What is the Primary Function of a Clutch Master Cylinder in a Vehicle’s Clutch System?

2025.05.12

2025.05.12

Industry News

Industry News

In the intricate system of automotive components that enable a smooth and responsive driving experience, the clutch mechanism holds a vital place, especially in vehicles with manual transmissions. At the core of this system lies the Clutch Master Cylinder, a small yet indispensable hydraulic component responsible for transferring the driver’s input into mechanical action. Though often overlooked by casual drivers, the Clutch Master Cylinder plays a crucial role in ensuring seamless gear changes and preserving the overall drivability of a vehicle.

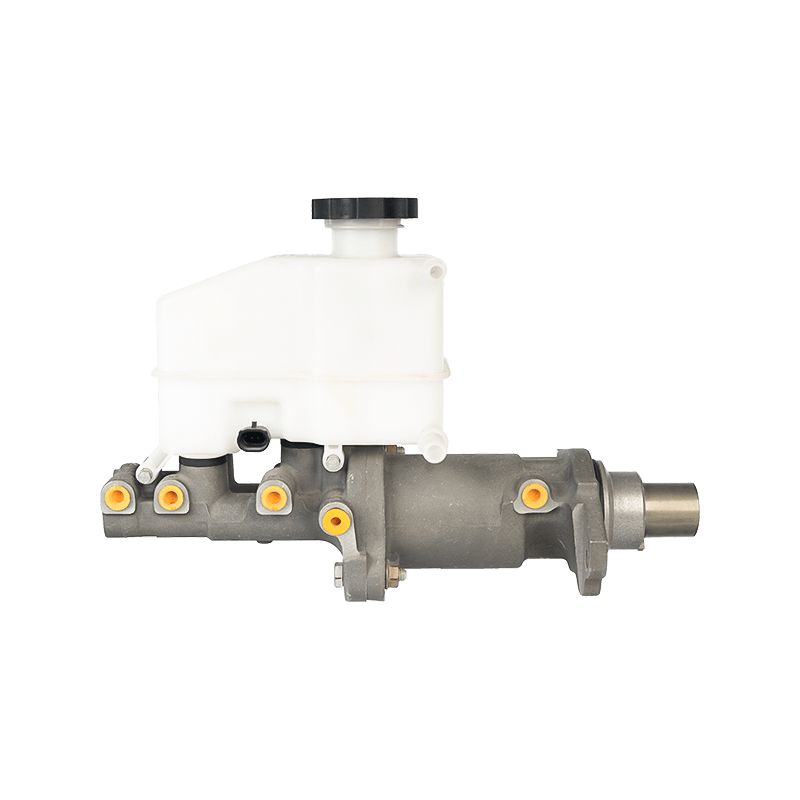

