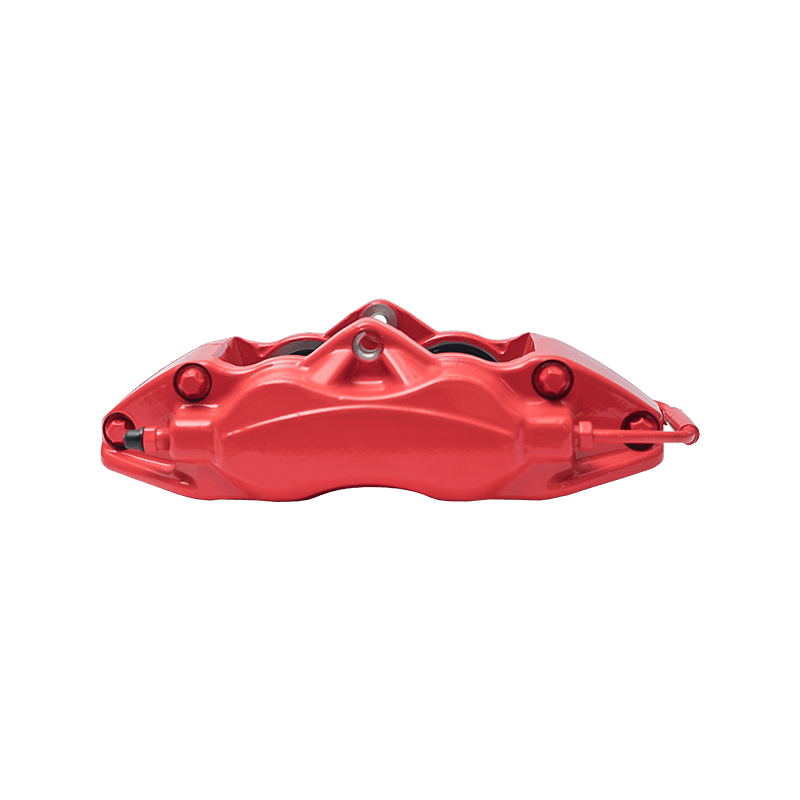

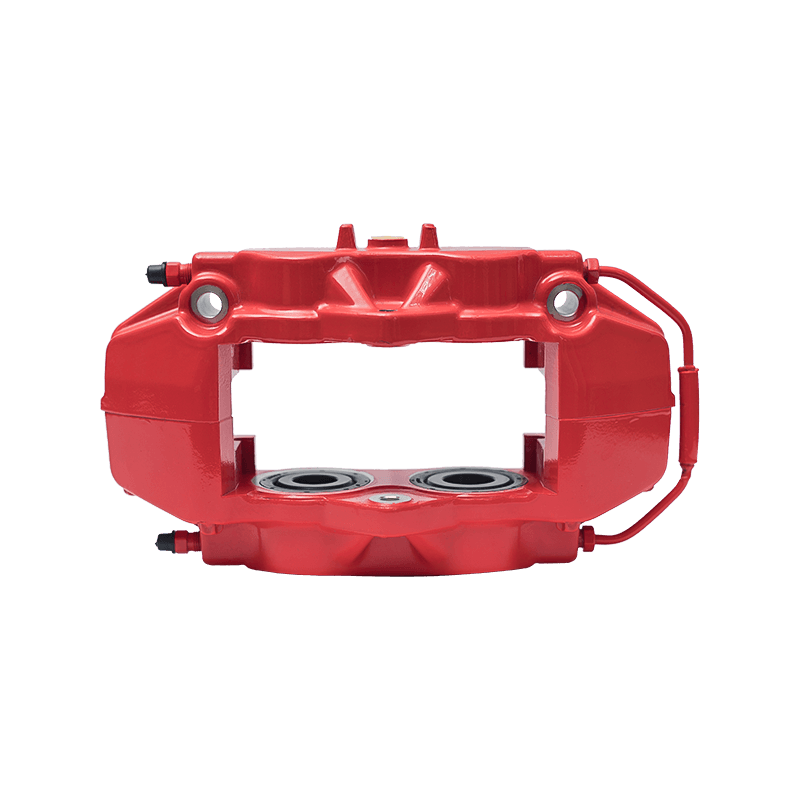

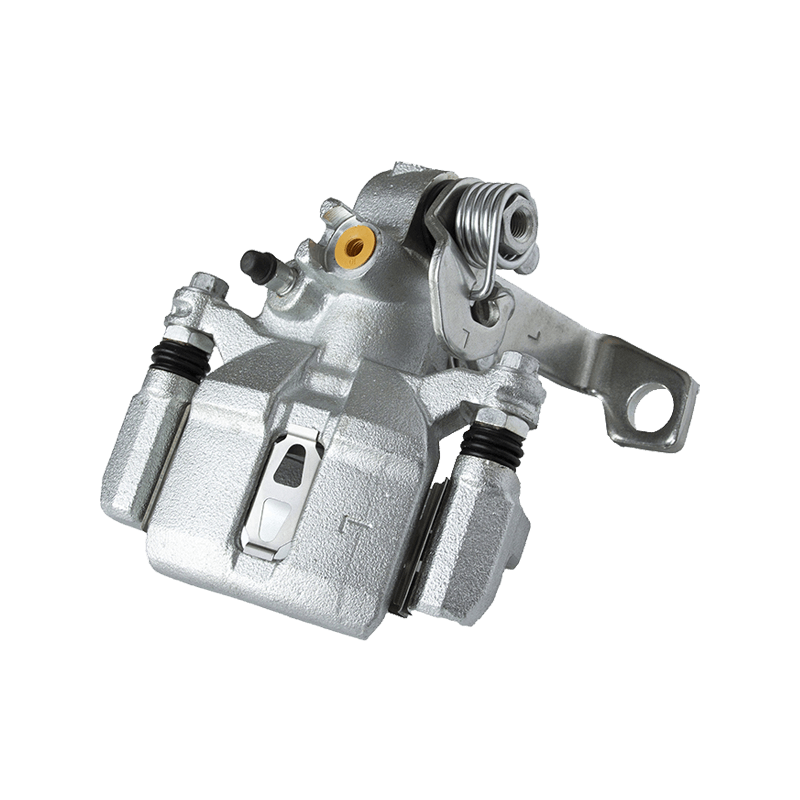

BB0401-3501100 Brake Caliper for Modified vehicle

|

OE NO |

BB0401-3501100 |

|

DESCRIP |

Caliper |

|

MODEL |

Modified vehicle |

Specifications

KEEP IN TOUCH

We have more than 1,000 brake shoes and brake pads for European, American, Russian, Japanese and Korean cars. The associated factories have created a highly experienced manufacturing team that exports thousands of auto part products worldwide. High quality and competitive prices are our targets. Our products have gained the certifications of ISO9001 and TS16949. We have built up a solid reputation with our customers in more than 30 countries.

We are looking forward to having a brighter and more successful business in the near future together with all of our clients all over the world.

-

Why Choose OE Quality Brake Pads? When selecting brake pads, OE QUALITY BRAKE PADS ensure precise fit, optimal braking performance, and long-term dur...

READ MORE -

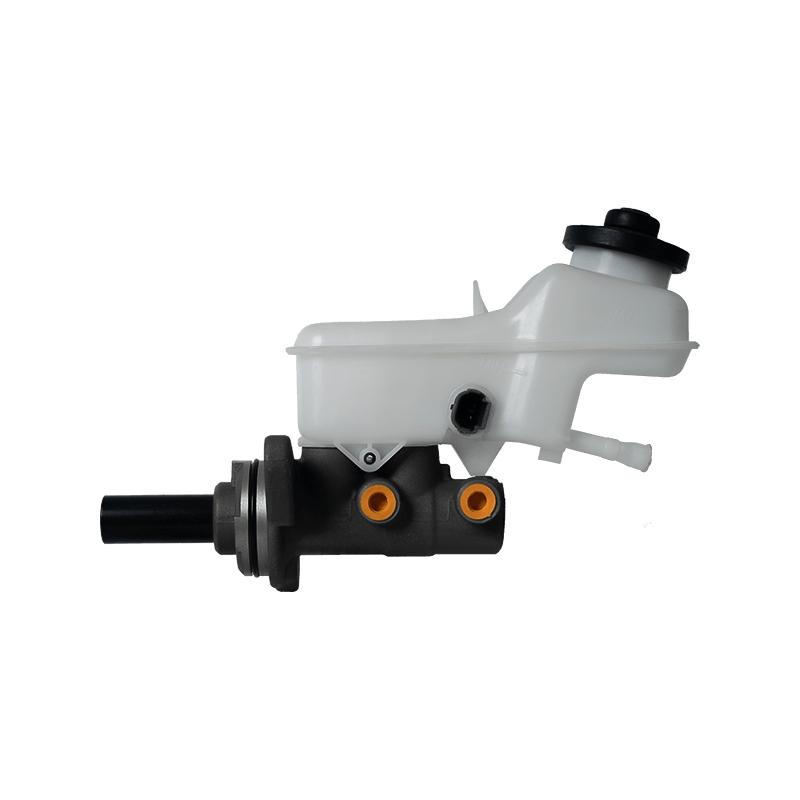

What is a Hydraulic Brake Master Cylinder? The hydraulic brake master cylinder is a critical component in a vehicle's braking system. It converts the...

READ MORE -

Why OE Quality Brake Pads Are the Best Choice for Your Car OE (Original Equipment) quality brake pads are specifically designed to match the specific...

READ MORE -

The direct answer: Yes. High-quality brake pads can reduce braking distance by 15%–30%, improve heat resistance, and significantly enhance driving saf...

READ MORE

The BB0401-3501100 modified car brake caliper is made of split forged aviation aluminum alloy. The weight of a single caliper is only 4.8 kg, which is 45% lighter than the traditional cast iron caliper. The compressive strength exceeds 380MPa, which is perfectly compatible with the installation