What is a brake caliper?

2025.09.10

2025.09.10

Industry News

Industry News

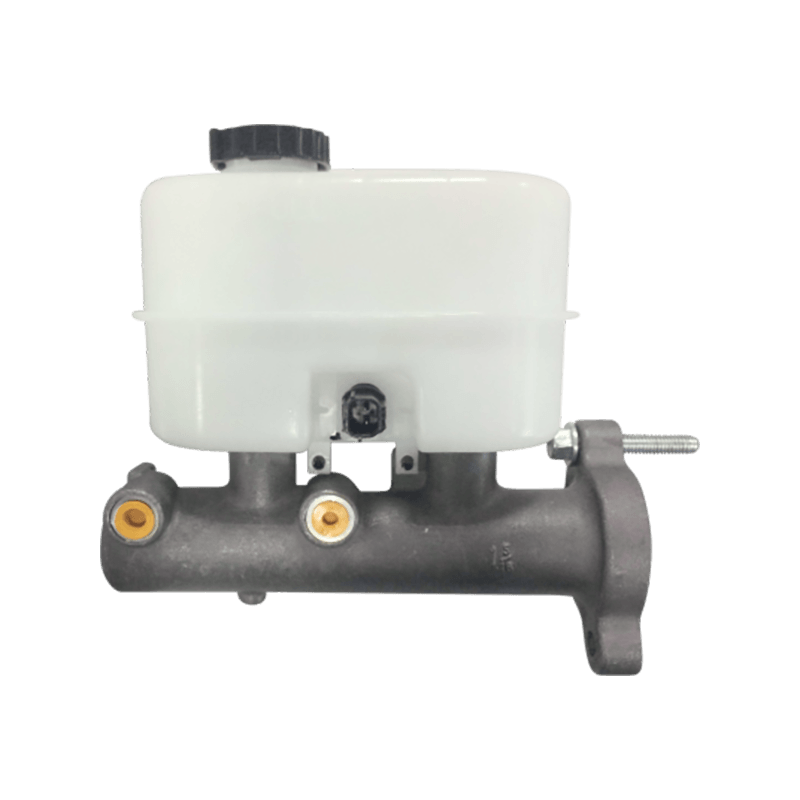

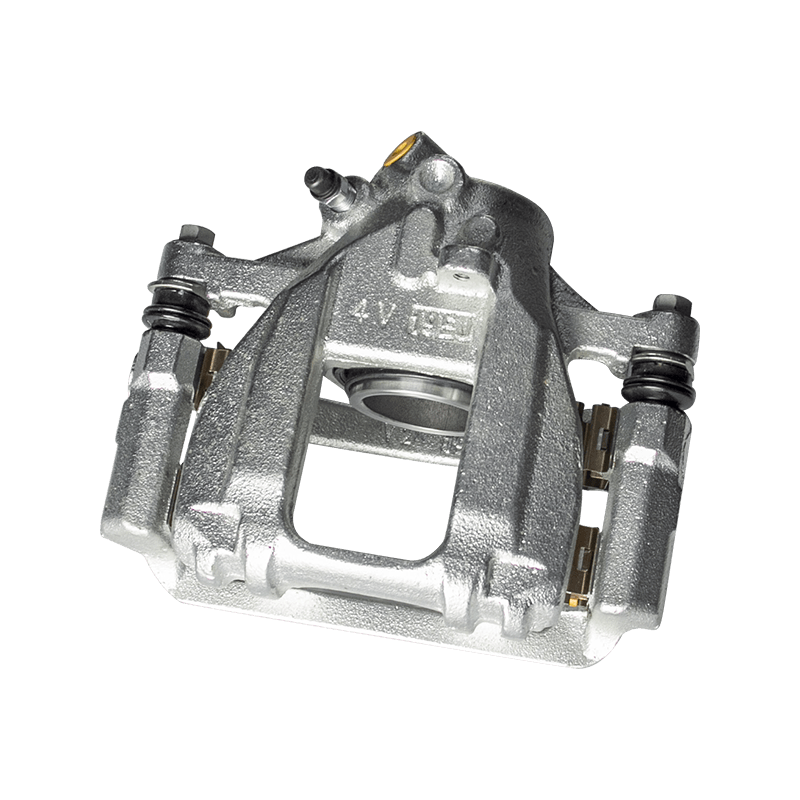

The brake caliper is the core actuator of the disc brake system. Its function is to slow down or stop the vehicle by clamping the brake disc to generate friction. The brake caliper has a built-in seal and spring system that can automatically compensate for the gap after the friction pad is worn. When the brake is released, the hydraulic pressure drops, and the elastic deformation of the seal pushes the piston back to restore the small gap between the friction pad and the brake disc, preventing the drag force caused by continuous friction.

