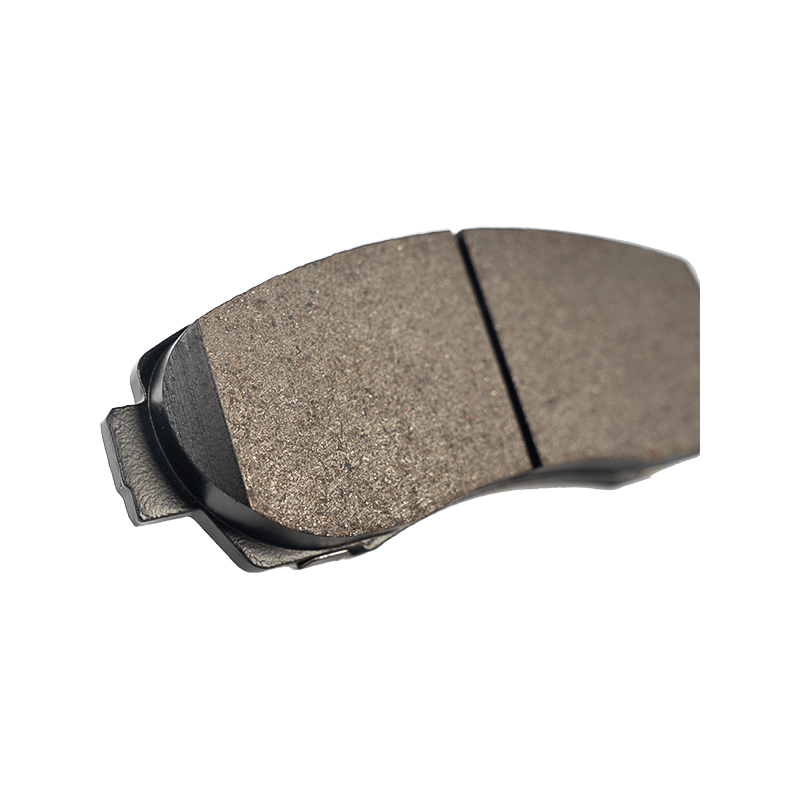

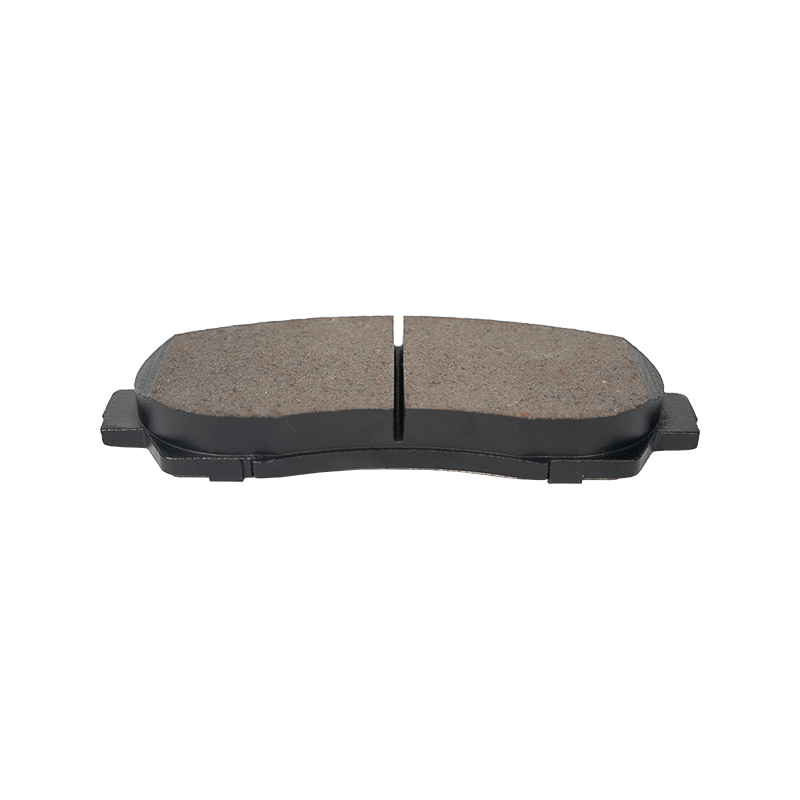

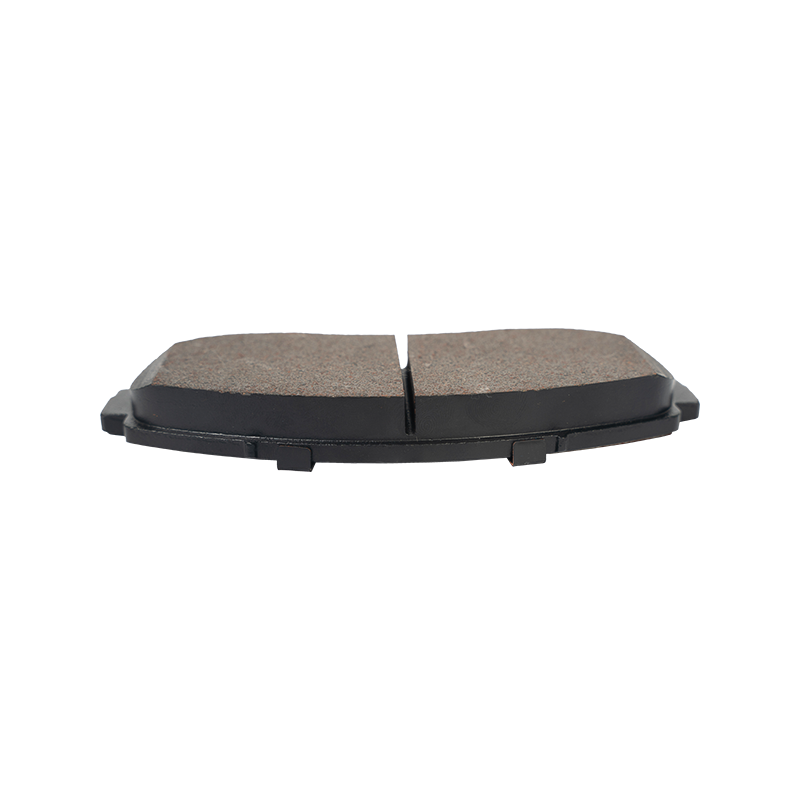

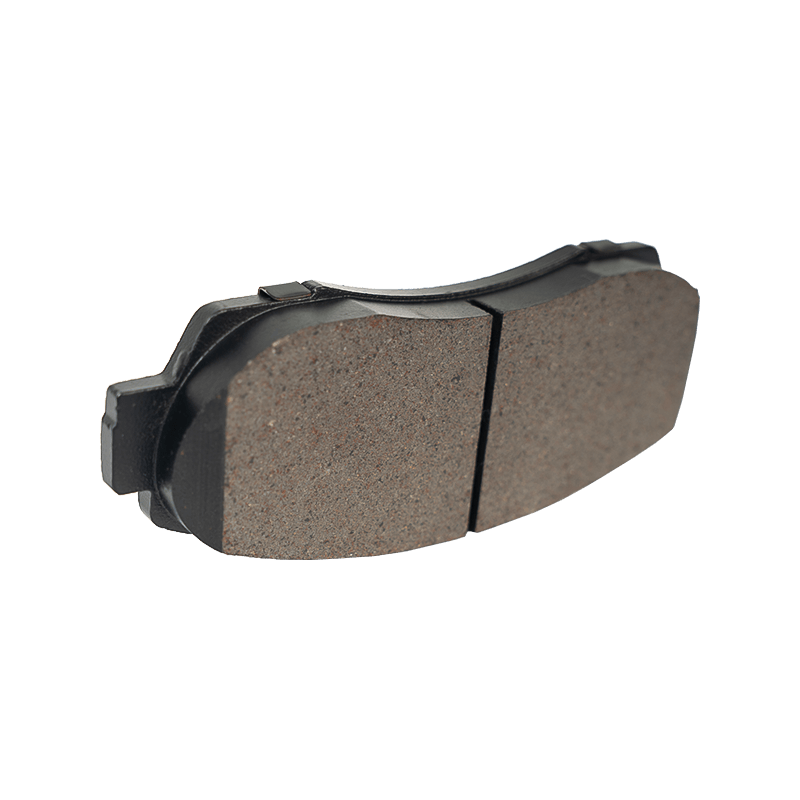

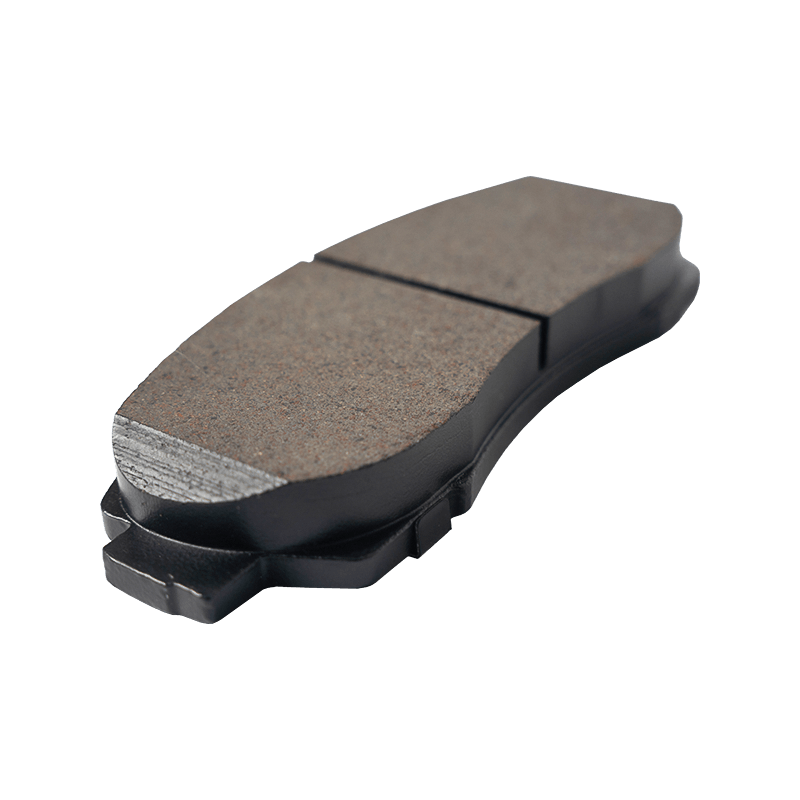

45022SHJA50 High Carbon Heat Resistant Brake Pads for Haval Honda

|

OE NO |

45022SHJA50 45022T0AA00 45022TK8A01 45022TP6A60 |

|

MODEL |

Haval Honda |

Specifications

KEEP IN TOUCH

We have more than 1,000 brake shoes and brake pads for European, American, Russian, Japanese and Korean cars. The associated factories have created a highly experienced manufacturing team that exports thousands of auto part products worldwide. High quality and competitive prices are our targets. Our products have gained the certifications of ISO9001 and TS16949. We have built up a solid reputation with our customers in more than 30 countries.

We are looking forward to having a brighter and more successful business in the near future together with all of our clients all over the world.

-

The automobile brake system is one of the most critical safety components in any vehicle. It controls speed, enables smooth stopping, and prevents acc...

READ MORE -

When you're driving, you probably don’t think much about your brake system—until you need it. The brake system in your car is one of the most importan...

