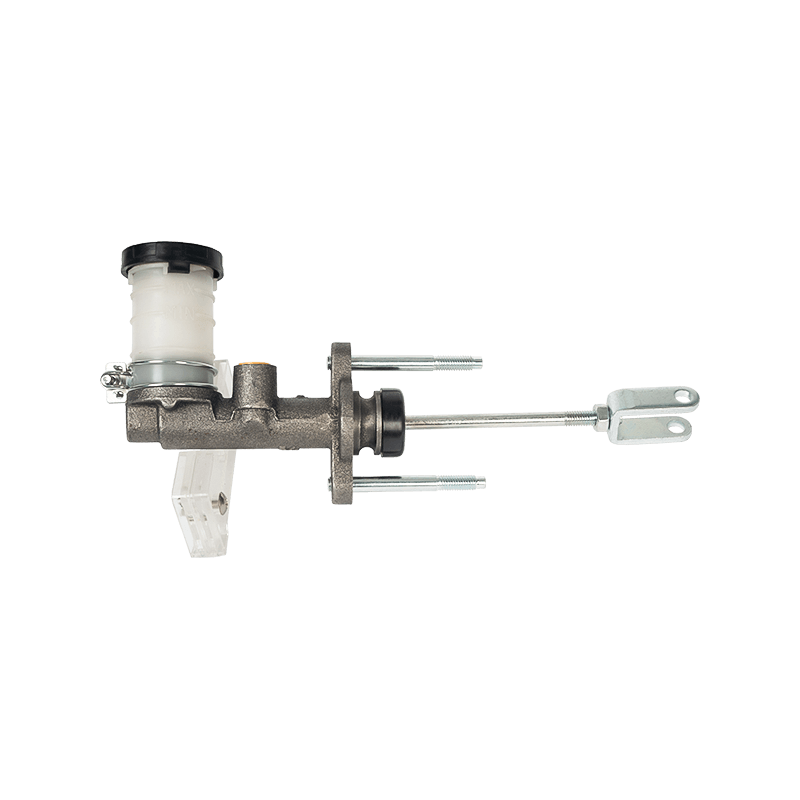

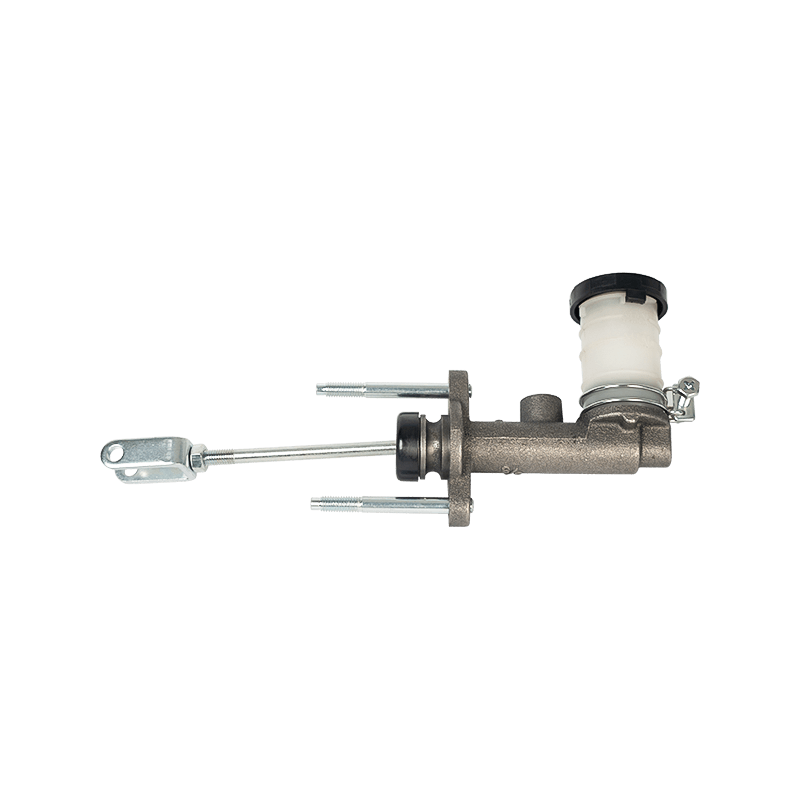

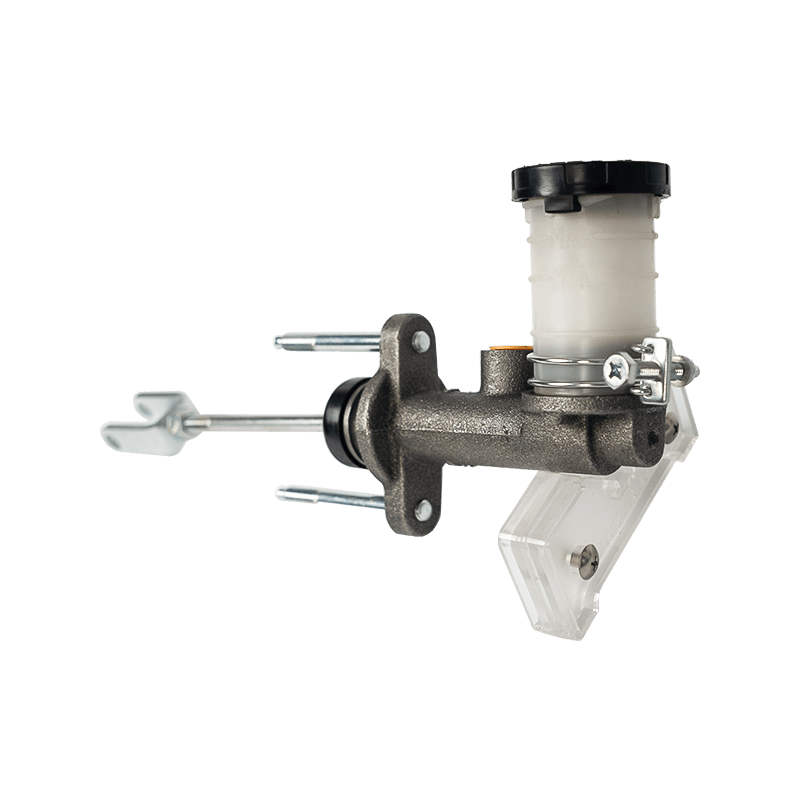

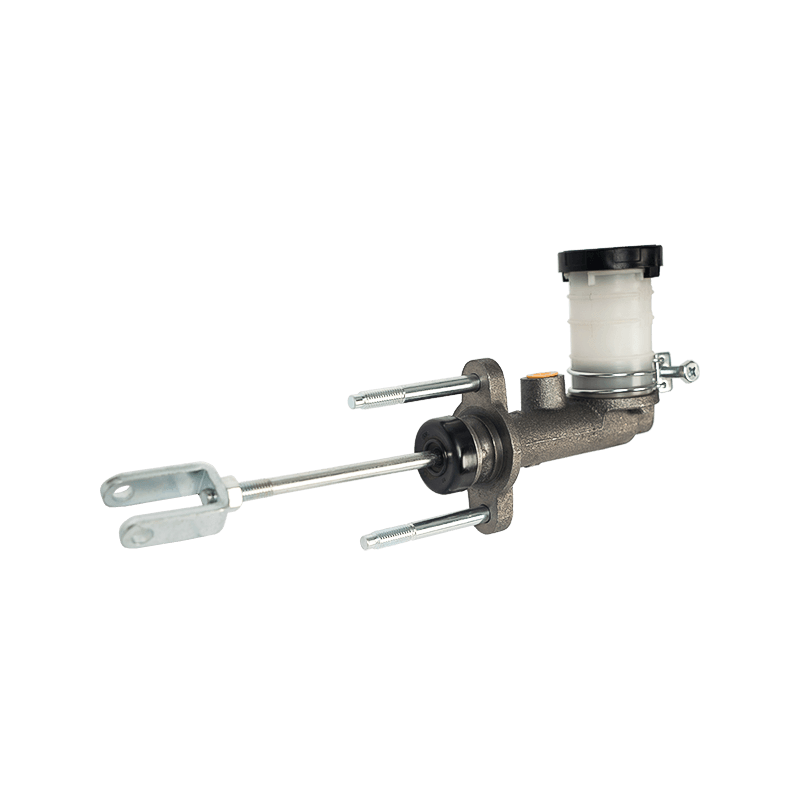

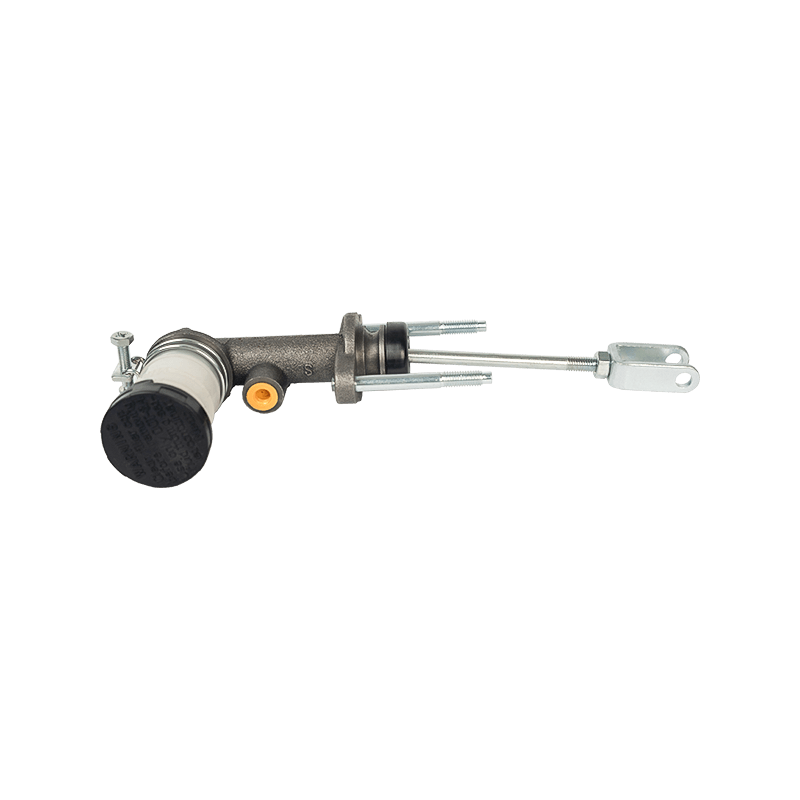

8971384830 Clutch Master Cylinder for ISUZU

|

OE NO |

8971384830 8971384832 8972010060 |

|

DESCRIP |

CMC |

|

MODEL |

ISUZU |

Specifications

KEEP IN TOUCH

We have more than 1,000 brake shoes and brake pads for European, American, Russian, Japanese and Korean cars. The associated factories have created a highly experienced manufacturing team that exports thousands of auto part products worldwide. High quality and competitive prices are our targets. Our products have gained the certifications of ISO9001 and TS16949. We have built up a solid reputation with our customers in more than 30 countries.

We are looking forward to having a brighter and more successful business in the near future together with all of our clients all over the world.

-

Why Choose OE Quality Brake Pads? When selecting brake pads, OE QUALITY BRAKE PADS ensure precise fit, optimal braking performance, and long-term dur...

