Specifications

KEEP IN TOUCH

We have more than 1,000 brake shoes and brake pads for European, American, Russian, Japanese and Korean cars. The associated factories have created a highly experienced manufacturing team that exports thousands of auto part products worldwide. High quality and competitive prices are our targets. Our products have gained the certifications of ISO9001 and TS16949. We have built up a solid reputation with our customers in more than 30 countries.

We are looking forward to having a brighter and more successful business in the near future together with all of our clients all over the world.

-

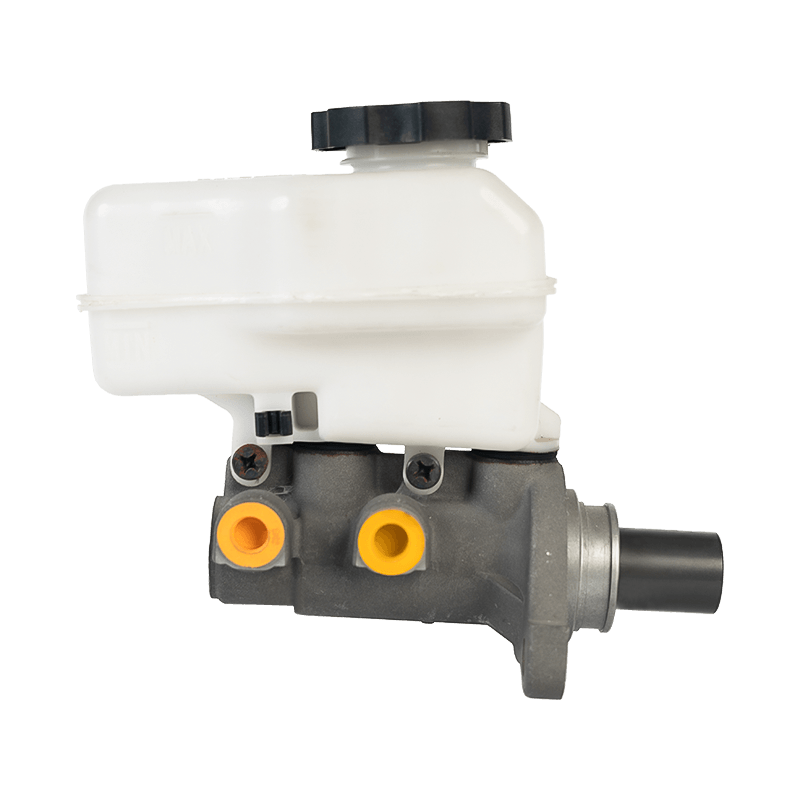

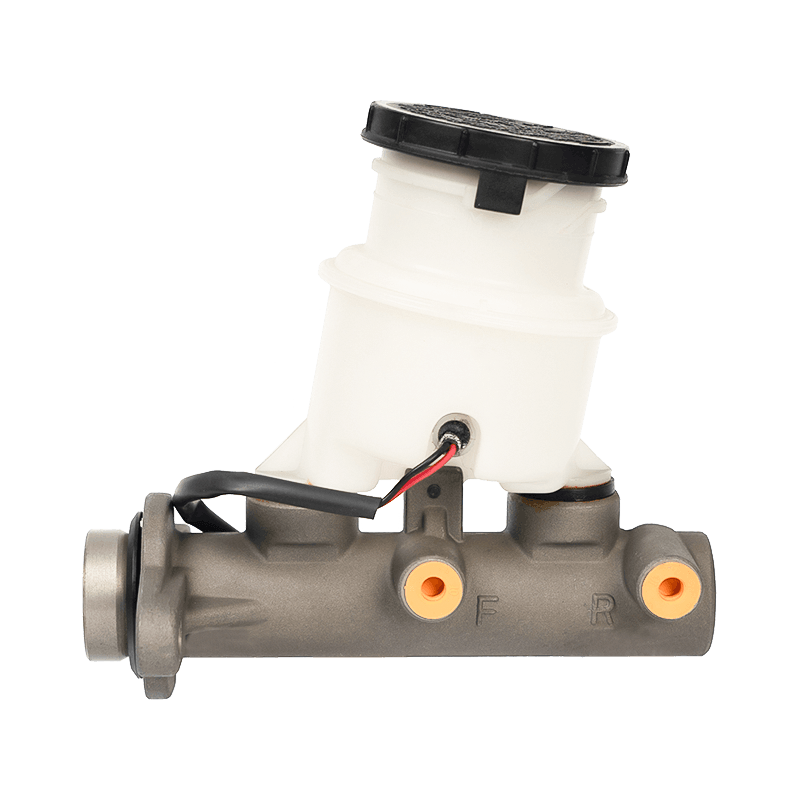

