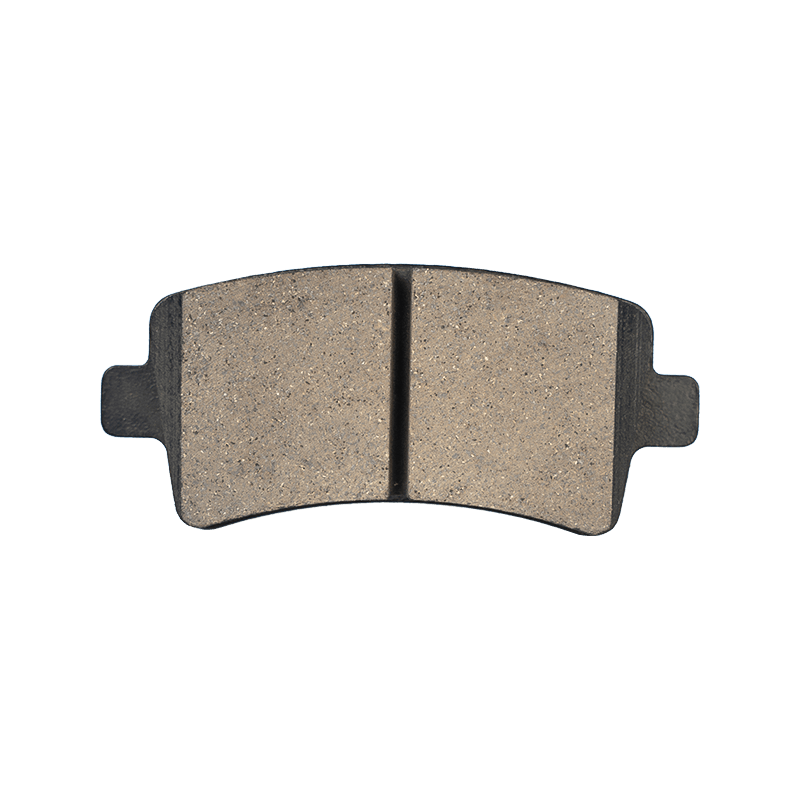

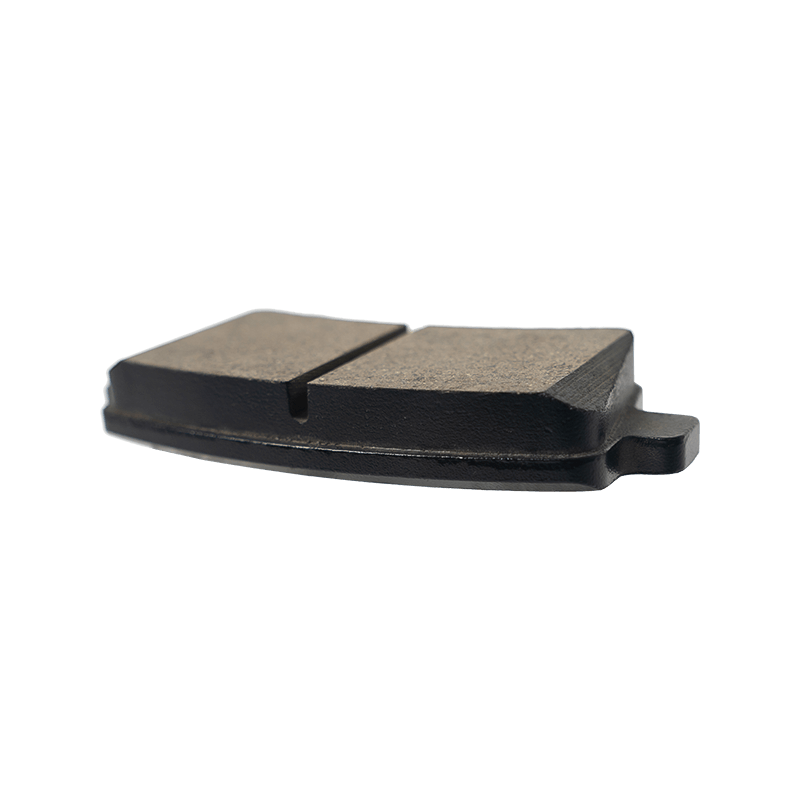

16586609 High Carbon Heat Resistant Brake Pads for BUICK CADILLAC

|

OE NO |

16586609 |

|

MODEL |

BUICK CADILLAC |

Specifications

KEEP IN TOUCH

We have more than 1,000 brake shoes and brake pads for European, American, Russian, Japanese and Korean cars. The associated factories have created a highly experienced manufacturing team that exports thousands of auto part products worldwide. High quality and competitive prices are our targets. Our products have gained the certifications of ISO9001 and TS16949. We have built up a solid reputation with our customers in more than 30 countries.

