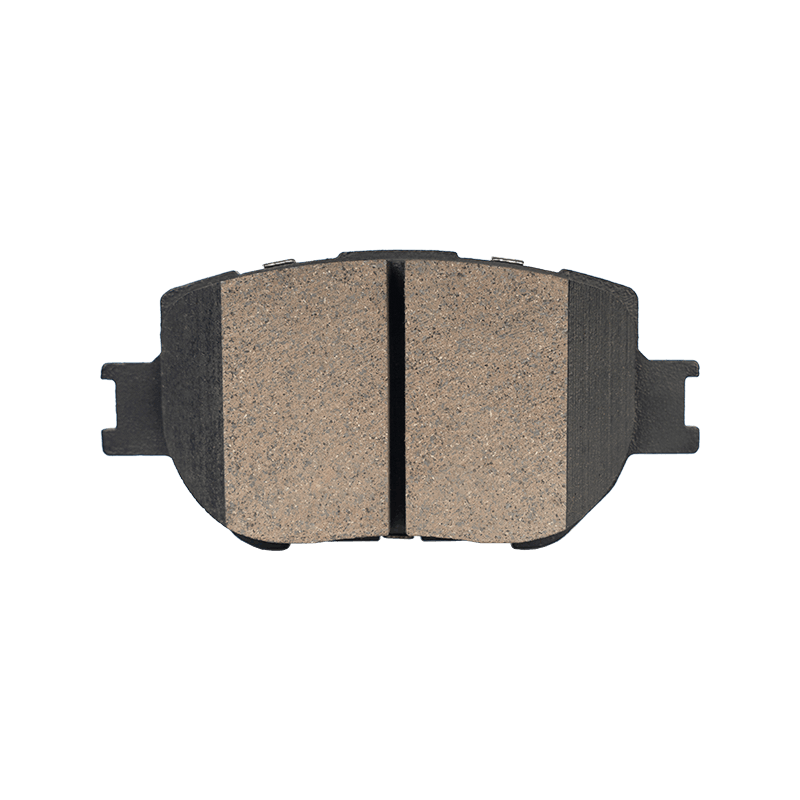

0446530280 High Endurance Brake Pad for Toyota Lexus

|

OE NO |

0446530280 0446520500 04465YZZDF 0446532191 |

|

MODEL |

Toyota Lexus |

Specifications

KEEP IN TOUCH

We have more than 1,000 brake shoes and brake pads for European, American, Russian, Japanese and Korean cars. The associated factories have created a highly experienced manufacturing team that exports thousands of auto part products worldwide. High quality and competitive prices are our targets. Our products have gained the certifications of ISO9001 and TS16949. We have built up a solid reputation with our customers in more than 30 countries.

We are looking forward to having a brighter and more successful business in the near future together with all of our clients all over the world.

-

The automobile brake system is one of the most critical safety components in any vehicle. It controls speed, enables smooth stopping, and prevents acc...

READ MORE -

When you're driving, you probably don’t think much about your brake system—until you need it. The brake system in your car is one of the most importan...

READ MORE -

Many customers often have these questions: "Are your brake pads wear-resistant?" "Will they make noise at high speeds?" "How long will they last? Will...

READ MORE -

In everyday driving, many car owners encounter strange noises when braking, such as "squeaking," "clicking," or "grinding" sounds. The brake caliper i...

READ MORE

0446530280 high durability brake pads have become a key component to ensure driving safety and reduce maintenance costs with the innovation of material technology and process. This product is developed based on semi-metal and ceramic composite technology. By optimizing the ratio of friction materials and structural design, the service life is increased to more than 50,000 kilometers while ensuring braking performance.

Its core technology is reflected in the innovative design of the composite friction layer. The friction material uses modified phenolic resin as the bonding matrix, and incorporates carbon fiber and ceramic microparticle reinforcement phases to form a honeycomb porous structure. This design not only stabilizes the dynamic friction coefficient in the range of 0.38-0.45, but also improves the heat dissipation efficiency through the pore structure. The temperature peak in ten consecutive 100km/h emergency braking tests is 18% lower than that of traditional semi-metal brake pads, effectively avoiding thermal decay. In terms of production technology, 0446530280 adopts two-stage hot pressing molding technology. After the raw materials are precisely proportioned, they are first pre-pressed at 160°C to form a porous skeleton, and then secondary solidification is completed at 230°C under high pressure, so that the material density is increased to more than 98%. The back plate part uses laser-welded high-strength alloy steel, combined with a wavy heat dissipation fin design and a patented vortex guide groove, which can reduce the friction interface temperature from 600°C to 200°C within 90 seconds.

In actual application, the brake pad shows all-weather adaptability. The J-shaped grinding twill and silencer designed on its surface control the braking noise below 42 decibels. At the same time, the contact pressure distribution is optimized through the unequal thickness structure design, and the friction coefficient can still be maintained above 0.35 even on slippery roads in the rainy season. In response to the special needs of the energy recovery system of new energy vehicles, the product optimizes the initial bite response speed, shortens the braking delay time to 0.18 seconds, and reduces dust generation with a low metal formula, effectively extending the wheel cleaning cycle.

Search

Search

Eng

Eng

English

English Español

Español Português

Português