Brake master cylinder: How to ensure driving safety?

2025.06.23

2025.06.23

Industry News

Industry News

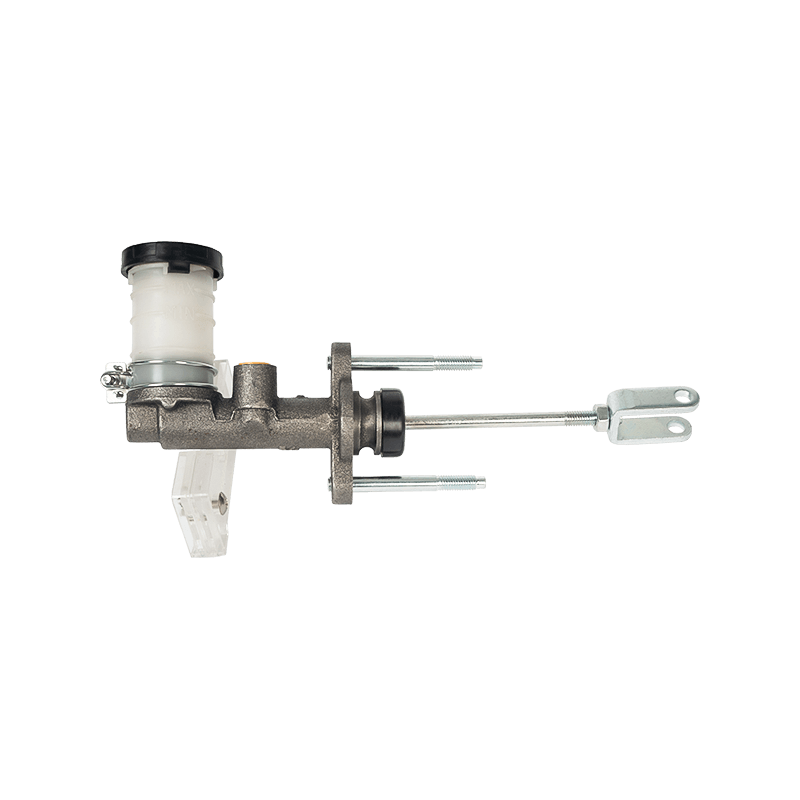

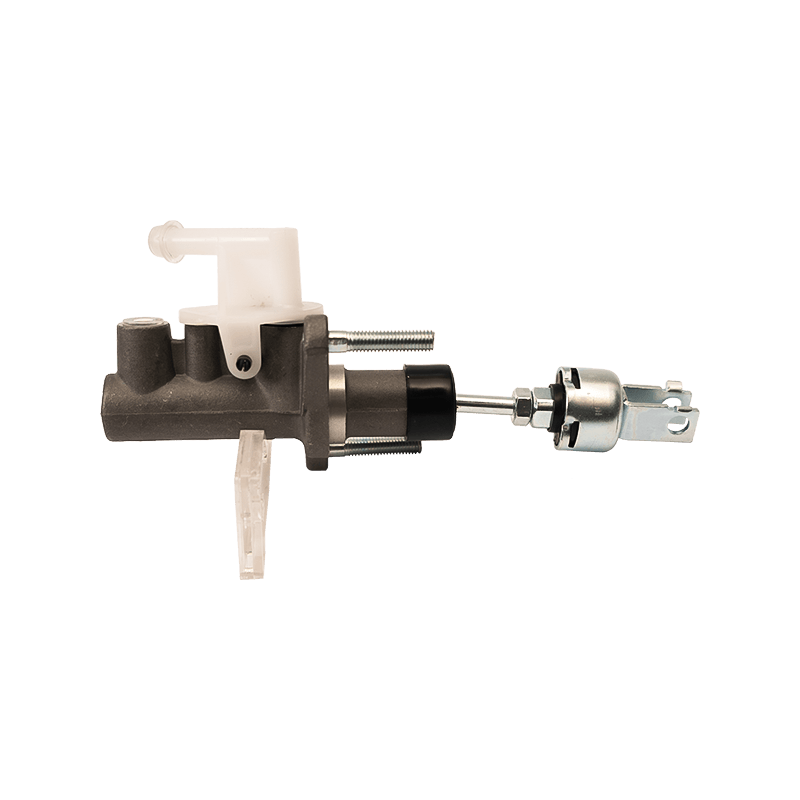

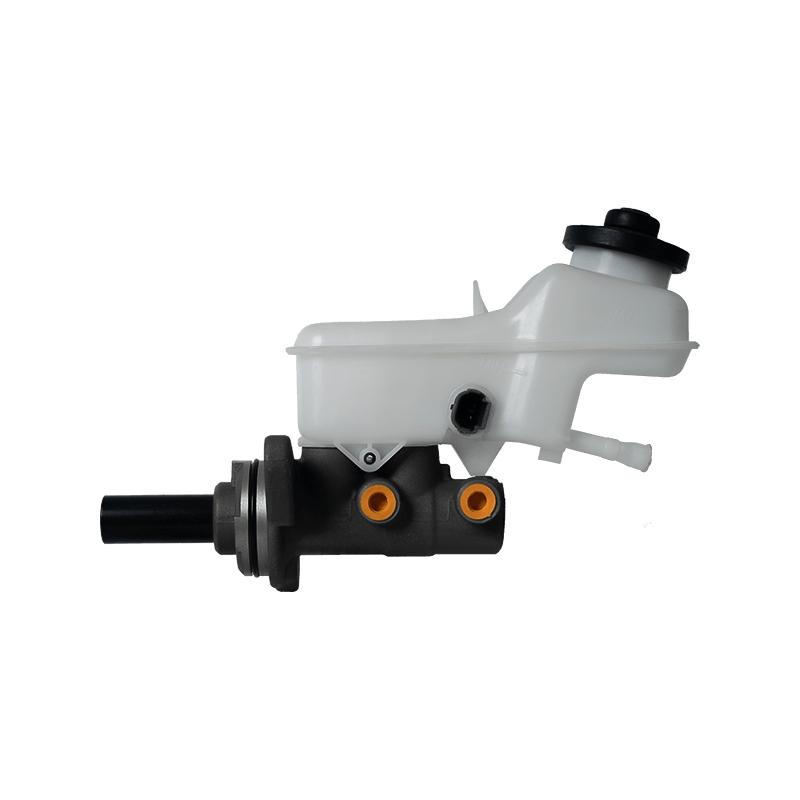

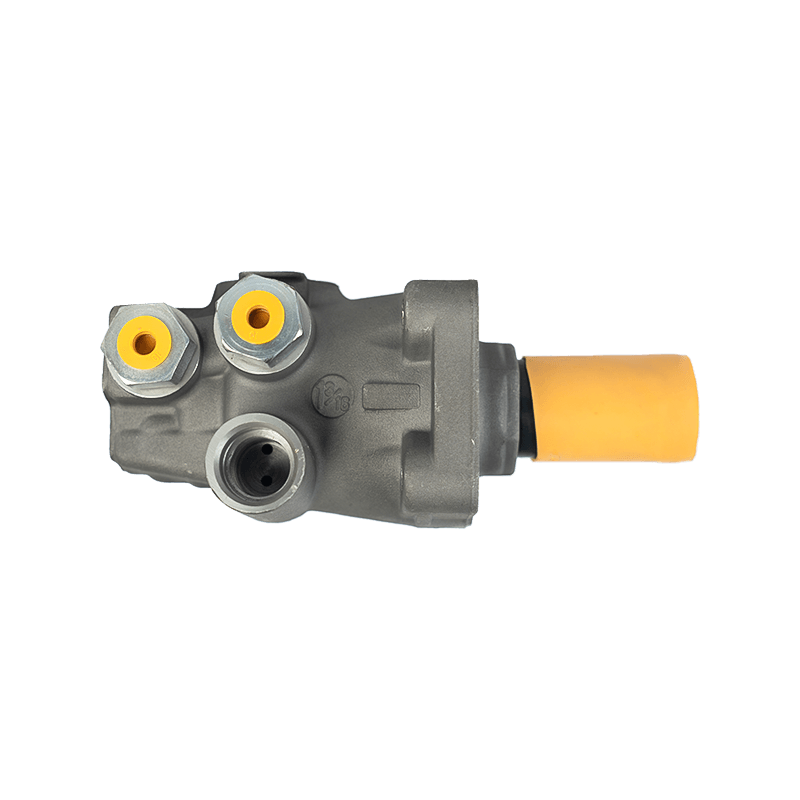

