What factors influence the wear rate of brake pads in automotive applications?

2025.05.12

2025.05.12

Industry News

Industry News

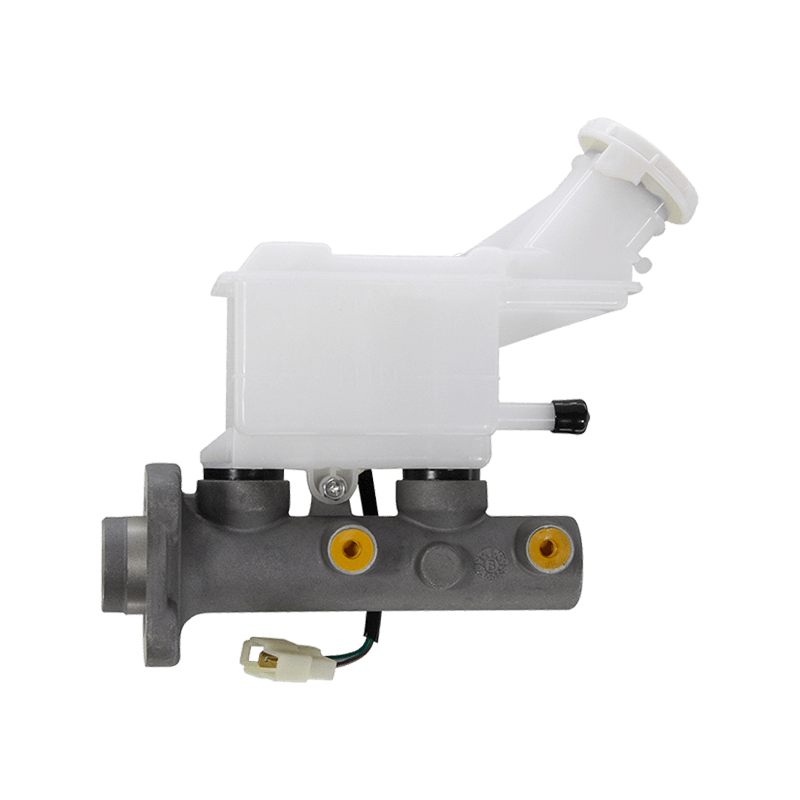

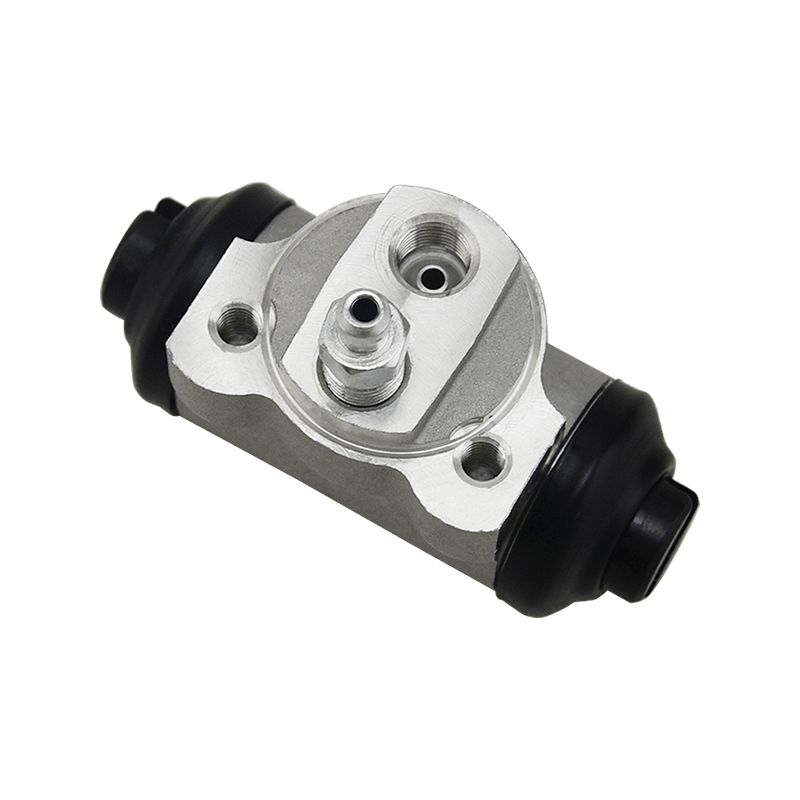

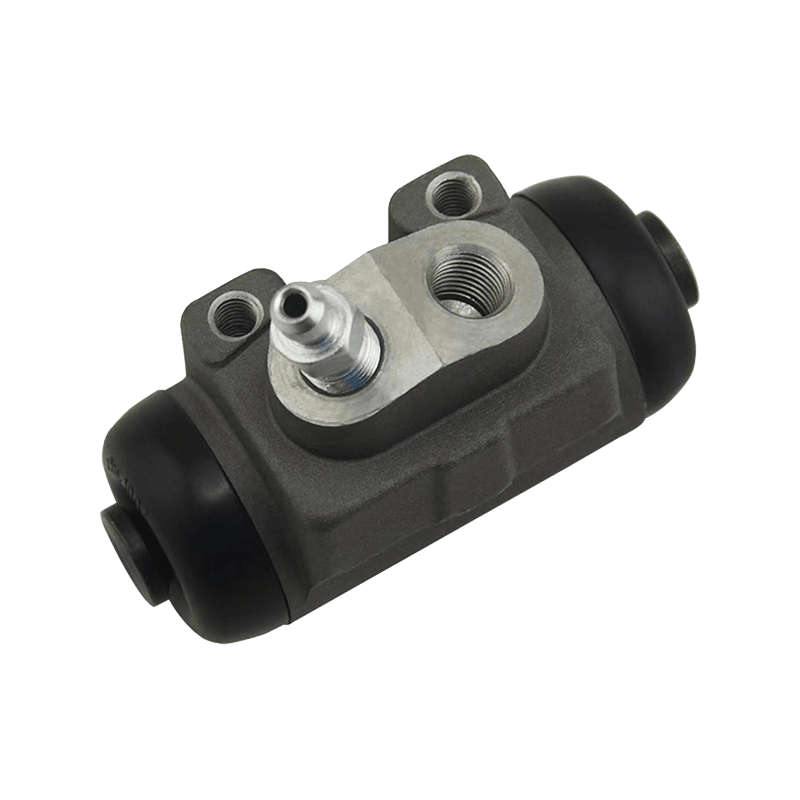

In the world of automotive safety, the braking system plays an irreplaceable role, and at the heart of that system lies the brake pad. This essential component, composed of a steel backing plate with friction material bonded to the surface that faces the disc brake rotor, is responsible for converting kinetic energy into thermal energy through friction. However, like all consumable parts, brake pads wear out over time. Understanding the factors that influence the wear rate of brake pads is crucial for vehicle performance, safety, and maintenance planning.

One of the primary factors affecting brake pad wear is driving style. Aggressive driving habits — such as frequent hard braking, rapid acceleration followed by sudden stops, and constant high-speed driving — generate excessive heat and pressure within the braking system. This accelerates the breakdown of the friction material on the brake pad, shortening its service life. In contrast, smooth, gradual braking and maintaining safe following distances can help extend the lifespan of brake pads.

Vehicle type and weight also have a significant impact on brake pad wear. Heavier vehicles, including SUVs, trucks, and commercial vehicles, place greater demands on the braking system due to their increased mass. This leads to higher friction forces and greater thermal loads during braking events. Consequently, the brake pads on such vehicles tend to wear more quickly compared to those on lighter passenger cars.

