Why can brake caliper become the core safety component of automobile braking system?

2025.06.12

2025.06.12

Industry News

Industry News

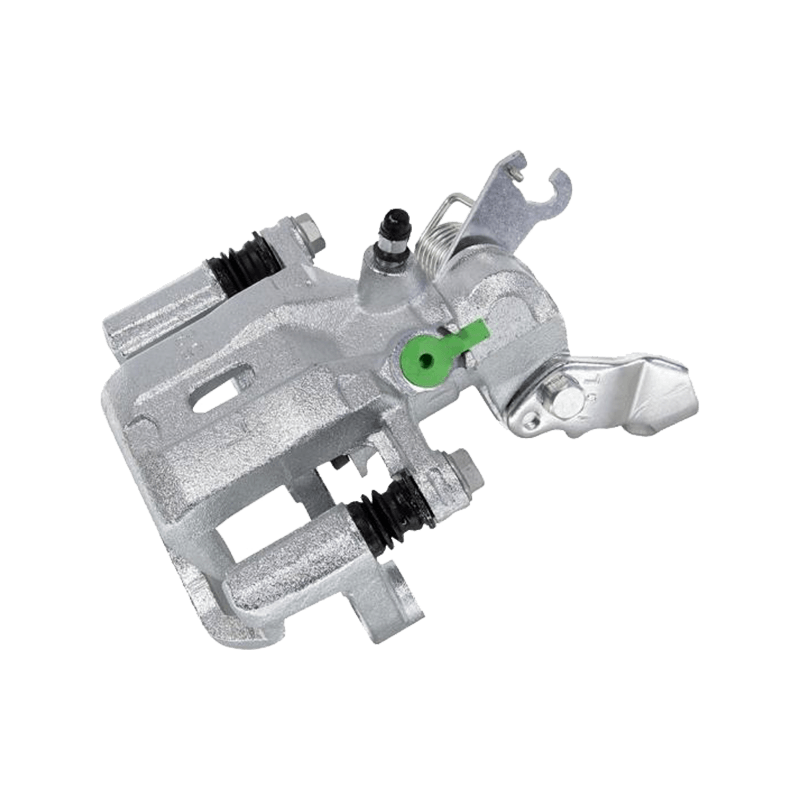

1. Structure and working principle of brake caliper

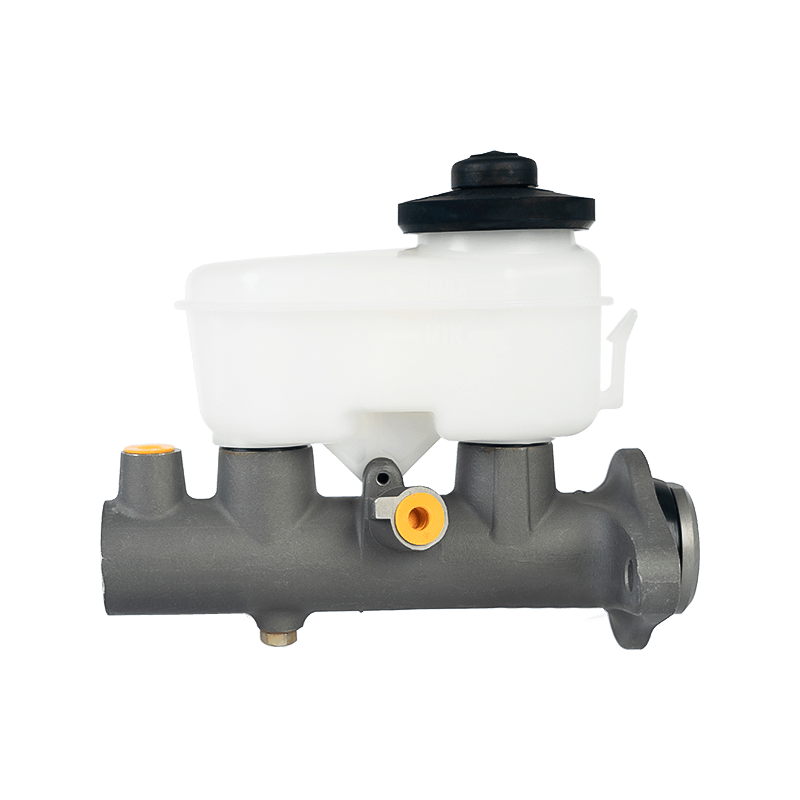

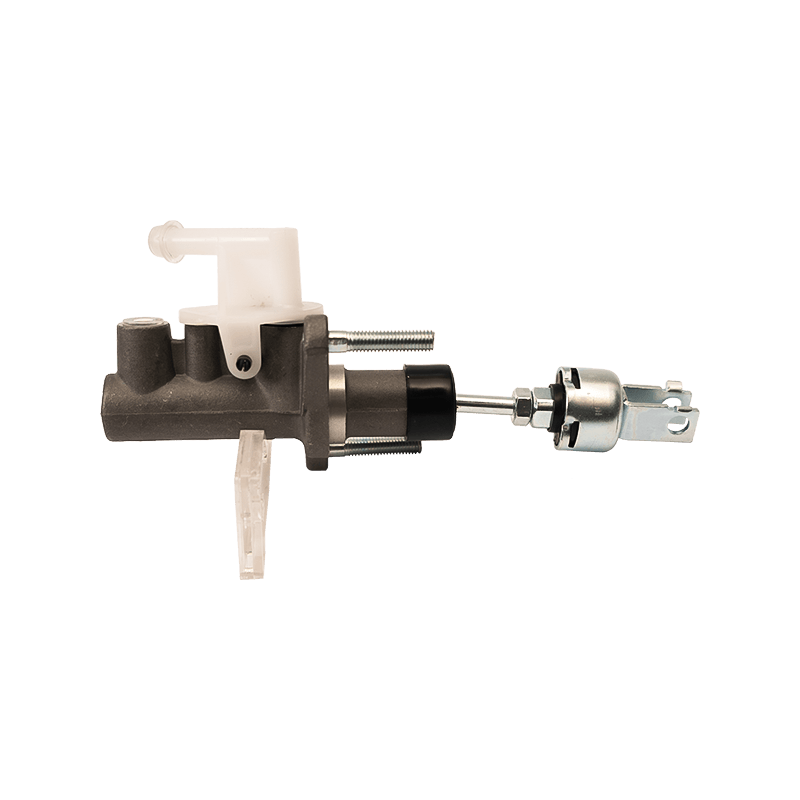

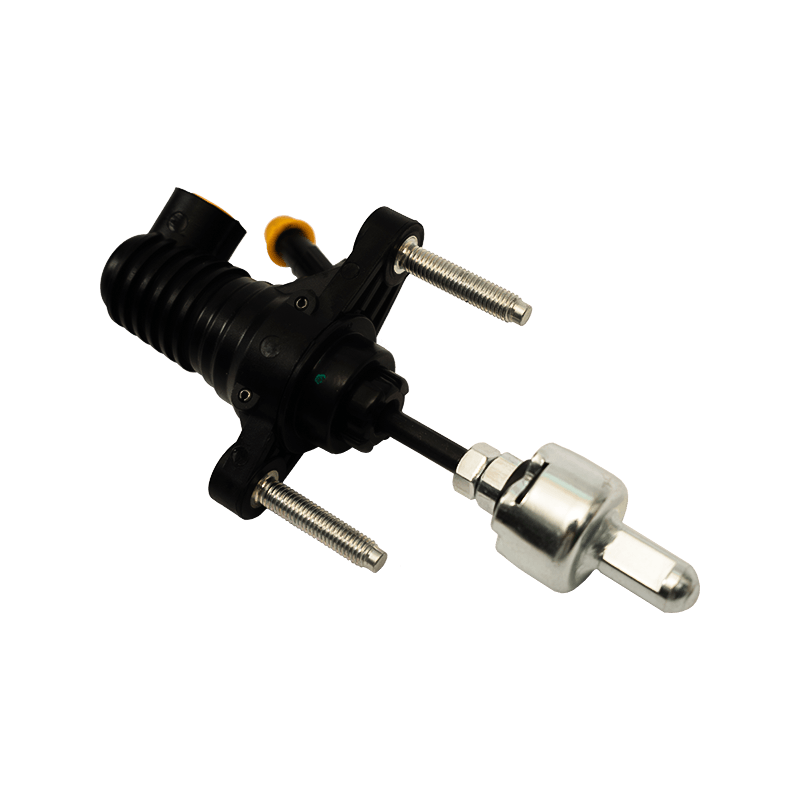

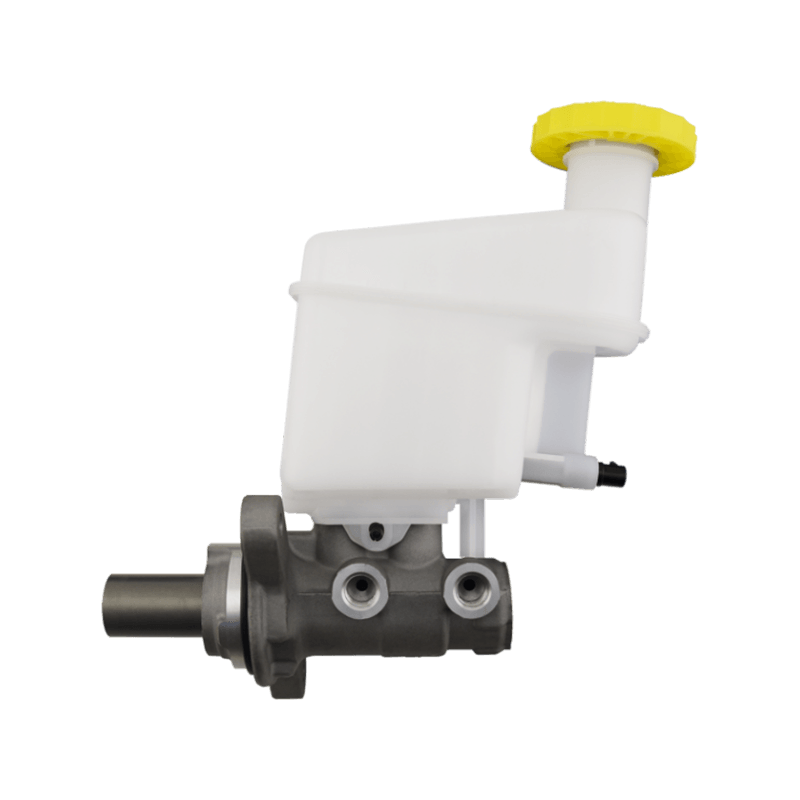

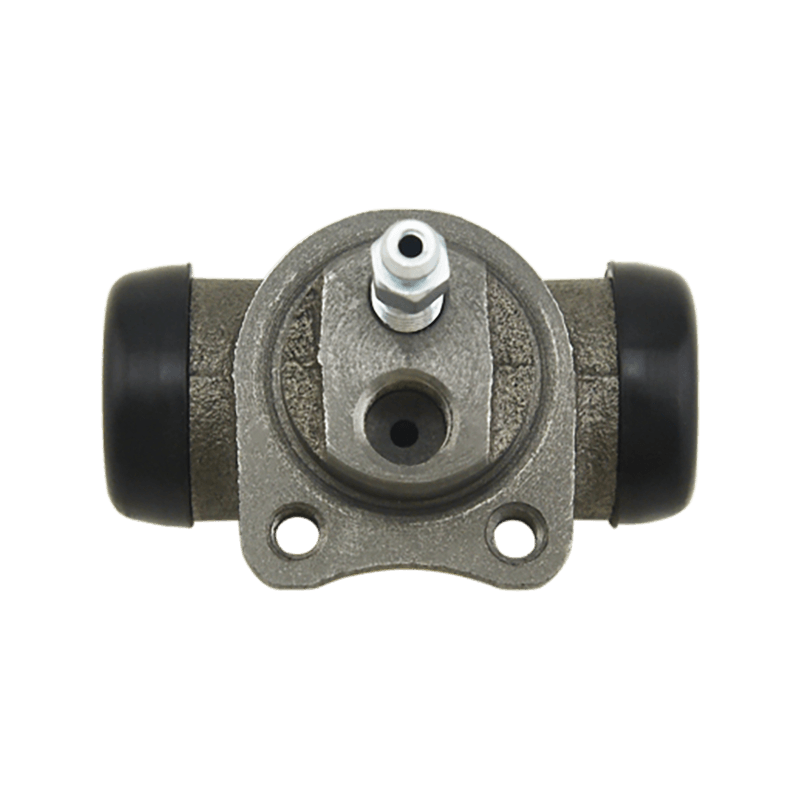

The main function of brake caliper is to press friction material to rotating brake disc through clamping force, and hydraulic transmission system converts the force of driver's stepping on brake pedal into braking torque. When brake fluid is pressed into the caliper body, the piston moves outward under the action of hydraulic pressure, pushing brake pad to contact with brake disc. In floating brake caliper design, the caliper body can slide slightly along the guide pin to make the brake pads on both sides evenly stressed; while fixed brake caliper adopts opposing piston design and applies pressure from both sides at the same time. This force conversion process can be completed in just a few milliseconds, converting vehicle kinetic energy into heat energy dissipation, and realizing rapid reduction of vehicle speed.

The selection of different materials has a direct impact on the performance of brake caliper. The caliper body is usually made of high-strength cast iron or aluminum alloy, which must withstand huge clamping force and maintain structural stability at high temperature. Piston material has evolved from cast iron to phenolic resin and then to stainless steel. Modern high-performance brake calipers even use ceramic pistons to reduce heat conduction and improve corrosion resistance. The seals are made of high temperature resistant and aging resistant materials to ensure elasticity within a special temperature range and prevent brake fluid leakage.

