We have more than 1,000 brake shoes and brake pads for European, American, Russian, Japanese and Korean cars. The associated factories have created a highly experienced manufacturing team that exports thousands of auto part products worldwide. High quality and competitive prices are our targets. Our products have gained the certifications of ISO9001 and TS16949. We have built up a solid reputation with our customers in more than 30 countries.

We are looking forward to having a brighter and more successful business in the near future together with all of our clients all over the world.

-

Why Choose OE Quality Brake Pads? When selecting brake pads, OE QUALITY BRAKE PADS ensure precise fit, optimal braking performance, and long-term dur...

READ MORE -

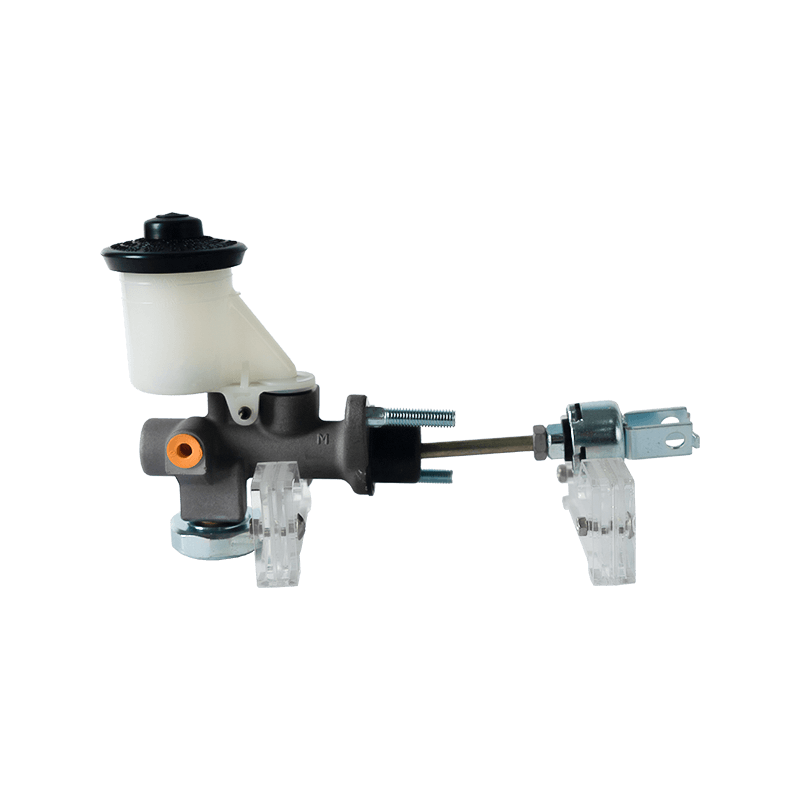

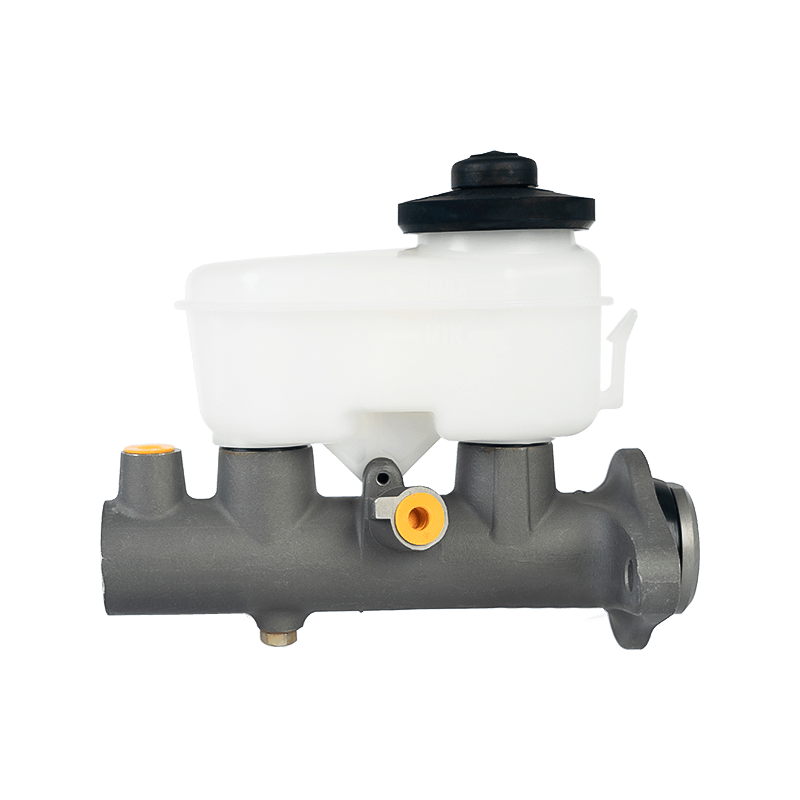

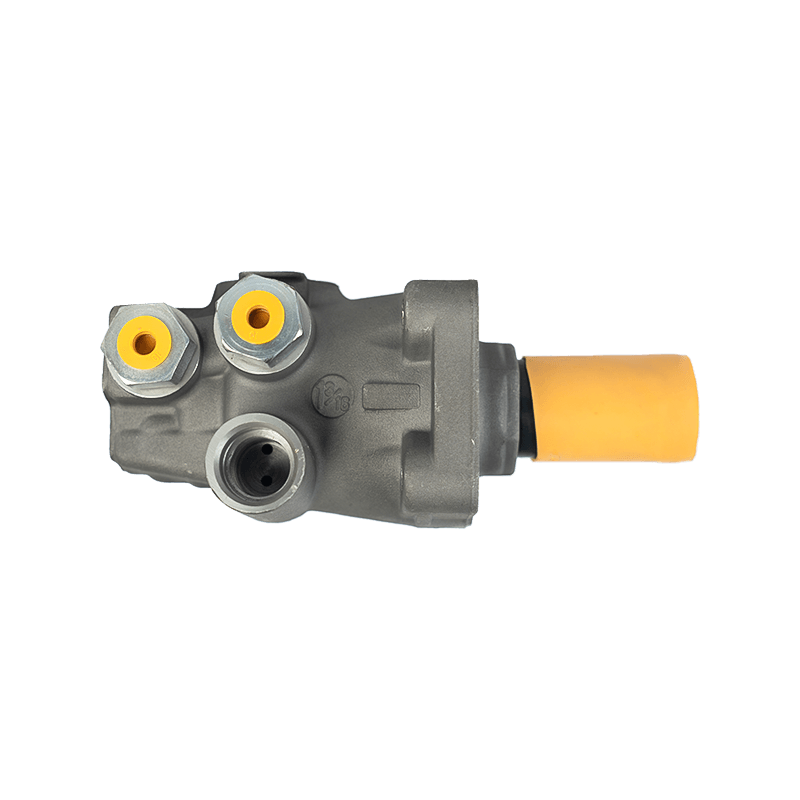

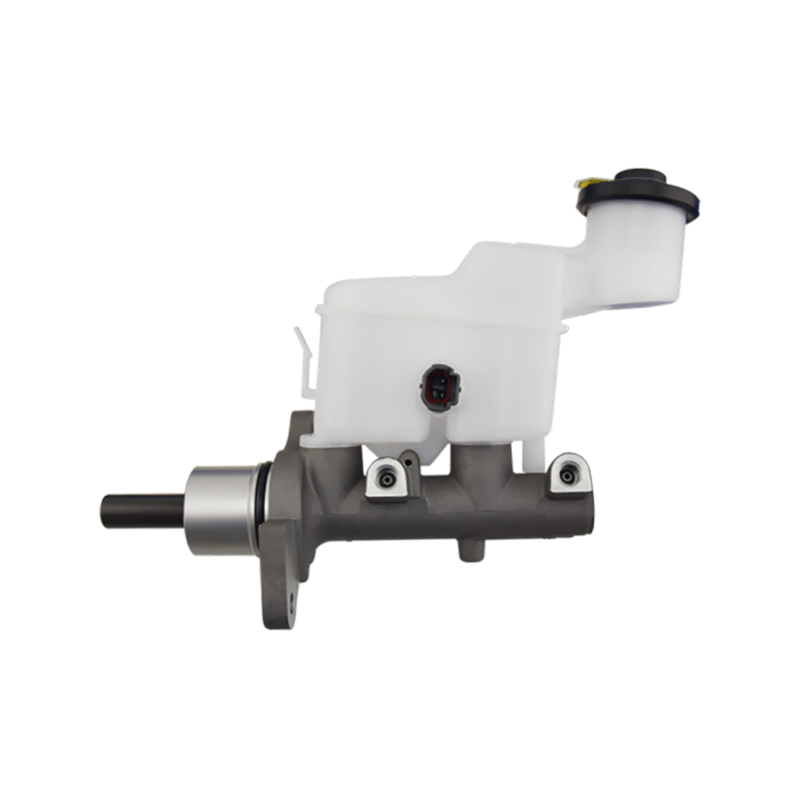

What is a Hydraulic Brake Master Cylinder? The hydraulic brake master cylinder is a critical component in a vehicle's braking system. It converts the...

READ MORE -

Why OE Quality Brake Pads Are the Best Choice for Your Car OE (Original Equipment) quality brake pads are specifically designed to match the specific...

READ MORE -

The direct answer: Yes. High-quality brake pads can reduce braking distance by 15%–30%, improve heat resistance, and significantly enhance driving saf...

