Specifications

KEEP IN TOUCH

We have more than 1,000 brake shoes and brake pads for European, American, Russian, Japanese and Korean cars. The associated factories have created a highly experienced manufacturing team that exports thousands of auto part products worldwide. High quality and competitive prices are our targets. Our products have gained the certifications of ISO9001 and TS16949. We have built up a solid reputation with our customers in more than 30 countries.

We are looking forward to having a brighter and more successful business in the near future together with all of our clients all over the world.

-

Why Choose OE Quality Brake Pads? When selecting brake pads, OE QUALITY BRAKE PADS ensure precise fit, optimal braking performance, and long-term dur...

READ MORE -

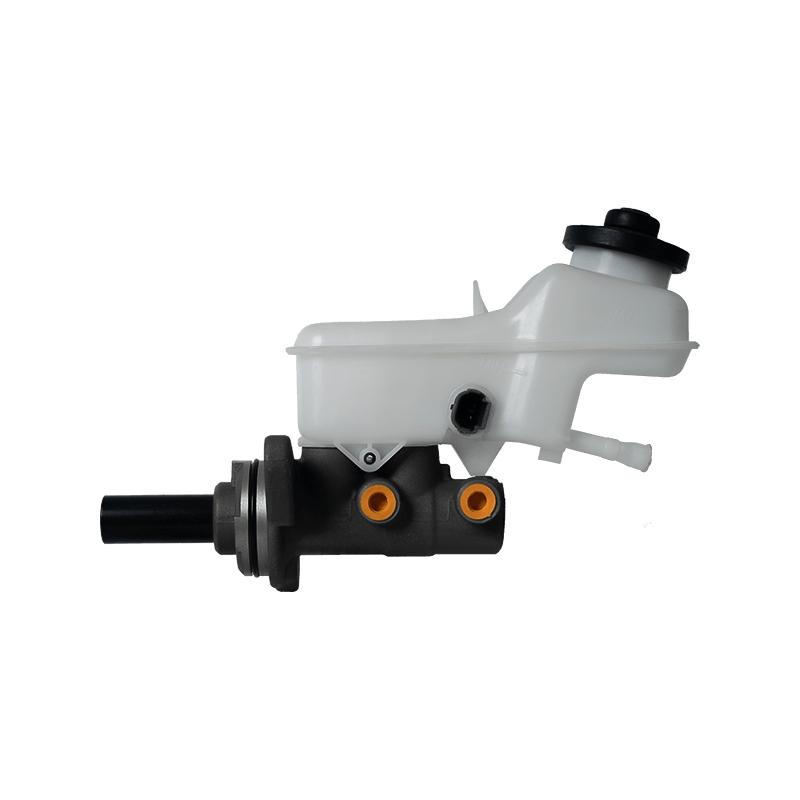

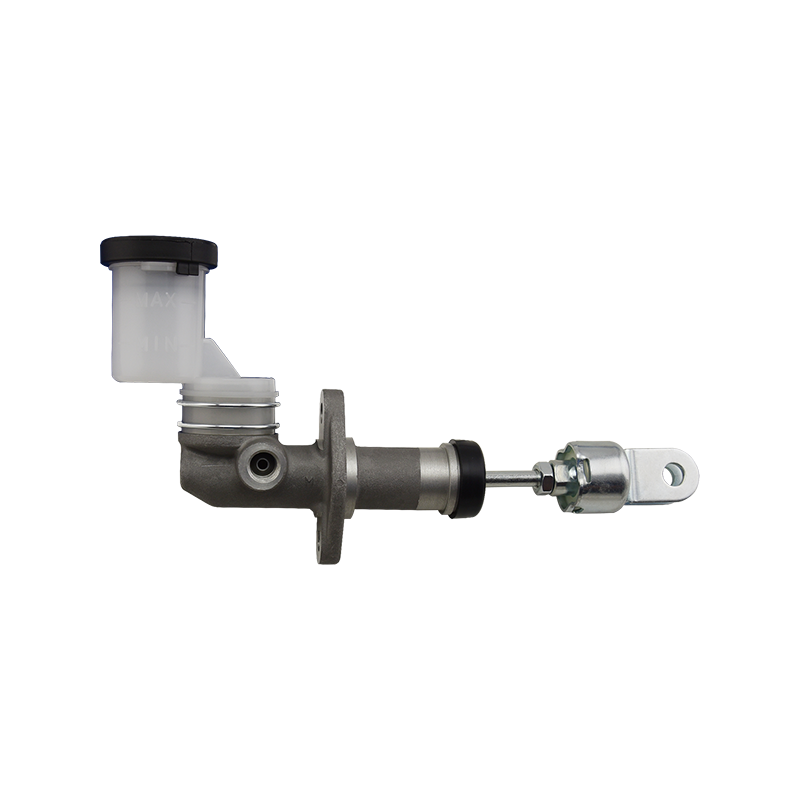

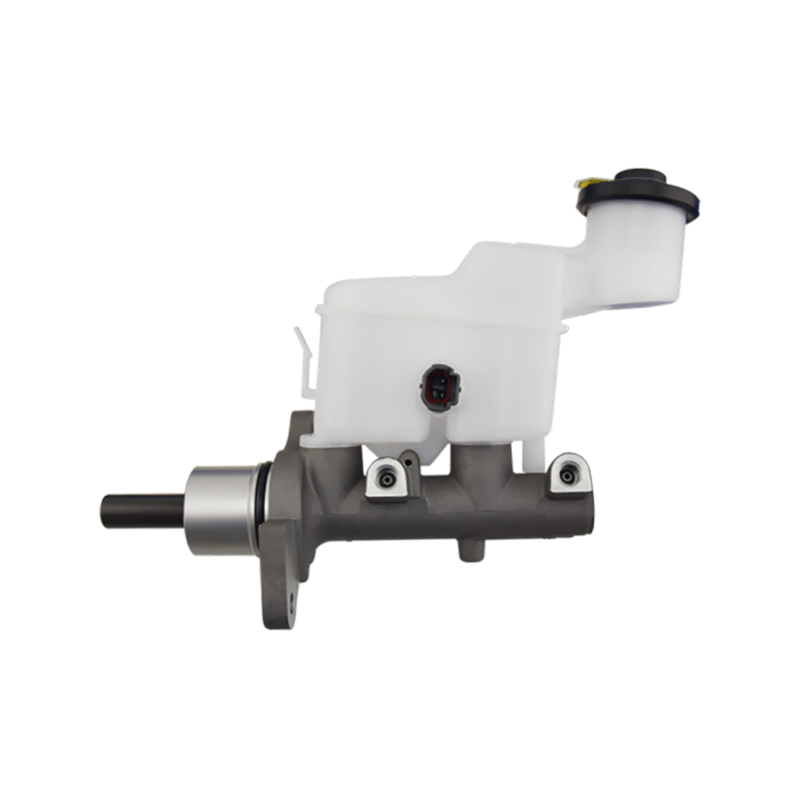

What is a Hydraulic Brake Master Cylinder? The hydraulic brake master cylinder is a critical component in a vehicle's braking system. It converts the...

READ MORE -

Why OE Quality Brake Pads Are the Best Choice for Your Car OE (Original Equipment) quality brake pads are specifically designed to match the specific...

READ MORE -

The direct answer: Yes. High-quality brake pads can reduce braking distance by 15%–30%, improve heat resistance, and significantly enhance driving saf...

