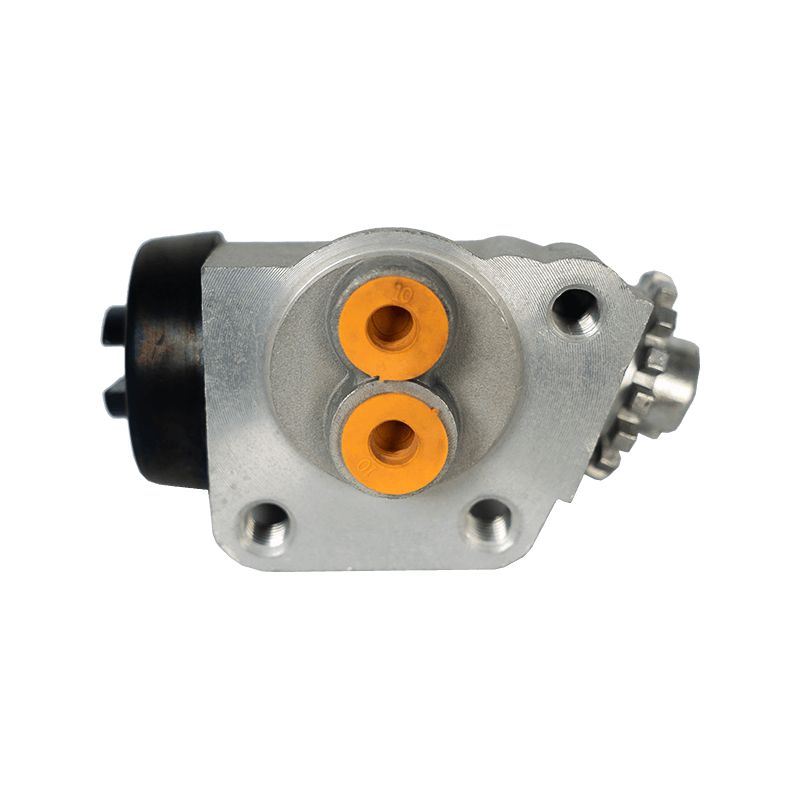

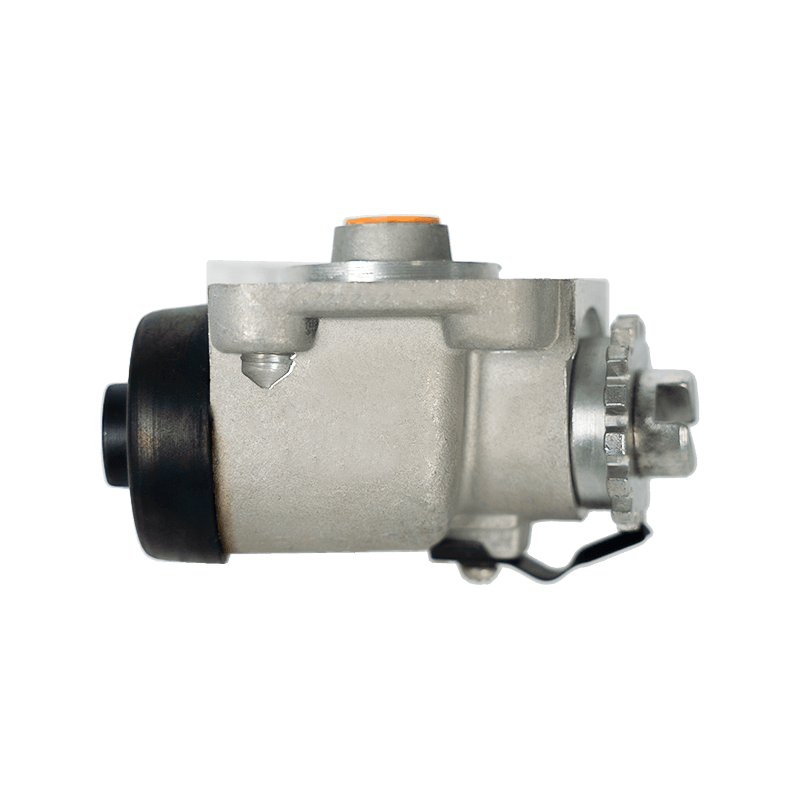

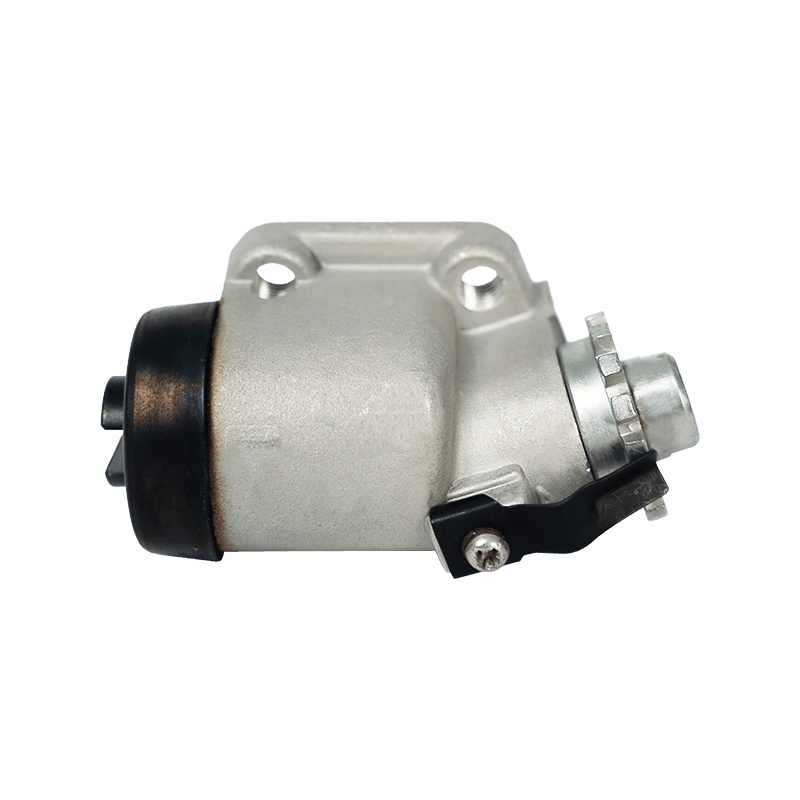

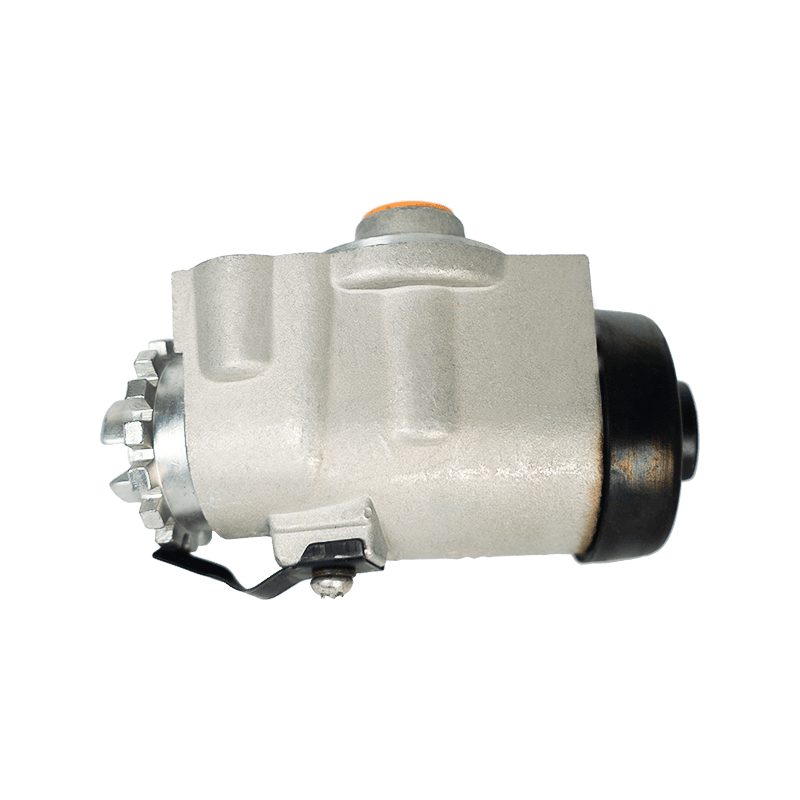

47520-29065 Brake Wheel Cylinder for Toyota

|

OE NO |

47520-29065 47520-29235 47570-32020 |

|

DESCRIP |

BWC |

|

MODEL |

Toyota |

Specifications

KEEP IN TOUCH

We have more than 1,000 brake shoes and brake pads for European, American, Russian, Japanese and Korean cars. The associated factories have created a highly experienced manufacturing team that exports thousands of auto part products worldwide. High quality and competitive prices are our targets. Our products have gained the certifications of ISO9001 and TS16949. We have built up a solid reputation with our customers in more than 30 countries.

