Specifications

KEEP IN TOUCH

We have more than 1,000 brake shoes and brake pads for European, American, Russian, Japanese and Korean cars. The associated factories have created a highly experienced manufacturing team that exports thousands of auto part products worldwide. High quality and competitive prices are our targets. Our products have gained the certifications of ISO9001 and TS16949. We have built up a solid reputation with our customers in more than 30 countries.

We are looking forward to having a brighter and more successful business in the near future together with all of our clients all over the world.

-

Why Choose OE Quality Brake Pads? When selecting brake pads, OE QUALITY BRAKE PADS ensure precise fit, optimal braking performance, and long-term dur...

READ MORE -

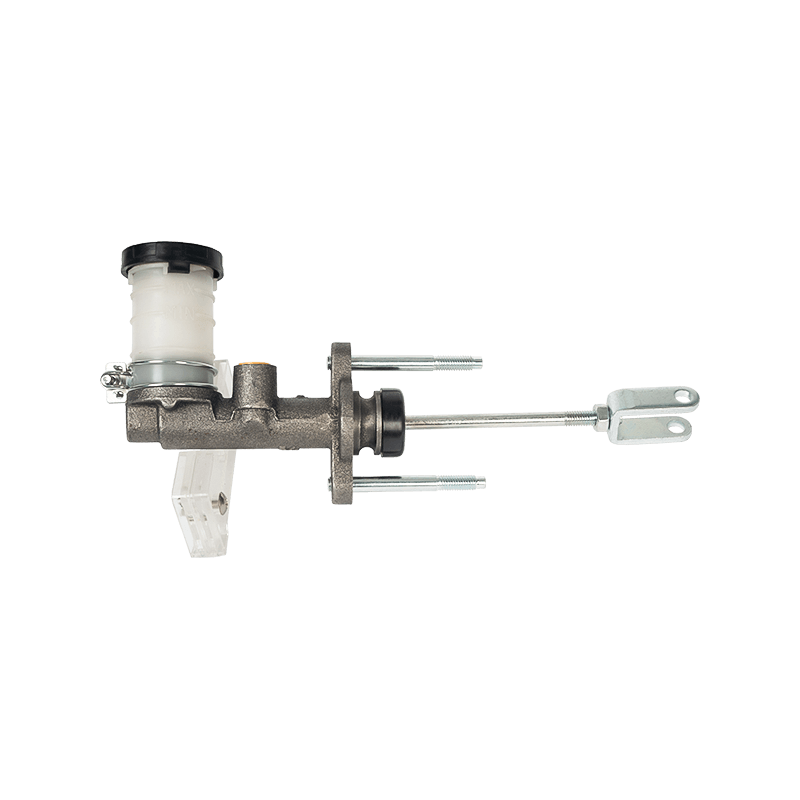

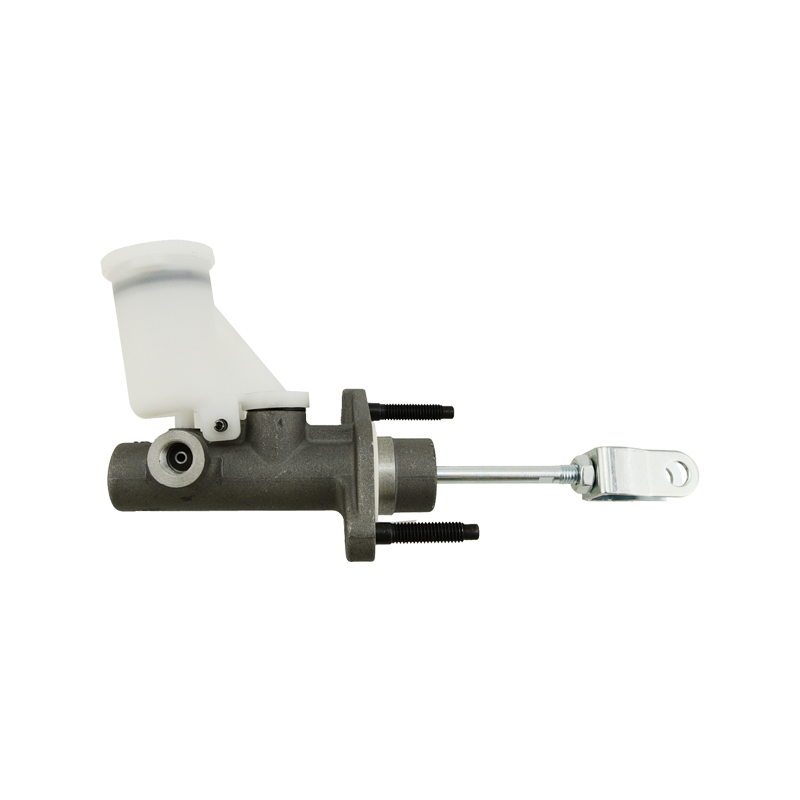

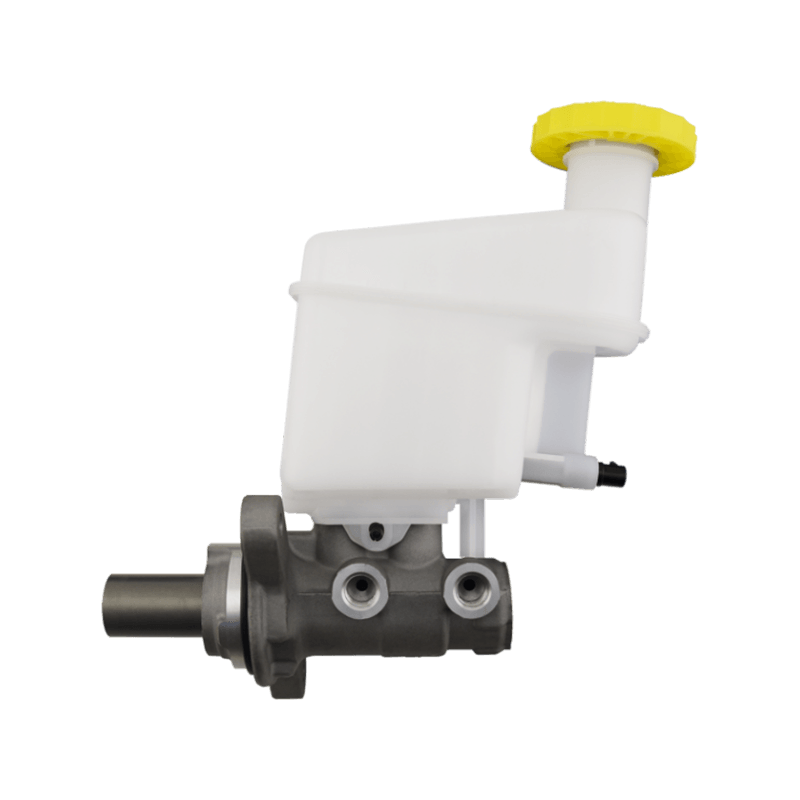

What is a Hydraulic Brake Master Cylinder? The hydraulic brake master cylinder is a critical component in a vehicle's braking system. It converts the...

READ MORE -

Why OE Quality Brake Pads Are the Best Choice for Your Car OE (Original Equipment) quality brake pads are specifically designed to match the specific...

READ MORE -

The direct answer: Yes. High-quality brake pads can reduce braking distance by 15%–30%, improve heat resistance, and significantly enhance driving saf...

