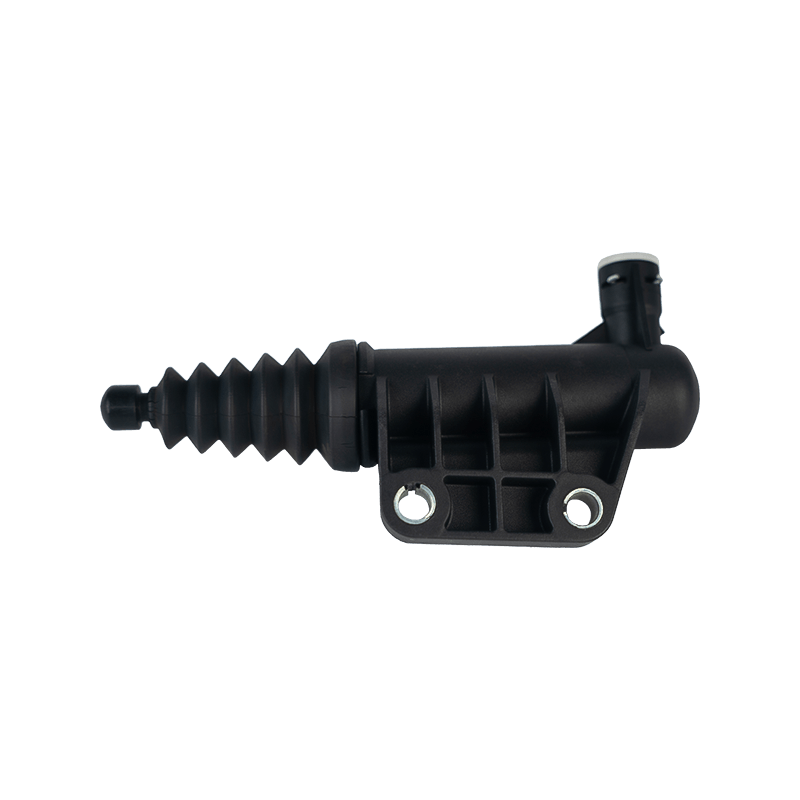

46541667 Clutch Slave Cylinder for FIAT

|

OE NO |

46541667 60801973 55196189 55227259 |

|

DESCRIP |

CSC |

|

MODEL |

FIAT |

Specifications

KEEP IN TOUCH

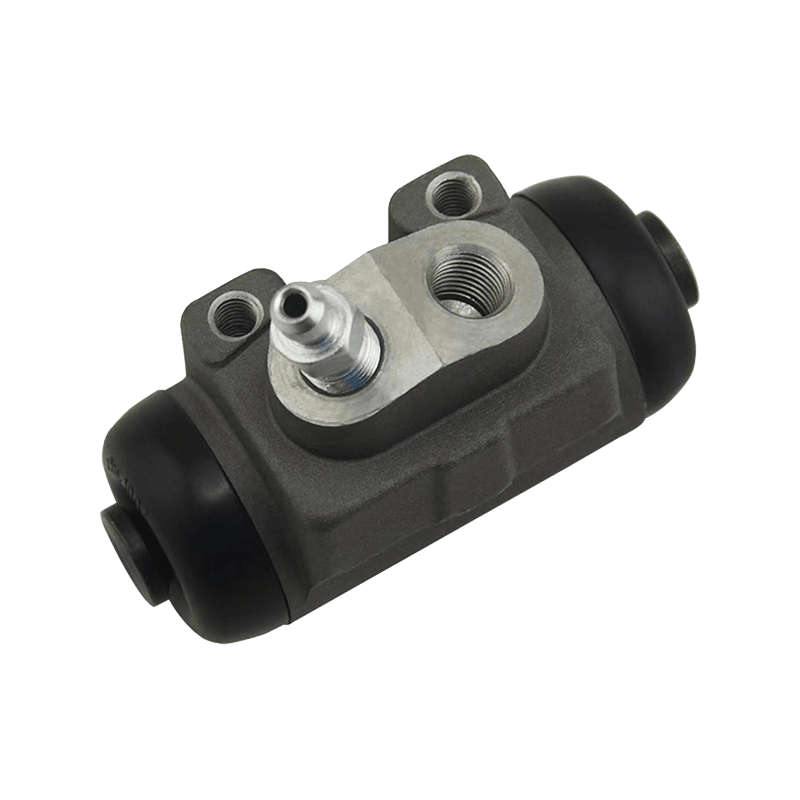

We have more than 1,000 brake shoes and brake pads for European, American, Russian, Japanese and Korean cars. The associated factories have created a highly experienced manufacturing team that exports thousands of auto part products worldwide. High quality and competitive prices are our targets. Our products have gained the certifications of ISO9001 and TS16949. We have built up a solid reputation with our customers in more than 30 countries.