1. Structure and classification of brake calipers

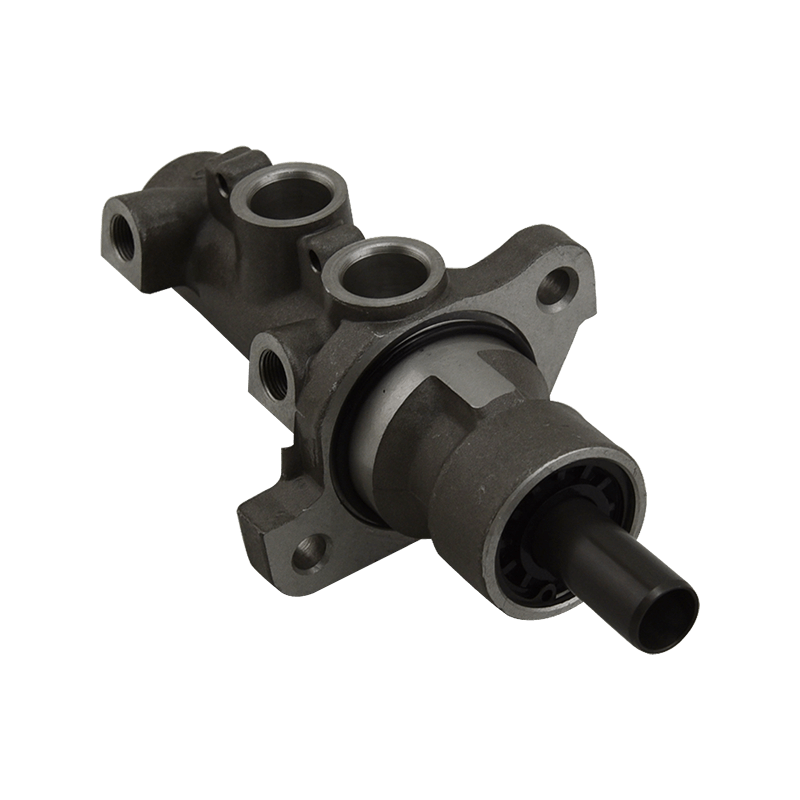

(1). Fixed brake caliper

Structural features: The caliper body is integrally cast, with 2-8 pistons symmetrically arranged on both sides (6 pistons are commonly used in high-performance vehicles), which push the brake pads on both sides synchronously through hydraulic pipelines.

Advantages: High rigidity (deformation <0.05mm), uniform distribution of braking force, suitable for high-speed and heavy-load scenarios.

Material: Monolithic aluminum alloy (A356-T6) with T heat treatment, tensile strength ≥310MPa.

