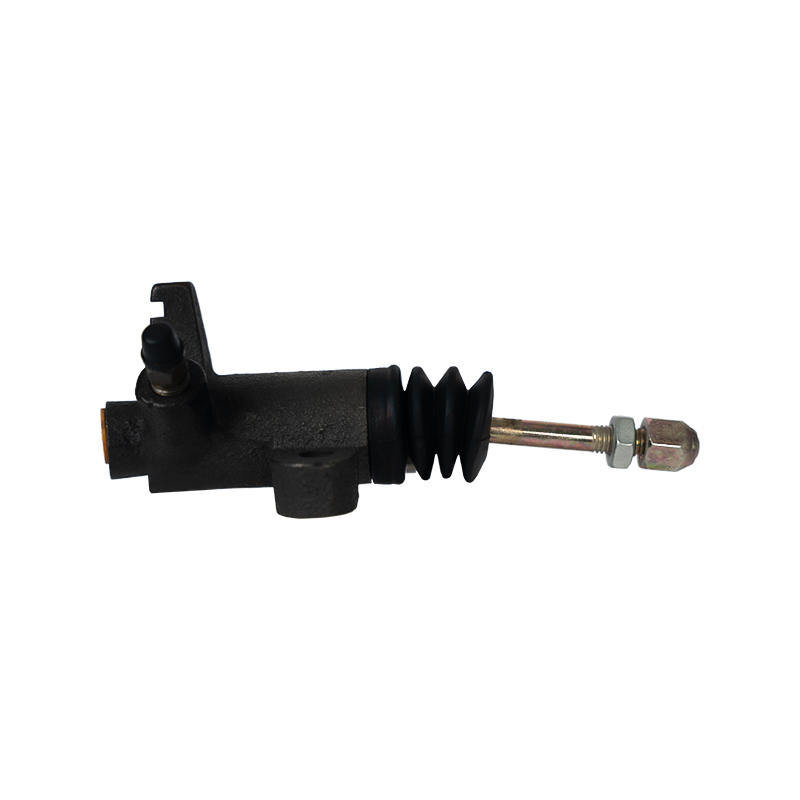

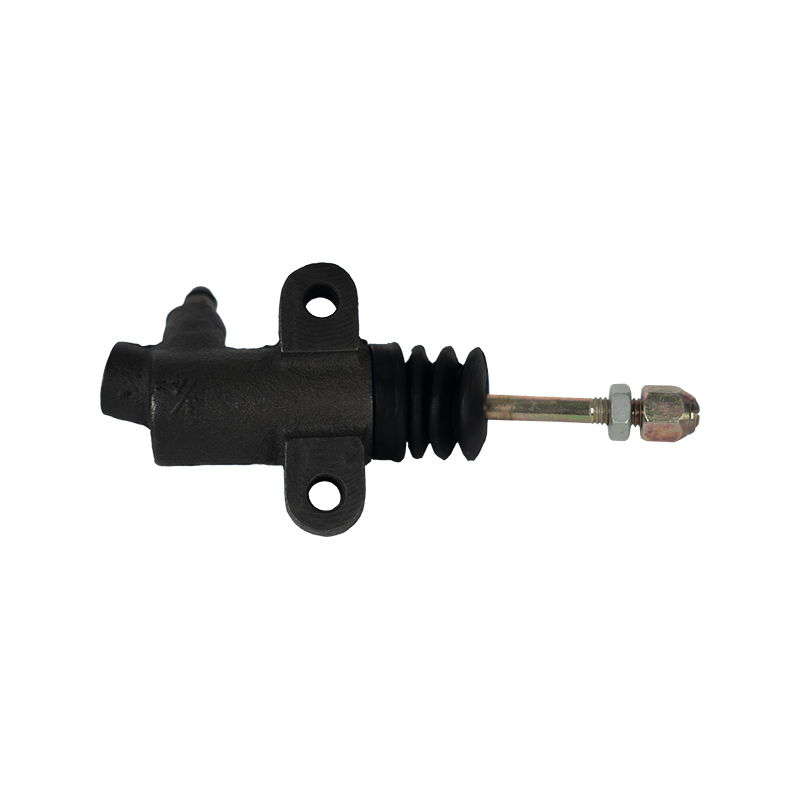

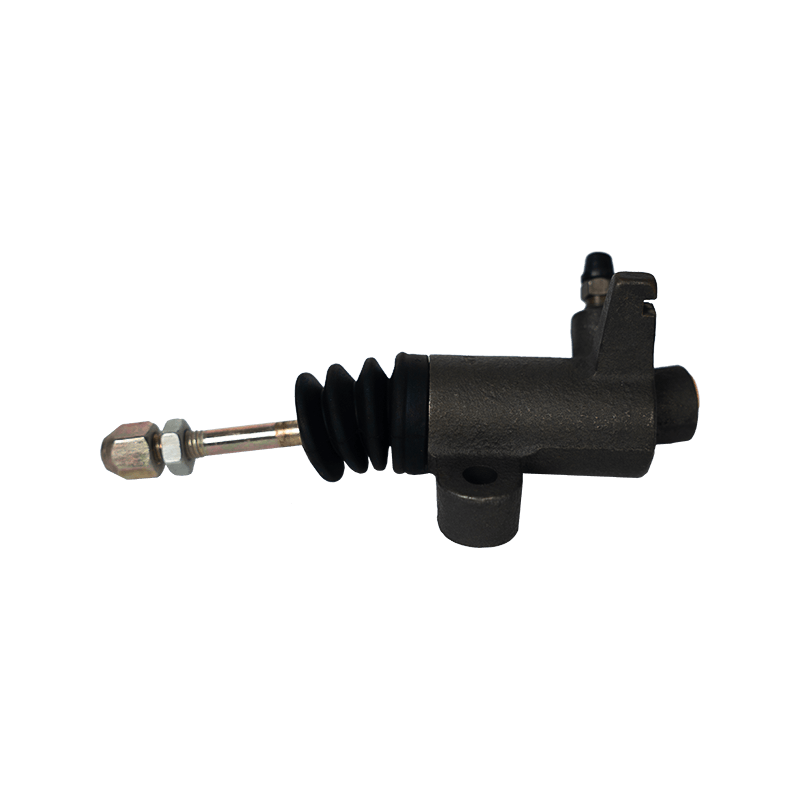

31470-20101 Clutch Slave Cylinder for Toyota

|

OE NO |

31470-20101 31470-20100 |

|

DESCRIP |

CSC |

|

MODEL |

Toyota |

Specifications

KEEP IN TOUCH

We have more than 1,000 brake shoes and brake pads for European, American, Russian, Japanese and Korean cars. The associated factories have created a highly experienced manufacturing team that exports thousands of auto part products worldwide. High quality and competitive prices are our targets. Our products have gained the certifications of ISO9001 and TS16949. We have built up a solid reputation with our customers in more than 30 countries.

We are looking forward to having a brighter and more successful business in the near future together with all of our clients all over the world.

-

Why Choose OE Quality Brake Pads? When selecting brake pads, OE QUALITY BRAKE PADS ensure precise fit, optimal braking performance, and long-term dur...

