Hydraulic Clutch Master Cylinder: Why can it become the "nerve center" of manual transmission cars?

2025.06.17

2025.06.17

Industry News

Industry News

Content

1. Working principle of hydraulic clutch master cylinder

Basic structure and workflow

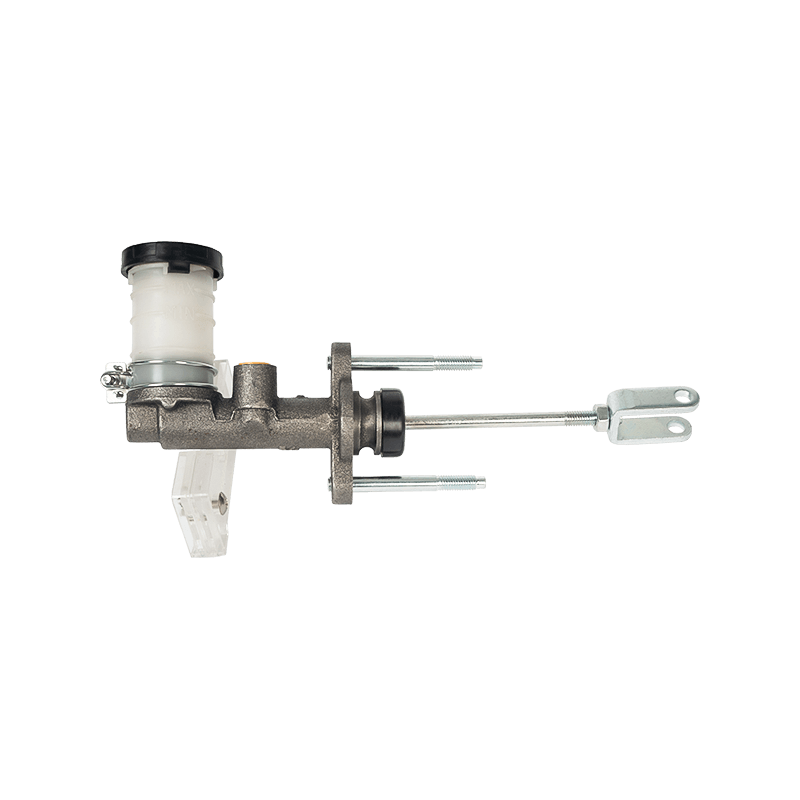

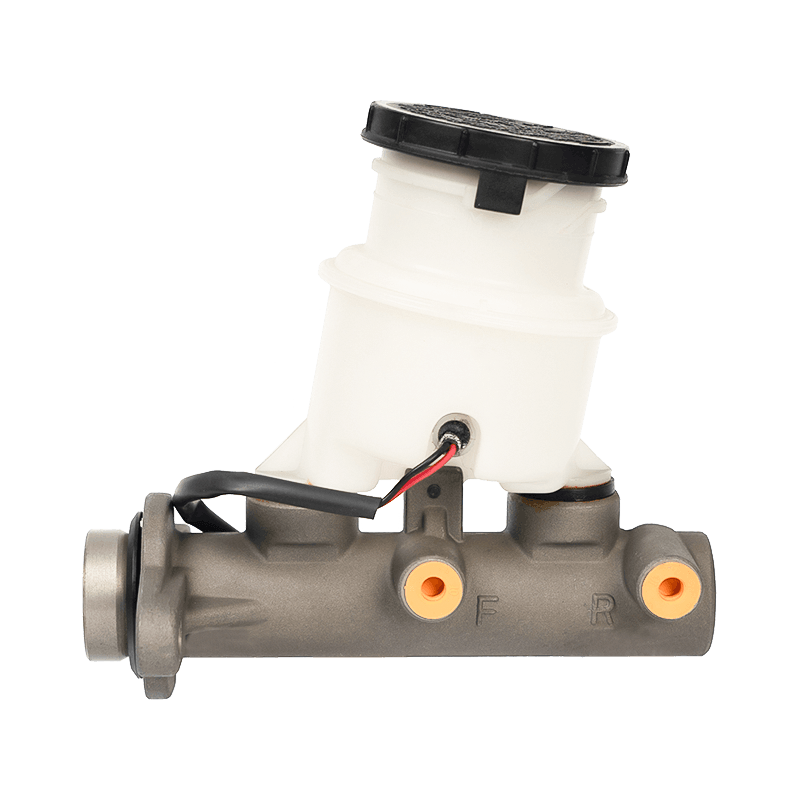

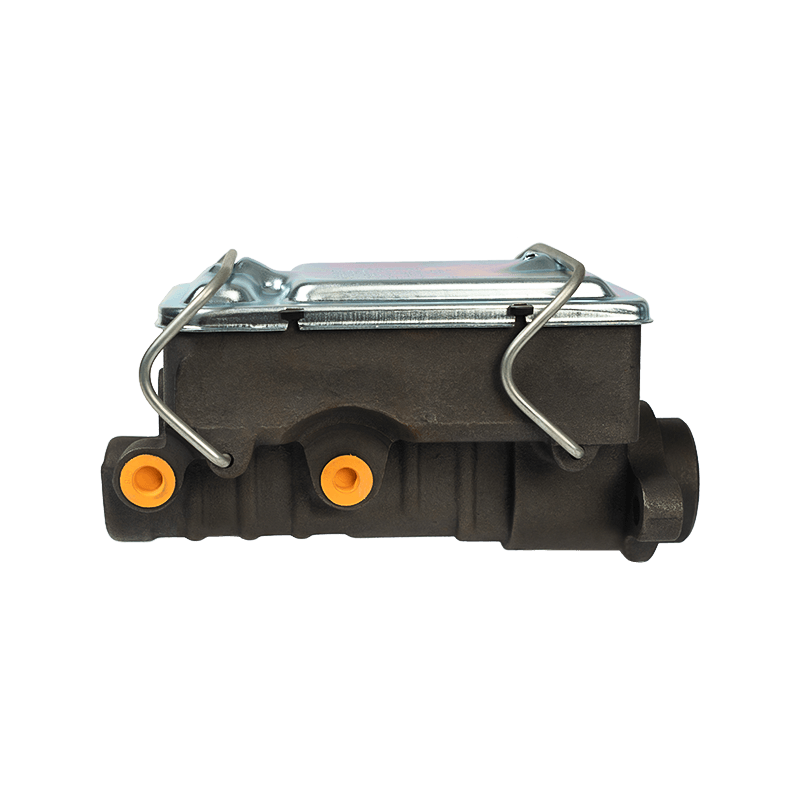

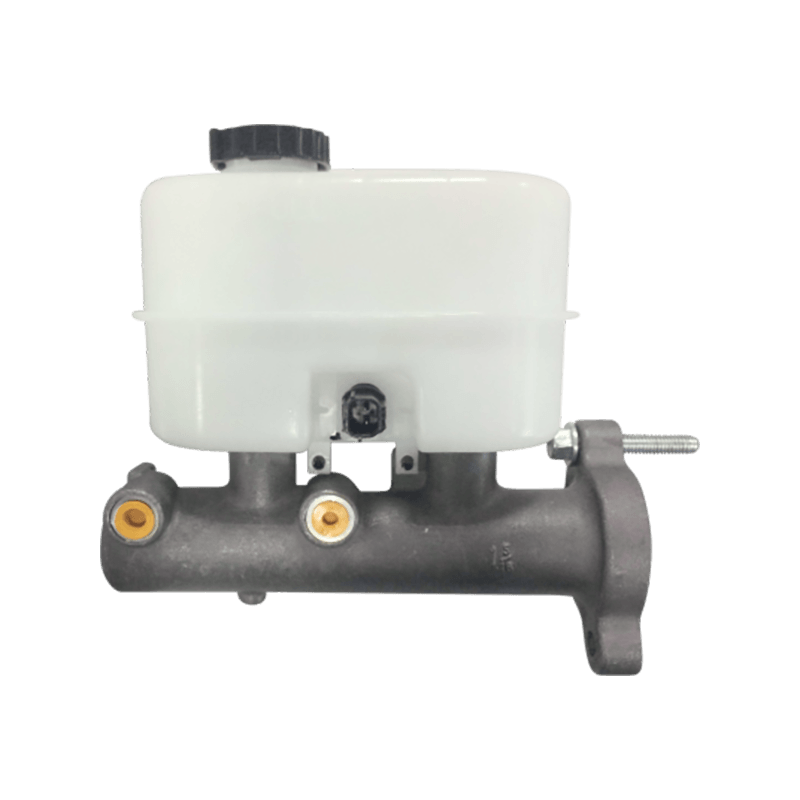

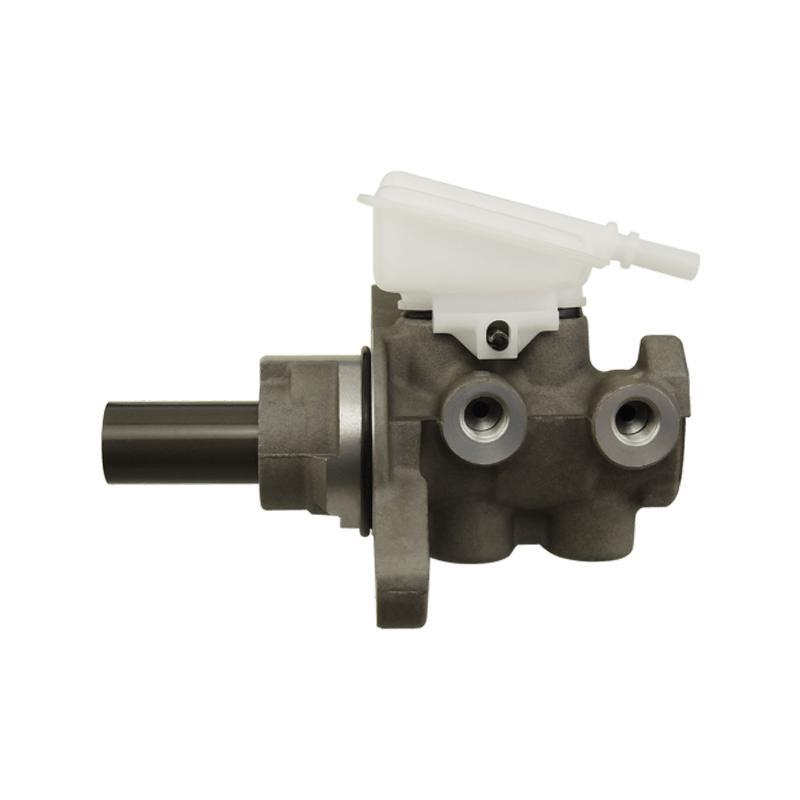

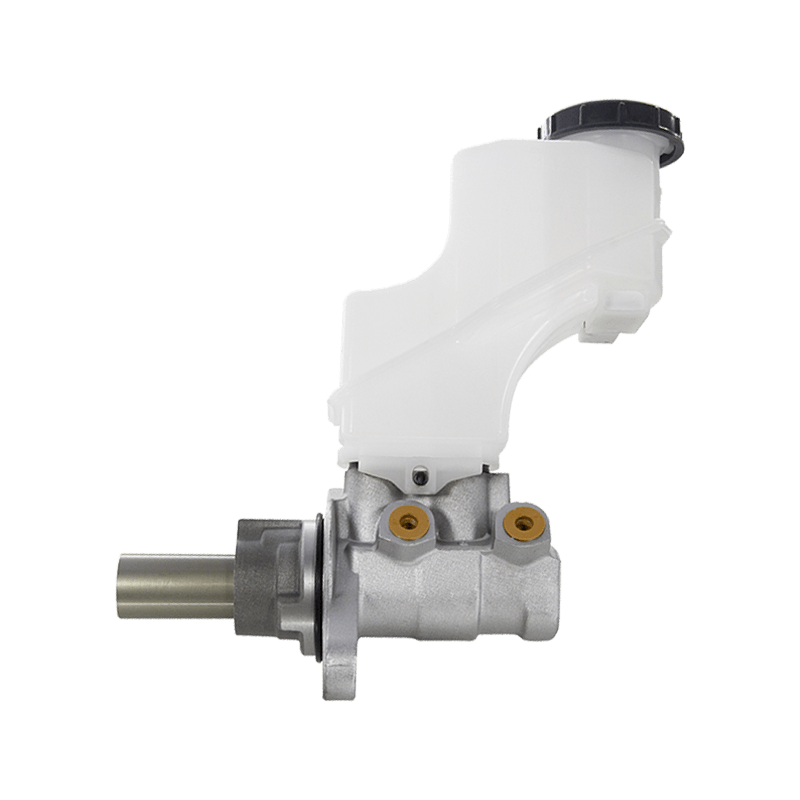