space of 18-22 inch wheels without the need to install flange gaskets. Its core technological breakthrough is reflected in the multi-piston dynamic pressure distribution system. The six-piston gradient layout combined with the dual-circuit hydraulic channel design can automatically adjust the output ratio of each piston according to the change of braking pressure. The actual measurement shows that the smoothness of the braking torque curve is improved by 60% when braking on a curve.

In terms of manufacturing process, the caliper adopts a composite process of five-axis linkage CNC finishing and low-pressure sand casting. The ingot is X-ray inspected to ensure that the internal porosity is less than 0.2%, the piston hole position tolerance is controlled within ±0.005mm, and the sealing groove is scanned at the nanometer level by the AI visual inspection system. The patented wave-shaped cooling fins and vortex guide groove design can reduce the friction interface temperature of 650℃ to 200℃ within 120 seconds, which is particularly suitable for high-frequency braking scenarios on track days. The back plate uses a topologically optimized hollow structure, and with a titanium alloy bracket, the shear resistance is increased to three times that of the traditional design. It has successfully passed the double-pulse endurance test simulating 300,000 kilometers, and the piston return error is always kept within ±0.015mm.

In the modification application scenario, BB0401-3501100 shows good adaptability. Its modular design supports personalized customization. After-sales service also reflects the characteristics of professional modification parts. The caliper is equipped with an NFC chip, and the production batch and warranty information can be traced by scanning with a mobile phone.

Search

Search

Eng

Eng

English

English Español

Español Português

Português