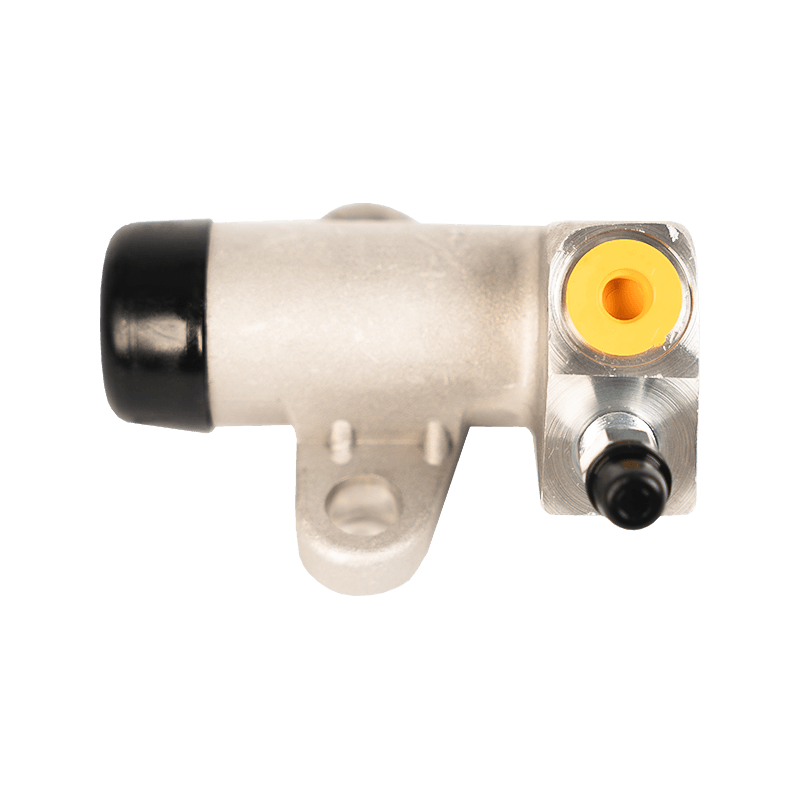

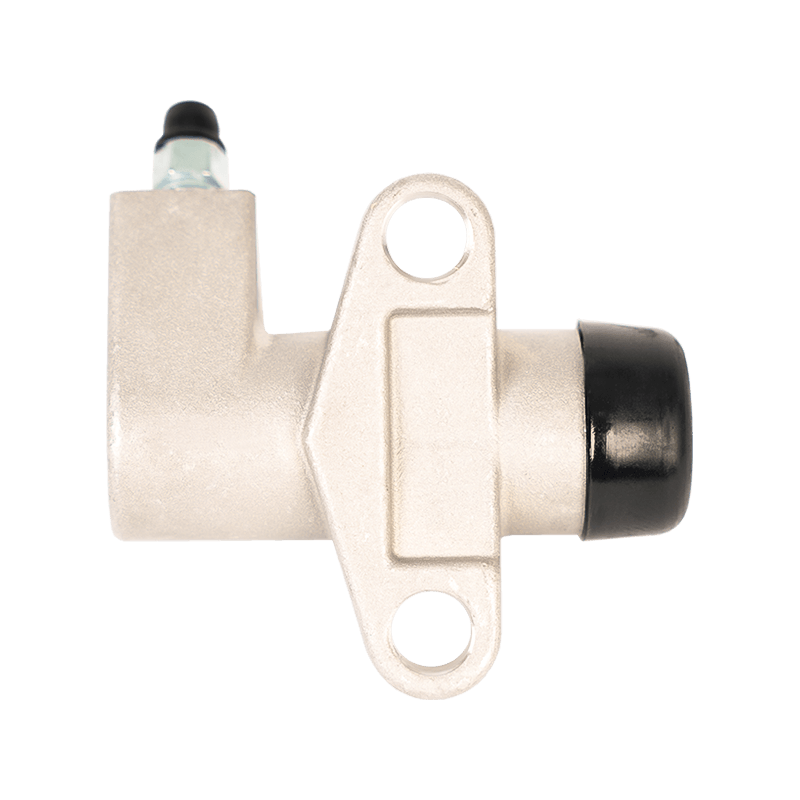

30620-18V01 Clutch Slave Cylinder for Nissan

|

OE NO |

30620-18V01 30620-18V02 30620-69F01 30620-69F03 30620-P6500 30620-S0100 30620-U7000 30620-U7001 30620-Y4001 |

|

MODEL |

Nissan |

Specifications

KEEP IN TOUCH

We have more than 1,000 brake shoes and brake pads for European, American, Russian, Japanese and Korean cars. The associated factories have created a highly experienced manufacturing team that exports thousands of auto part products worldwide. High quality and competitive prices are our targets. Our products have gained the certifications of ISO9001 and TS16949. We have built up a solid reputation with our customers in more than 30 countries.

