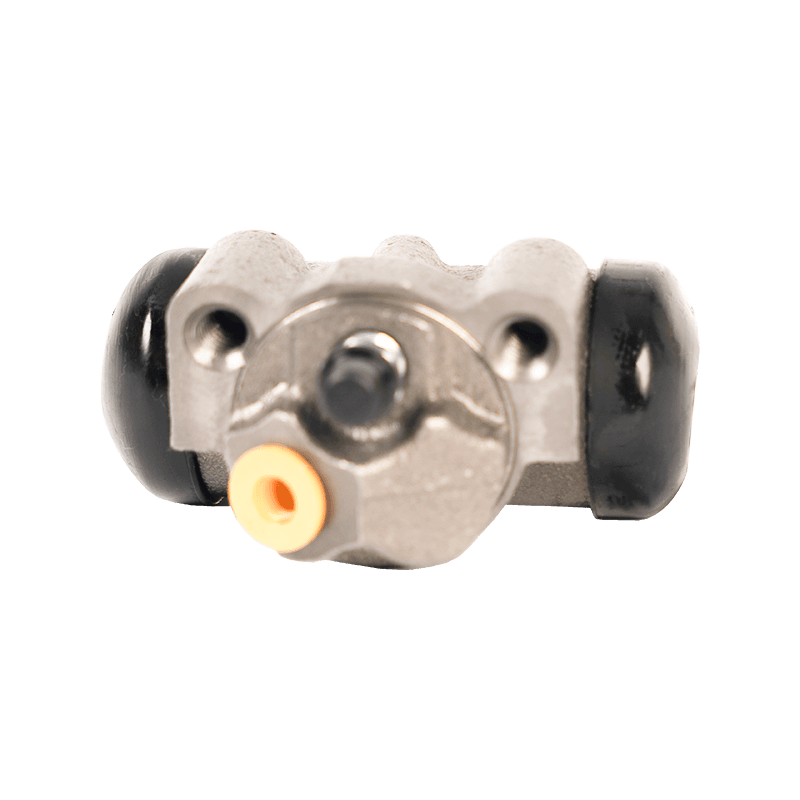

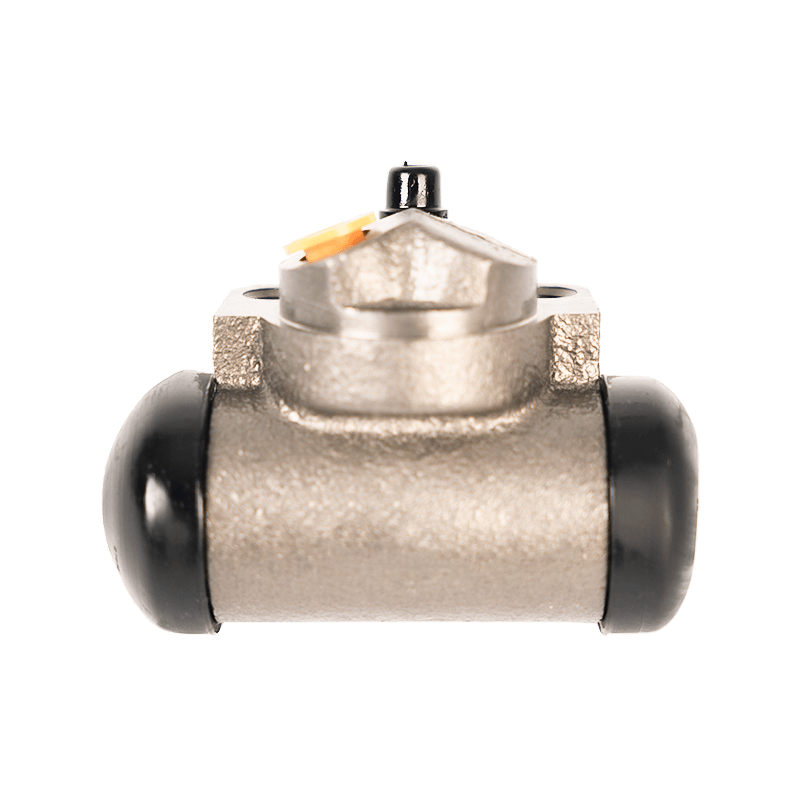

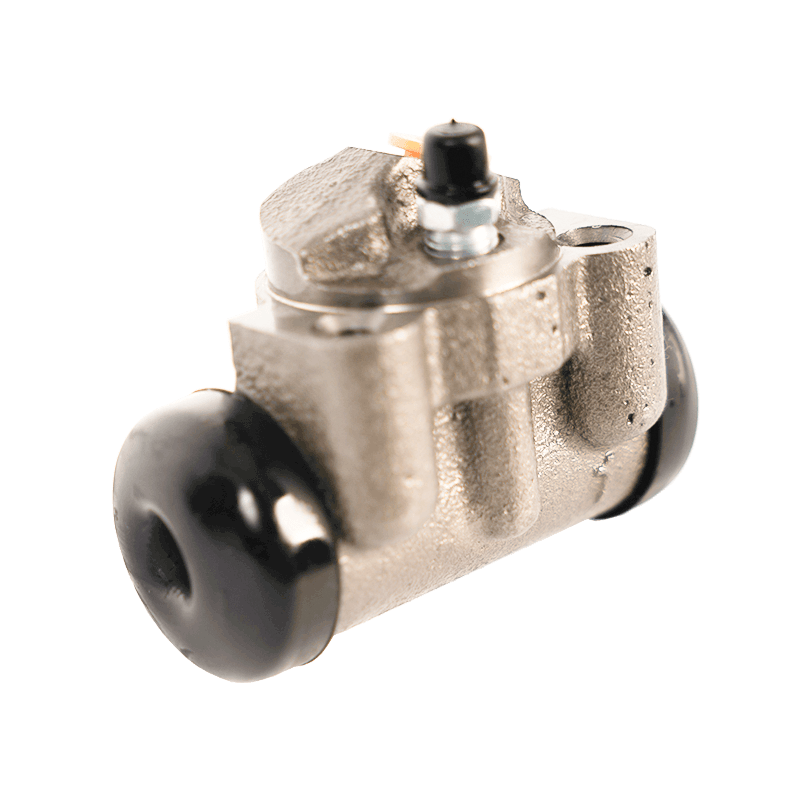

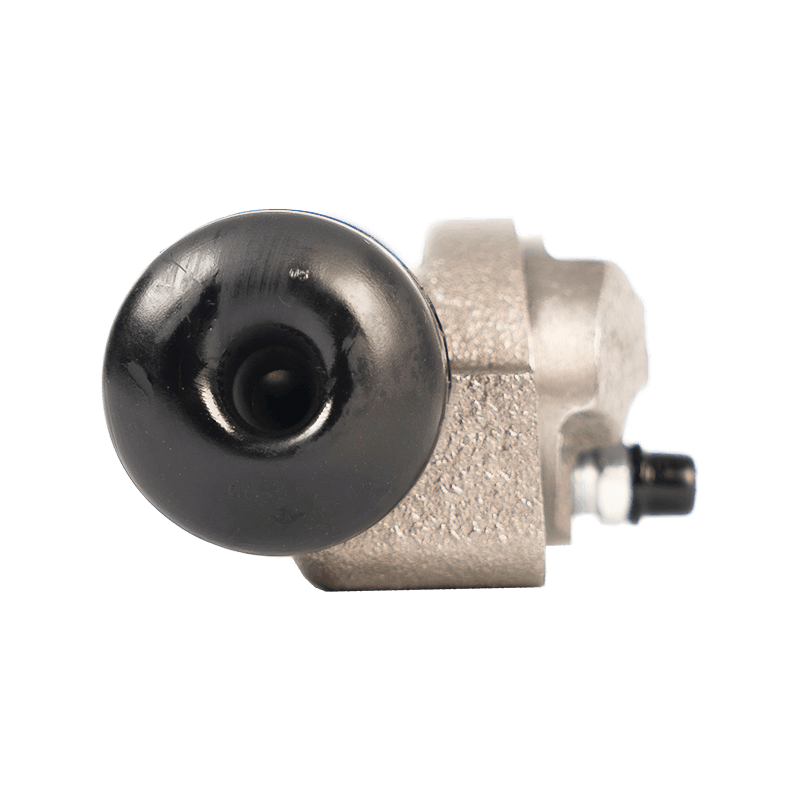

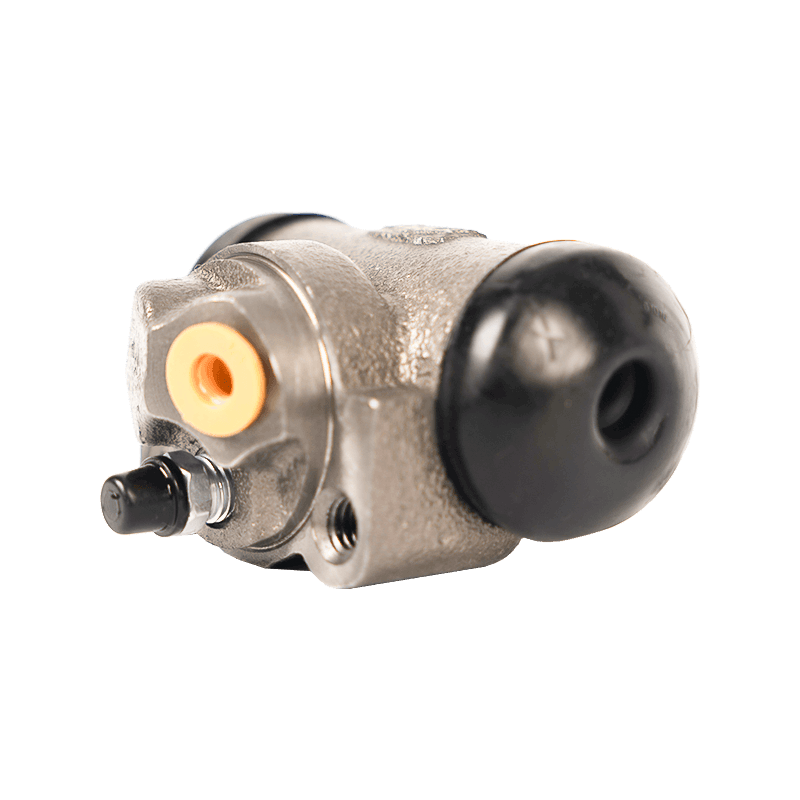

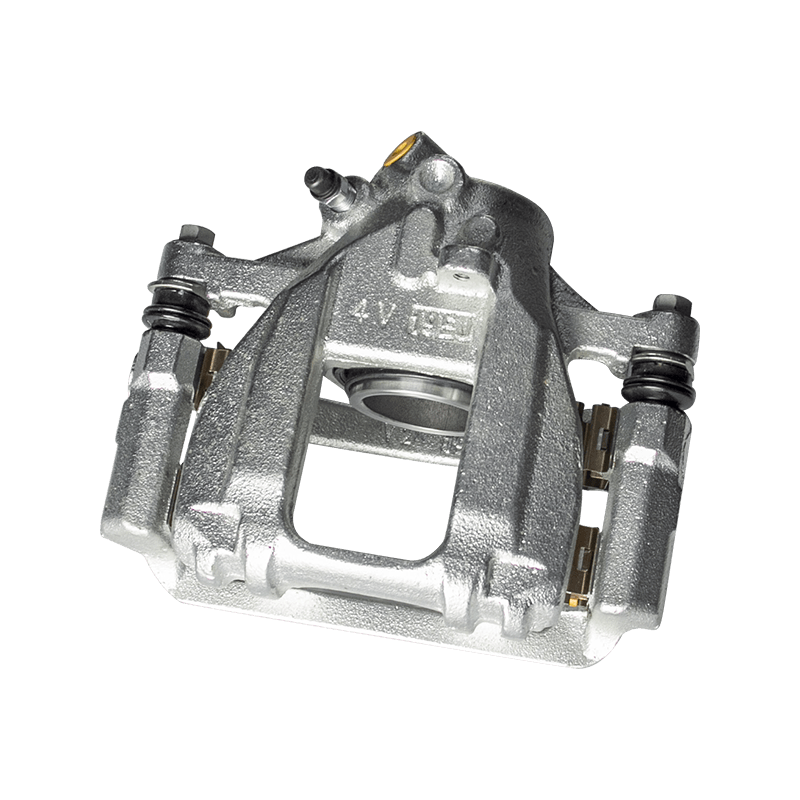

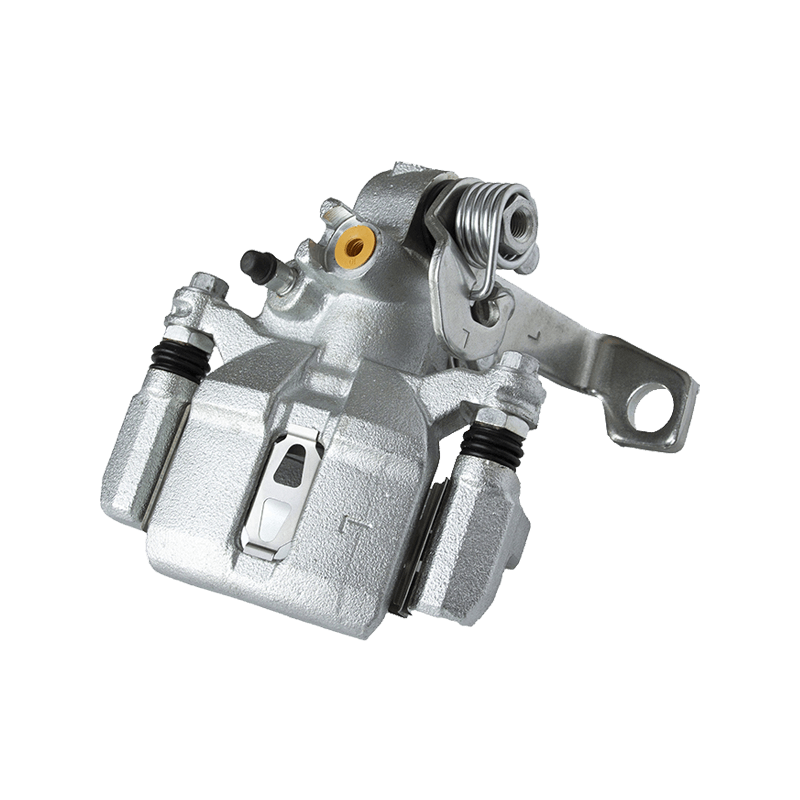

2S4611049 Brake Wheel Cylinder for Ford

It is usually mounted on the axle, near the wheel that is to be equipped for braking. Air pressure is fed through an inlet port. The air pushes against the diaphragm and the push rod. The push rod is connected by a clevis and pin to a crank arm-type lever called a 'slack adjuster.

|

OE NO |

2S4611049 |

|

MODEL |

Ford |

Specifications

KEEP IN TOUCH

We have more than 1,000 brake shoes and brake pads for European, American, Russian, Japanese and Korean cars. The associated factories have created a highly experienced manufacturing team that exports thousands of auto part products worldwide. High quality and competitive prices are our targets. Our products have gained the certifications of ISO9001 and TS16949. We have built up a solid reputation with our customers in more than 30 countries.

We are looking forward to having a brighter and more successful business in the near future together with all of our clients all over the world.

-

Why Choose OE Quality Brake Pads? When selecting brake pads, OE QUALITY BRAKE PADS ensure precise fit, optimal braking performance, and long-term dur...