We are looking forward to having a brighter and more successful business in the near future together with all of our clients all over the world.

-

Why Choose OE Quality Brake Pads? When selecting brake pads, OE QUALITY BRAKE PADS ensure precise fit, optimal braking performance, and long-term dur...

READ MORE -

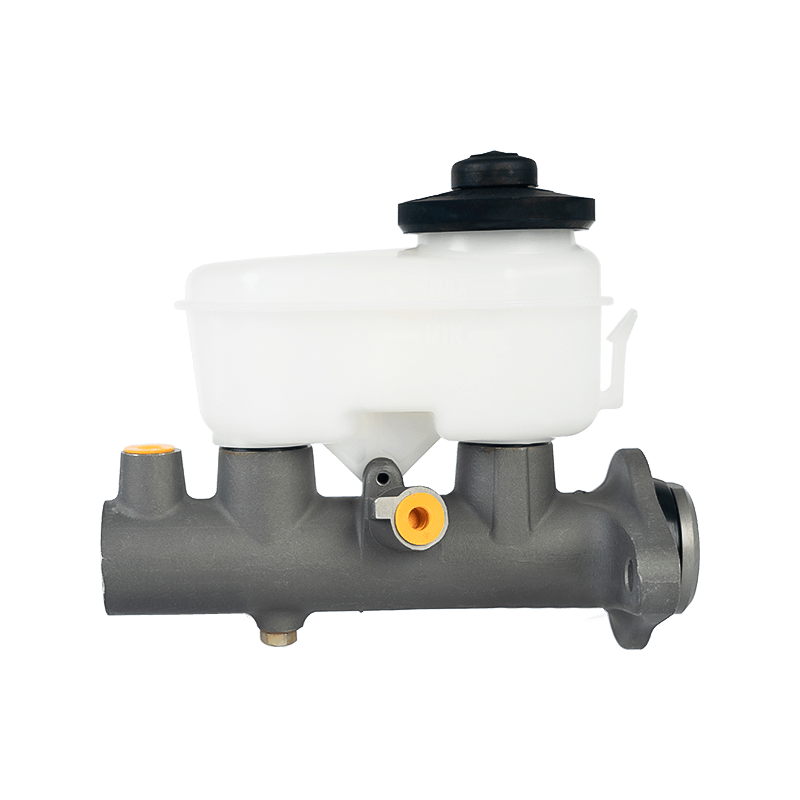

What is a Hydraulic Brake Master Cylinder? The hydraulic brake master cylinder is a critical component in a vehicle's braking system. It converts the...

READ MORE -

Why OE Quality Brake Pads Are the Best Choice for Your Car OE (Original Equipment) quality brake pads are specifically designed to match the specific...

READ MORE -

The direct answer: Yes. High-quality brake pads can reduce braking distance by 15%–30%, improve heat resistance, and significantly enhance driving saf...