Hydraulic clutch master cylinder usually consists of the following core components:

Reservoir: Stores brake fluid (DOT3/DOT4) to ensure that there is no air mixed in the hydraulic system.

Piston and push rod: When the pedal is pressed, the push rod pushes the piston to compress the hydraulic oil.

Compensation hole and oil inlet valve: balance the pressure and prevent oil from flowing back.

Workflow:

The driver presses the clutch pedal → the push rod pushes the master cylinder piston forward.

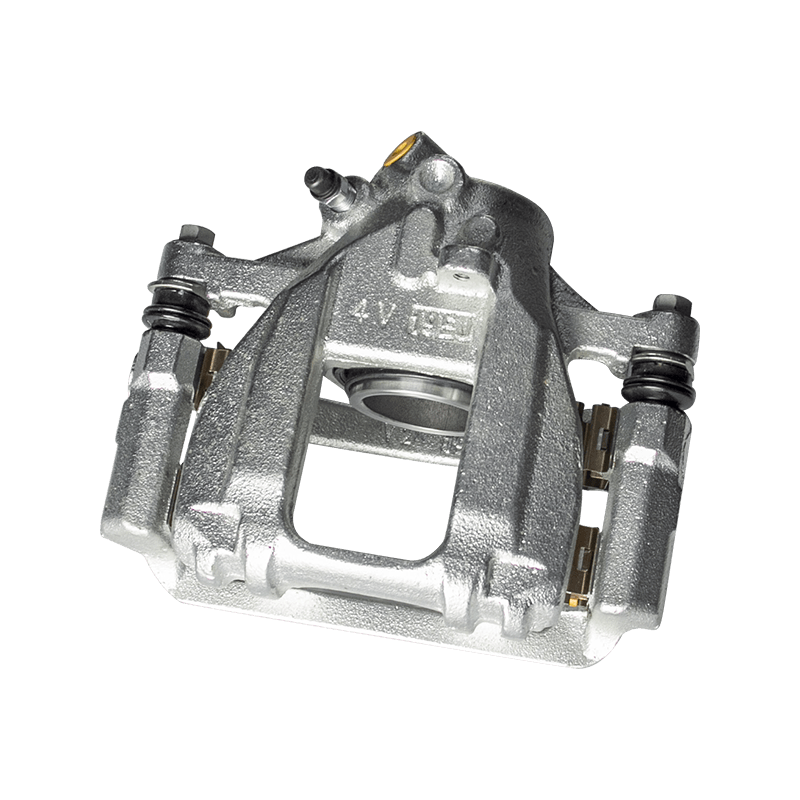

The piston compresses the hydraulic oil and transmits the pressure to the clutch slave cylinder (slave cylinder) through the pipeline.

The slave cylinder pushes the clutch fork to separate the pressure plate and cut off the power connection between the engine and the gearbox.

Advantages of hydraulic vs mechanical clutch

|

Comparison Items |

Hydraulic Clutch |

Mechanical (cable) Clutch |

|

Operation force |

Lighter, less fatigue-prone during long-term driving |

Requires greater pedaling force |

|

Accuracy |

Linear pressure transmission, clear joint points |

The wire is easily stretched, resulting in blurred travel |

|

Adaptability |

Suitable for models with complex engine compartment layout |

Only suitable for short-distance transmission |

2. Main advantages of hydraulic clutch master cylinder

Maintenance convenience

The modular design makes it only 30-60 minutes to replace the master cylinder without disassembling the gearbox.

The master cylinder and brake fluid of most models share a reservoir tank, which simplifies the maintenance process.

