Specifications

KEEP IN TOUCH

We have more than 1,000 brake shoes and brake pads for European, American, Russian, Japanese and Korean cars. The associated factories have created a highly experienced manufacturing team that exports thousands of auto part products worldwide. High quality and competitive prices are our targets. Our products have gained the certifications of ISO9001 and TS16949. We have built up a solid reputation with our customers in more than 30 countries.

We are looking forward to having a brighter and more successful business in the near future together with all of our clients all over the world.

-

The automobile brake system is one of the most critical safety components in any vehicle. It controls speed, enables smooth stopping, and prevents acc...

READ MORE -

When you're driving, you probably don’t think much about your brake system—until you need it. The brake system in your car is one of the most importan...

READ MORE -

Many customers often have these questions: "Are your brake pads wear-resistant?" "Will they make noise at high speeds?" "How long will they last? Will...

READ MORE -

In everyday driving, many car owners encounter strange noises when braking, such as "squeaking," "clicking," or "grinding" sounds. The brake caliper i...

READ MORE

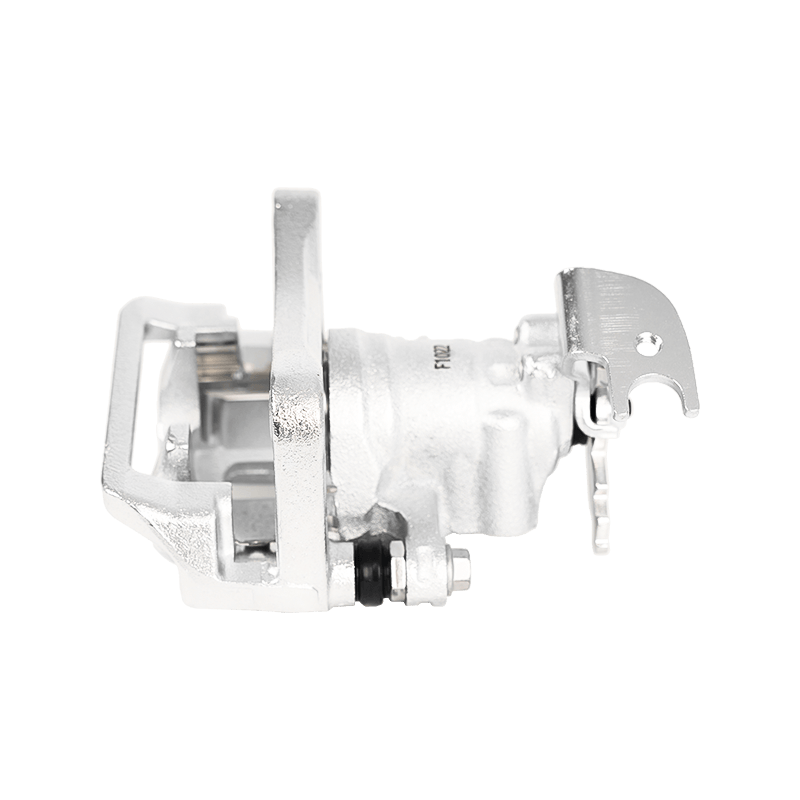

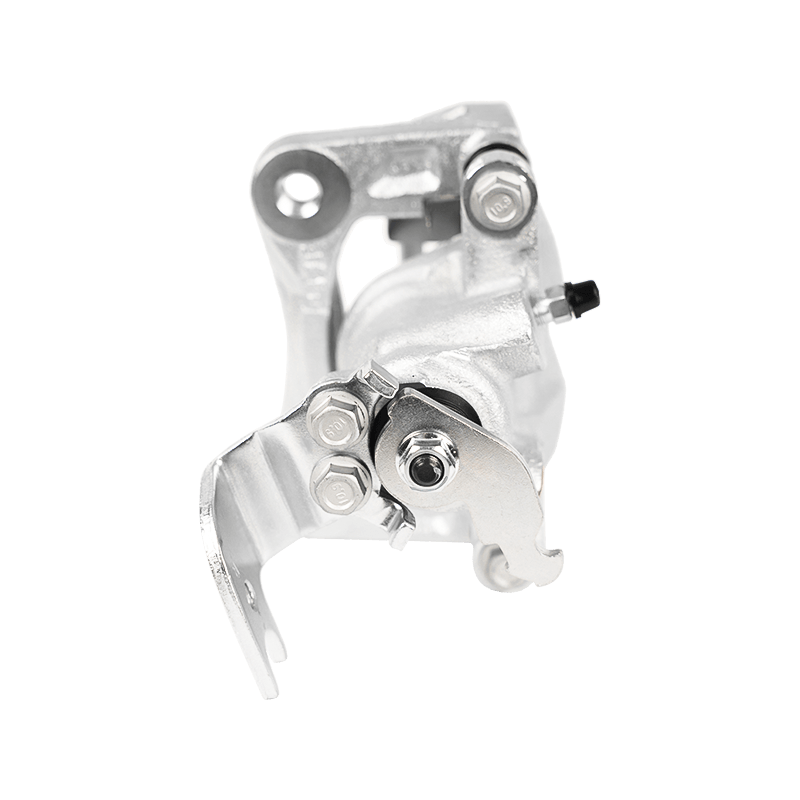