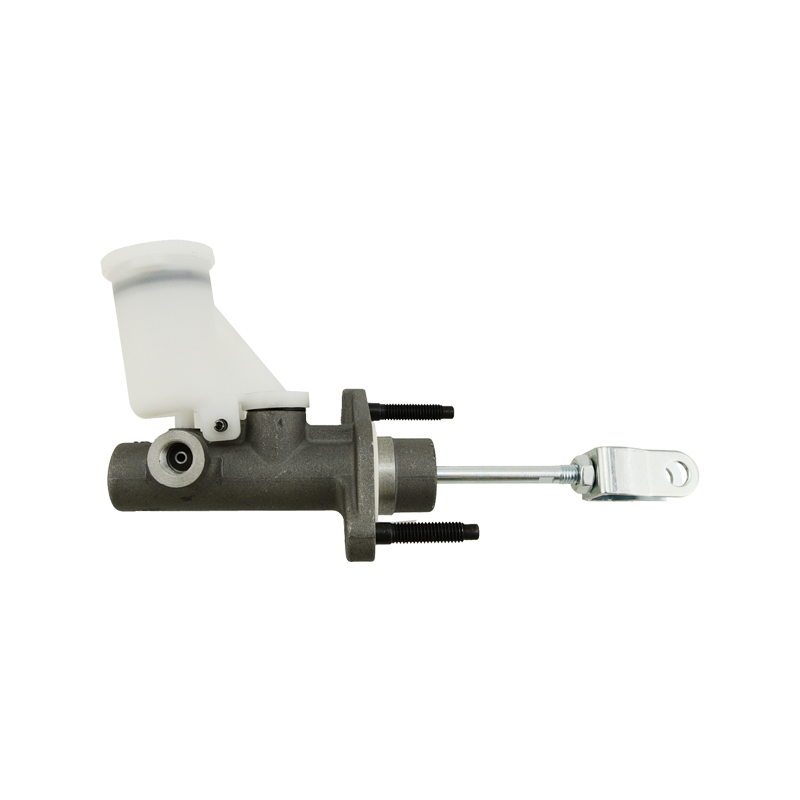

What is a Hydraulic Brake Master Cylinder? The hydraulic brake master cylinder is a critical component in a vehicle's braking system. It converts the...

READ MORE -

Why OE Quality Brake Pads Are the Best Choice for Your Car OE (Original Equipment) quality brake pads are specifically designed to match the specific...

READ MORE -

The direct answer: Yes. High-quality brake pads can reduce braking distance by 15%–30%, improve heat resistance, and significantly enhance driving saf...

READ MORE -

The automobile brake system is one of the most critical safety components in any vehicle. It controls speed, enables smooth stopping, and prevents acc...