The material composition of the brake pad itself is another crucial determinant of its wear characteristics. Modern brake pads are commonly made from organic, semi-metallic, or ceramic materials, each with distinct properties. Organic brake pads, made from materials like rubber, carbon compounds, and resins, tend to wear faster but offer quieter operation. Semi-metallic pads contain metal fibers for enhanced strength and heat resistance but can wear down rotors more aggressively. Ceramic brake pads offer long service life and produce less dust, although they may be more costly. Selecting the right brake pad material for the vehicle’s usage conditions is essential for balancing wear rate, performance, and cost.

Environmental factors such as road conditions and climate further influence brake pad wear. Driving in mountainous regions, where frequent braking on steep descents is necessary, or in urban areas with constant stop-and-go traffic, can accelerate the wear process. Additionally, wet, muddy, or dusty environments introduce abrasives and contaminants that increase friction material degradation. Extreme temperatures — both hot and cold — also affect the performance and longevity of brake pads by impacting friction levels and thermal cycling stress.

Another often overlooked factor is the condition of the disc brake rotor. An unevenly worn or damaged rotor can cause inconsistent contact with the brake pad, leading to uneven pad wear, reduced braking efficiency, and even increased vibration or noise. Regular inspection and maintenance of both brake pads and rotors are critical to ensuring even wear and optimal braking performance.

Load conditions and vehicle usage frequency also play a role. Commercial vehicles or delivery fleets that carry heavy loads and operate daily are subjected to more frequent braking cycles, causing brake pads to wear at an accelerated rate. Conversely, vehicles that are infrequently used might suffer from pad deterioration due to corrosion or material hardening, which can impair braking efficiency over time.

Search

Search

Eng

Eng

English

English Español

Español Português

Português