Specifications

KEEP IN TOUCH

We have more than 1,000 brake shoes and brake pads for European, American, Russian, Japanese and Korean cars. The associated factories have created a highly experienced manufacturing team that exports thousands of auto part products worldwide. High quality and competitive prices are our targets. Our products have gained the certifications of ISO9001 and TS16949. We have built up a solid reputation with our customers in more than 30 countries.

We are looking forward to having a brighter and more successful business in the near future together with all of our clients all over the world.

-

Why Choose OE Quality Brake Pads? When selecting brake pads, OE QUALITY BRAKE PADS ensure precise fit, optimal braking performance, and long-term dur...

READ MORE -

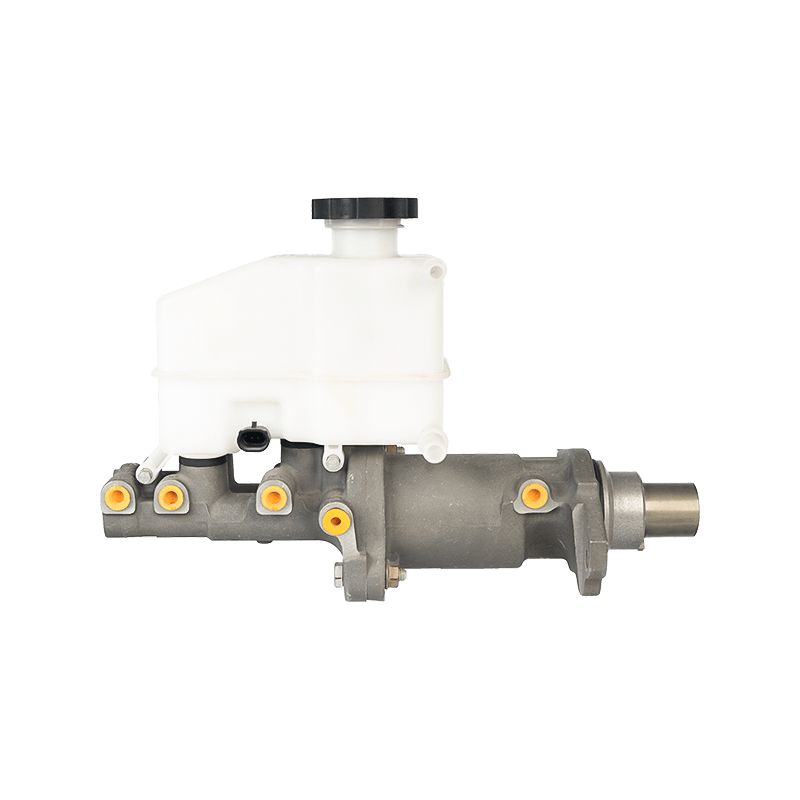

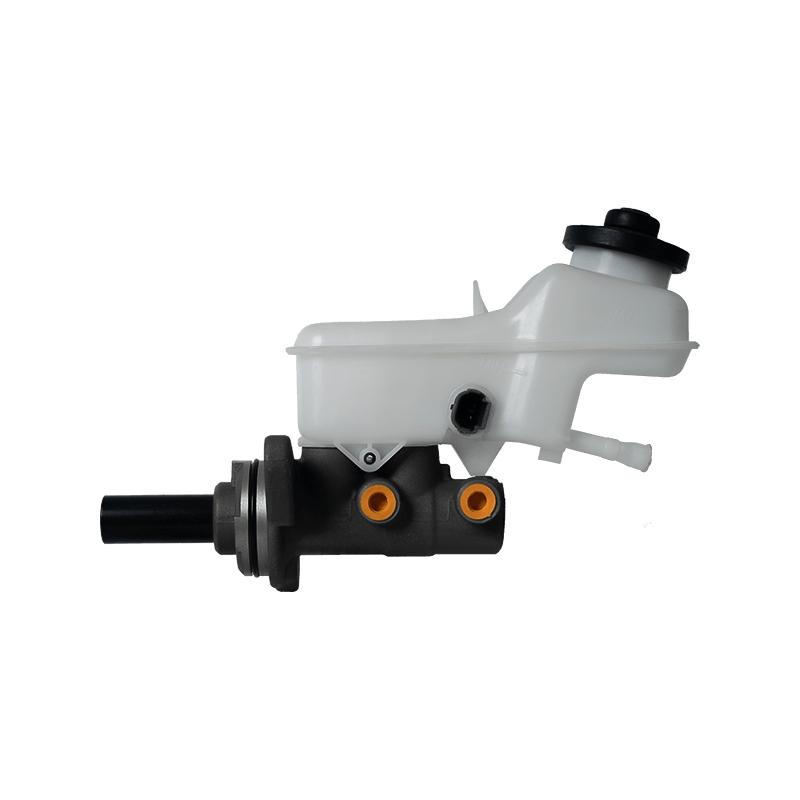

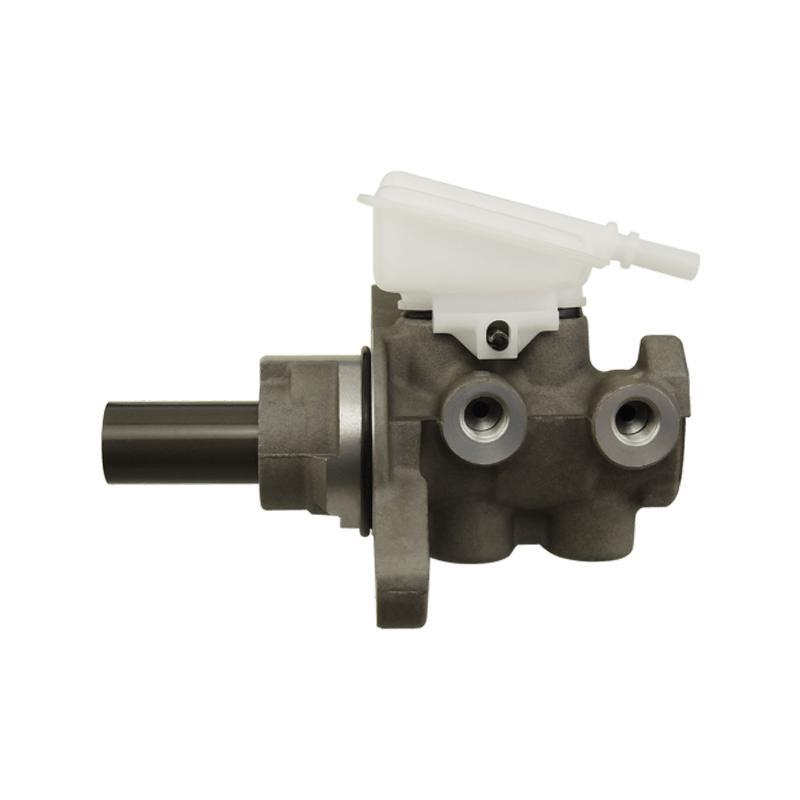

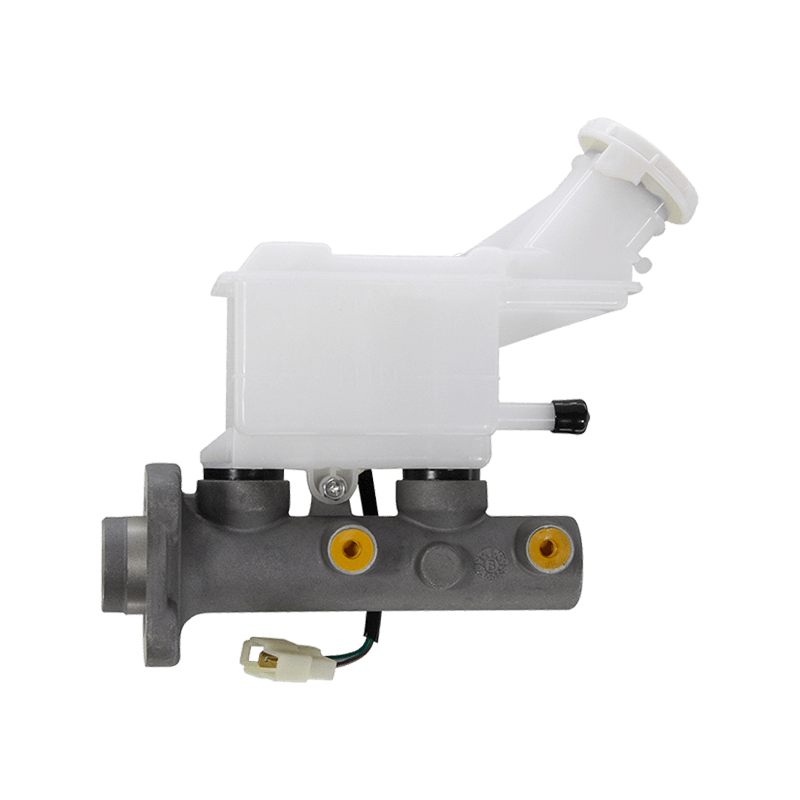

What is a Hydraulic Brake Master Cylinder? The hydraulic brake master cylinder is a critical component in a vehicle's braking system. It converts the...