READ MORE

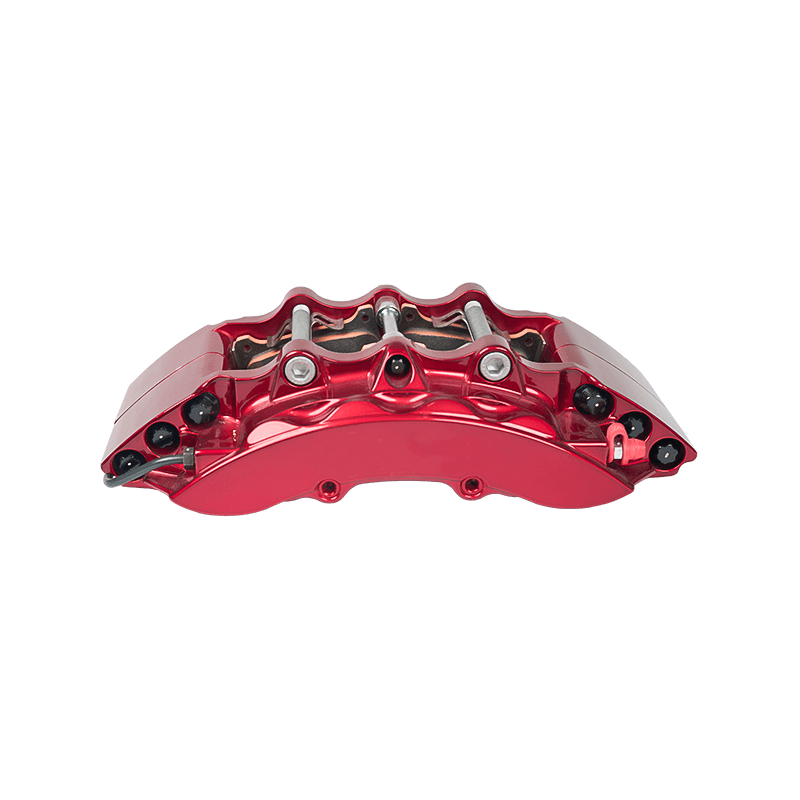

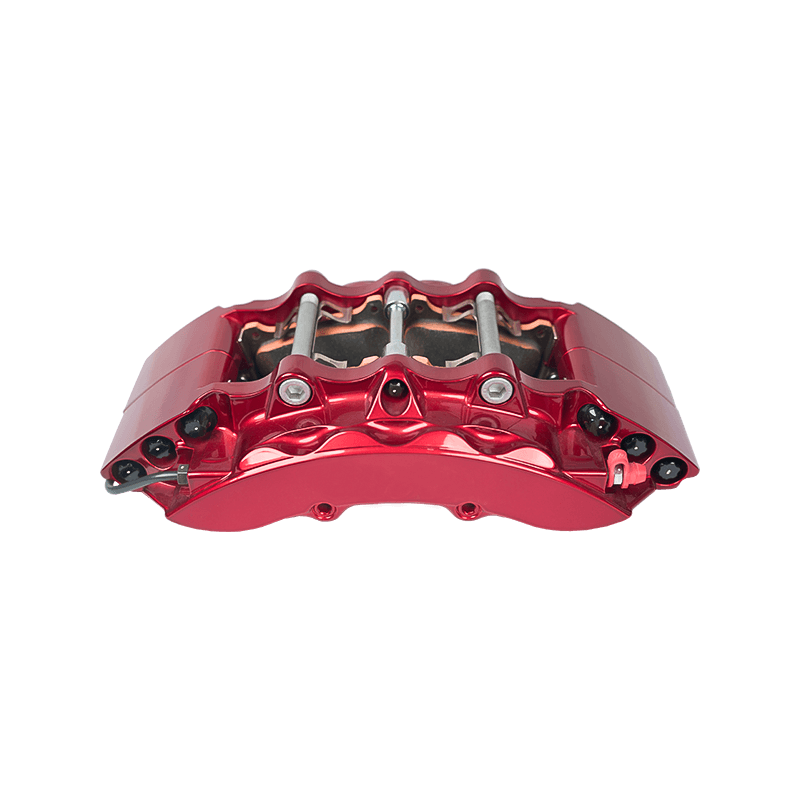

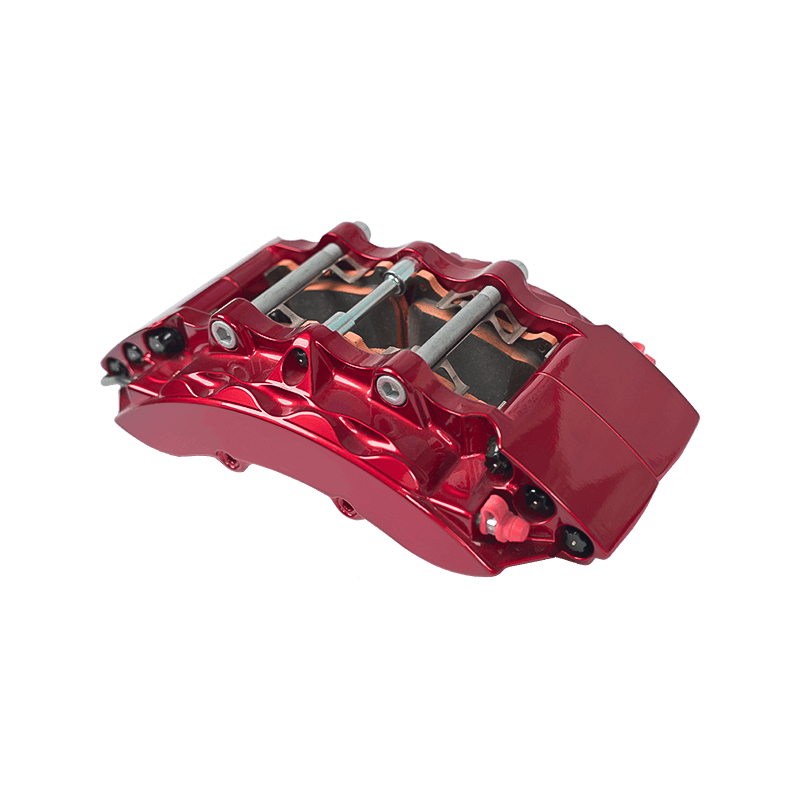

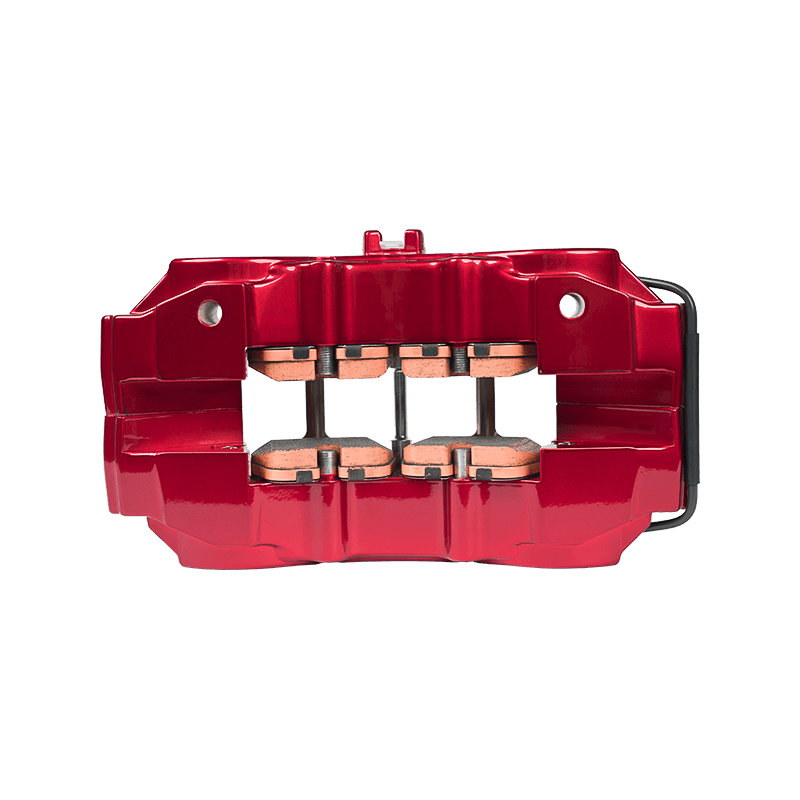

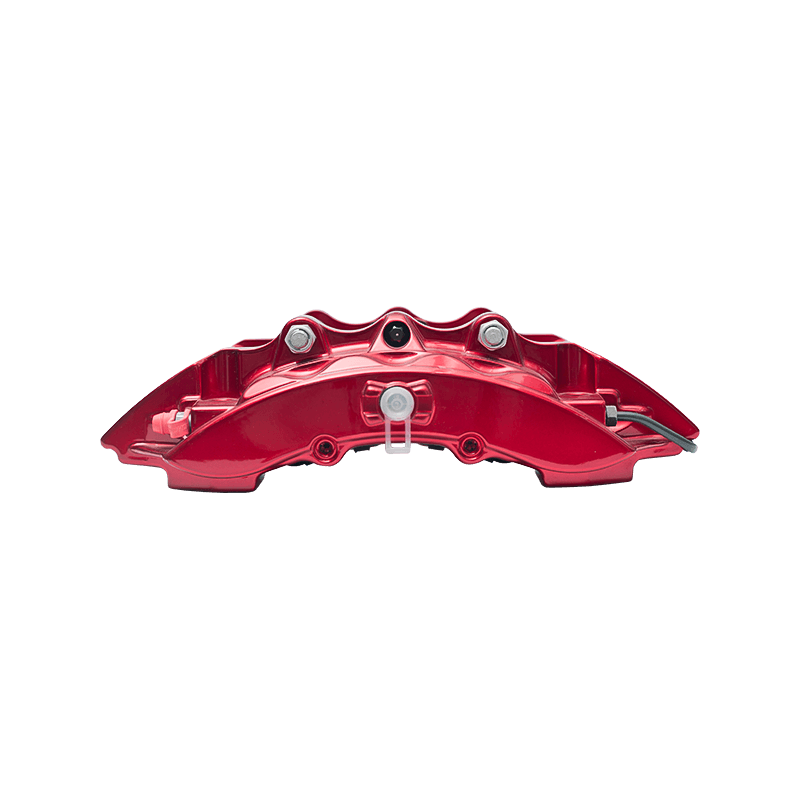

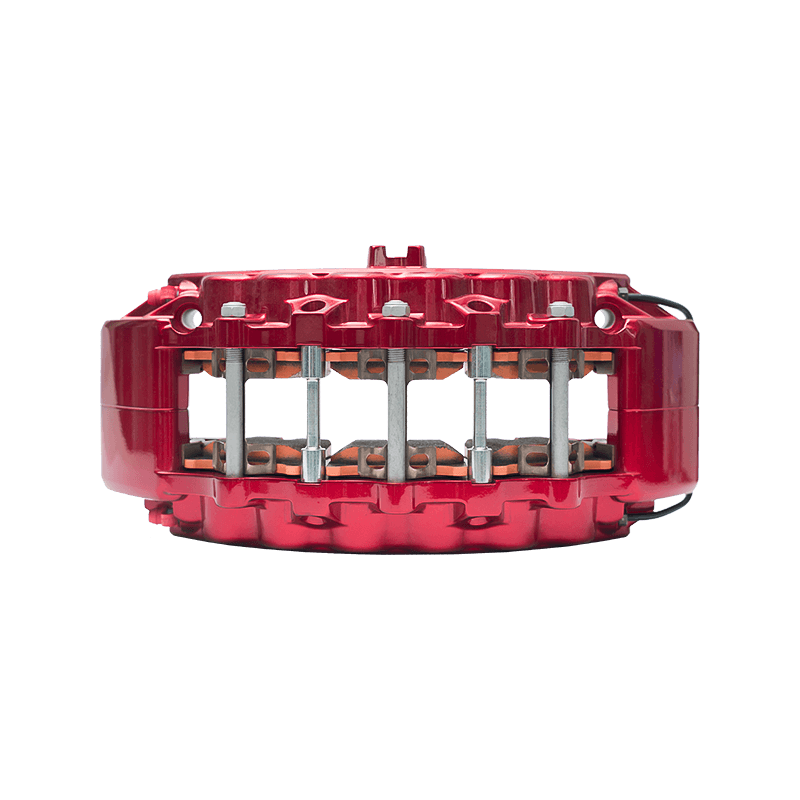

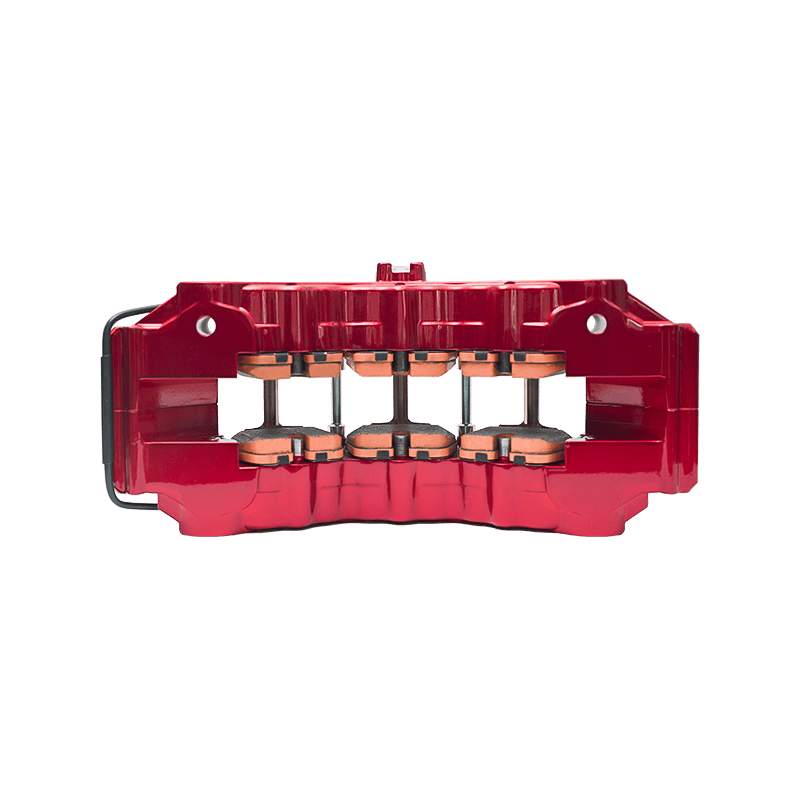