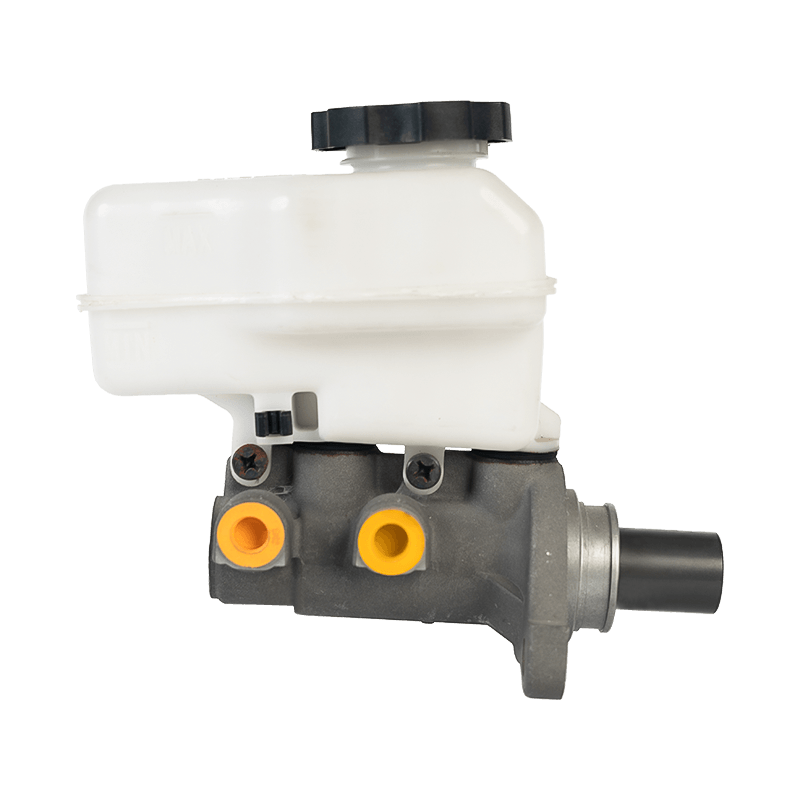

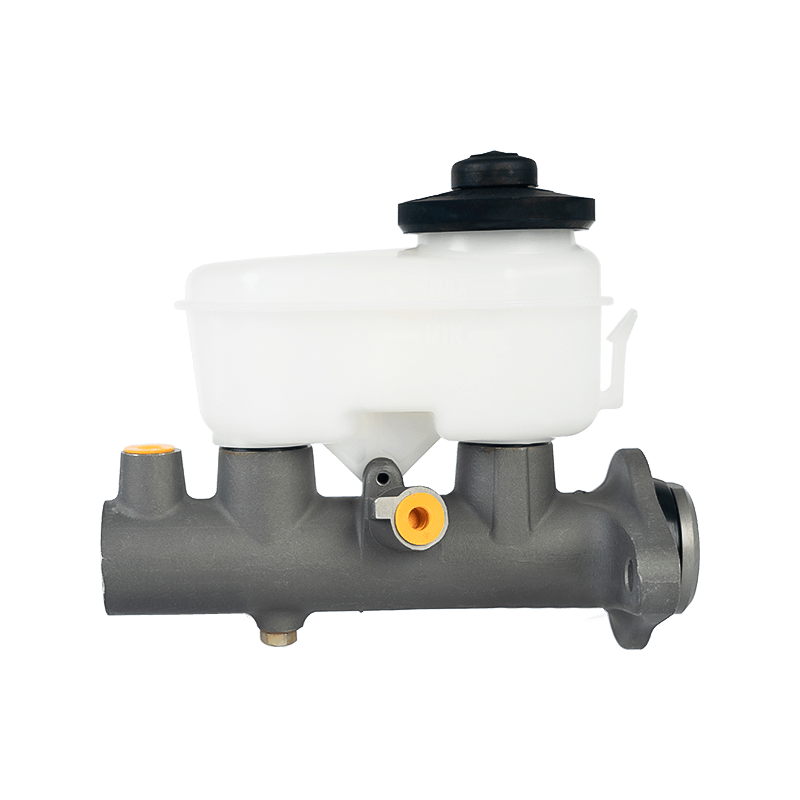

The primary function of the Clutch Master Cylinder is to convert the mechanical force applied to the clutch pedal into hydraulic pressure, which is then transmitted through the clutch hydraulic line to the clutch slave cylinder. This hydraulic pressure forces the slave cylinder to engage or disengage the clutch assembly by moving the release bearing against the clutch pressure plate. In simpler terms, when a driver presses the clutch pedal, the Clutch Master Cylinder initiates the process of separating the engine from the transmission, allowing for gear changes without causing damage or undue wear to the drivetrain components.