Thermal management design is the key to brake caliper engineering. During continuous braking, the friction surface temperature can rise to more than 600°C, resulting in thermal expansion and changes in material properties. High-quality brake calipers increase the surface area by optimizing the design of heat dissipation fins to accelerate heat dissipation; the internal oil channel layout avoids local overheating of the brake fluid to produce air resistance. The application of thermal barrier coating technology further isolates the conduction of high temperature to the hydraulic system and protects the seals and brake fluid performance.

2. Maintenance and performance maintenance of brake calipers

Correct installation is the basis for ensuring the performance of brake calipers. Special high-temperature grease is required for guide pin lubrication, and ordinary butter will liquefy and flow at high temperatures. Special tools are required to apply pressure evenly when the piston returns to its original position to avoid damage to the seal due to deflection. Torque tightening specifications must be strictly followed to ensure connection reliability. Professional repair stations use torque angle meters and sequential tightening processes to control installation errors within ±2%.

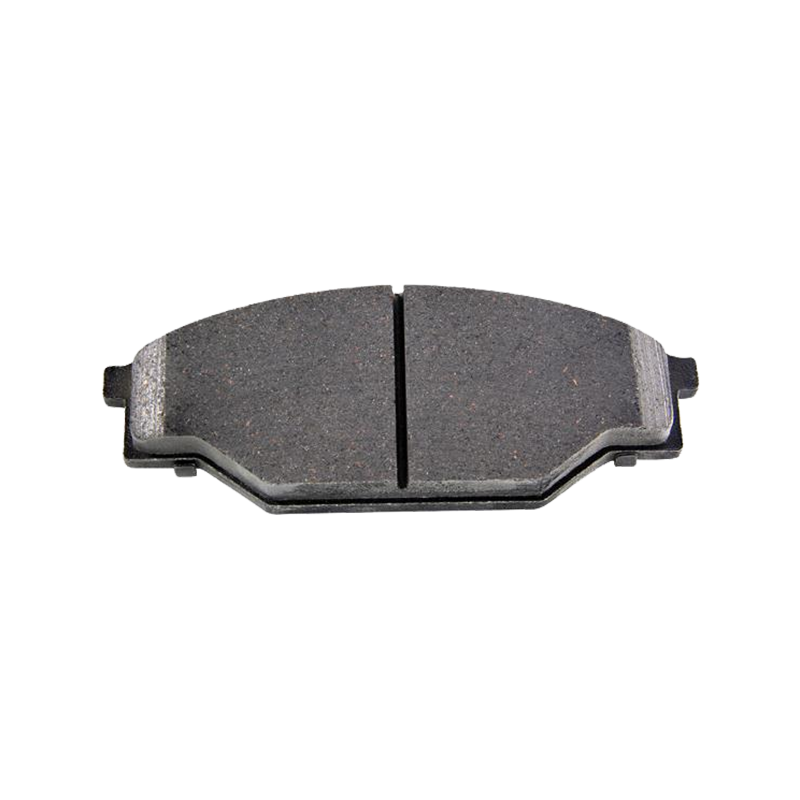

Daily inspections can detect potential problems in a timely manner. The thickness of the friction plate should be measured regularly and must be replaced when it is worn to 2-3mm (or the alarm indicator contacts). Damage to the piston dust cover can lead to water and dust intrusion, which is a common cause of jamming and needs to be dealt with immediately. The detection of the active resistance of the guide pin is also very important. The sliding resistance measured by a spring scale should be within the range of 5-15N. The large-size brake caliper set needs to match the original vehicle hydraulic system pressure. Blindly increasing it may cause insufficient fluid supply to the brake master cylinder.

3. The position of the brake caliper in the safety system

As the final executor of the braking system, the performance of the brake caliper directly affects the key safety indicator of braking distance. Test data shows that high-quality brake calipers can shorten the braking distance from 100 to 0km/h by 2-3 meters, which may be the decisive factor in avoiding collisions in emergency situations. Its thermal stability determines the reliability under harsh working conditions such as continuous downhill, avoiding brake failure caused by thermal decay. The progressive force characteristics of the brake caliper also make the ABS system work more accurately and maintain directional controllability during braking.

The development of brake caliper technology has always evolved in sync with the safety concept of the entire vehicle. From simply meeting braking needs in the early days to integrating electronic control, lightweight and intelligent functions today, brake calipers have developed into high-tech components that integrate mechanics, hydraulics and electronics. Its improved performance provides a more precise execution foundation for autonomous driving systems and is a key part of the future smart travel ecosystem.

Search

Search

Eng

Eng

English

English Español

Español Português

Português