READ MORE -

Many customers often have these questions: "Are your brake pads wear-resistant?" "Will they make noise at high speeds?" "How long will they last? Will...

READ MORE -

In everyday driving, many car owners encounter strange noises when braking, such as "squeaking," "clicking," or "grinding" sounds. The brake caliper i...

READ MORE

45022SHJA50 high-carbon heat-resistant brake pads have become an important guarantee for vehicle braking safety due to their high temperature resistance and material innovation. This type of brake pad uses high-carbon carbon fiber composite materials as the core friction layer, combined with silicon nitride ceramic coating and stainless steel fiber reinforcement technology, which increases the high temperature resistance threshold to above 800℃, while taking into account lightweight and friction stability, meeting the performance requirements under high-speed braking and special working conditions.

The material design of the brake pad reflects the development of high-end technology. The high-carbon carbon fiber matrix not only has a density as low as 1.8g/m³, which is 40% lighter than traditional metal brake pads, but also has excellent thermal conductivity, can maintain structural integrity at high temperatures, and avoid brake failure caused by thermal expansion of metal materials. The introduction of silicon nitride ceramic coating on the surface significantly improves the wear resistance of the product through high hardness and low thermal conductivity characteristics. In the multi-layer structure design, the superposition of the silicate fiber high temperature resistant layer and the stainless steel fiber reinforcement layer further optimizes the thermal attenuation gradient, ensuring that the friction coefficient fluctuates by less than 8% in the range of -40℃ to 800℃.

45022SHJA50 is suitable for mid-to-high-end models equipped with ABS/ESP systems, and is especially optimized for the high-torque braking requirements of new energy vehicles. Its quick response characteristics and lightweight design increase the range of electric vehicles by about 1.5%. It is worth noting that this product extends the brake pad refurbishment cycle to 150,000 kilometers through unequal thickness structural design and anti-oxidation coating technology, increases material utilization by 40%, and reduces the cost of use throughout the life cycle.

Search

Search

Eng

Eng

English

English Español

Español Português

Português