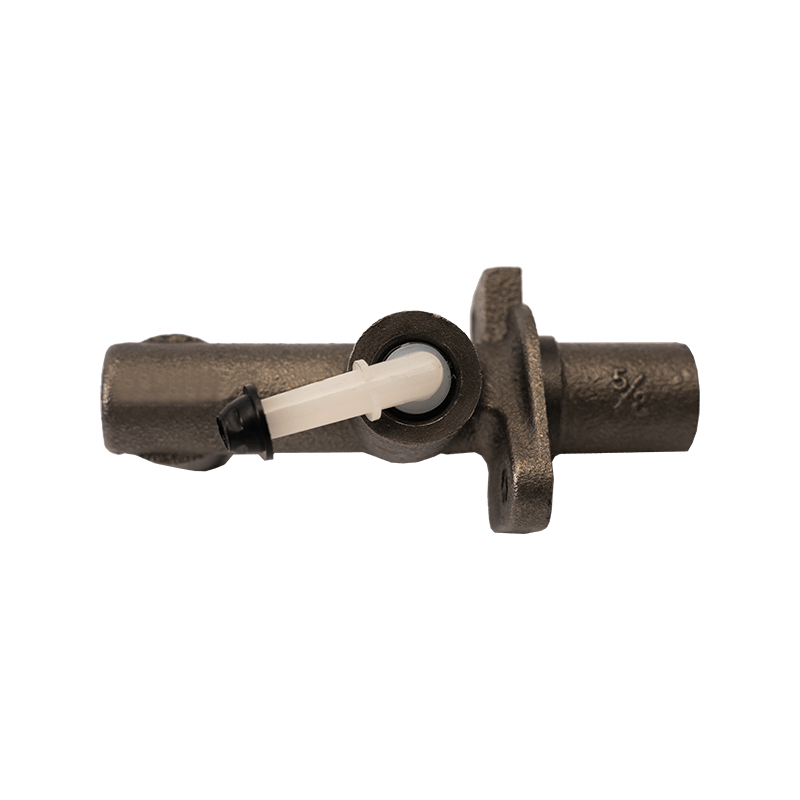

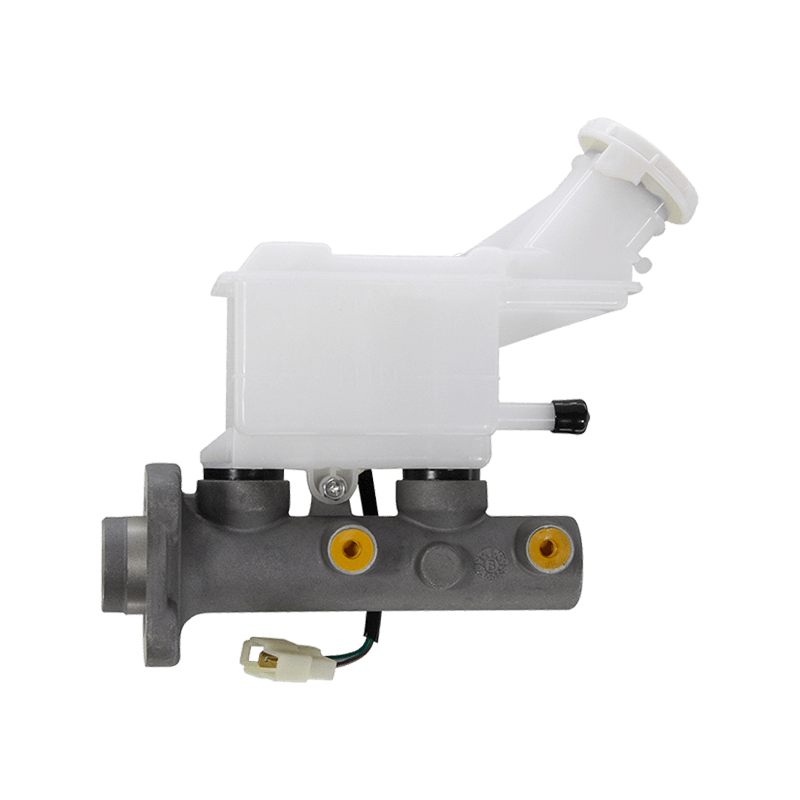

Constructed with precision-engineered components, the Clutch Master Cylinder typically consists of a cylindrical body, a piston, a reservoir for clutch fluid, and various seals and return springs. When the driver depresses the clutch pedal, it pushes a rod connected to the piston within the master cylinder. This action pressurizes the hydraulic fluid in the cylinder’s bore, forcing it through the connected hydraulic lines toward the slave cylinder. Upon release of the clutch pedal, the return spring inside the Clutch Master Cylinder pushes the piston back to its original position, drawing more fluid from the reservoir and preparing the system for the next operation.

The reliability of the Clutch Master Cylinder is vital to the performance of the vehicle’s clutch system. Any loss of hydraulic pressure due to internal seal wear, air ingress, or fluid leakage can lead to issues such as clutch slippage, difficulty shifting gears, or a spongy pedal feel. Regular inspection and timely replacement of worn or damaged Clutch Master Cylinders are essential to maintain safe and efficient vehicle operation.

In addition to its mechanical function, the Clutch Master Cylinder also directly influences the tactile feedback experienced by the driver. The responsiveness and resistance felt at the clutch pedal are determined by the master cylinder’s bore size, piston travel, and internal hydraulic pressure. High-performance or heavy-duty vehicles may require Clutch Master Cylinders with reinforced components or increased fluid capacity to handle the demands of increased torque and load.

Modern automotive designs have introduced integrated clutch master-slave assemblies in certain applications, offering compact configurations that streamline installation and servicing. Nevertheless, the fundamental role of the Clutch Master Cylinder remains unchanged: to serve as the starting point of the hydraulic chain reaction that enables safe, precise, and controlled gear engagement in vehicles equipped with manual or semi-automatic transmissions.

Search

Search

Eng

Eng

English

English Español

Español Português

Português