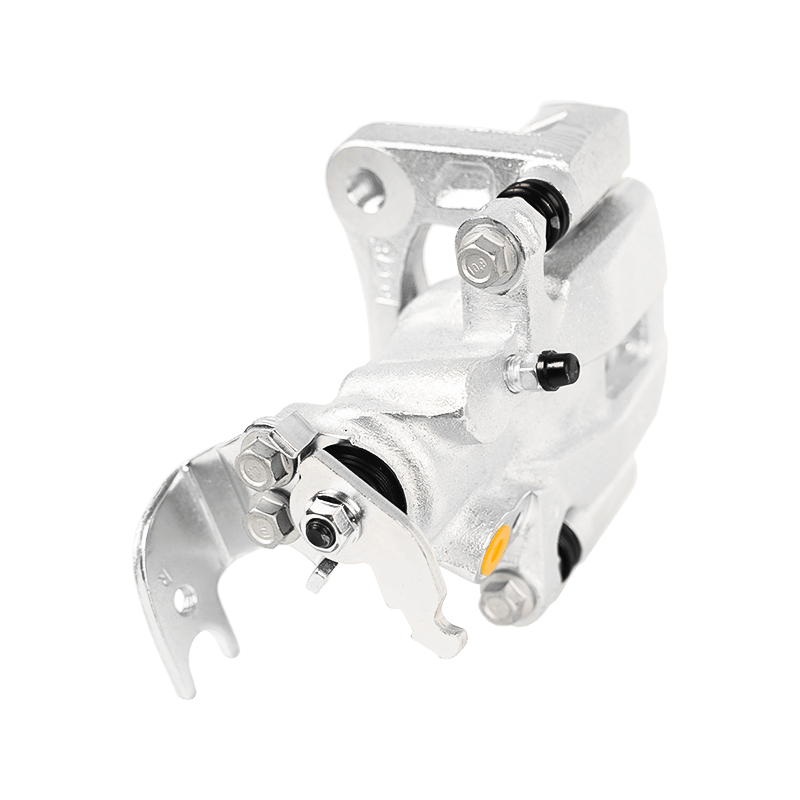

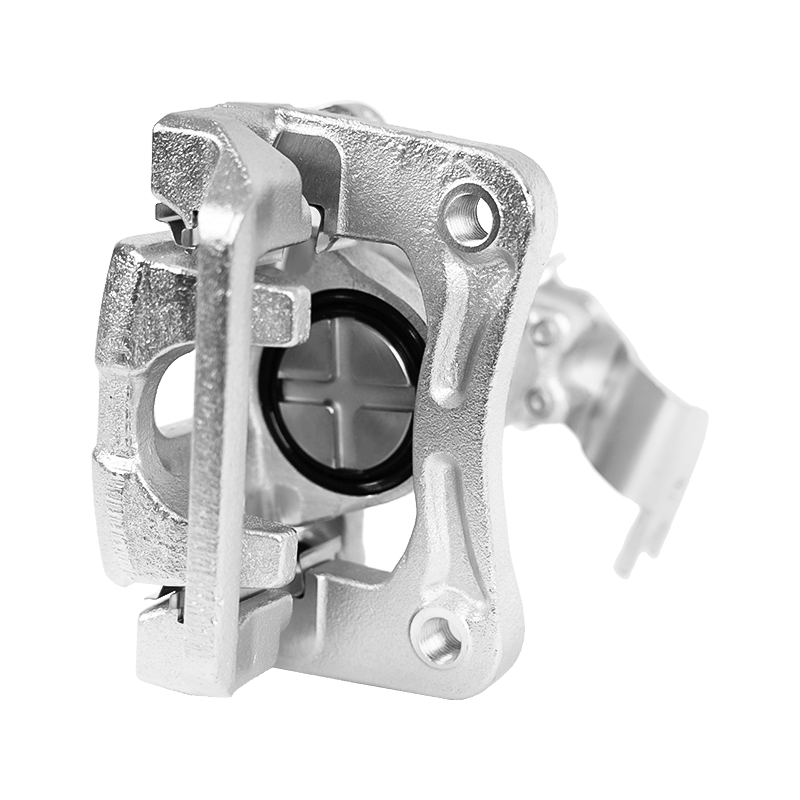

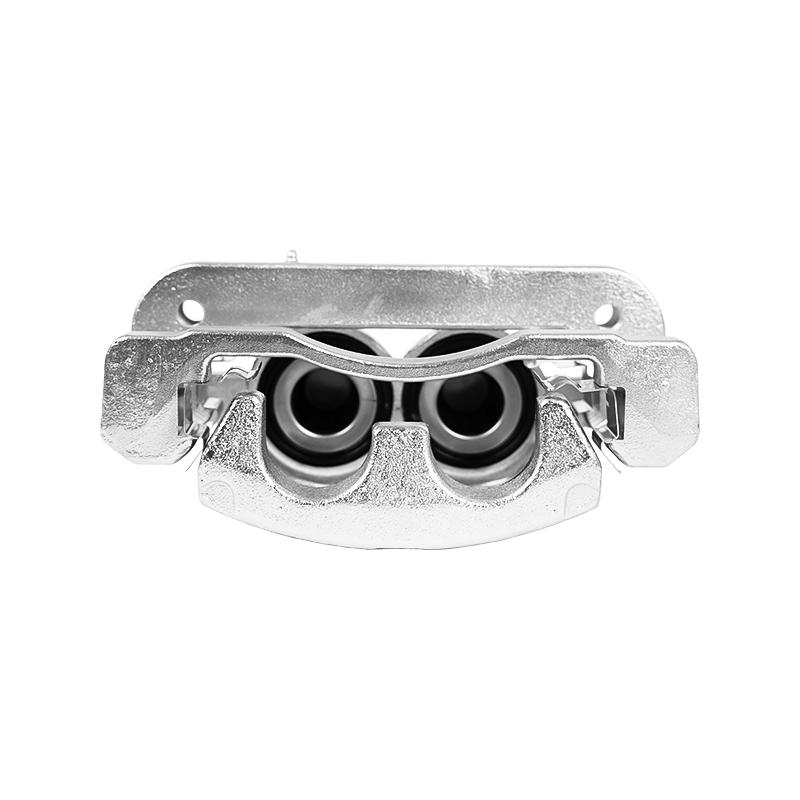

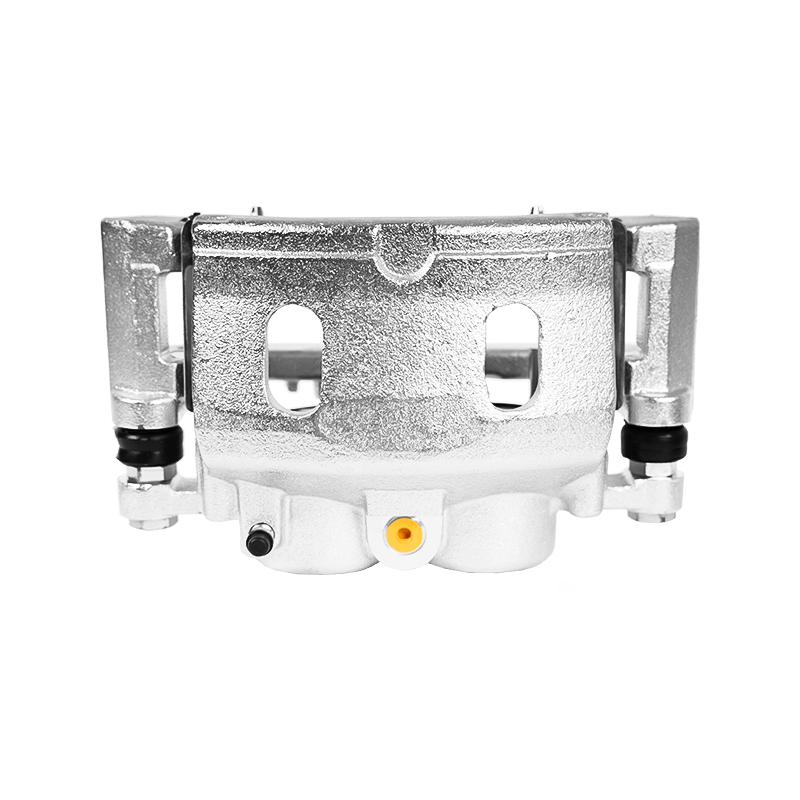

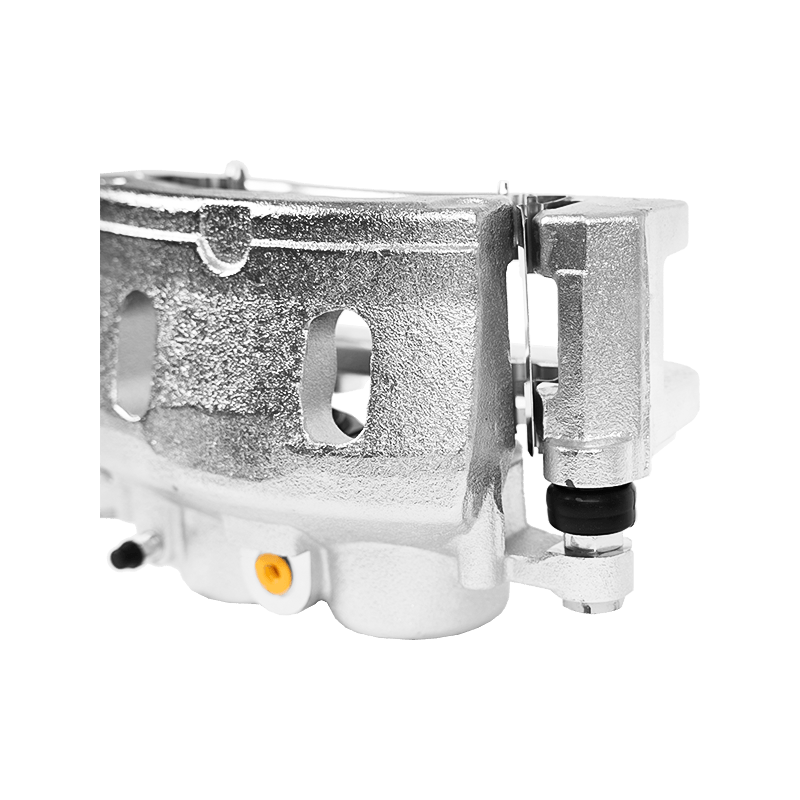

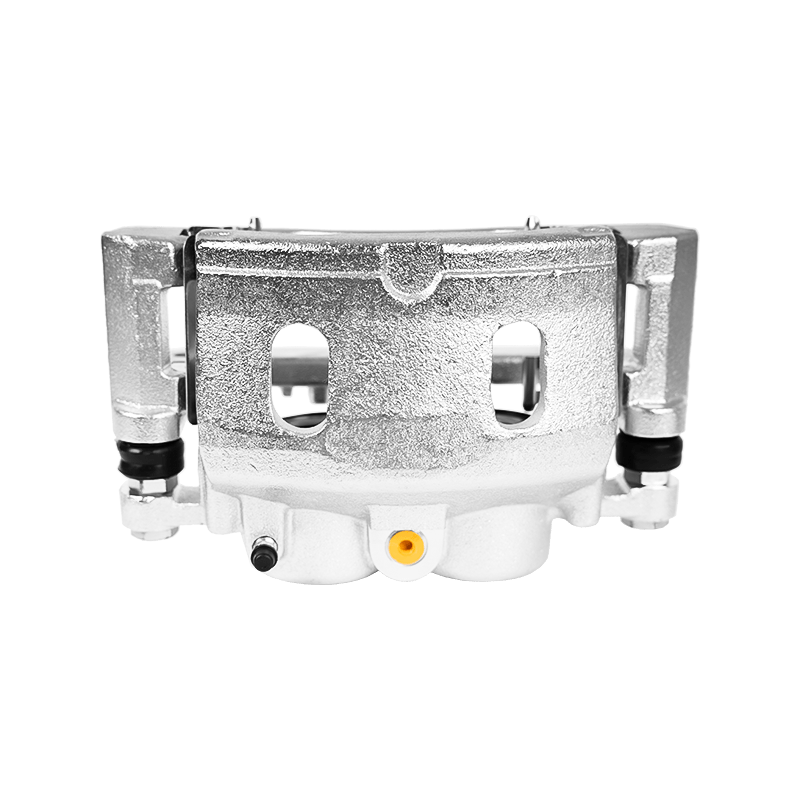

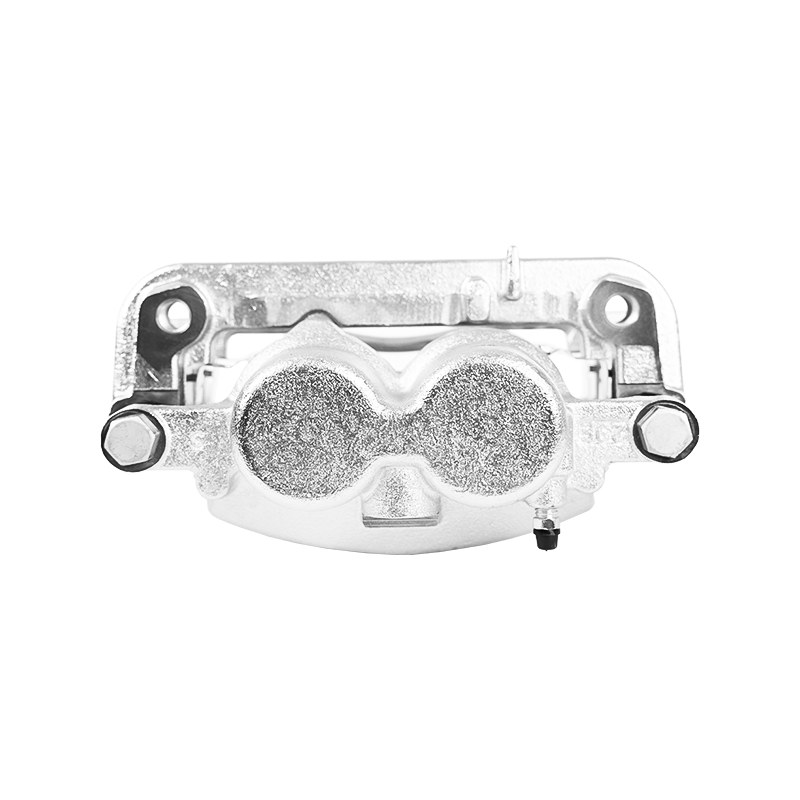

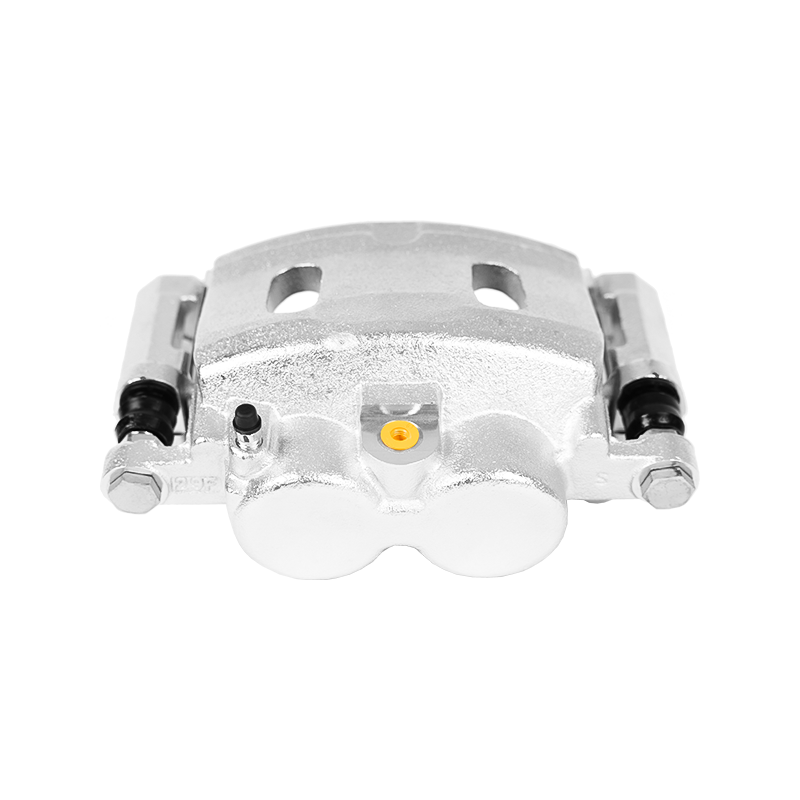

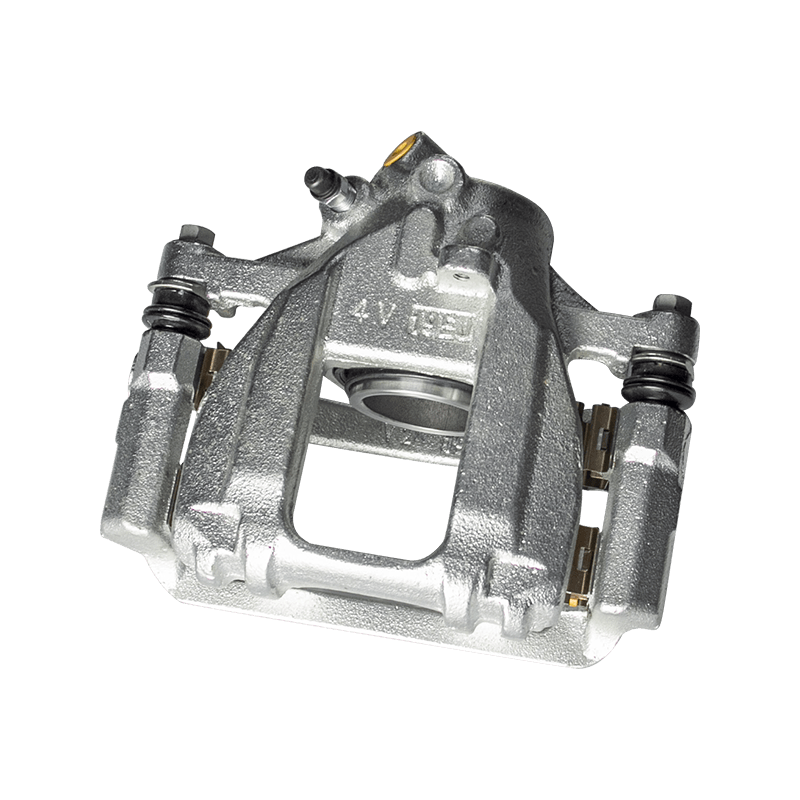

Among the key components of the automobile braking system, the 43018-TA0-A01 brake caliper, as Honda's original certified right rear brake caliper, has become the core guarantee of braking safety for many models with its precise design and reliable performance. This caliper was developed for the 