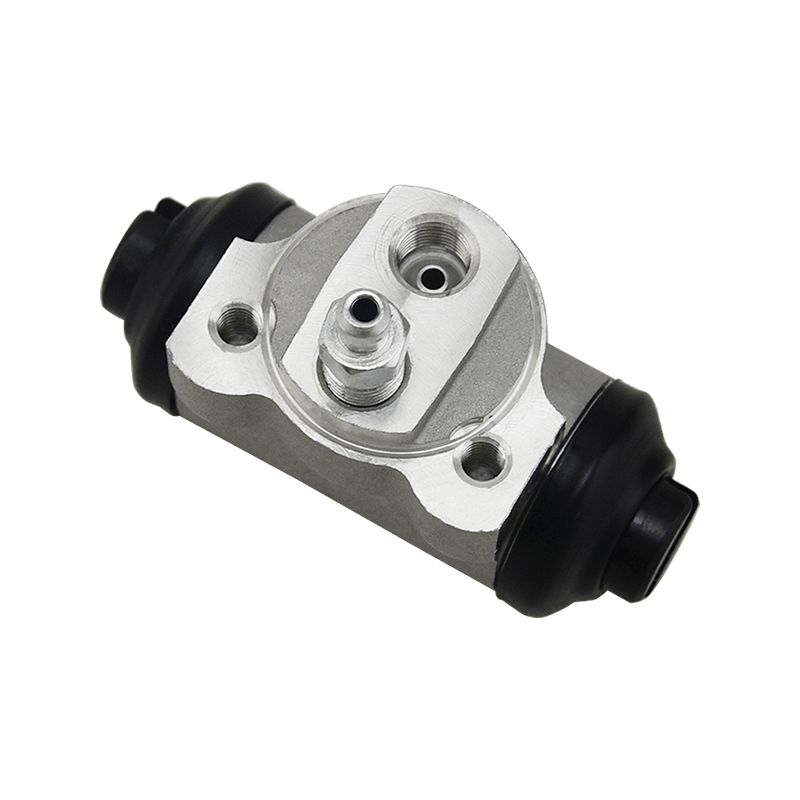

(2). Floating brake caliper

Structural features: 1-2 pistons are set on one side, and the caliper body can slide along the guide pin, using the reaction force to push the brake pad on the other side.

Advantages: Low cost, small size, and accounts for more than 75% of the passenger car market share.

Key components: Phenolic resin guide pin bushing, friction coefficient ≤0.15.

2. Working Principle

Hydraulic Transmission

Brake fluid (DOT4 standard) at master cylinder pressure (typically 6-10 MPa) pushes a piston, pressing the brake pad against the brake disc.

The piston diameter is proportional to the braking force (common sizes: Φ38mm/Φ42mm/Φ48mm).

Friction Energy Conversion

The friction coefficient between the brake pad and the brake disc is μ≈0.35-0.45, and the instantaneous temperature can reach 600°C (competition-grade carbon-ceramic discs can withstand 1200°C).

The efficiency of converting kinetic energy into thermal energy is >90%, requiring forced convection cooling via heat sink fins (8-12mm spacing).

3. Common faults of brake calipers

(1). Piston sticking

Fault phenomenon:

Abnormal wear of one-side brake pad (difference in thickness between inner and outer pads > 2mm)

Wheel drag after braking (rotational resistance > 30N·m)

Root cause:

Damage of piston dust boot leads to mud/water intrusion (accounting for 62% of fault cases)

Brake fluid contamination causes seal ring to swell (risk increases when DOT4 moisture absorption rate > 3%)

Solution: Disassemble and clean the piston cylinder and replace imported fluororubber seals (such as Japanese NOK brand)

(2). Guide pin failure

Fault manifestation:

Abnormal noise when braking (metal scraping sound)

Brake pedal travel becomes longer

Failure mechanism:

High temperature carbonization of grease (decomposition of mineral grease at > 180℃)

Aging of bushing plastic (PA66-GF25 material life is usually 5 years)

Treatment: Use special grease (such as Permatex Ultra Disc Brake Lube) and replace reinforced bushing with PTFE coating

(3). Internal leakage

Symptoms:

Brake fluid tank level continues to drop

Piston reset is slow (>0.5 seconds)

Leak point detection: Pressurize to 15MPa and test, if pressure drop>1MPa/10 minutes, it is considered to be failure

Key parameters: Piston and cylinder clearance should be ≤0.1mm (if exceeded, chrome plating repair is required)

(4). External leakage

Danger signs:

Oil stains on the inside of the wheel hub (to be distinguished from wheel hub bearing grease)

Braking distance extended by more than 20%

Emergency treatment: Immediately replace the entire caliper assembly (temporary repairs are prohibited)

Search

Search

Eng

Eng

English

English Español

Español Português

Português