READ MORE

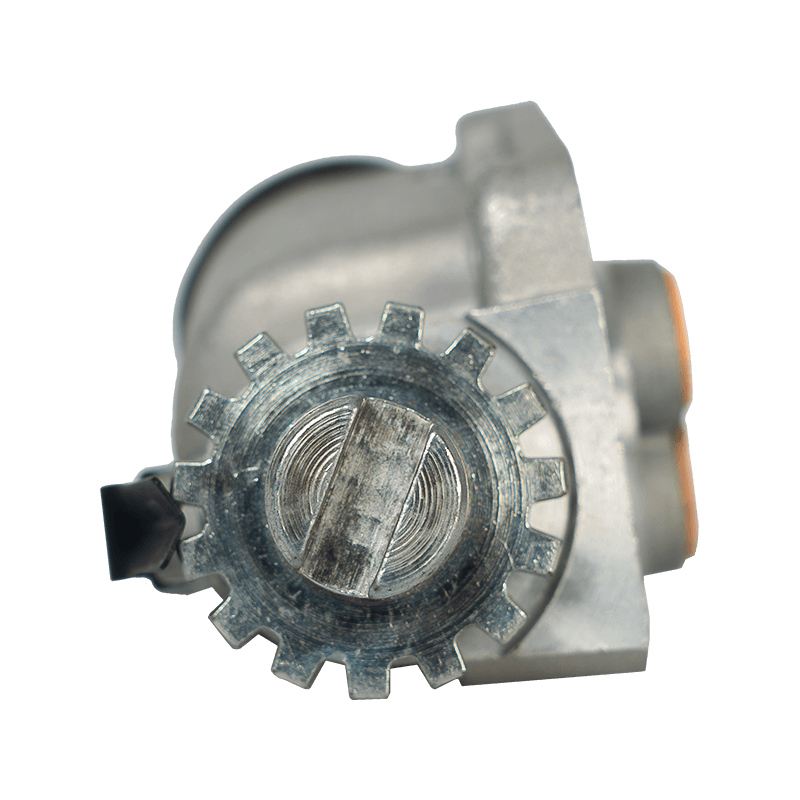

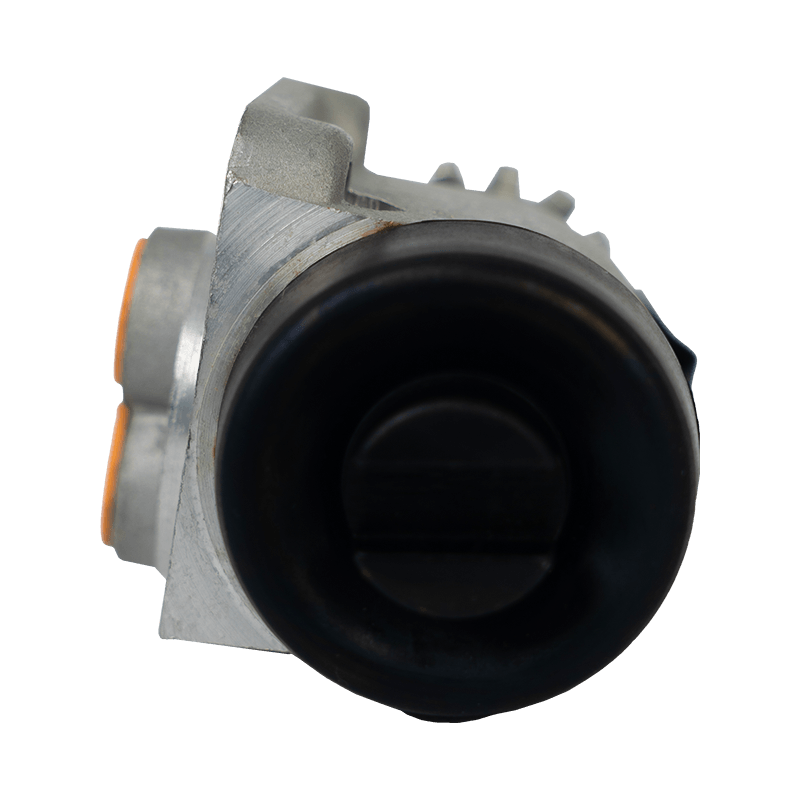

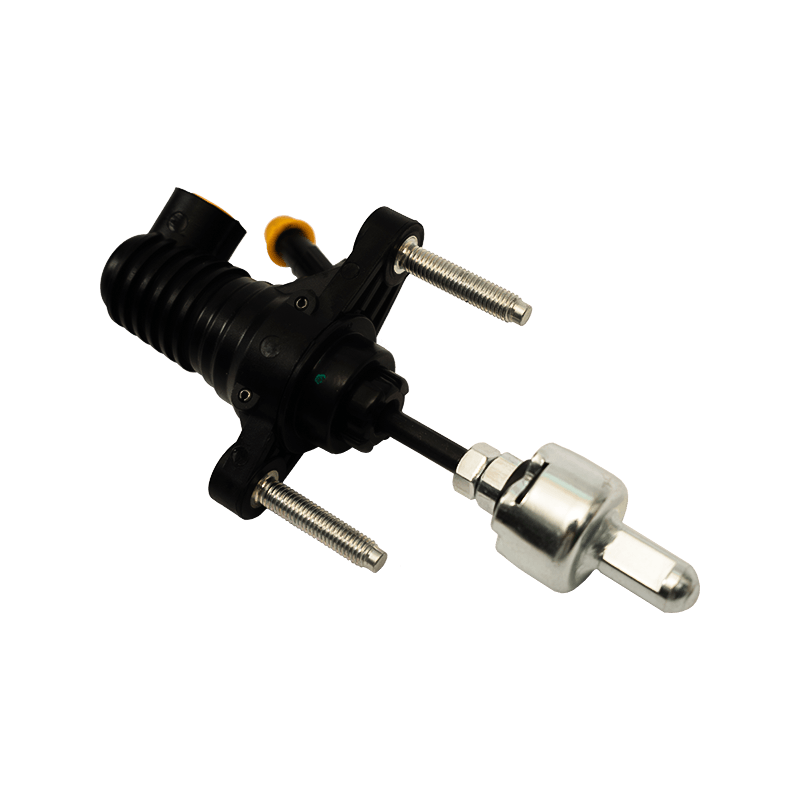

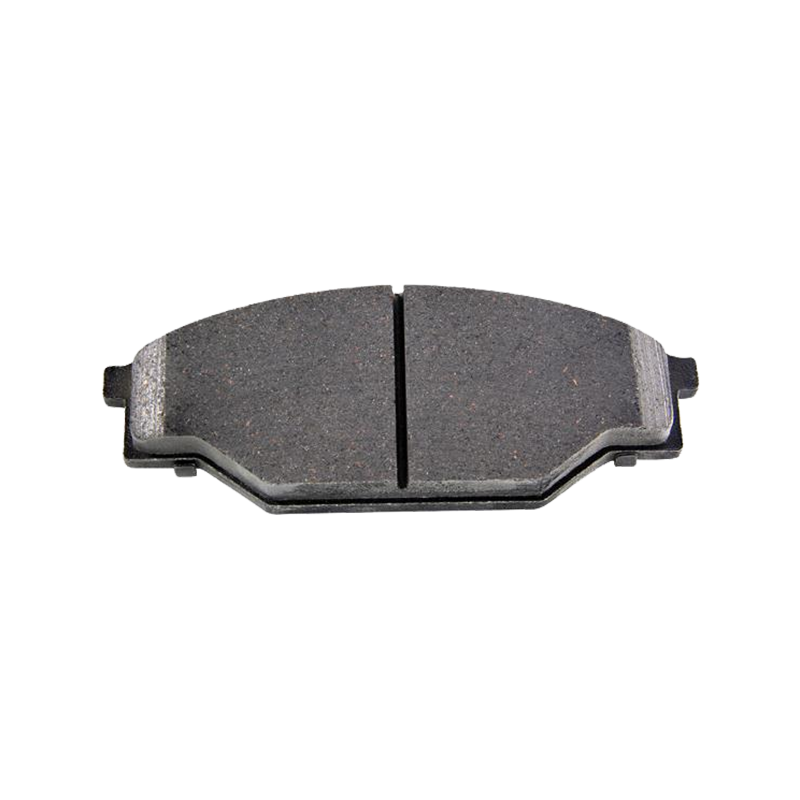

47520-29065 Toyota Brake Wheel Cylinder has become a reliable choice for multiple generations of Toyota models due to its high strength and precise adaptability. As the key execution unit of the hydraulic brake system, its core function is to convert the hydraulic energy transmitted by the master cylinder into mechanical thrust, drive the brake pads to contact and rub with the brake drum or disc, and achieve vehicle deceleration and parking. The wheel cylinder is made of aluminum alloy and cast iron composite material, combined with anodizing treatment process, while ensuring strength, taking into account lightweight and corrosion resistance.

In terms of engineering design, the 47520-29065 wheel cylinder adopts a single piston structure, the piston diameter is 1 1/8 inches, the thread size is M10x1, and it is suitable for double-collar brake systems. Its sealing system is made of fluororubber material, with a temperature range of -40℃ to 180℃, which can cope with frequent heavy-load braking conditions. Test data shows that the temperature fluctuation of the wheel cylinder does not exceed ±15℃ after multiple consecutive braking, and the friction coefficient is stable in the range of 0.38-0.42.

47520-29065 Toyota brake wheel cylinder strictly complies with JIS D2601 standard and performs well in -40℃ extreme cold environment and desert high temperature tests. Its aluminum alloy shell optimizes the heat dissipation structure and cooperates with the ventilated brake drum design to reduce the thermal attenuation effect after continuous braking and improve the vehicle's all-terrain adaptability.

Search

Search

Eng

Eng

English

English Español

Español Português

Português