We are looking forward to having a brighter and more successful business in the near future together with all of our clients all over the world.

-

Why Choose OE Quality Brake Pads? When selecting brake pads, OE QUALITY BRAKE PADS ensure precise fit, optimal braking performance, and long-term dur...

READ MORE -

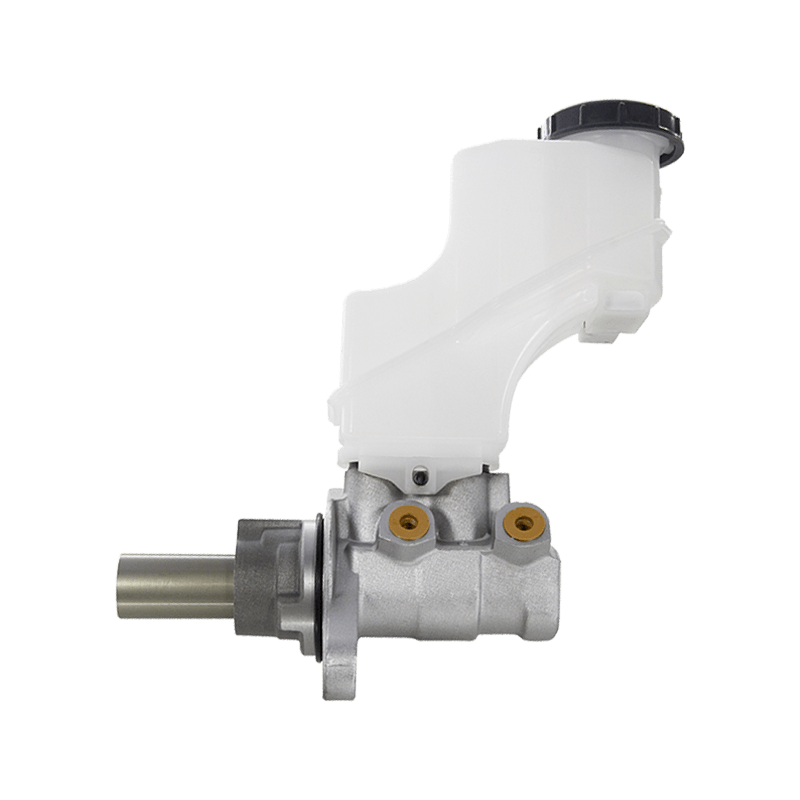

What is a Hydraulic Brake Master Cylinder? The hydraulic brake master cylinder is a critical component in a vehicle's braking system. It converts the...

READ MORE -

Why OE Quality Brake Pads Are the Best Choice for Your Car OE (Original Equipment) quality brake pads are specifically designed to match the specific...

READ MORE -

The direct answer: Yes. High-quality brake pads can reduce braking distance by 15%–30%, improve heat resistance, and significantly enhance driving saf...