We are looking forward to having a brighter and more successful business in the near future together with all of our clients all over the world.

-

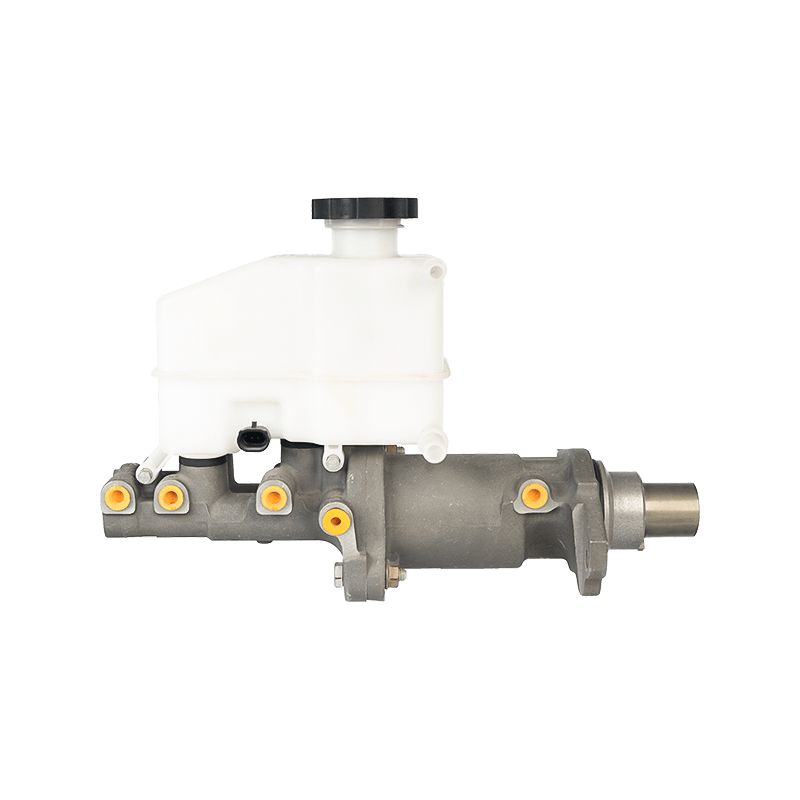

The automobile brake system is one of the most critical safety components in any vehicle. It controls speed, enables smooth stopping, and prevents acc...

READ MORE -

When you're driving, you probably don’t think much about your brake system—until you need it. The brake system in your car is one of the most importan...

READ MORE -

Many customers often have these questions: "Are your brake pads wear-resistant?" "Will they make noise at high speeds?" "How long will they last? Will...