READ MORE

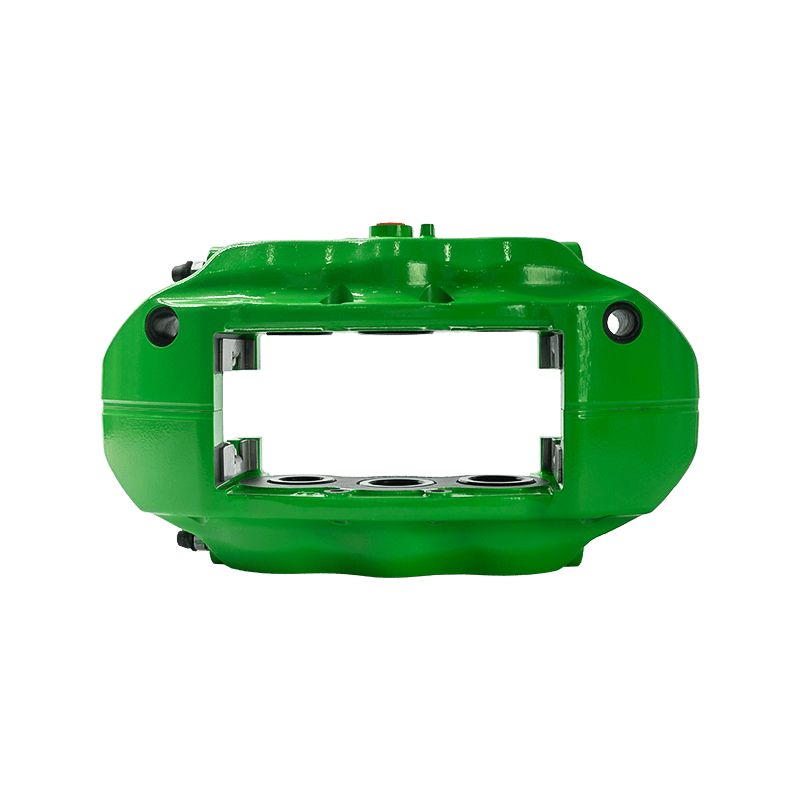

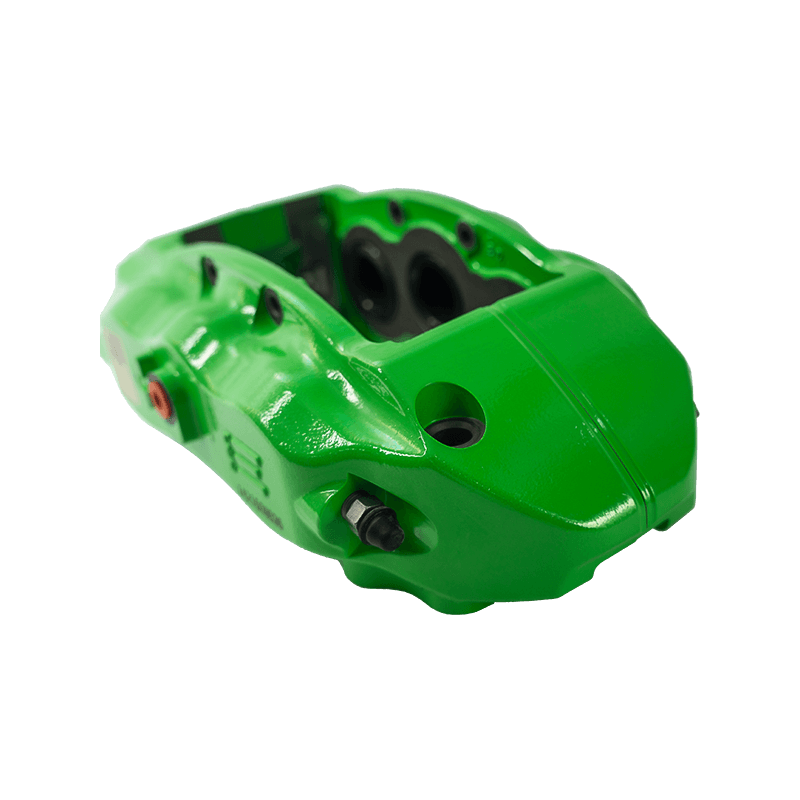

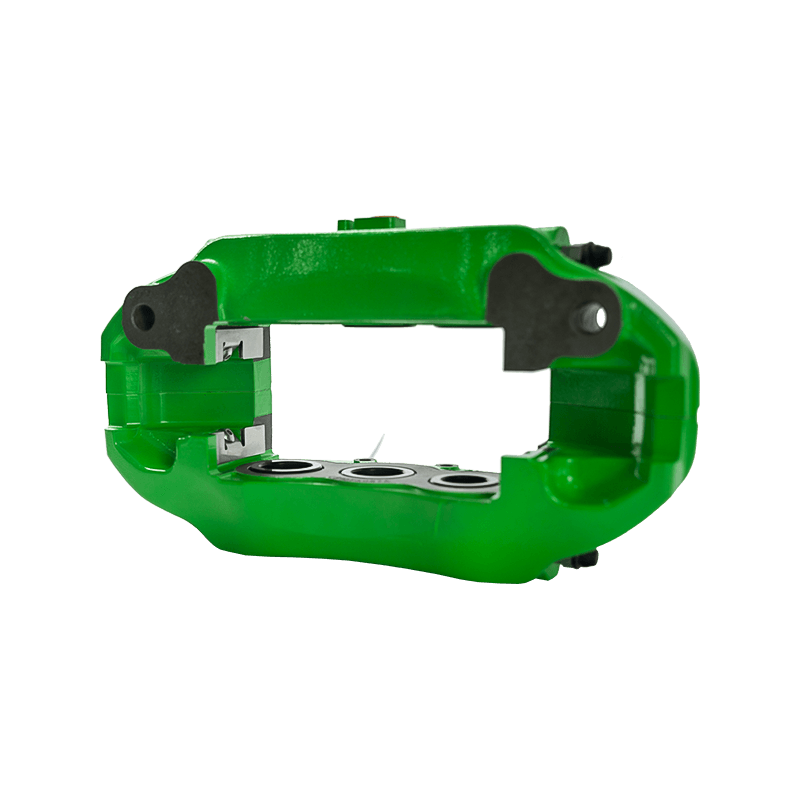

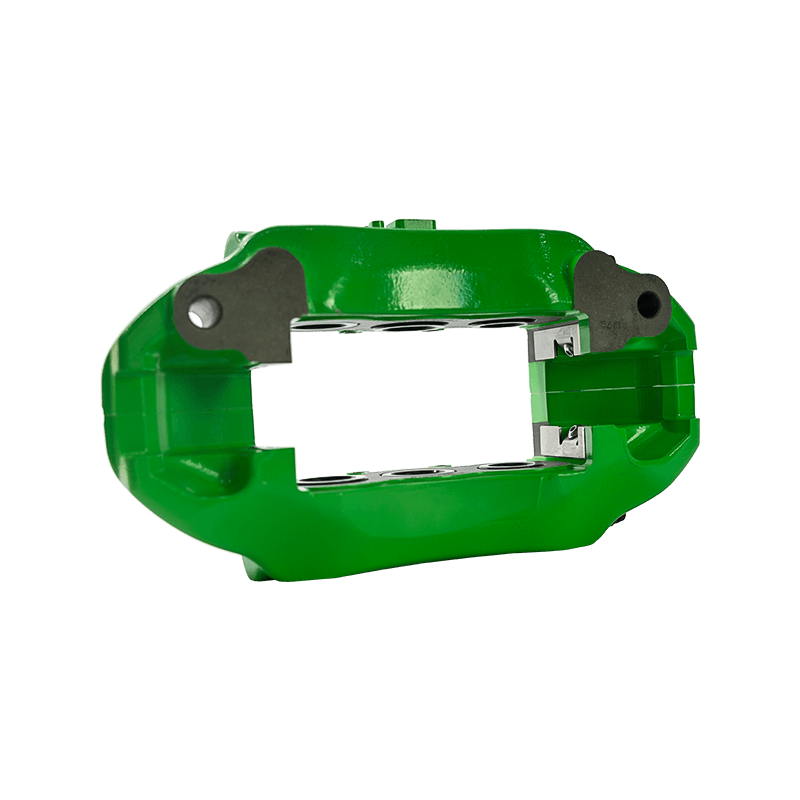

As the core component of the braking system, the RW838005(B) brake caliper has become an efficient braking solution in the field of logistics and construction machinery with its precision engineering design and industrial-grade durability. The brake caliper is designed for heavy-duty forklifts, port machinery and mining transportation vehicles. It is suitable for 8-ton forklift platforms such as Hangcha CPCD80-RW28. It is made using a split casting process. The weight of a single caliper is controlled within 14.5 kg, which is 18% lighter than the traditional structure, while the compressive strength is increased to 380MPa. Its dual-piston symmetrical layout and the enhanced hydraulic cylinder with a diameter of 42mm can output a braking torque of 5800N·m, shortening the 100-0km/h braking distance to within 42 meters under full load conditions, which is 30% more efficient than ordinary calipers.

In terms of material technology, RW838005(B) innovatively applies silicon nitride gradient coating technology. The sealing system uses a fluororubber composite material, and its oil resistance is increased to three times that of traditional nitrile rubber. With the double-channel dust cover design, it can effectively resist the salt spray environment of the port and the erosion of mine dust, and the maintenance cycle is extended to 12,000 hours. In terms of manufacturing technology, the caliper is produced in accordance with ISO/TS16949 standards. The casting process adopts a low-pressure sand mold process, and X-ray flaw detection is used to ensure that the internal porosity of the casting is less than 0.3%. The five-axis linkage CNC machine tool is used in the precision machining stage, and the roundness error of the piston hole is controlled within ±0.005mm.

In actual application, RW838005(B) shows good scene adaptability. Its wavy heat dissipation fins and vortex guide groove design, combined with the enhanced brake disc with a diameter of 282mm, can reduce the friction interface temperature from 600℃ to 180℃ within 90 seconds, perfectly meeting the continuous braking needs of the port container stacker. For the enhanced version designed for heavy-load transportation scenarios in mines, a buffer spring structure is added to the bottom of the piston, which can absorb 30% of the impact load. In actual measurements, no thermal cracks were found in the 30-minute continuous braking test.

Search

Search

Eng

Eng

English

English Español

Español Português

Português