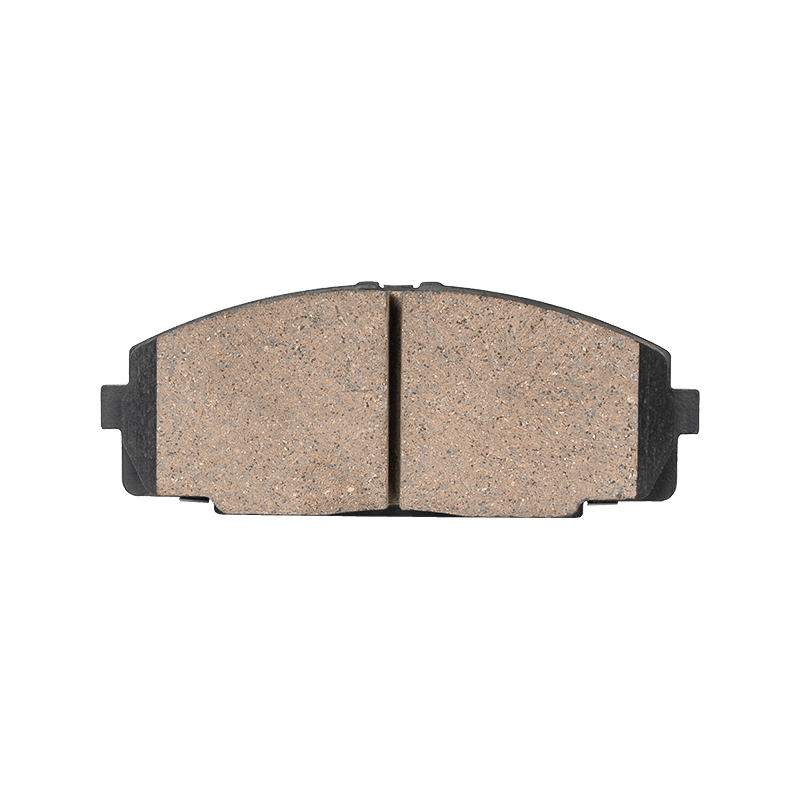

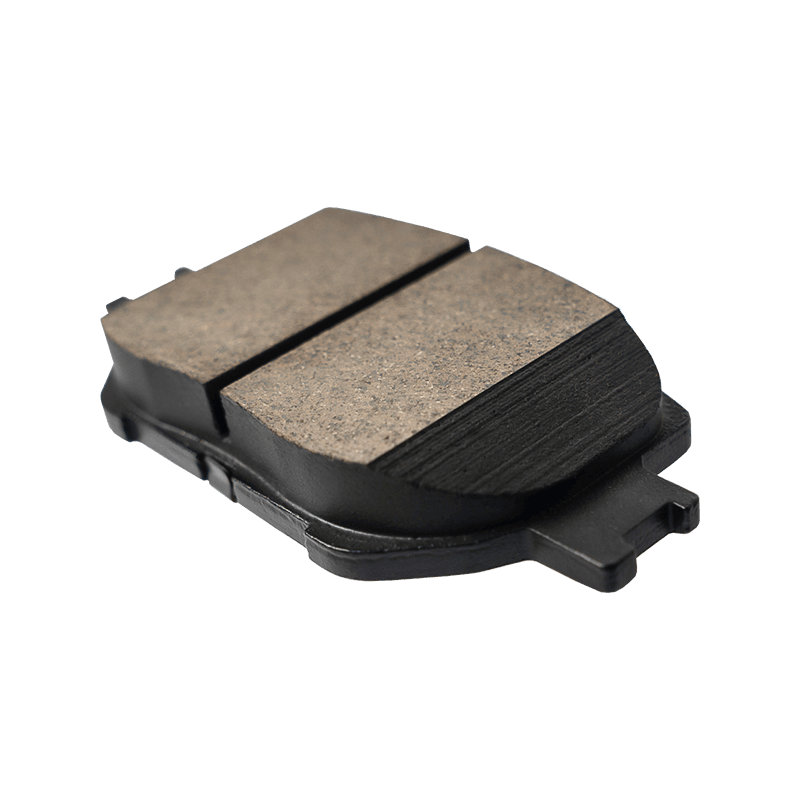

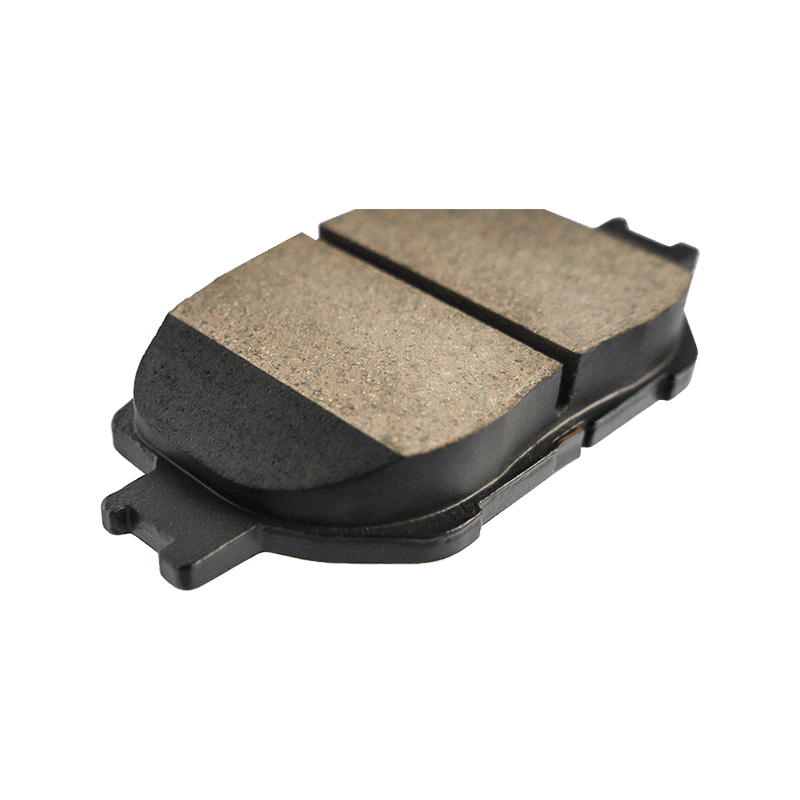

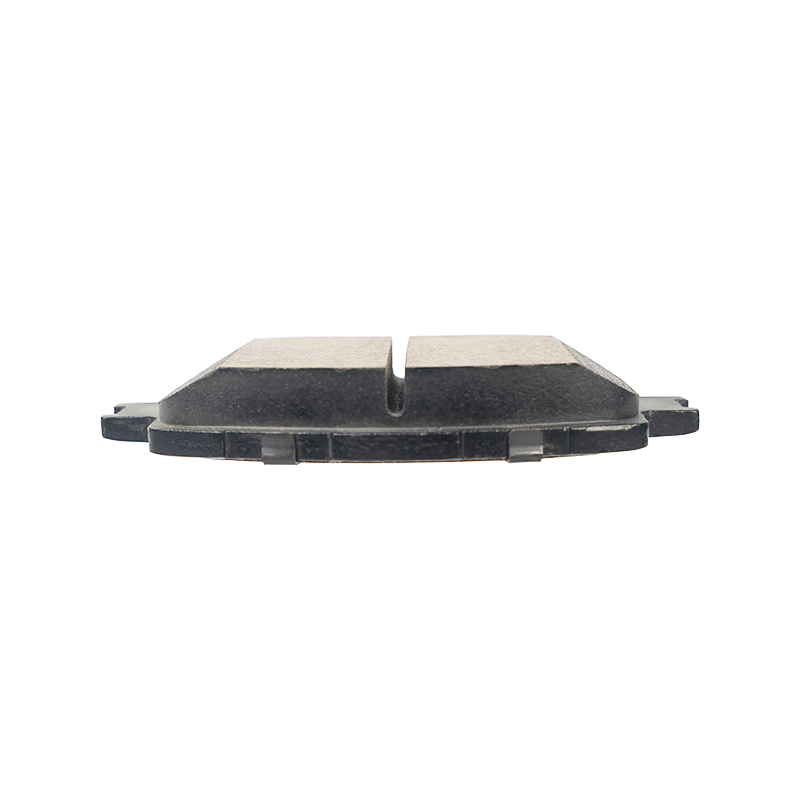

0446526320 Ultra High Performance Disc Brake Pad for Toyota

|

OE NO |

0446526320 0446526130 0449126260 |

|

MODEL |

Toyota |

Specifications

KEEP IN TOUCH

We have more than 1,000 brake shoes and brake pads for European, American, Russian, Japanese and Korean cars. The associated factories have created a highly experienced manufacturing team that exports thousands of auto part products worldwide. High quality and competitive prices are our targets. Our products have gained the certifications of ISO9001 and TS16949. We have built up a solid reputation with our customers in more than 30 countries.

We are looking forward to having a brighter and more successful business in the near future together with all of our clients all over the world.

-

The automobile brake system is one of the most critical safety components in any vehicle. It controls speed, enables smooth stopping, and prevents acc...

READ MORE -

When you're driving, you probably don’t think much about your brake system—until you need it. The brake system in your car is one of the most importan...

READ MORE -

Many customers often have these questions: "Are your brake pads wear-resistant?" "Will they make noise at high speeds?" "How long will they last? Will...

READ MORE -

In everyday driving, many car owners encounter strange noises when braking, such as "squeaking," "clicking," or "grinding" sounds. The brake caliper i...

READ MORE

0446526320Ultra-high-performance disc brake pads use optimized semi-metallic composite materials, integrating ceramic particles and carbon fiber reinforcement technology, achieving quiet and low-dust characteristics while ensuring braking performance, meeting the high-frequency urban logistics transportation needs of more than 300 kilometers per day.