Efficient power transmission

The transmission efficiency of the hydraulic system is as high as 95%, which is much higher than the 70%-80% of mechanical cable pulling, especially suitable for high-torque engines (such as diesel vehicles).

By adjusting the master cylinder piston diameter (commonly 19-22mm), it can adapt to the clamping force requirements of different clutches.

Durability and sealing design

The inner wall of the master cylinder is anodized or chrome-plated to reduce piston wear.

High-performance rubber seals (such as NBR material) are resistant to high temperatures (-40℃~120℃) and brake fluid corrosion, and their service life can reach more than 100,000 kilometers.

3. Common faults and diagnostic methods

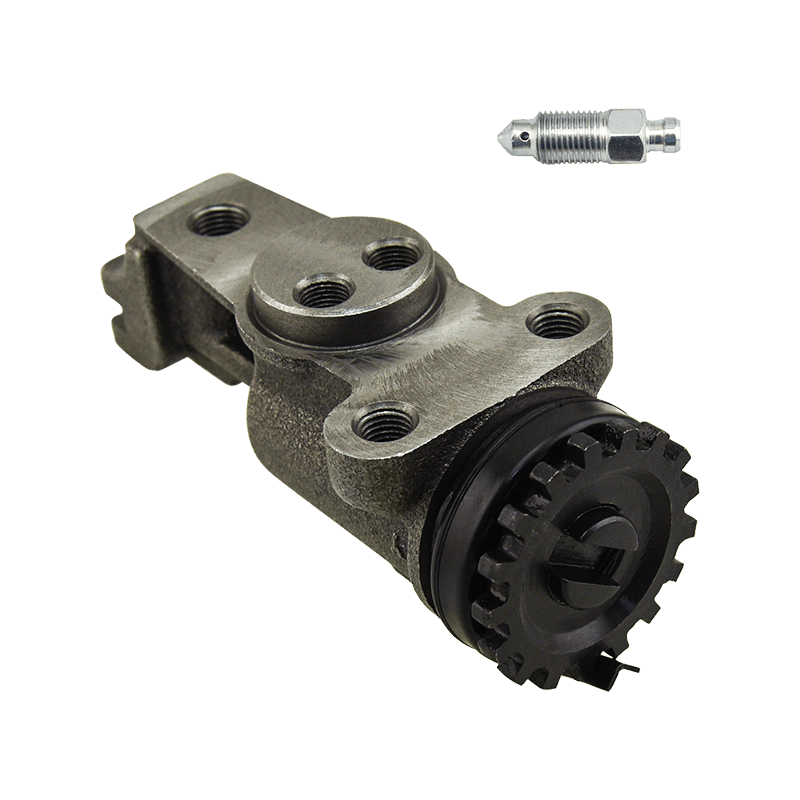

- Clutch pedal is soft/non-rebound

Possible reasons: air enters the hydraulic system and the master cylinder seal ring is aging.

Solution steps:

Check the fluid level of the reservoir and add brake fluid to the "MAX" line.

Air exhaust operation: After pressing the pedal several times, keep pressing it and loosen the master cylinder bleed screw to exhaust the air.

- Oil leakage

Leak point judgment:

Front end of the master cylinder: The piston seal ring fails and the master cylinder assembly needs to be replaced.

Pipeline interface: Tighten the joint or replace the sealing gasket.

- Abnormal pedal stroke

If the pedal gradually becomes heavier, it may be that the master cylinder compensation hole is blocked and needs to be cleaned or replaced.

4. Maintenance and upgrade suggestions

Regular maintenance

Replace the brake fluid every 2 years or 40,000 kilometers (DOT4 has strong hygroscopicity and is prone to corrosion of hydraulic components).

Check the status of the master cylinder piston and seal every 50,000 kilometers and replace them preventively if necessary.

Upgrade plan

Competitive models: Use a large-diameter master cylinder (such as 23mm) with a metal oil pipe to improve the response speed.

Extreme environment: Use a silicone-based brake fluid (DOT5.1), which is resistant to high temperatures and does not absorb moisture.

Search

Search

Eng

Eng

English

English Español

Español Português

Português