READ MORE -

Why OE Quality Brake Pads Are the Best Choice for Your Car OE (Original Equipment) quality brake pads are specifically designed to match the specific...

READ MORE -

The direct answer: Yes. High-quality brake pads can reduce braking distance by 15%–30%, improve heat resistance, and significantly enhance driving saf...

READ MORE

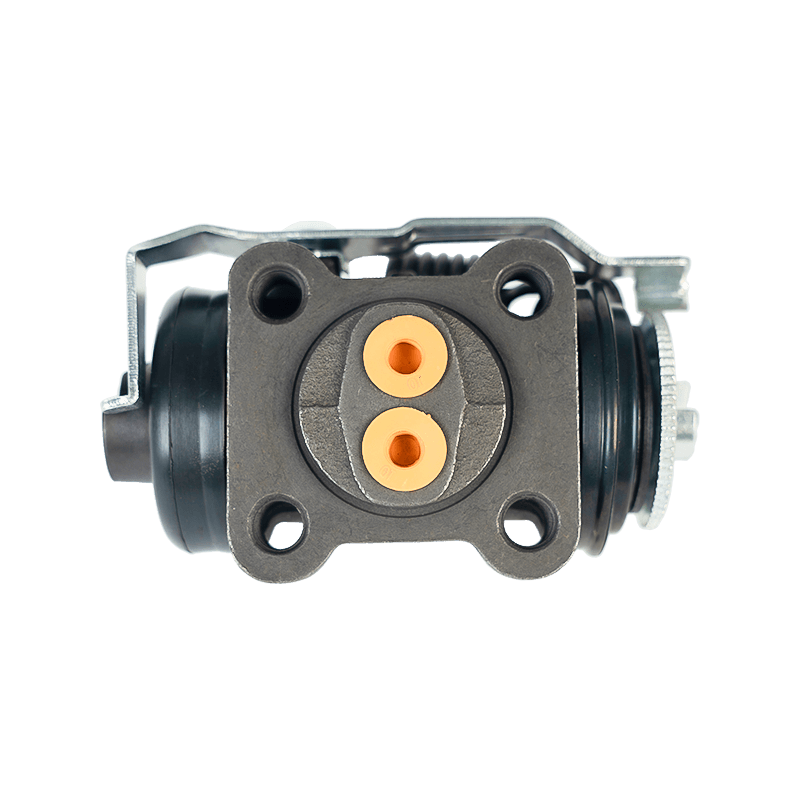

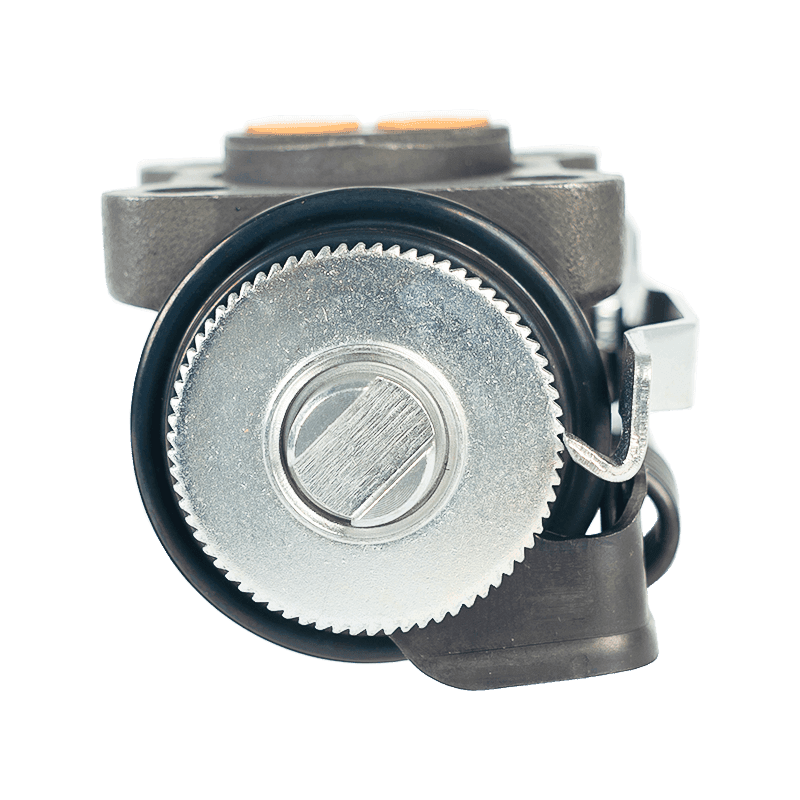