READ MORE -

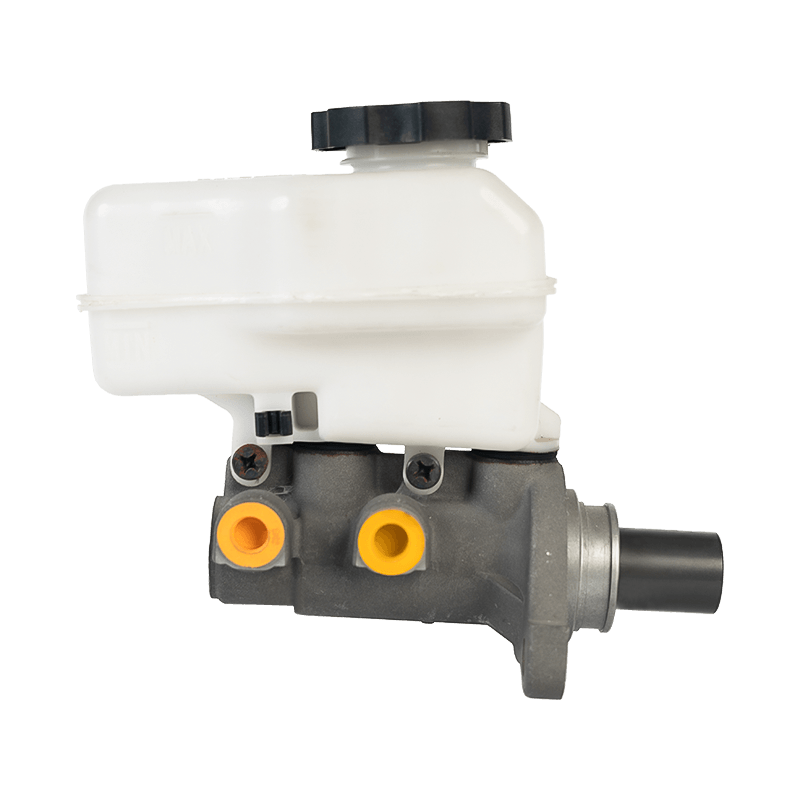

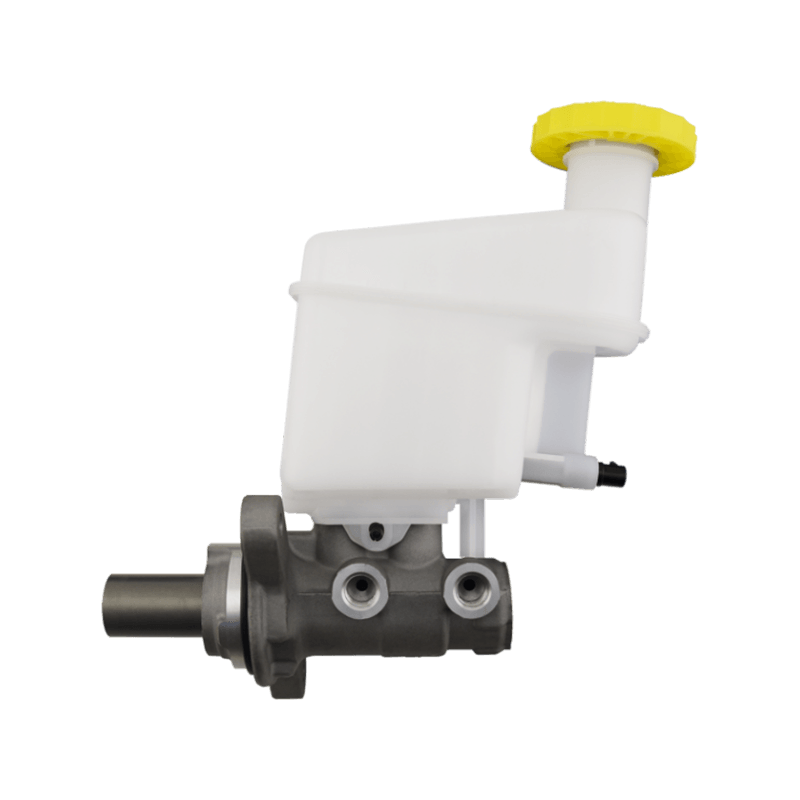

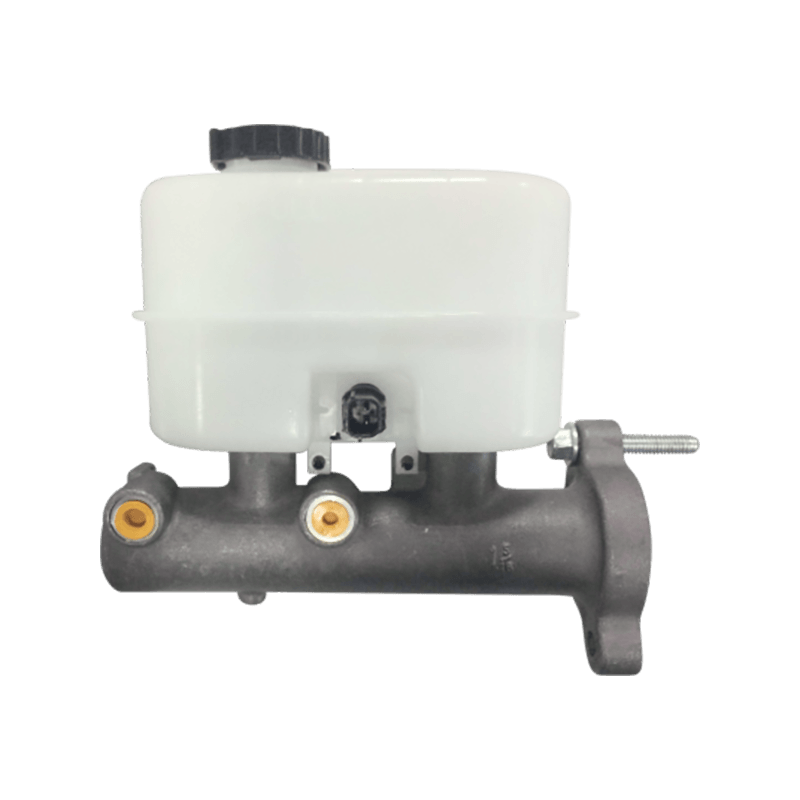

What is a Hydraulic Brake Master Cylinder? The hydraulic brake master cylinder is a critical component in a vehicle's braking system. It converts the...

READ MORE -

Why OE Quality Brake Pads Are the Best Choice for Your Car OE (Original Equipment) quality brake pads are specifically designed to match the specific...

READ MORE -

The direct answer: Yes. High-quality brake pads can reduce braking distance by 15%–30%, improve heat resistance, and significantly enhance driving saf...

READ MORE

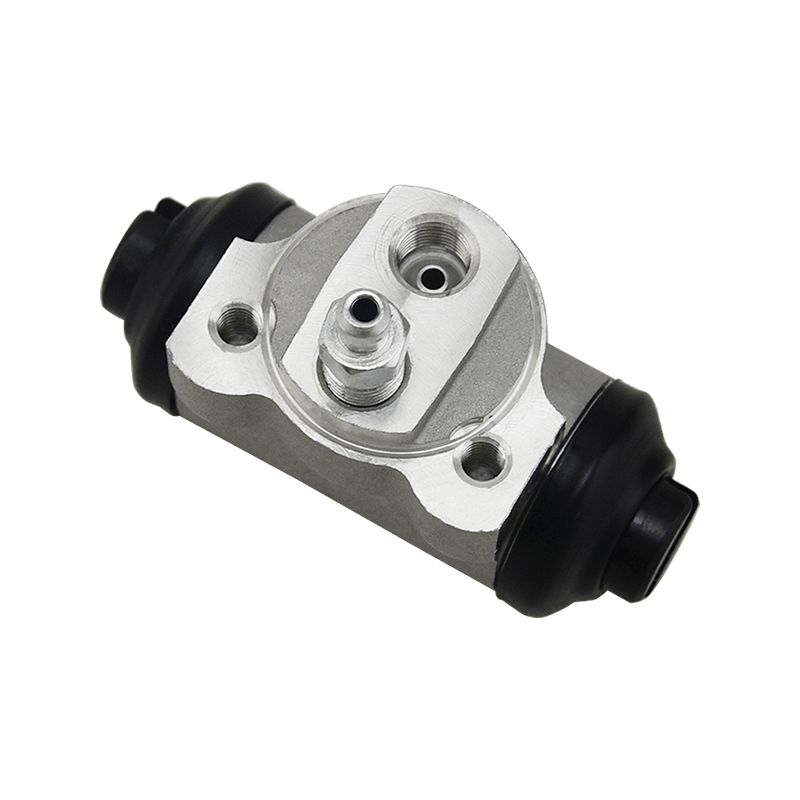

31470-20101 Clutch Slave Cylinder For Toyota is made of high-strength cast iron, with electrophoretic anti-rust treatment on the surface. The piston diameter is 3/4 inches (19.05mm), and the peak working pressure can reach 32MPa. The core function is to convert the clutch pedal input into hydraulic thrust, control the engagement and disengagement of the clutch plate, and ensure the smoothness of power transmission.

The adaptability of this slave cylinder focuses on Toyota classic car series, including the Corona RT100 series produced from 1973 to 1979, and is especially optimized for the 2.0L 18R engine version. Its OE number is the same as 31470-20100, and it has passed third-party certifications such as TRW PJD182 and DJ PARTS CS1067, and is compatible with multi-brand replacement parts.

If the slave pump has piston return hysteresis or seal leakage, it is recommended to replace the assembly directly instead of repairing it. When operating, you need to disconnect the hydraulic oil pipe and drain the system first, use a 10mm socket to remove the fixing bolts and then separate the slave pump. After installation, you need to drain the hydraulic system: connect the special tool to the exhaust valve, continuously step on the clutch pedal until no bubbles are discharged, and lock the exhaust valve to 8-10N·m torque.

Search

Search

Eng

Eng

English

English Español

Español Português

Português