We are looking forward to having a brighter and more successful business in the near future together with all of our clients all over the world.

-

Why Choose OE Quality Brake Pads? When selecting brake pads, OE QUALITY BRAKE PADS ensure precise fit, optimal braking performance, and long-term dur...

READ MORE -

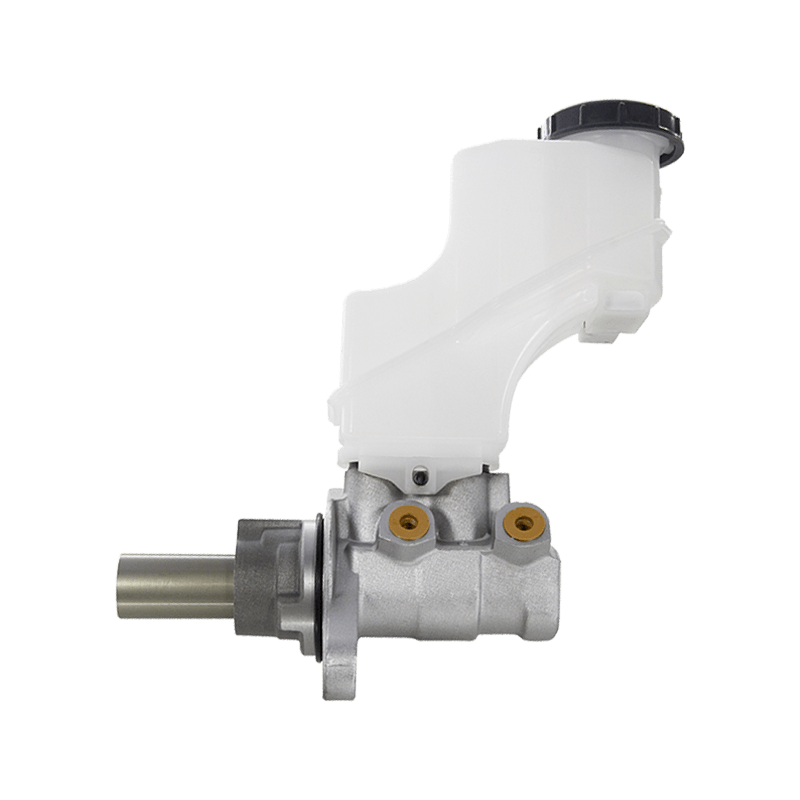

What is a Hydraulic Brake Master Cylinder? The hydraulic brake master cylinder is a critical component in a vehicle's braking system. It converts the...

READ MORE -

Why OE Quality Brake Pads Are the Best Choice for Your Car OE (Original Equipment) quality brake pads are specifically designed to match the specific...

READ MORE -

The direct answer: Yes. High-quality brake pads can reduce braking distance by 15%–30%, improve heat resistance, and significantly enhance driving saf...

READ MORE

46541667 Clutch Slave Cylinder For FIAT is the core component of the clutch system. Its function is to accurately convert the mechanical force input by the pedal into hydraulic thrust to control the separation and engagement of the clutch plate. This component is cast with a high-strength aluminum alloy and engineering plastic composite material, and the surface is supplemented with electrophoresis anti-rust process. The piston diameter is designed to be 19.05mm, and the working pressure peak can reach 32MPa. It is suitable for Fiat Doblo (2001-2024 models), Punto (1999-2012 models), Stilo (2001-2010 models) and other main models.

46541667 slave cylinder adopts a single piston structure, and the piston seal ring is made of high-temperature resistant fluororubber material. The temperature range of tolerance covers -40°C to 120°C, which can cope with the heat accumulation generated by continuous semi-clutch operation. Its guide pin system has been nitrided and hardened, and with the double-layer dust cover design, the efficiency of blocking mud and sand intrusion is more than 85%, reducing the risk of guide pin jamming.

In maintenance practice, if the piston return hysteresis or sealing ring leakage occurs in the slave pump, it is recommended to replace the assembly directly. When operating, you need to disconnect the hydraulic oil pipe and drain the system first, and use a 10mm sleeve to remove the fixing bolts and then separate the slave pump. After installing the new slave pump, the hydraulic system needs to be drained. The 46541667 slave pump has passed special environmental tests, and the hydraulic response speed deviation does not exceed 0.15 seconds under extreme cold of -40°C and high temperature of 50°C. Its optimized heat dissipation structure combined with EPDM rubber material can reduce the thermal attenuation effect after continuous braking.

Search

Search

Eng

Eng

English

English Español

Español Português

Português