READ MORE

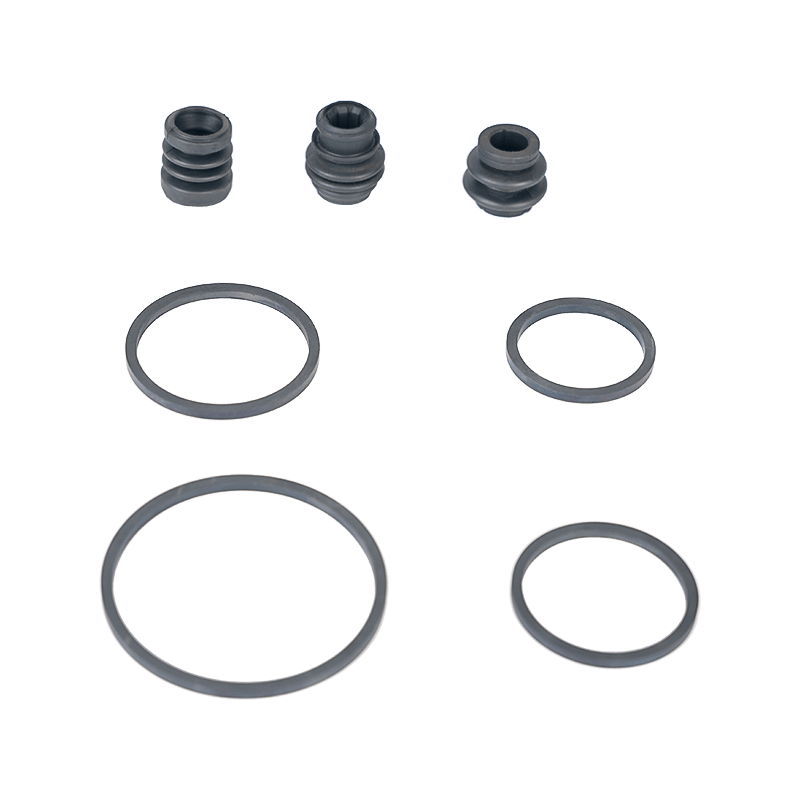

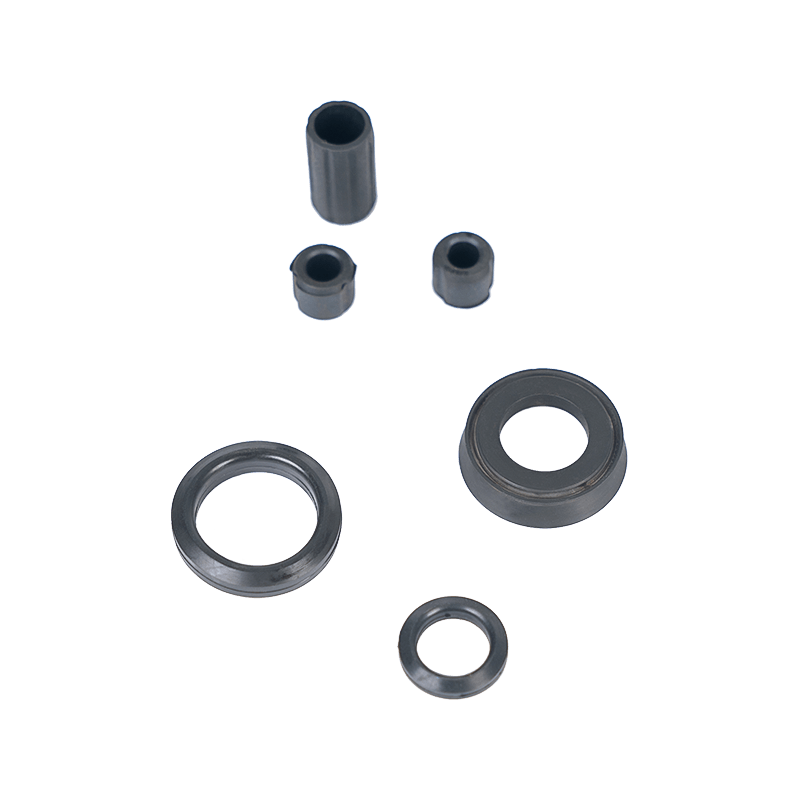

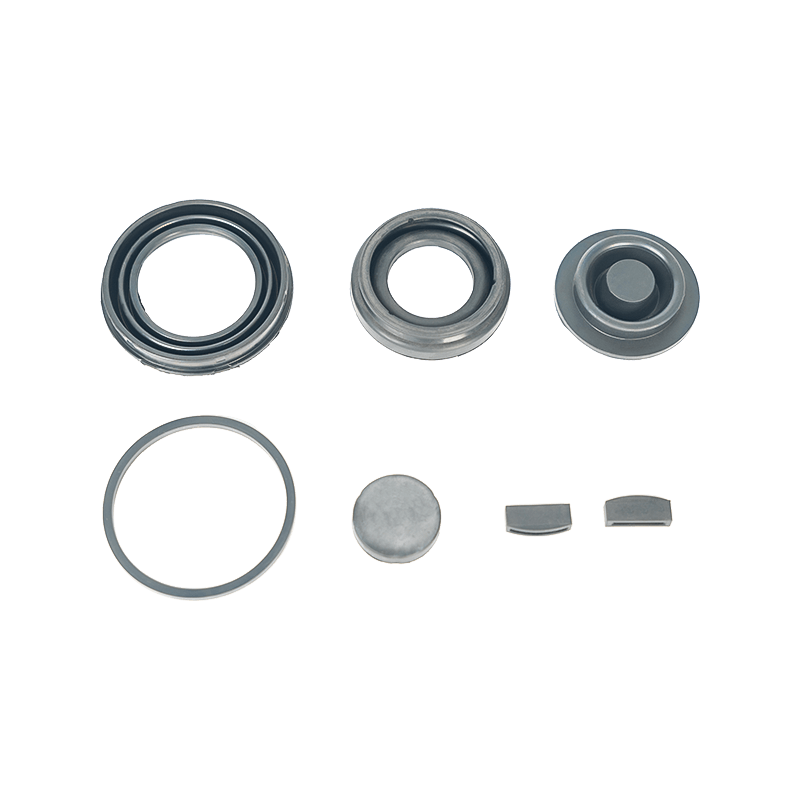

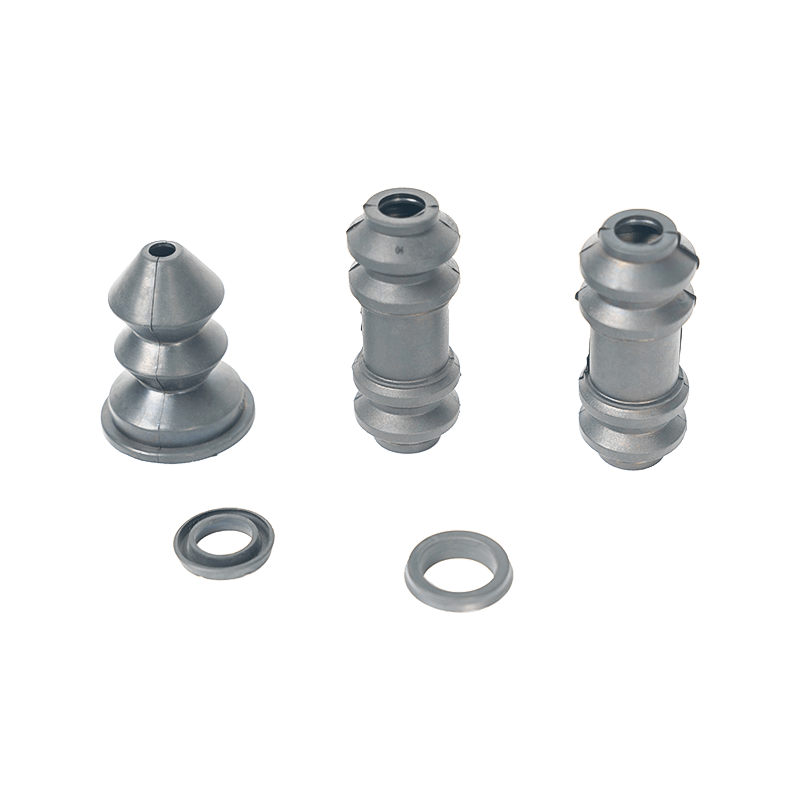

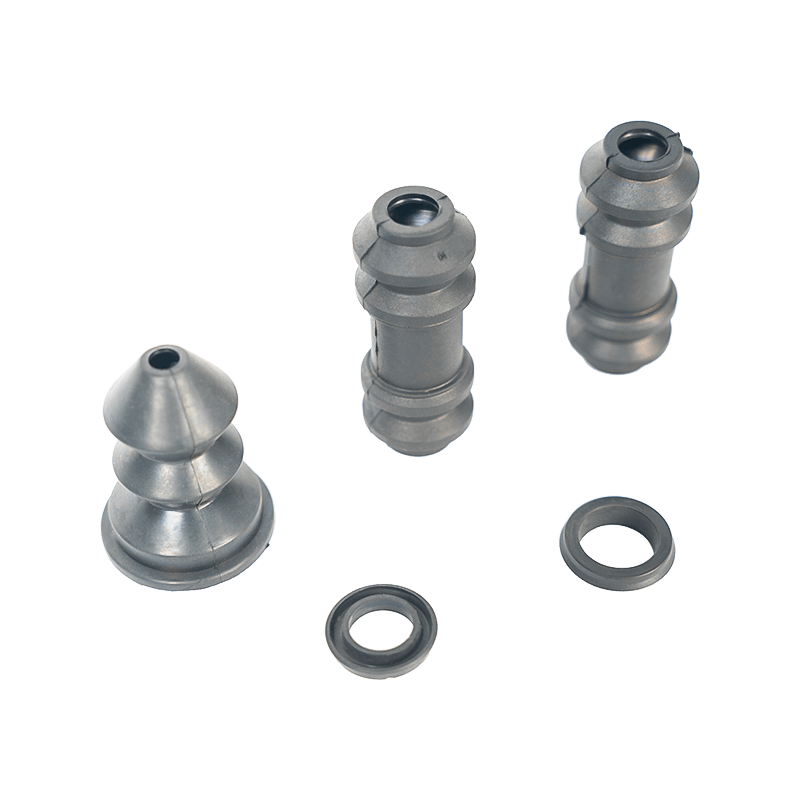

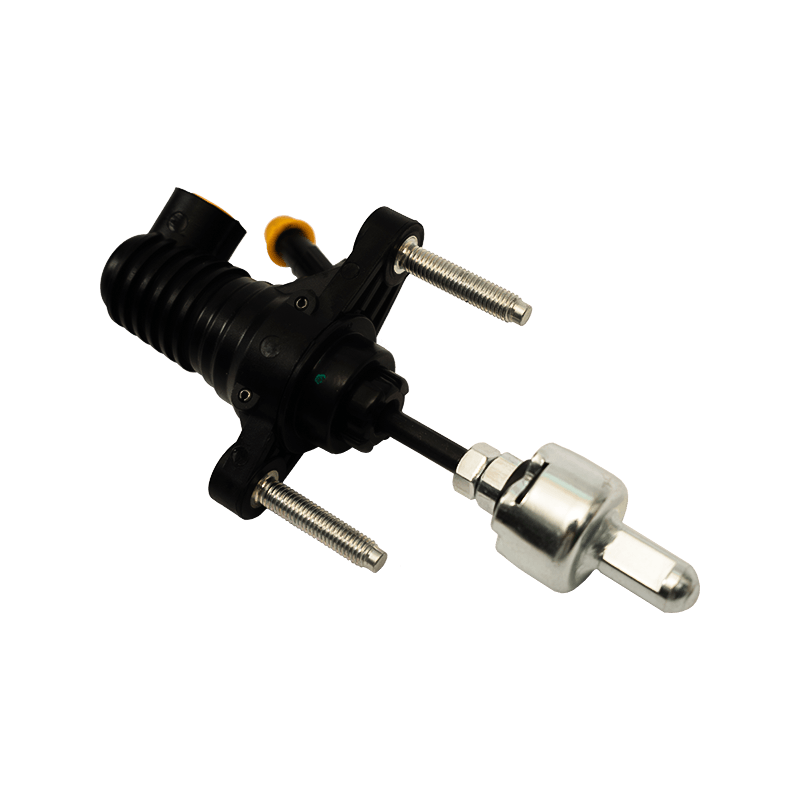

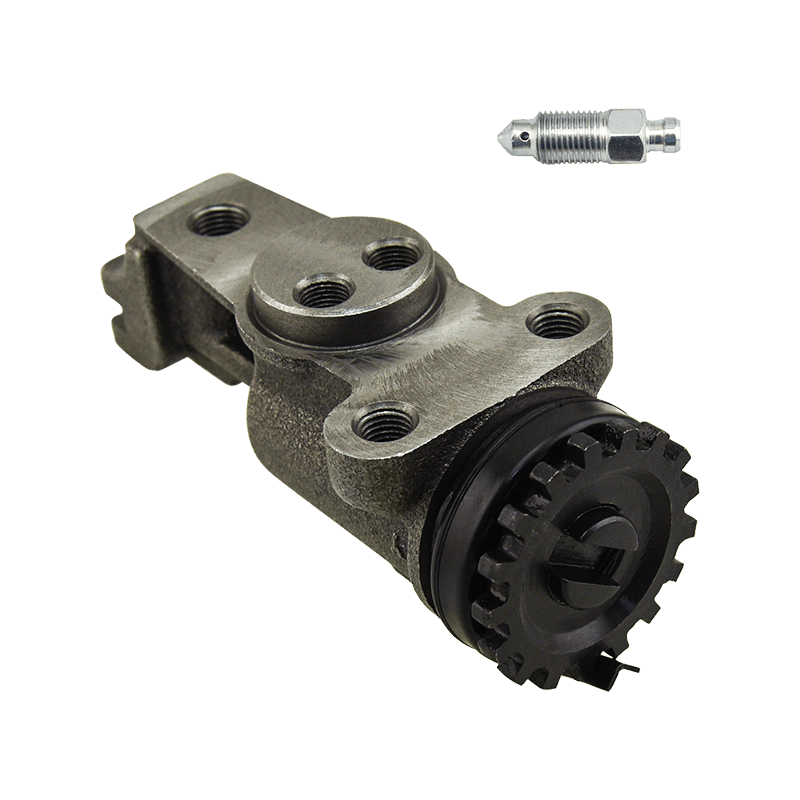

As the automotive market services continue to upgrade, auto parts repair kits, as carriers of integrated maintenance solutions, are reshaping the efficiency standards of the maintenance industry with systematic and precise design concepts. The repair kit integrates the seals, gaskets, fasteners and special tools required for specific maintenance scenarios into a standardized set. For example, the engine valve cover repair kit integrates oil seals, bolts and sealing strips, while the clutch master cylinder repair kit covers components such as pistons, springs and dust covers. Its modular design not only reduces the time cost of scattered procurement, but also ensures the reliability of the coordinated work of various components through strict compatibility testing.

From the perspective of application scenarios, the actual application of the repair kit meets the maintenance needs of existing vehicles. The repair kit integrates the seals, gaskets, fasteners and supporting tools required for specific maintenance scenarios into a standardized set, avoiding time loss. This modular design shortens the maintenance time by more than 40%. The repair kit reduces the additional procurement costs caused by missing accessories during the maintenance process by pre-setting key consumables (such as sealing strips, noise-proof sheets) and special tools.

Search

Search

Eng

Eng

English

English Español

Español Português

Português