2008-2015 Honda Accord VIII and Acura TSX models. It is made of gray cast iron and is suitable for solid brake discs with a diameter of 282mm and a thickness of 9mm. It achieves stable braking force output through a single piston design. Its compact geometry and 6.8-pound lightweight design ensure seamless compatibility with the original wheel hub, and no additional wheel spacing adjustment or flange gasket is required during installation.

From the technical characteristics, the 43018-TA0-A01 brake caliper combines the advantages of Honda's Nissin braking system. The silicon nitride coating formed by the chemical vapor deposition process on the piston surface has a hardness of 1600HV and a high temperature resistance threshold of over 550℃. Even under continuous emergency braking conditions, the thermal decay rate can still be controlled within 8%. Its internal seal is made of fluororubber, which has an anti-aging performance three times higher than that of traditional nitrile rubber. Combined with the multi-layer pleated design of the dust cover, it effectively isolates mud and water erosion, extending the maintenance cycle to more than 100,000 kilometers. Honda's original test data shows that the distance of vehicles equipped with this caliper is stable within 39.5 meters in the 100-0km/h braking test, and the braking noise is less than 45 decibels, perfectly balancing the performance and comfort requirements.

In terms of manufacturing process, 43018-TA0-A01 strictly follows Honda's global unified standards. During the production process, a CNC five-axis machining center is used to perform micron-level finishing on the piston hole, and the inner wall roughness Ra value is ≤0.8μm to ensure the maximum transmission efficiency of the hydraulic oil. The back plate is connected to the high-strength alloy bracket through a laser welding process, with a shear strength of 380MPa, and can withstand a longitudinal impact force of 1.5 tons under full load.

Search

Search

Eng

Eng

English

English Español

Español Português

Português