1. Working principle and core function of brake master cylinder

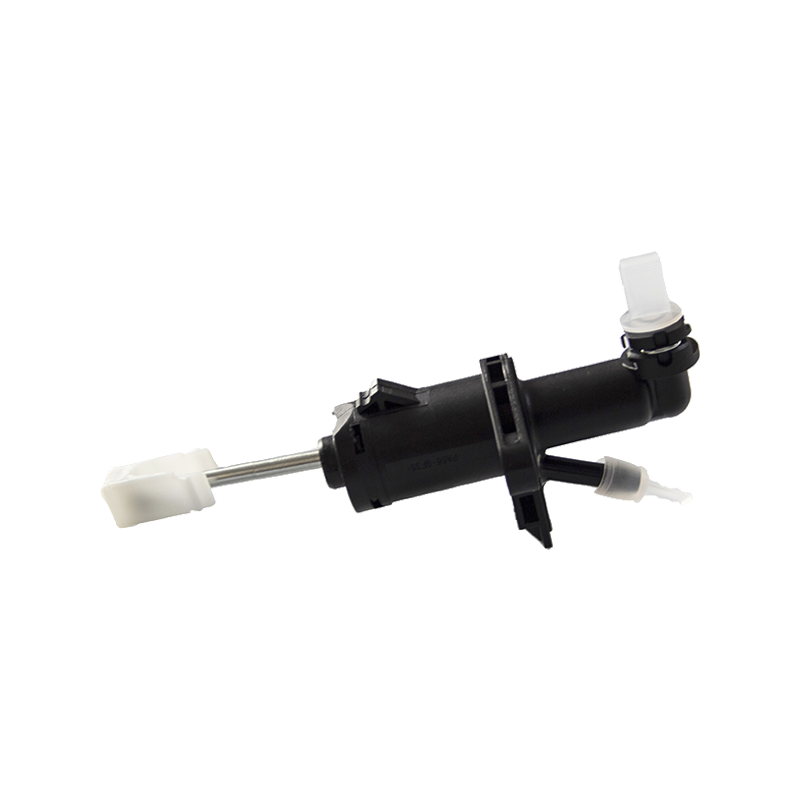

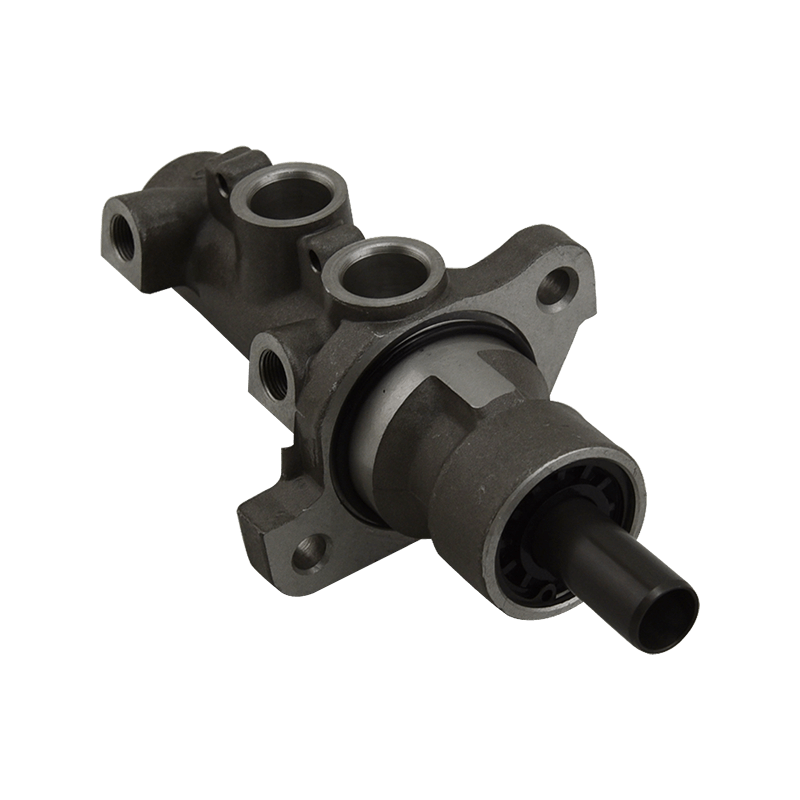

The brake master cylinder is the power source of the hydraulic brake system. Its core function is to convert the mechanical pedal force into hydraulic pressure and transmit it to each wheel brake through the brake pipe. According to Pascal's principle, the hydraulic pressure generated in the master cylinder can be evenly transmitted in a closed system, so that the brake cylinders of the four wheels can obtain the same pressure of brake fluid.

