Specifications

KEEP IN TOUCH

We have more than 1,000 brake shoes and brake pads for European, American, Russian, Japanese and Korean cars. The associated factories have created a highly experienced manufacturing team that exports thousands of auto part products worldwide. High quality and competitive prices are our targets. Our products have gained the certifications of ISO9001 and TS16949. We have built up a solid reputation with our customers in more than 30 countries.

We are looking forward to having a brighter and more successful business in the near future together with all of our clients all over the world.

-

Why Choose OE Quality Brake Pads? When selecting brake pads, OE QUALITY BRAKE PADS ensure precise fit, optimal braking performance, and long-term dur...

READ MORE -

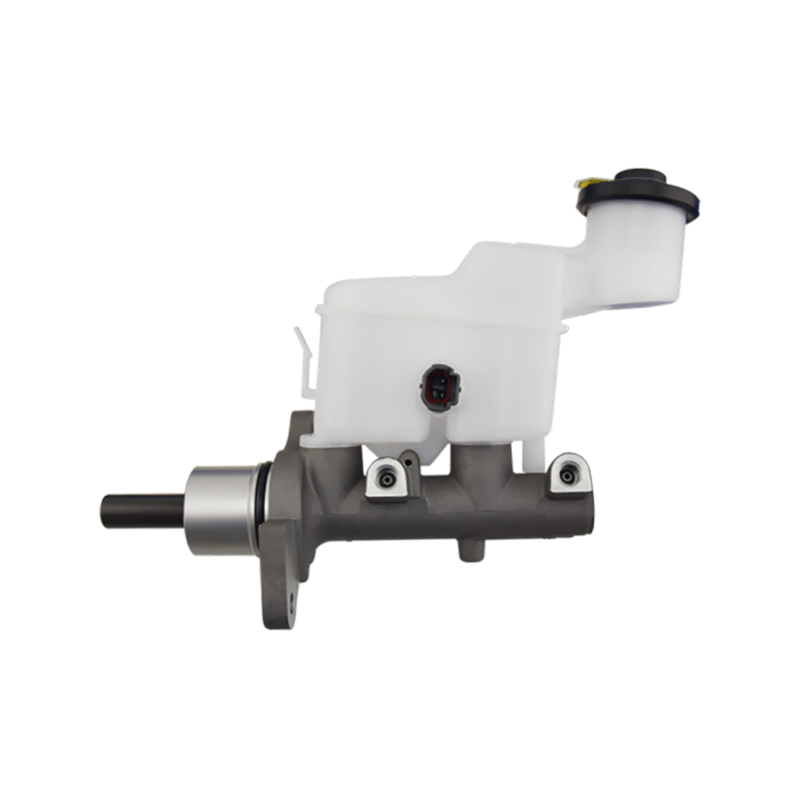

What is a Hydraulic Brake Master Cylinder? The hydraulic brake master cylinder is a critical component in a vehicle's braking system. It converts the...

READ MORE -

Why OE Quality Brake Pads Are the Best Choice for Your Car OE (Original Equipment) quality brake pads are specifically designed to match the specific...

READ MORE -

The direct answer: Yes. High-quality brake pads can reduce braking distance by 15%–30%, improve heat resistance, and significantly enhance driving saf...

