up a solid reputation with our customers in more than 30 countries.

We are looking forward to having a brighter and more successful business in the near future together with all of our clients all over the world.

-

The automobile brake system is one of the most critical safety components in any vehicle. It controls speed, enables smooth stopping, and prevents acc...

READ MORE -

When you're driving, you probably don’t think much about your brake system—until you need it. The brake system in your car is one of the most importan...

READ MORE -

Many customers often have these questions: "Are your brake pads wear-resistant?" "Will they make noise at high speeds?" "How long will they last? Will...

READ MORE -

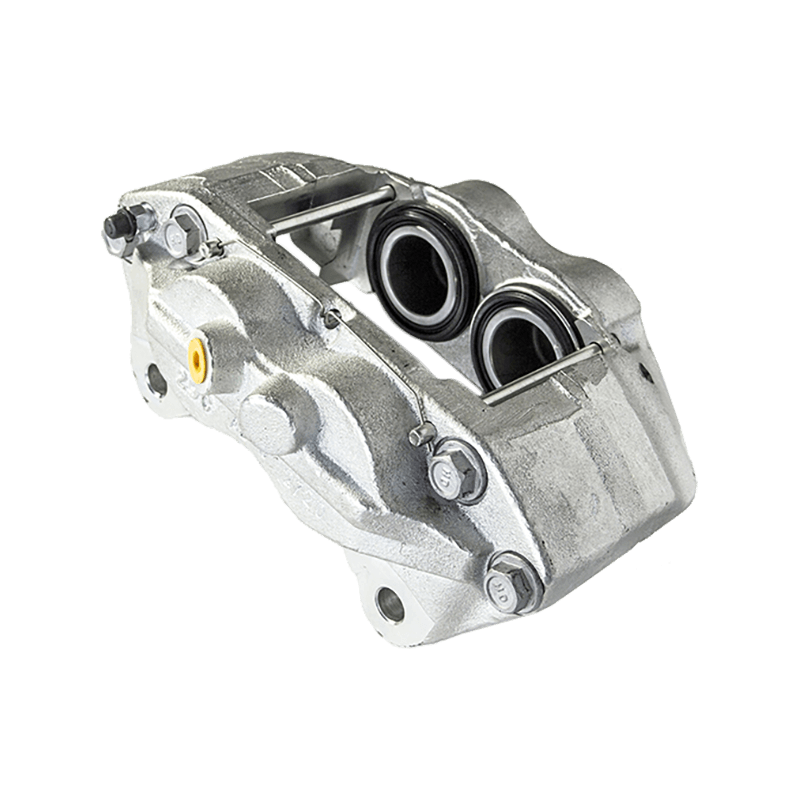

In everyday driving, many car owners encounter strange noises when braking, such as "squeaking," "clicking," or "grinding" sounds. The brake caliper i...

READ MORE

As the core component of Toyota's hydraulic clutch system, the 31410-38050 Clutch Master Cylinder For Toyota has become a key component to ensure the efficiency of vehicle power transmission with its precision design and reliable performance. This master cylinder converts the pedal operation into the mechanical movement of the release bearing through the hydraulic principle. When the driver steps on the clutch, the piston in the master cylinder compresses the hydraulic oil to generate pressure, which is transmitted to the slave cylinder through the pipeline to drive the release fork, so as to achieve smooth separation and engagement between the engine and the gearbox.

This model is specially designed to match Toyota's 2L engine and specific models, and can be adapted to a variety of classic models. It is manufactured strictly in accordance with the original OE standard (31410-38050), and the interface size and pipeline layout are consistent with Toyota's original parts, ensuring seamless installation without changing the body structure during the replacement process. The product uses a high-strength cast iron or aluminum alloy casting body, with wear-resistant PU sealing components and metal pistons inside, and a precision filter paper filtration system to effectively block impurities in the hydraulic oil. This multi-layer protection design allows the master pump to maintain stable output under extreme conditions of -40°C to 120°C, suitable for high-intensity use in Southeast Asian tropical climates and heavy-load transportation scenarios. The manufacturer has verified through bench testing that the component can withstand more than 500,000 pedaling cycles, and its service life is more than 60% longer than that of ordinary aftermarket parts.

Search

Search

Eng

Eng

English

English Español

Español Português

Português