Basic working process:

Pedal force transmission: The driver presses the brake pedal, and the push rod pushes the master cylinder piston

Pressure establishment: The piston movement compresses the brake fluid in the master cylinder to establish hydraulic pressure

Pressure distribution: The hydraulic pressure is transmitted to the brake cylinders of the four wheels through the pipeline at the same time

Braking force generation: The piston of the cylinder is pressed outward, pushing the brake pad to contact the brake disc/drum

Pressure release: When the pedal is released, the return spring resets the piston and the hydraulic pressure is released

Key performance parameters:

Working pressure range: 0-100bar (ordinary passenger car)

Piston diameter: usually 19-25.4mm (3/4"-1")

Reservoir capacity: 150-300ml

Response time: <100ms (from pedal action to pressure establishment)

2. Common faults and maintenance points

The reliability of the brake master cylinder directly affects driving safety. Understanding common fault phenomena helps to maintain in time.

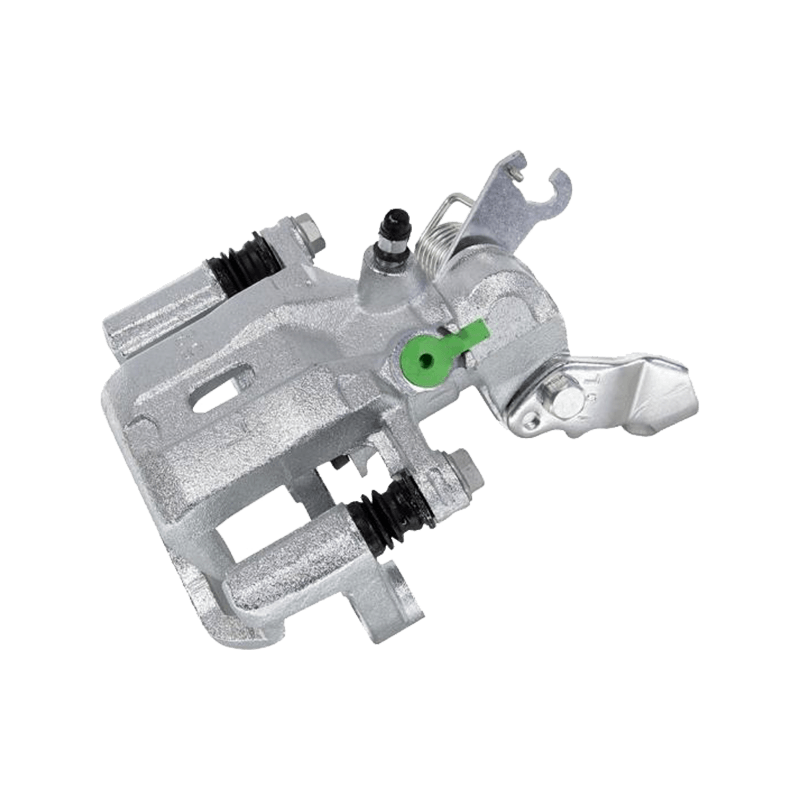

- Typical failure modes:

Internal leakage: insufficient pressure maintenance due to aging of the sealing ring (pedal sinks slowly)

External leakage: cracks in the shell or oil seepage at the seal (the liquid level in the reservoir continues to drop)

Piston sticking: impurity contamination causes poor pedal return (brake drag)

Air blockage: brake fluid vaporizes at high temperatures (pedal is soft)

- Maintenance recommendations:

Brake fluid replacement: every 2 years or 40,000 kilometers (drain the old fluid first and then refill)

Seal inspection: replace all rubber seals during each disassembly

Cleaning requirements: use isopropyl alcohol to clean the piston surface, grease is prohibited

Exhaust operation: follow the manual order (usually right rear-left rear-right front-left front)

- Diagnostic method:

Pressure test: special tools detect pressure build-up speed and holding capacity

Leak test: keep the pedal force for 1 minute, the pressure drop should be <10bar

Stroke measurement: free stroke is usually 1-3mm, working stroke ≤60mm

Search

Search

Eng

Eng

English

English Español

Español Português

Português