READ MORE

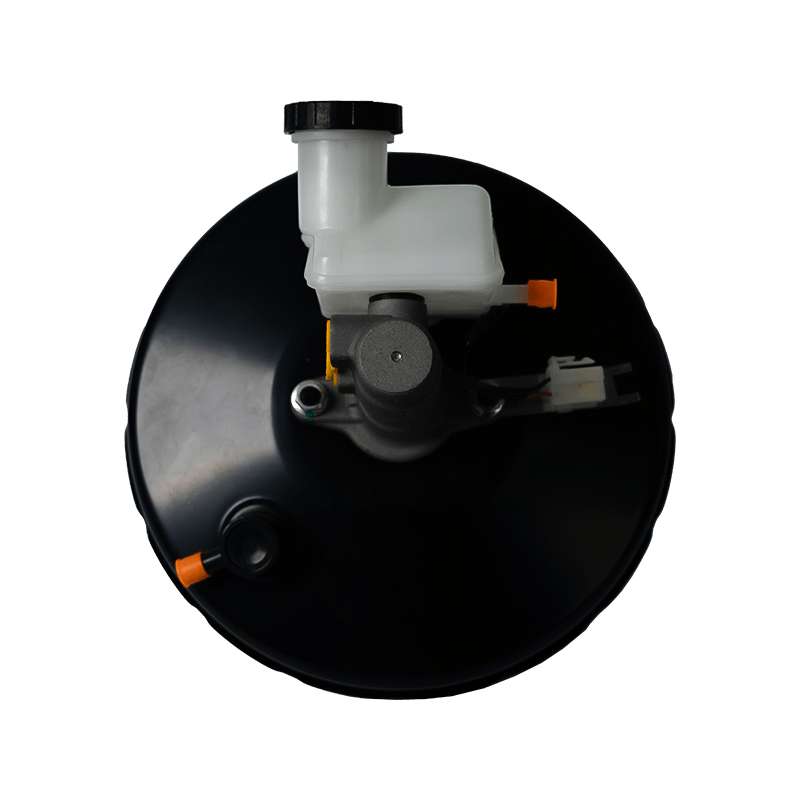

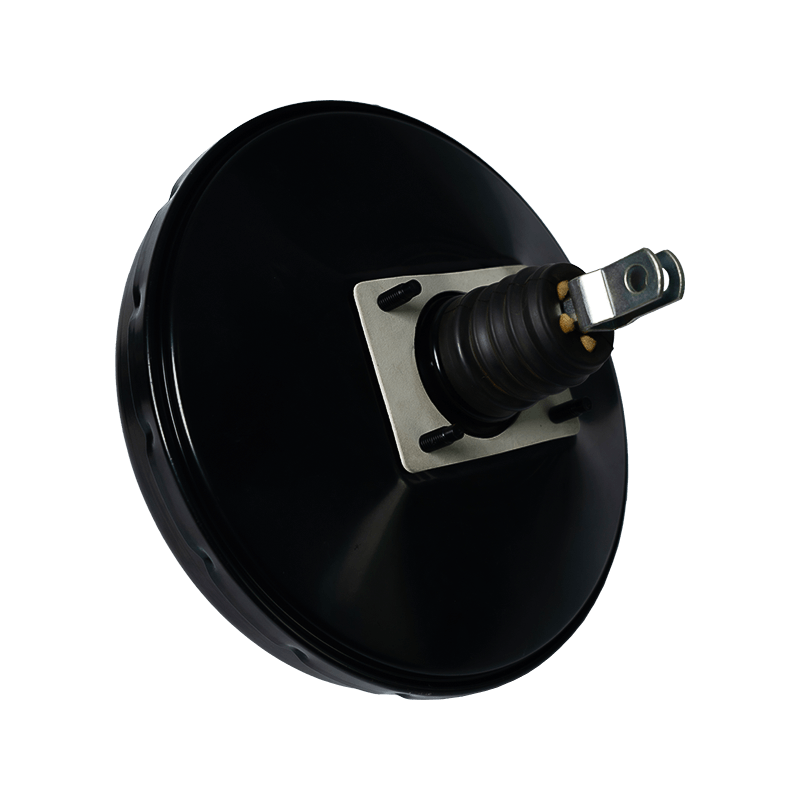

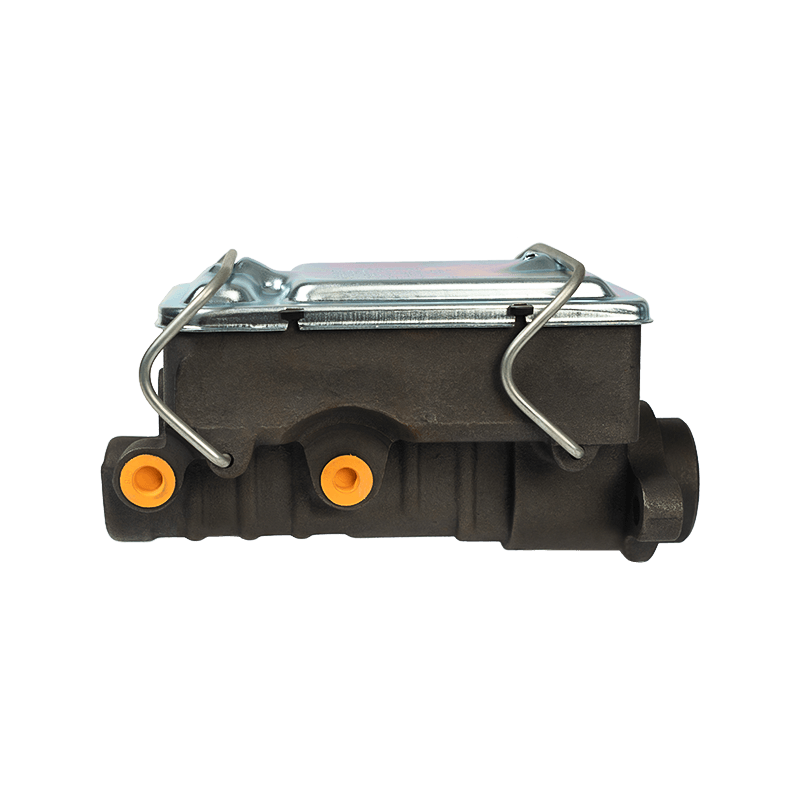

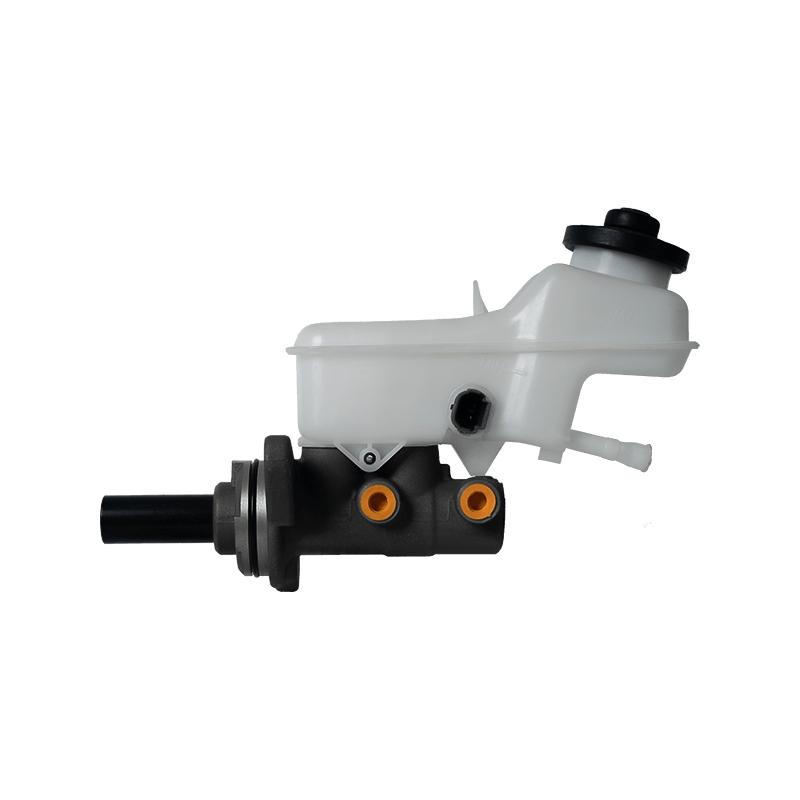

Toyota's 3540100-GC010 Brake Master Cylinder is a core brake component developed based on international standardized technology. It is designed for commercial vehicles and hybrid platforms. Its core function is to convert the driver's pedal force into balanced hydraulic output, and achieve precise distribution of front and rear wheel braking force through a dual-chamber series structure. The component adopts a high-strength aluminum alloy casting process (in accordance with T/ZZB 2389-2021 standards), the master cylinder diameter is 28.58mm, and can withstand 32MPa hydraulic pressure.

The 3540100-GC010 Brake Master Cylinder adopts a dual-piston compensation valve structure and is equipped with fast filling valve technology to ensure hydraulic stability under extreme braking conditions. Its sealing system is made of high-temperature resistant fluororubber (in accordance with HG2865-1997 standard), with an operating temperature range of -40℃ to 180℃, and the piston return time is strictly controlled within 1.5 seconds (meeting the technical requirements of QC/T 311-1999). Test data shows that after 15 consecutive emergency brakes from 100-0km/h, the hydraulic fluctuation amplitude is less than 0.3MPa, and the friction coefficient is stable in the range of 0.38-0.42, effectively suppressing the thermal decay phenomenon.

The threaded interface of this model of master cylinder adopts a front port 1/2"-20 inverted design, which perfectly matches the brake line layout of Toyota commercial vehicles and avoids the risk of leakage caused by tolerance. Its OE number is fully compatible with derivative models such as 3540100-GC011 and 3540100-GC015, and has passed TS16949 certification, supporting the coordinated operation with third-party replacement parts such as TRW BWN153 and AISIN MCT-033.

Search

Search

Eng

Eng

English

English Español

Español Português

Português