Its core technological breakthrough is reflected in the innovative design of composite friction materials. The friction layer is based on modified phenolic resin, and incorporates 15% silicon carbide ceramic particles and 5% stainless steel short fibers to form a gradient distribution structure. The Mohs hardness of the surface ceramic particles reaches level 9, which can effectively reduce the wear rate of the brake disc; the middle stainless steel fiber network improves the thermal conductivity. In the actual measurement of ten consecutive emergency braking tests, the peak temperature of the friction interface is 22% lower than that of traditional semi-metallic brake pads, and the thermal decay rate is controlled within 5%. What is more worth mentioning is that nano-graphene lubricant is specially added to the formula to stabilize the dynamic friction coefficient in the range of 0.38-0.42, and the braking distance is shortened by 8%-12% compared with similar products.

In the production process, two-stage hot pressing technology is used to complete the material densification at a high temperature of 230°C and a pressure of 15MPa. The porosity is less than 2%, and the shear strength is increased to 1.5 times that of traditional process products. The back plate is made of galvanized alloy steel plate, combined with a wavy heat dissipation fin design and a patented vortex guide groove, which can reduce the friction interface temperature from 650°C to 180°C within 120 seconds, effectively avoiding thermal cracks. In view of the frequent start-stop conditions of commercial vehicles, the product optimizes the initial bite response speed, shortens the braking delay time to 0.15 seconds, and reduces the dust generation by 60% compared to ordinary semi-metallic brake pads, and extends the wheel cleaning cycle by more than 3 times.

Search

Search

Eng

Eng

English

English Español

Español Português

Português