READ MORE -

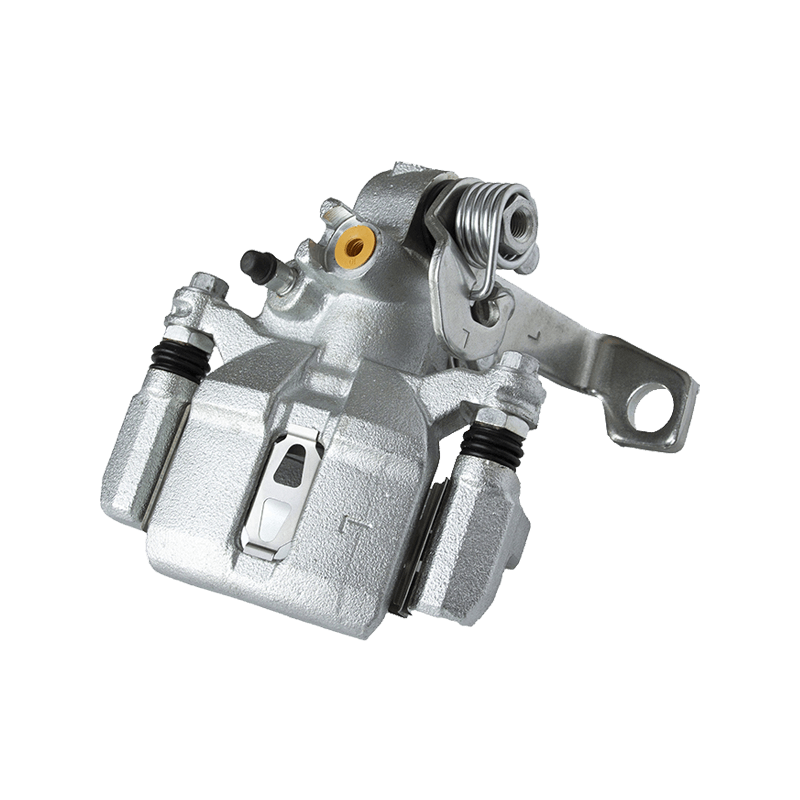

In everyday driving, many car owners encounter strange noises when braking, such as "squeaking," "clicking," or "grinding" sounds. The brake caliper i...

READ MORE

16586609 High-carbon heat-resistant brake pads are based on three-dimensional woven high-carbon carbon fibers, and use silicon nitride gradient coating and ceramic fiber composite reinforcement technology to increase the operating temperature threshold to above 850°C. At the same time, the fluctuation range of the friction coefficient is controlled within 5% in a low-temperature environment of -50°C, showing stable braking performance in all weather and all scenarios.

The friction layer of this product combines the carbon fiber preform with nano-silicon carbide particles through a chemical vapor deposition process to form a honeycomb porous structure with a porosity of only 1.8%, which is 60% higher than that of traditional high-carbon brake pads. In the surface gradient coating, the Mohs hardness of silicon nitride reaches 9.5, and the thickness is controlled between 80-120 microns, which not only prevents hard particles from scratching the brake disc, but also forms an aerodynamic effect on the friction interface through the micro-groove design, reducing the braking noise to below 42 decibels. It is worth noting that rare earth oxide modification technology is introduced in the product design. The synergistic effect of cerium oxide and lanthanum oxide not only reduces the high-temperature oxidation rate, but also achieves a stable dynamic friction coefficient range of 0.48-0.52 through the self-lubricating properties of rare earth elements, ensuring that the thermal decay rate is less than 7% after ten consecutive 100km/h emergency brakes.

The 16586609 brake pad adopts microwave assisted sintering technology, and the carbon fiber orientation is arranged by electromagnetic field at a high temperature of 1500℃, so that the longitudinal compressive strength exceeds 380MPa, and the transverse toughness is increased to 3 times that of traditional products. The back plate uses laser selective melting 3D printing technology, combining titanium aluminum alloy skeleton with topological optimization hollow design, reducing weight by 25% while increasing heat dissipation area by 40%. With the patented vortex guide groove design, the surface temperature of the brake disc can be reduced from 600℃ to 200℃ within 90 seconds. The product is suitable for electric supercars, heavy-duty trucks and special engineering machinery.

Search

Search

Eng

Eng

English

English Español

Español Português

Português