READ MORE -

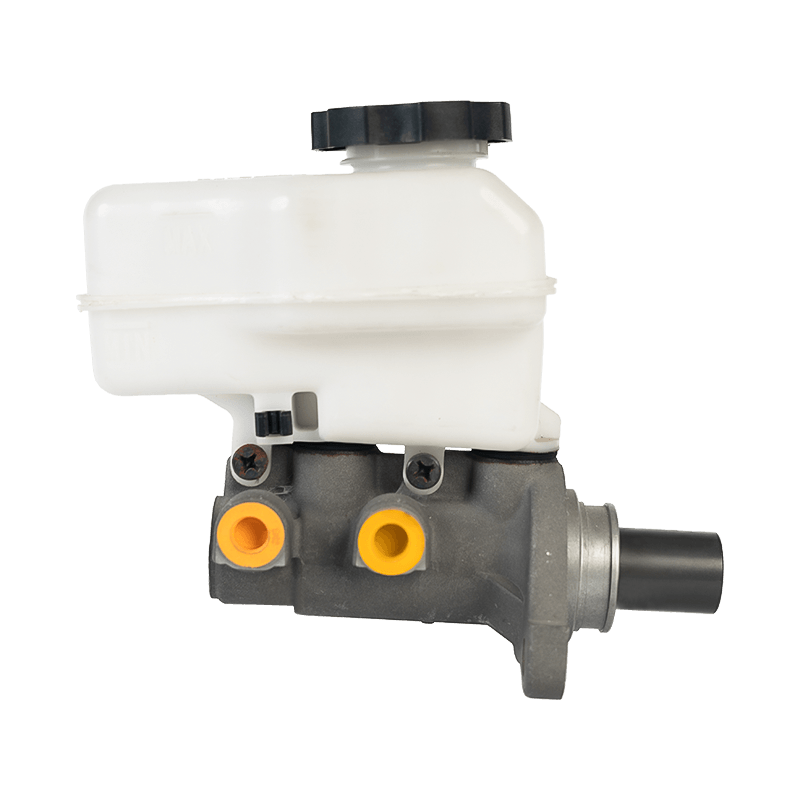

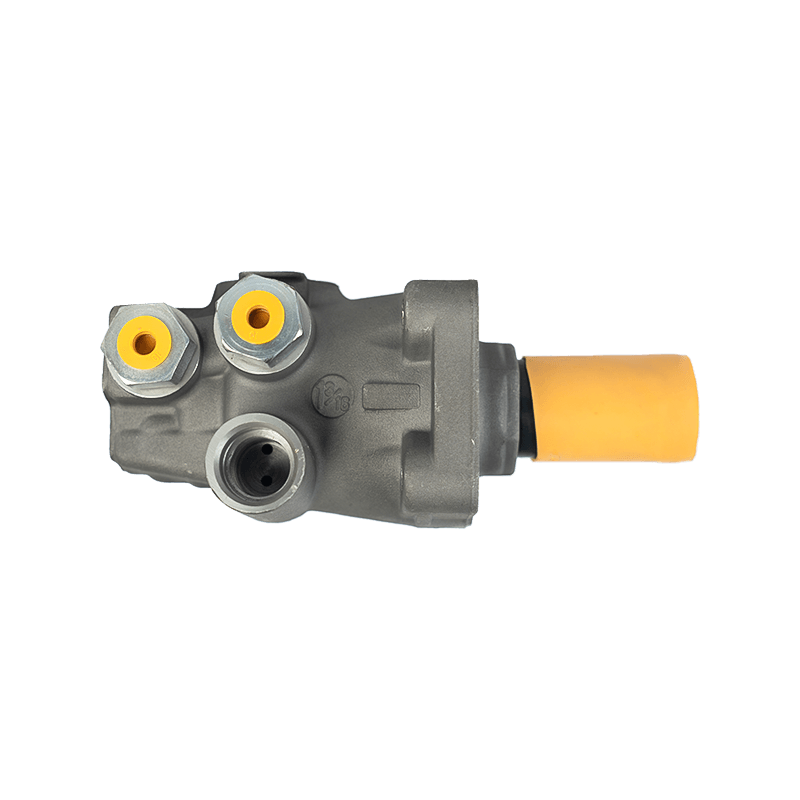

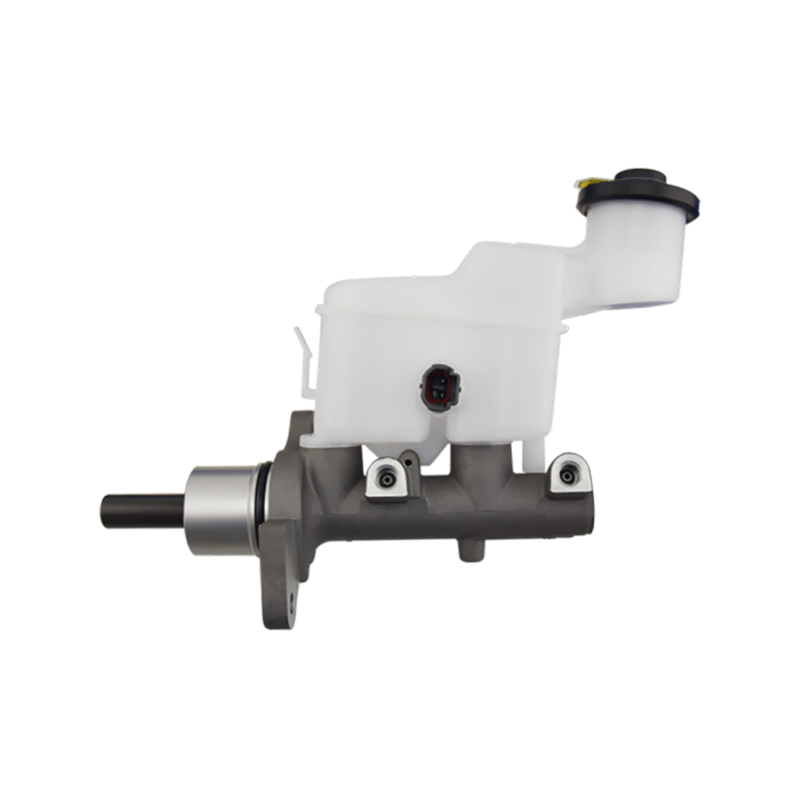

What is a Hydraulic Brake Master Cylinder? The hydraulic brake master cylinder is a critical component in a vehicle's braking system. It converts the...

READ MORE -

Why OE Quality Brake Pads Are the Best Choice for Your Car OE (Original Equipment) quality brake pads are specifically designed to match the specific...

READ MORE -

The direct answer: Yes. High-quality brake pads can reduce braking distance by 15%–30%, improve heat resistance, and significantly enhance driving saf...

READ MORE

8971384830 Clutch Master Cylinder For ISUZU is a core hydraulic transmission component designed for ISUZU multi-purpose vehicles and SUVs. As the key execution unit of the clutch system, its core function is to convert the driver's pedal force into precise hydraulic thrust to control the separation and engagement of the clutch plate. The master cylinder is cast with high-strength aluminum alloy, and the surface is treated with electrophoresis anti-rust. The piston diameter is 19.05mm and can withstand 32MPa hydraulic pressure.

The master cylinder adopts a single piston structure, and the piston seal ring is made of fluororubber, with a temperature range of -40℃ to 180℃. Its guide pin system is nitrided and hardened, and with a double-layer dust cover design, the efficiency of blocking mud and sand intrusion is more than 85%, reducing the risk of jamming. Its internal structure includes components such as piston, stator, rotating head and pressure regulating valve. The release bearing is driven by the pressure change in the oil pipe to achieve precise control of power transmission.

During the use and maintenance of the product, if the clutch pedal position increases or hydraulic leakage occurs, it is recommended to replace the master cylinder assembly directly. When operating, you need to disconnect the oil pipe and drain the system first, use a 10mm socket to remove the fixing bolts and install the new pump, and then perform the secondary pressure draining method with DOT4 standard brake fluid to ensure that there are no bubbles remaining in the system.

Search

Search

Eng

Eng

English

English Español

Español Português

Português