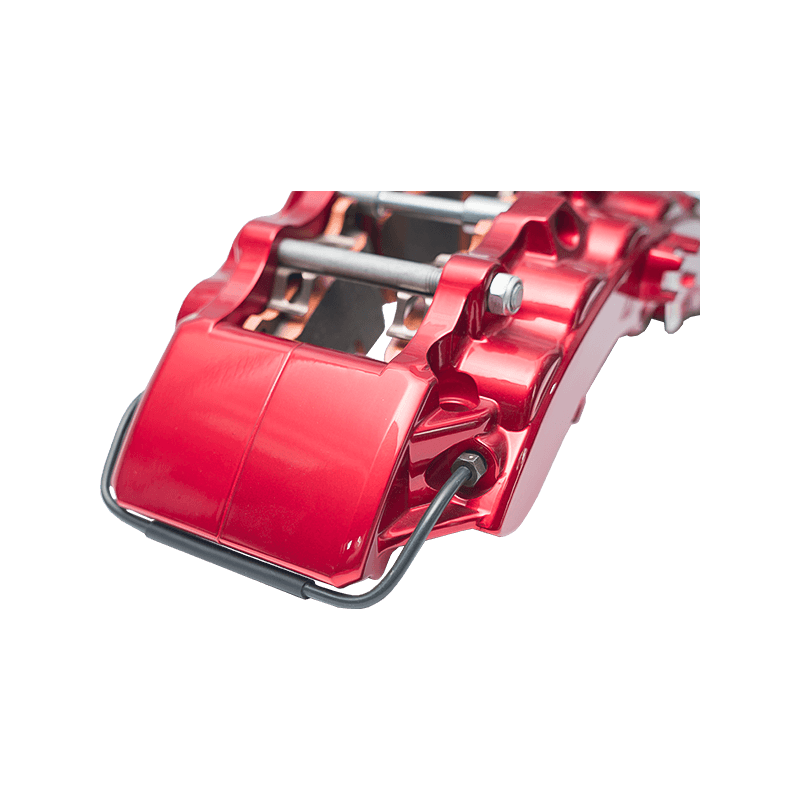

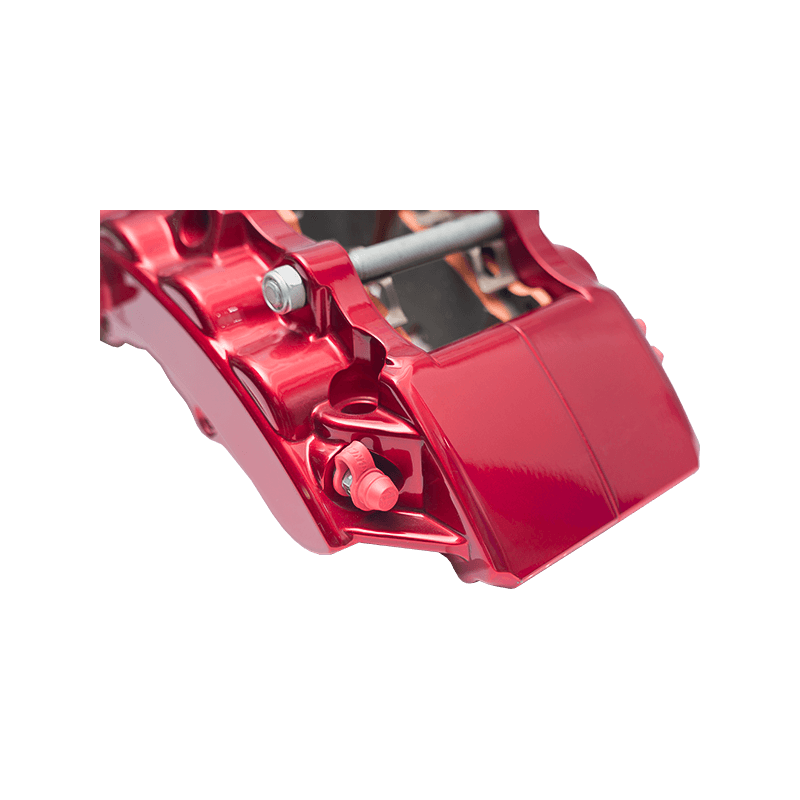

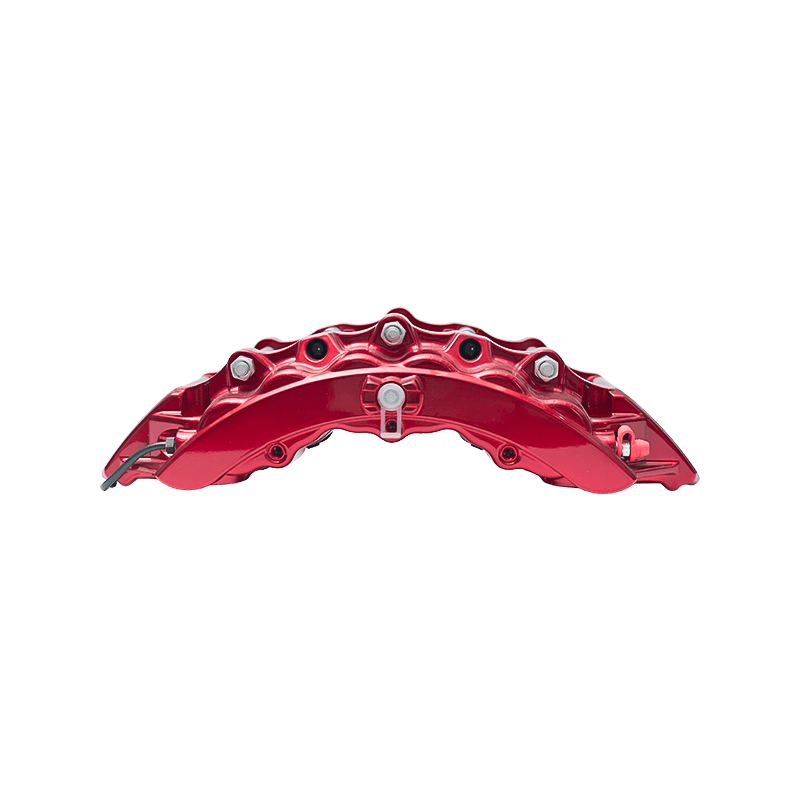

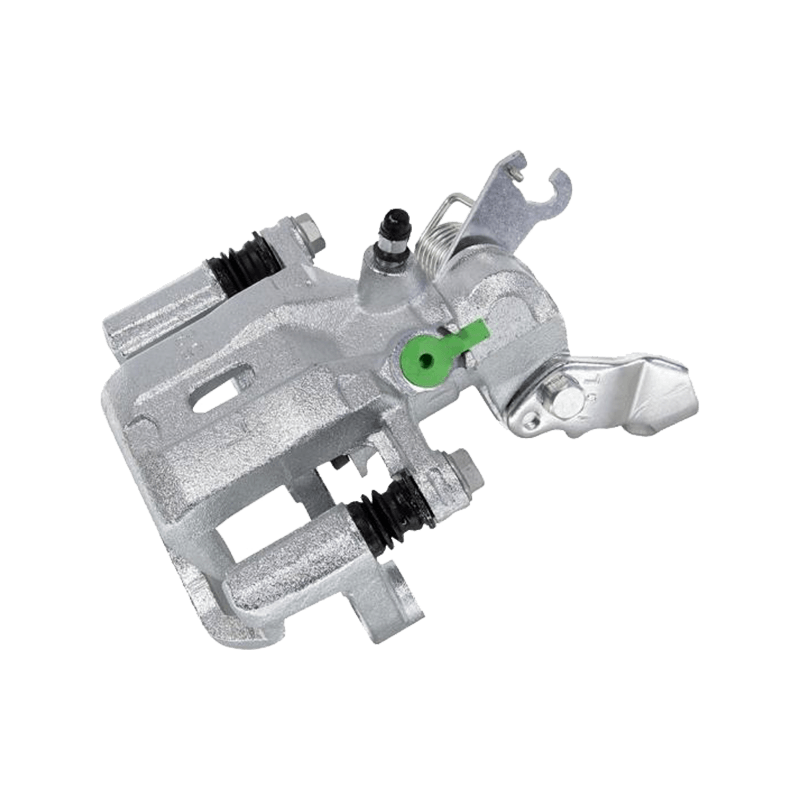

The 8FPM4L brake caliper is a core component of the heavy machinery braking system. The brake caliper adopts a composite drive mechanism of spring activation and pneumatic release. The spring module provides basic braking force through preload, while compressed air (working pressure range 4-8 bar) is used to quickly release the brake, with a response time of only 0.3 seconds. Its dual-piston symmetrical layout and enhanced hydraulic cylinder with a diameter of 45mm can output a braking torque of up to 4500N·m, suitable for 200-355mm brake discs, and suitable for heavy-duty scenarios such as port cranes and mining transport vehicles.

In terms of product material technology, the piston surface of the 8FPM4L adopts silicon nitride gradient coating technology, and a 3μm thick ceramic layer is formed by chemical vapor deposition, with a hardness of 1600HV and a high temperature resistance threshold of over 750℃. The frame is made of high-strength alloy steel cast by low-pressure sand mold, and the internal porosity is controlled within 0.3%. The brake caliper supports modular customization. Users can choose the thruster installation direction (left/right side) and manual wear compensation mechanism, and achieve friction plate gap calibration with an accuracy of 0.1mm by rotating the adjusting bolt.

Search

Search

Eng

Eng

English

English Español

Español Português

Português