READ MORE -

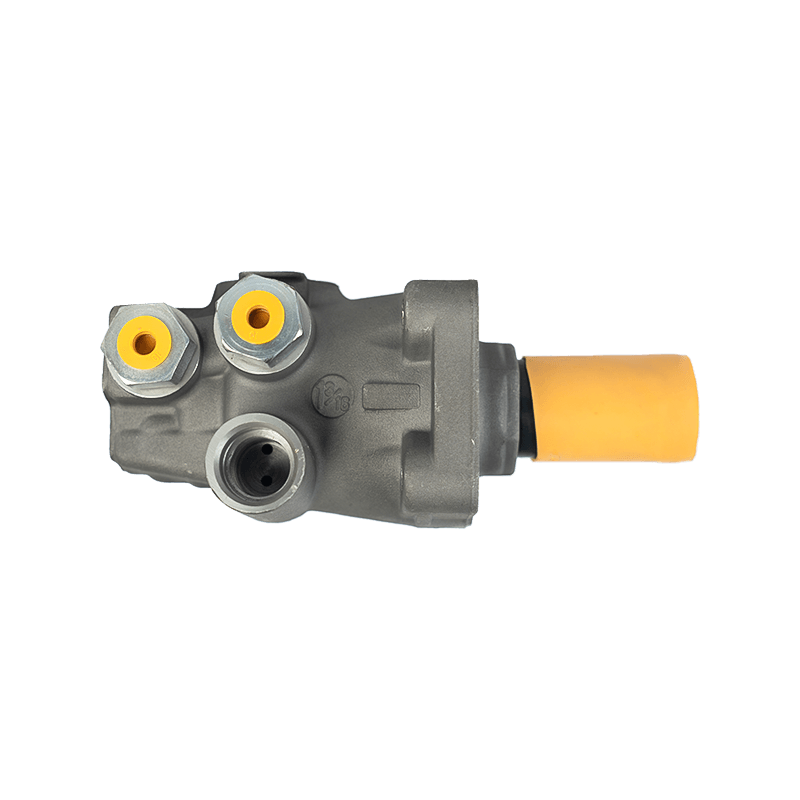

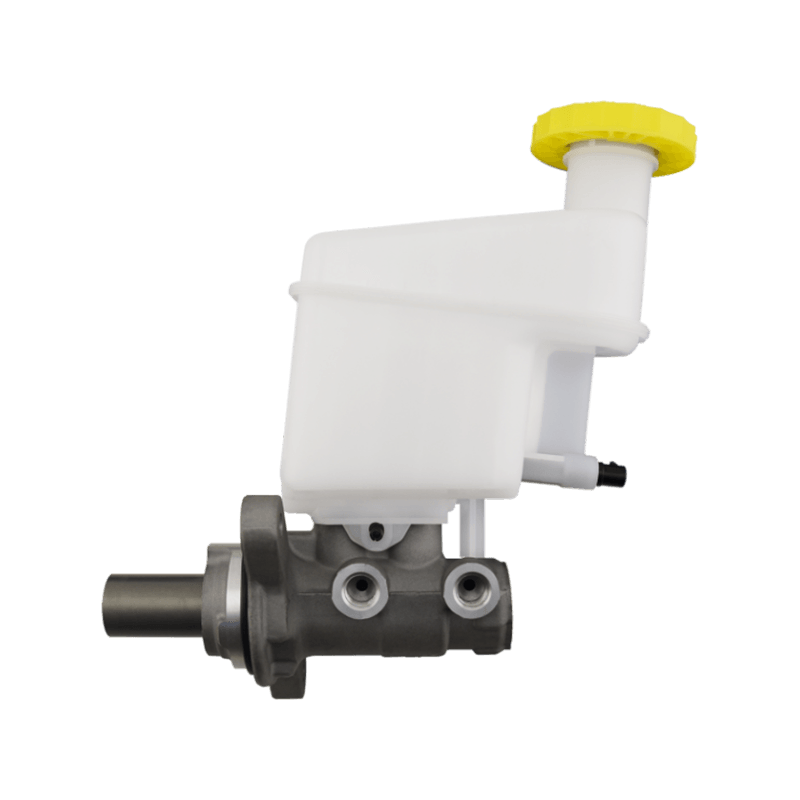

What is a Hydraulic Brake Master Cylinder? The hydraulic brake master cylinder is a critical component in a vehicle's braking system. It converts the...