READ MORE

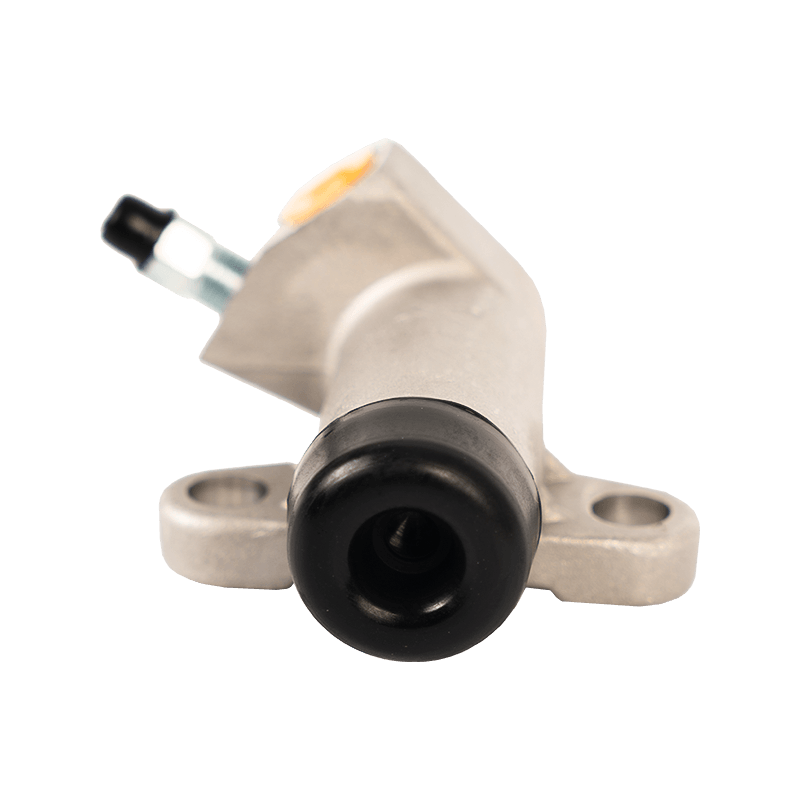

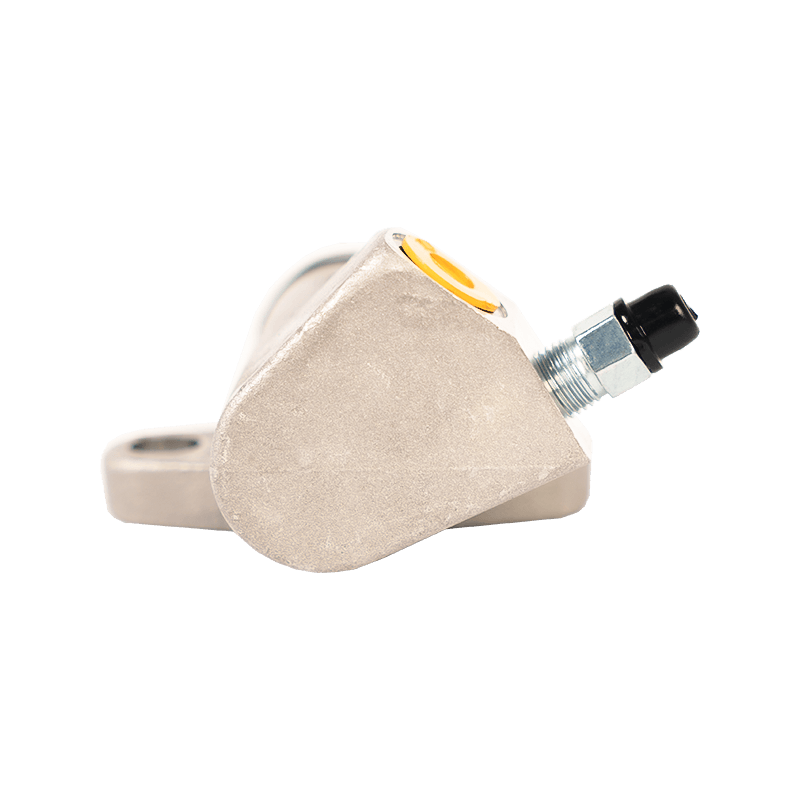

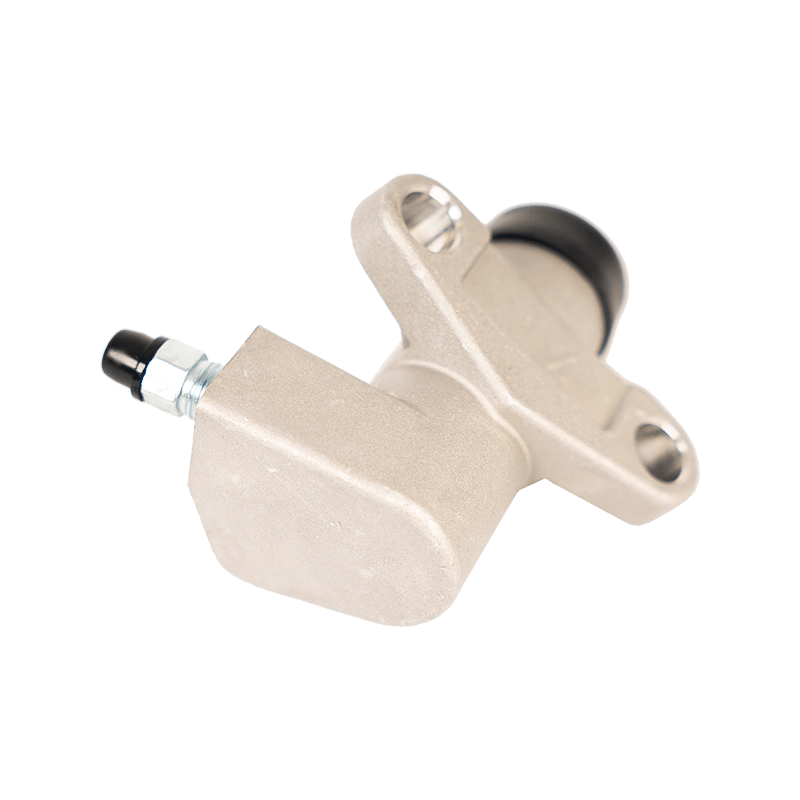

30620-18V01 Clutch Slave Cylinder For Nissan is an original hydraulic actuator designed for classic models such as 240SX. The slave cylinder is cast with high-strength cast iron, and the surface is treated with electrophoresis for rust prevention. The piston diameter is 3/4 inches (19.05mm), and the peak working pressure can reach 32MPa. The core function is to convert the clutch pedal input into hydraulic thrust, drive the release bearing to achieve precise engagement and separation of the clutch plate and the flywheel. Its thread specifications and oil pipe interface design perfectly match the original vehicle hydraulic system layout to ensure the sealing of the brake fluid conduction path.

The slave cylinder adopts a single-cylinder structure, and the piston seal ring is made of high-temperature resistant fluororubber. The temperature range covers -40℃ to 120℃, which can effectively cope with high-frequency semi-clutch operations under urban congested road conditions. The guide pin system has been nitrided and hardened, and with a multi-layer dust cover structure, it can block more than 85% of the intrusion of mud and sand, reducing the risk of guide pin jamming. Facing special climate environments, its brake fluid is compatible with DOT3/DOT4 standards, and maintains hydraulic response speed at low temperatures of -40°C, ensuring smooth clutch operation when starting in cold areas.

When purchasing the product, it is necessary to match the VIN code or the original vehicle wheel cylinder engraving number, and pay attention to the changes in interface specifications of some modified models after 1995. The original accessories package includes the wheel cylinder assembly, fixing bolts and dust cover, and the third-party repair kit provides additional copper sealing gaskets and special grease.

Search

Search

Eng

Eng

English

English Español

Español Português

Português