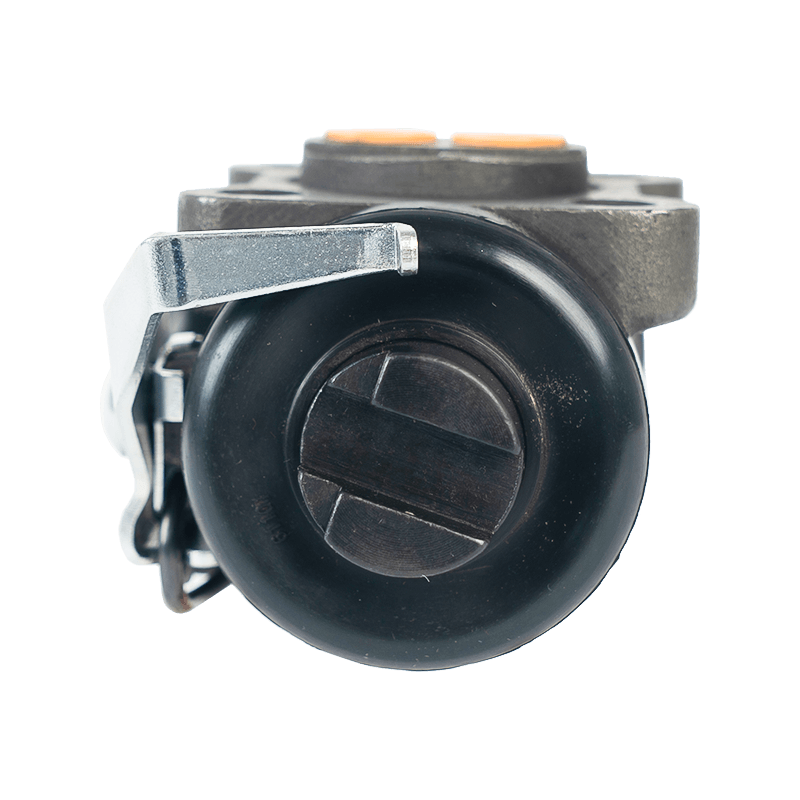

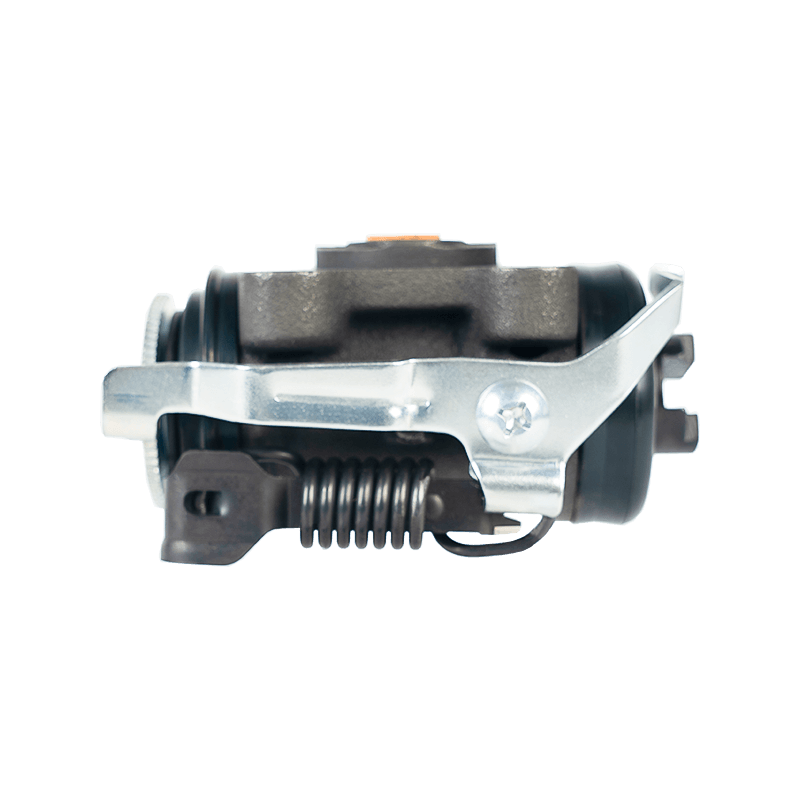

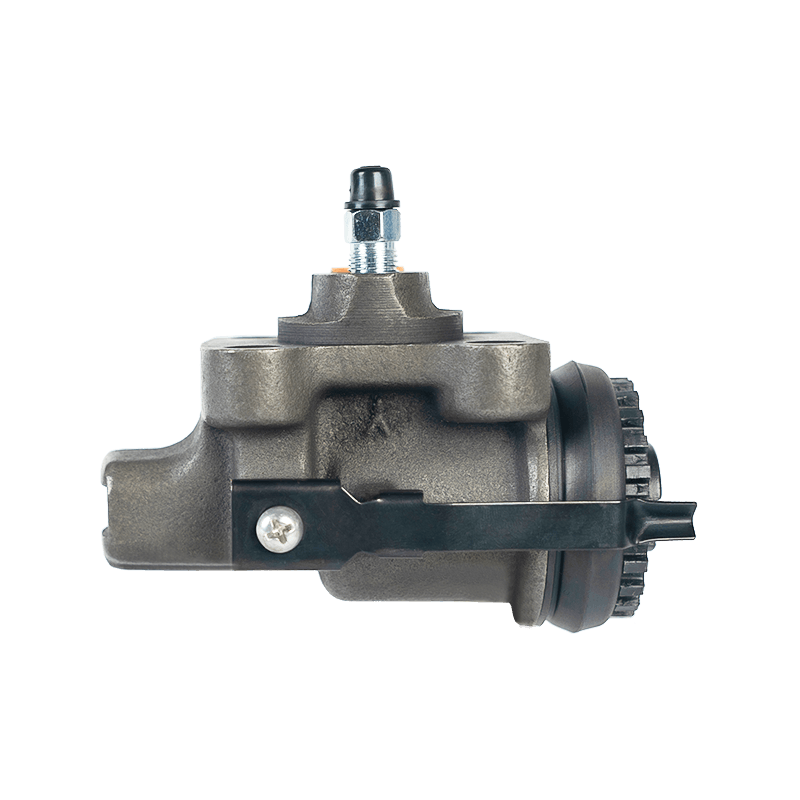

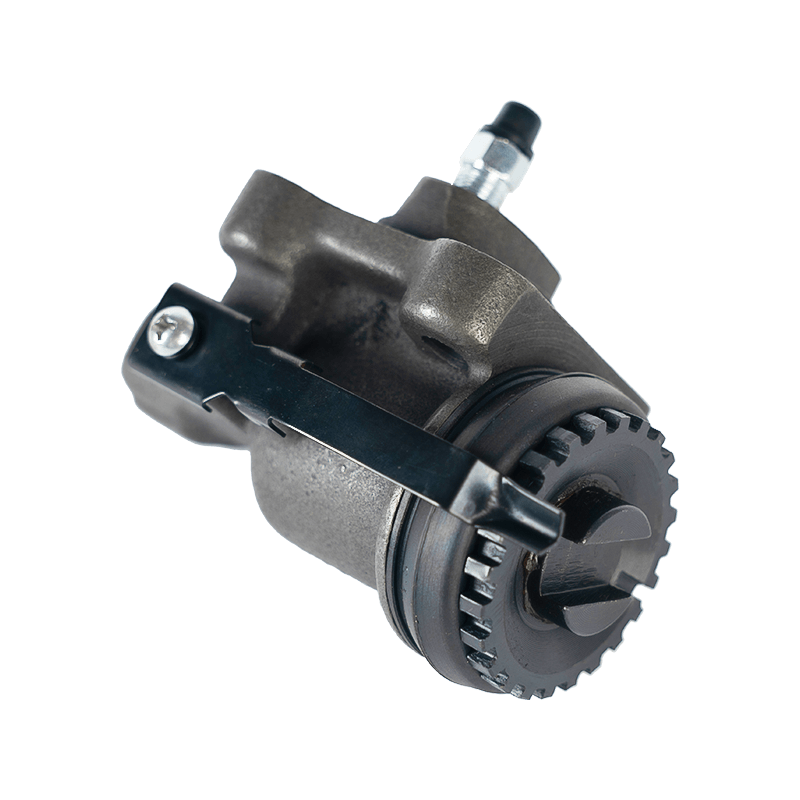

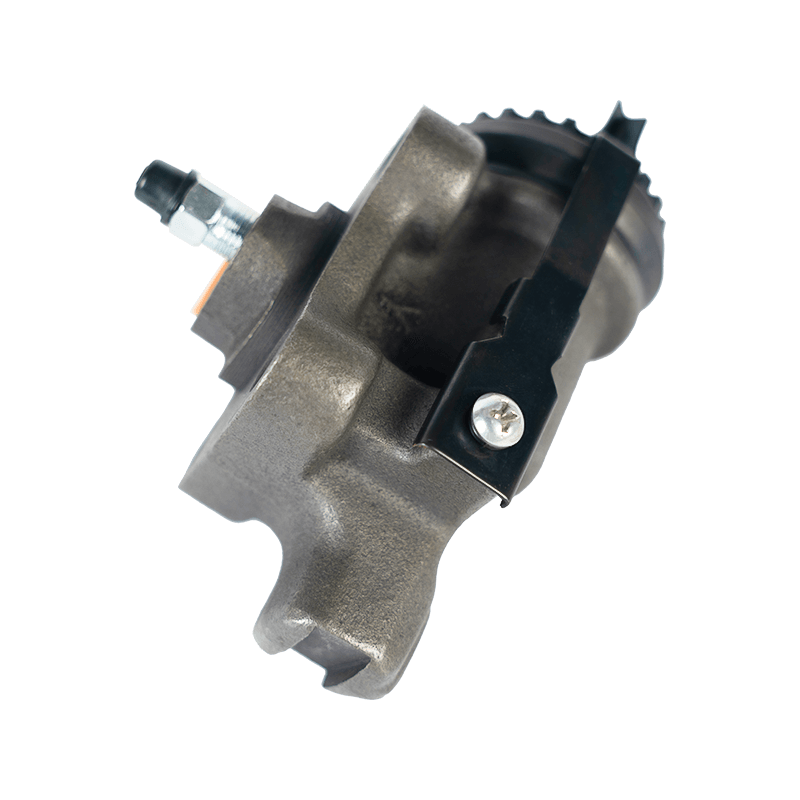

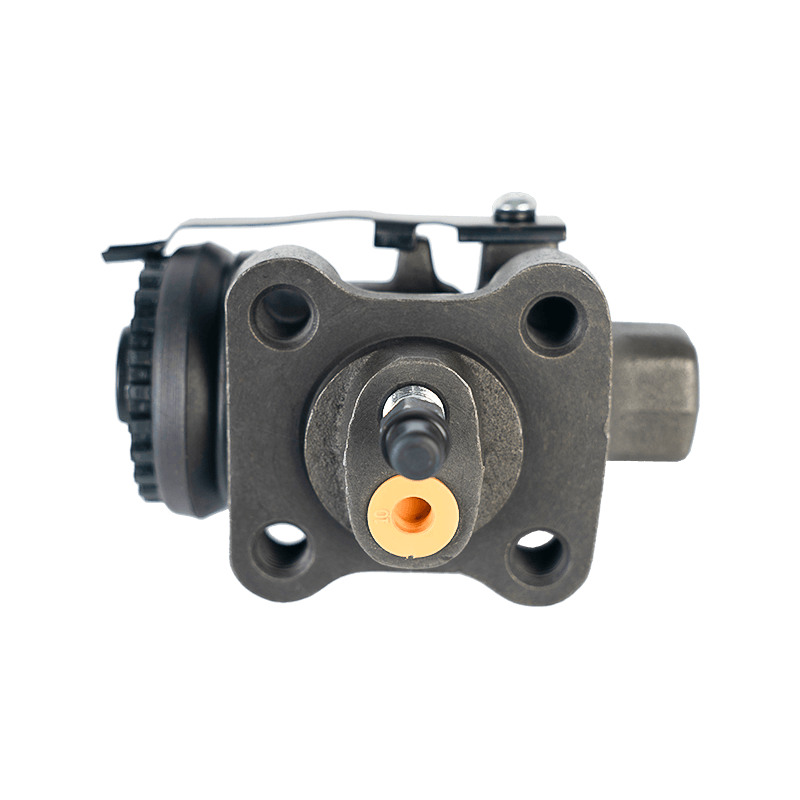

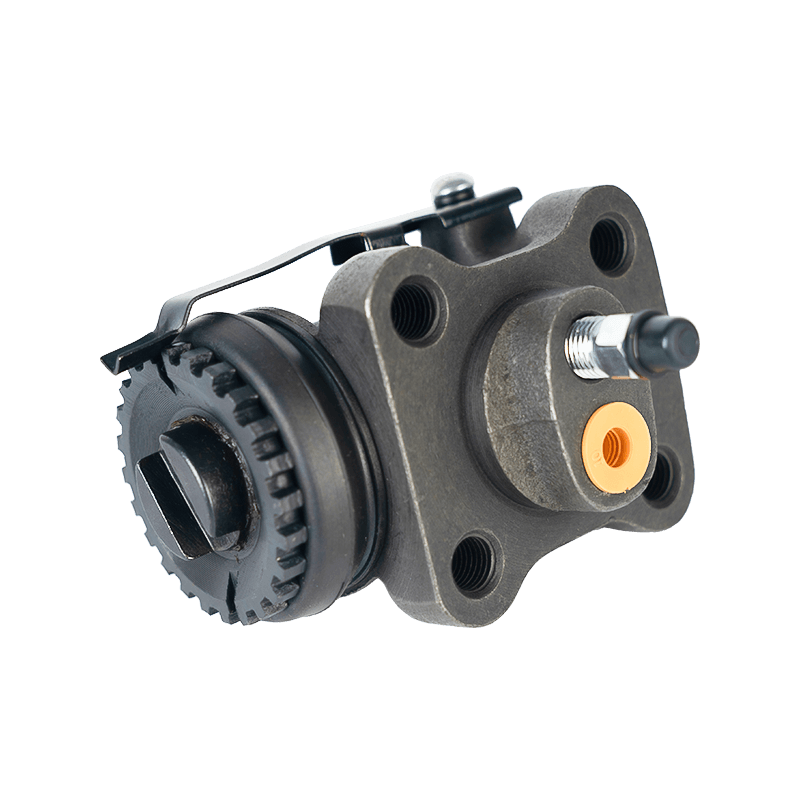

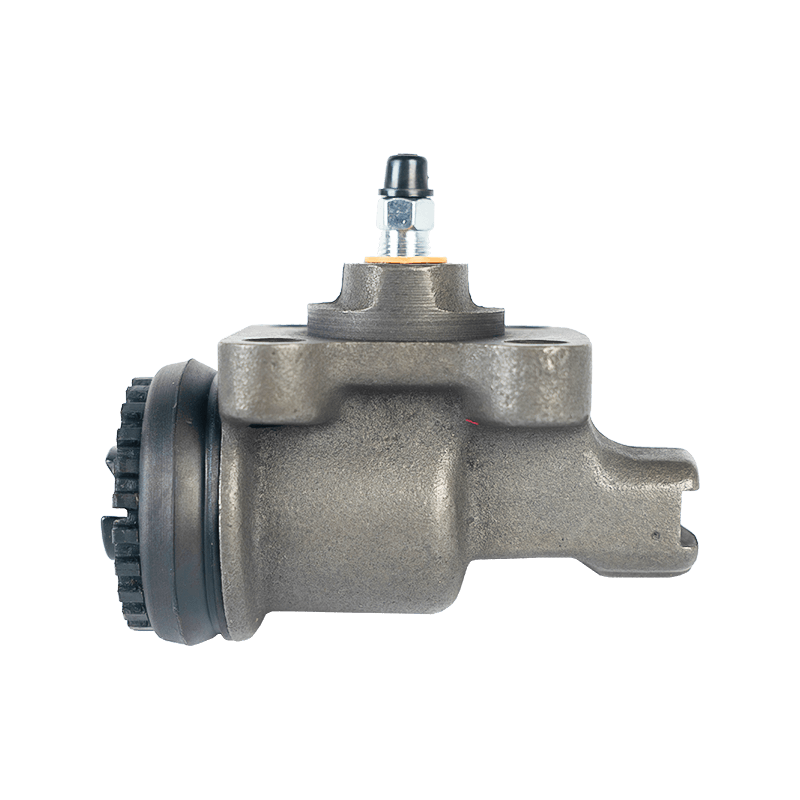

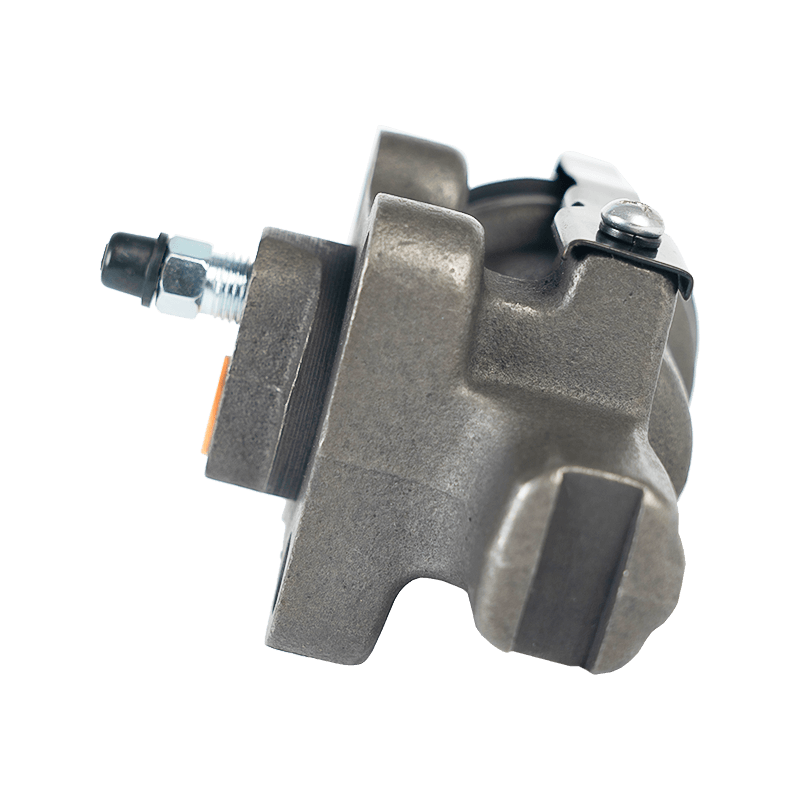

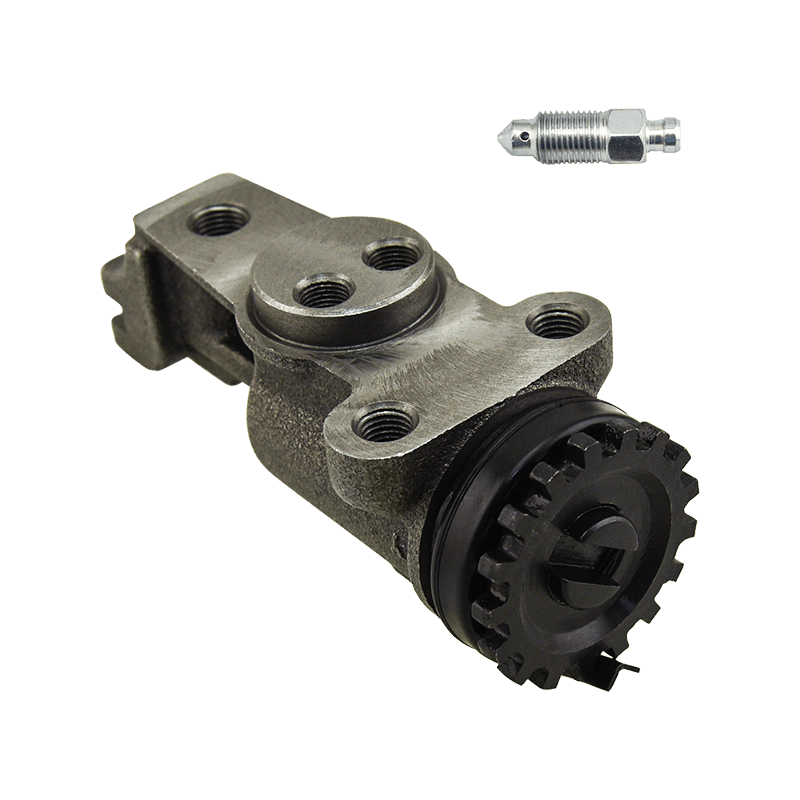