READ MORE -

Why OE Quality Brake Pads Are the Best Choice for Your Car OE (Original Equipment) quality brake pads are specifically designed to match the specific...

READ MORE -

The direct answer: Yes. High-quality brake pads can reduce braking distance by 15%–30%, improve heat resistance, and significantly enhance driving saf...

READ MORE

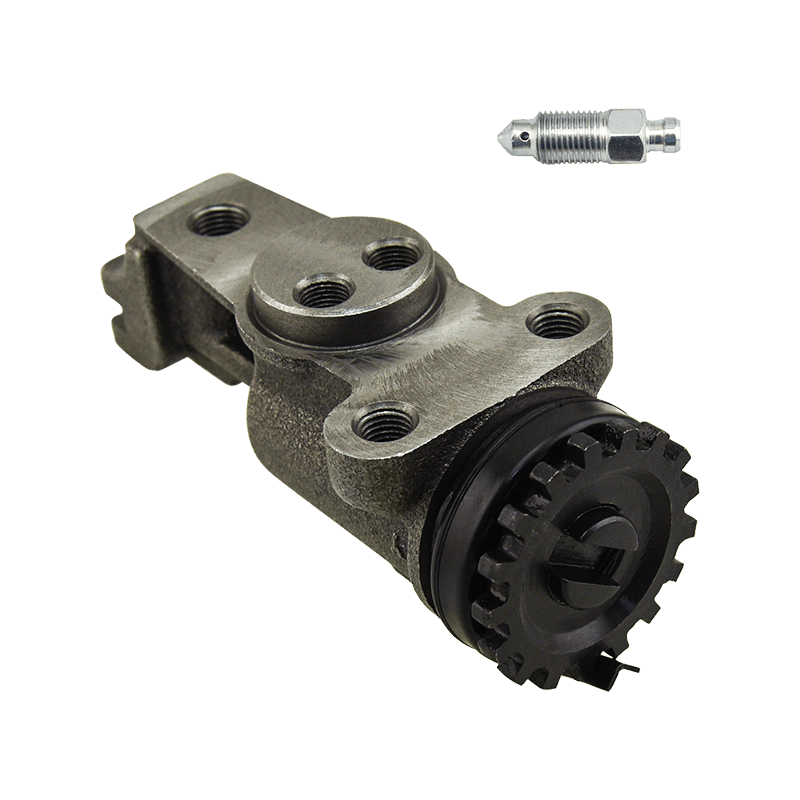

As the core component of the automobile braking system, the performance of the brake wheel cylinder directly affects the safety and handling stability of the vehicle. 2S4611049 Brake Wheel Cylinder For Ford usually adopts a plunger structure, embedded in the brake drum, and uses the brake fluid to push the piston to make the brake shoe contact the drum surface; while the disc wheel cylinder is integrated in the brake caliper, using the hydraulic changes in the cylinder to drive the piston to squeeze the brake pad and brake disc to achieve efficient braking force. The installation of the rear brake wheel cylinder of Ford Mondeo and other models must strictly follow the operating steps. For example, special tools must be used to protect the brake oil pipe during disassembly, and two people must cooperate to exhaust after installation to ensure that there is no air residue in the hydraulic system. This precise design and operating specifications reflect the importance of the wheel cylinder in the accuracy of brake response.

From the perspective of later maintenance, the failure of the wheel cylinder is often manifested as uneven braking force or leakage, and the piston activity and seal aging must be checked regularly. Improper operation during installation (such as damage to the oil pipe or residual air) may cause the brake pedal to be soft or the braking distance to be extended. Therefore, it is recommended to use original or ISO/TUV certified replacement parts and use professional tools for repair to maintain the overall effectiveness of the brake system.

The design and performance of the 2S4611049 Ford brake cylinder must be guaranteed by multiple aspects such as adaptability verification, manufacturing process and standardized installation to realize its core value as a "safety guardian".

Search

Search

Eng

Eng

English

English Español

Español Português

Português