READ MORE

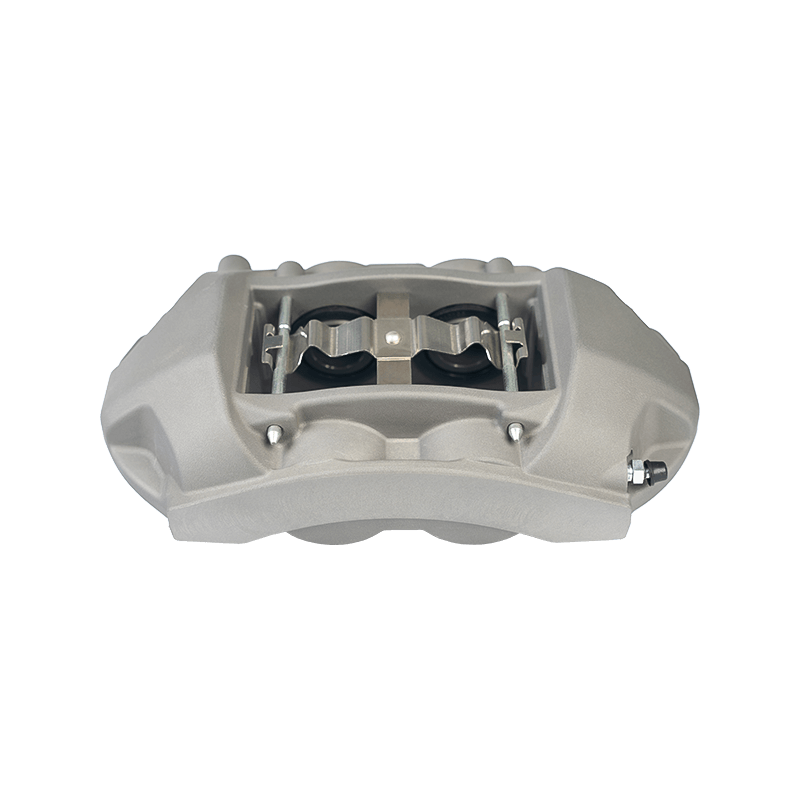

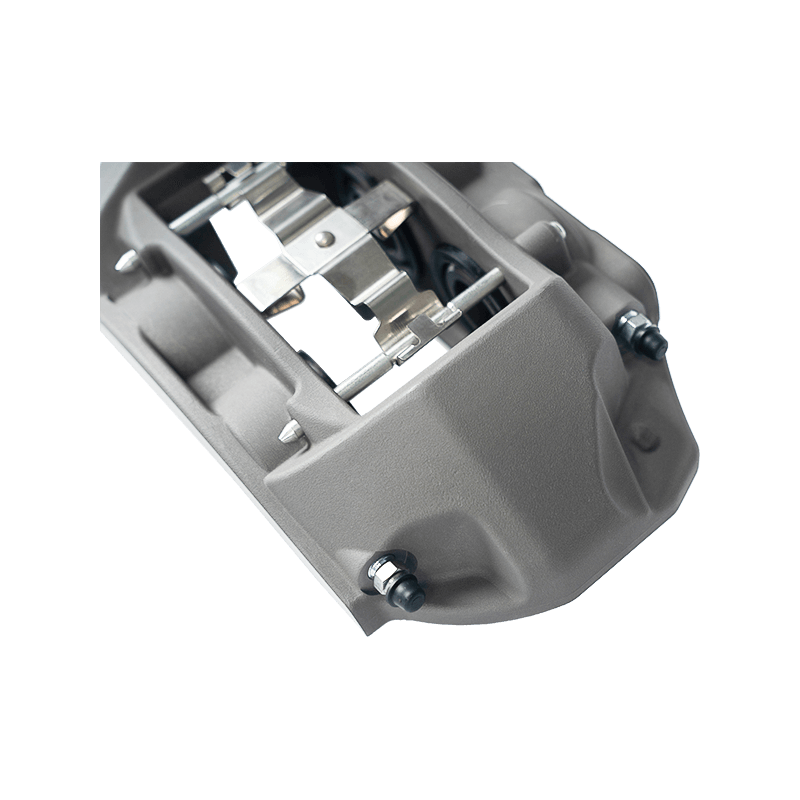

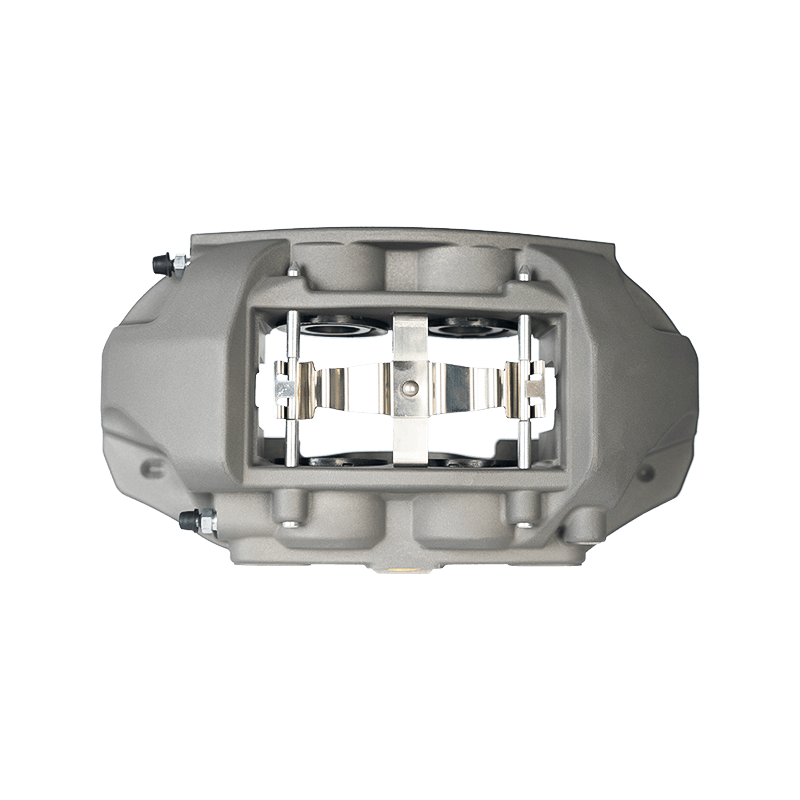

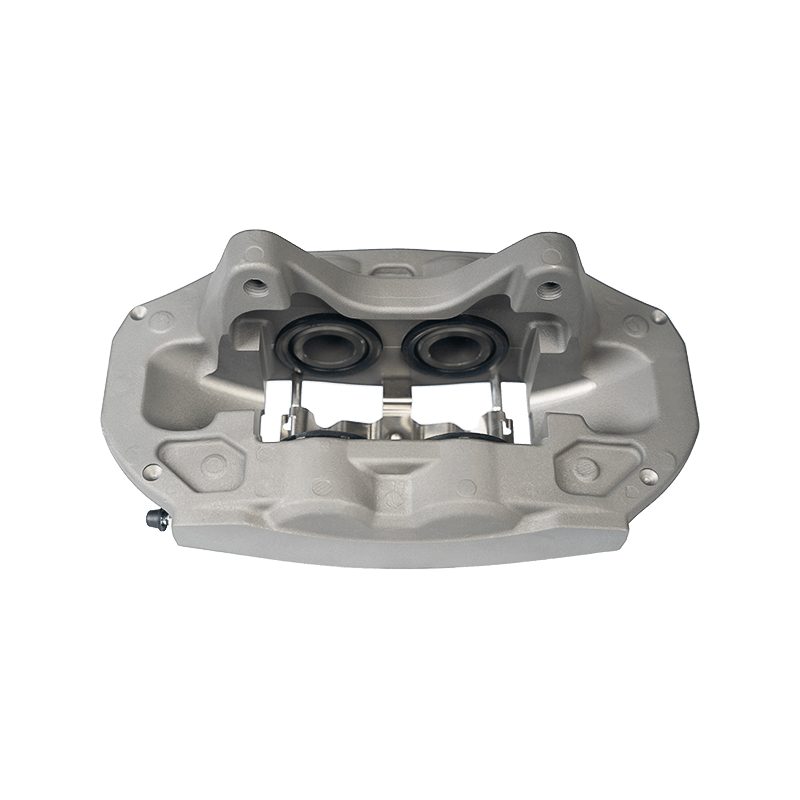

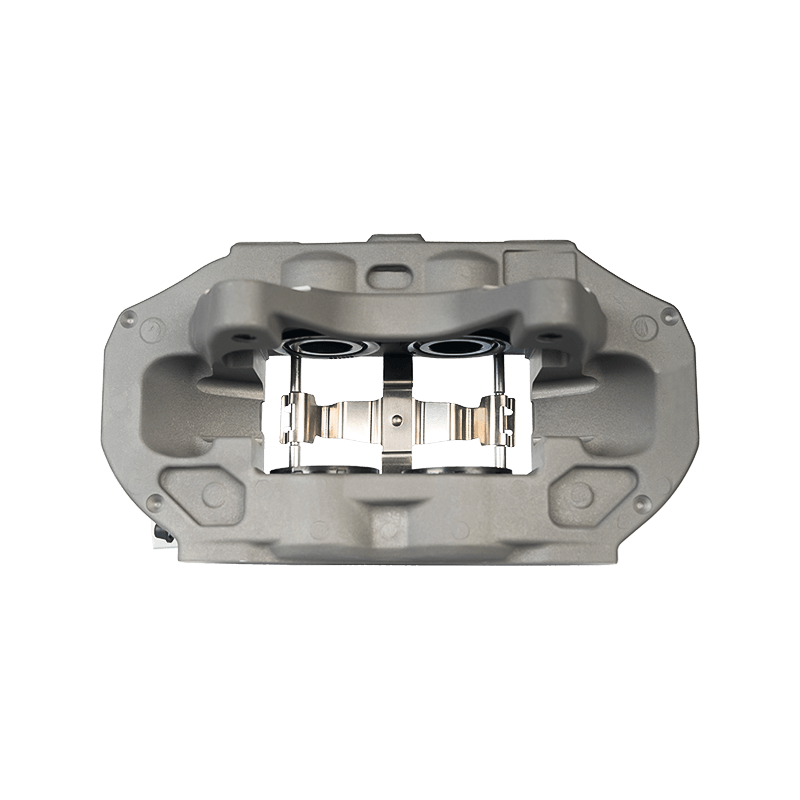

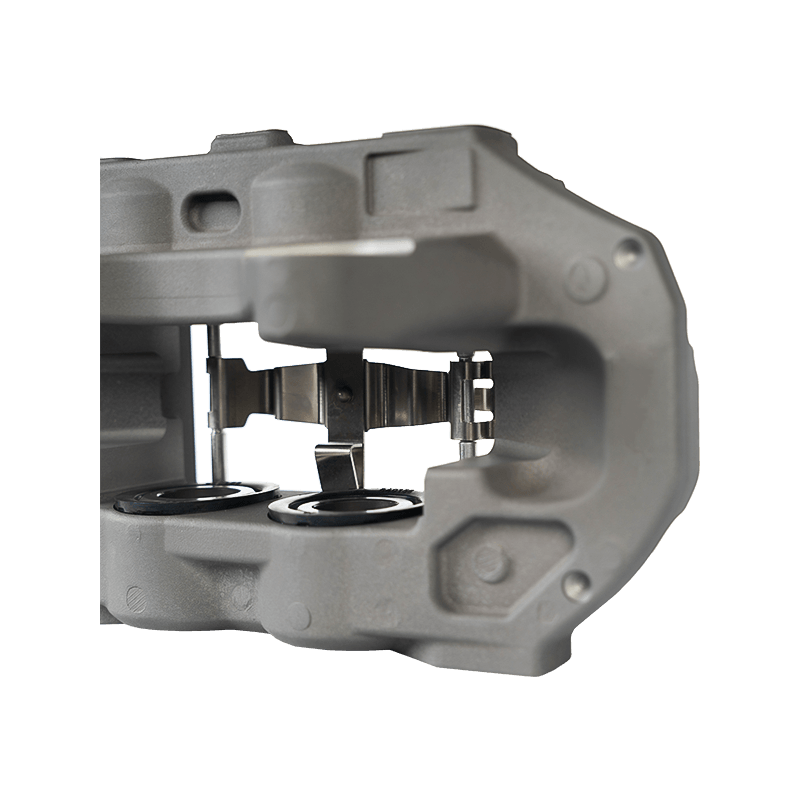

As the exclusive high-performance brake component for Tesla Model S/X/3/Y and other models, the 104462100 brake caliper has redefined the safety braking standard in the electric era with its material technology and intelligent design. This caliper is specially optimized for Tesla's 800V high-voltage platform and intelligent driving system. It is made of carbon fiber ceramic composite material. The weight of a single caliper is only 3.8 kg, which is 65% lighter than the traditional cast iron caliper. At the same time, the compressive strength exceeds 420MPa, and there is no need to install flange gaskets or adjust the wheelbase.

The friction layer of the brake caliper adopts a graphene-enhanced silicon carbide ceramic matrix, with silicon carbide particles accounting for 40%, and a Mohs hardness of 9.5. With the laser-engraved honeycomb microporous structure, the friction coefficient is stable in the range of 0.48-0.52 during emergency braking at 100km/h. The piston system uses a titanium-aluminum alloy gradient piston group. The 42mm diameter main piston and the 36mm auxiliary piston work together through a dynamic pressure distribution algorithm. With the Tesla Booster brake booster, the 100-0km/h braking distance is shortened to 31.6 meters.

In the driving scene, its built-in MEMS micro-electromechanical sensor array can monitor the friction surface temperature, pressure distribution and wear in real time. The data is transmitted to the Autopilot system at a rate of 10Mbps through the on-board CAN-FD bus, predicting the braking demand 0.5 seconds in advance and optimizing the energy recovery strategy.

Search

Search

Eng

Eng

English

English Español

Español Português

Português