47580-36210 Brake Wheel Cylinder For Toyota is a core brake component designed for commercial vehicles and off-road vehicles. As a key execution unit of the hydraulic brake system, its core function is to convert the hydraulic energy transmitted by the master cylinder into mechanical thrust, drive the brake pads to contact and rub with the brake drum or disc, and achieve vehicle deceleration and parking.

In terms of engineering design, the 47580-36210 slave cylinder adopts a single piston structure, and the piston seal is made of high-temperature resistant fluororubber material with a temperature tolerance range of -40℃ to 180℃, which can cope with high-frequency braking scenarios such as mining transportation and construction site operations. Its hardened guide pin system is combined with a double-layer dust cover design to effectively block the intrusion of mud and sand, reducing the risk of jamming by more than 60%. In response to the brake energy recovery needs of new energy vehicles, its hydraulic response speed and motor reverse torque are synchronized at the millisecond level, which is suitable for electrification modification scenarios.

In daily use, common faults of the slave cylinder are piston return hysteresis or seal leakage. It is recommended to adopt a three-step maintenance method: first use special grease to clean the guide pin track, then polish the oxidized surface of the piston, and finally replace the brake fluid and drain the system. If the rust area of the inner wall of the slave cylinder exceeds 30%, it is recommended to directly replace the assembly and update the brake oil pipe at the same time.

Search

Search

Eng

Eng

English

English Español

Español Português

Português