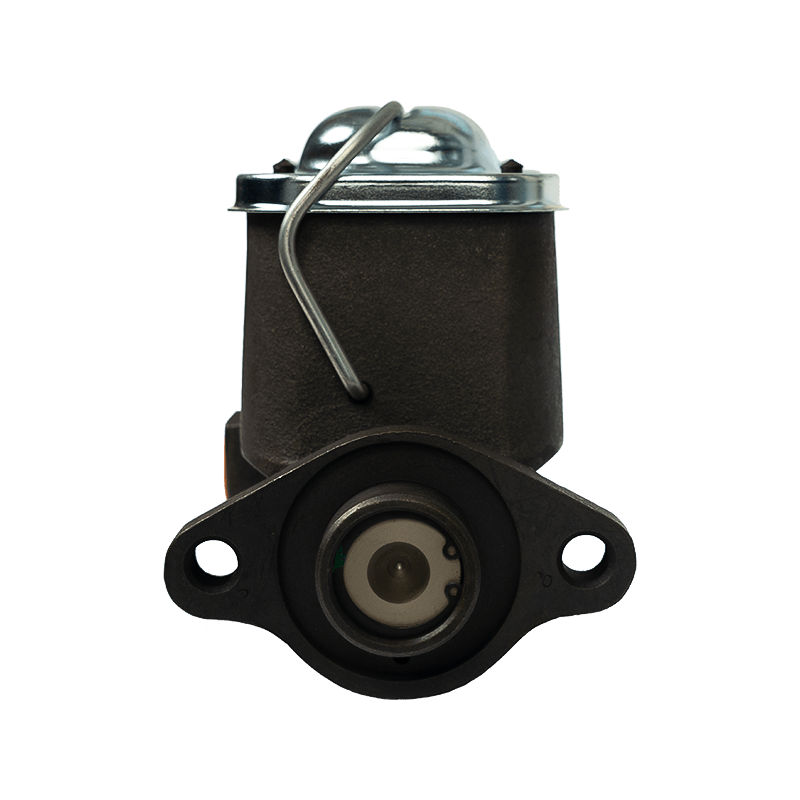

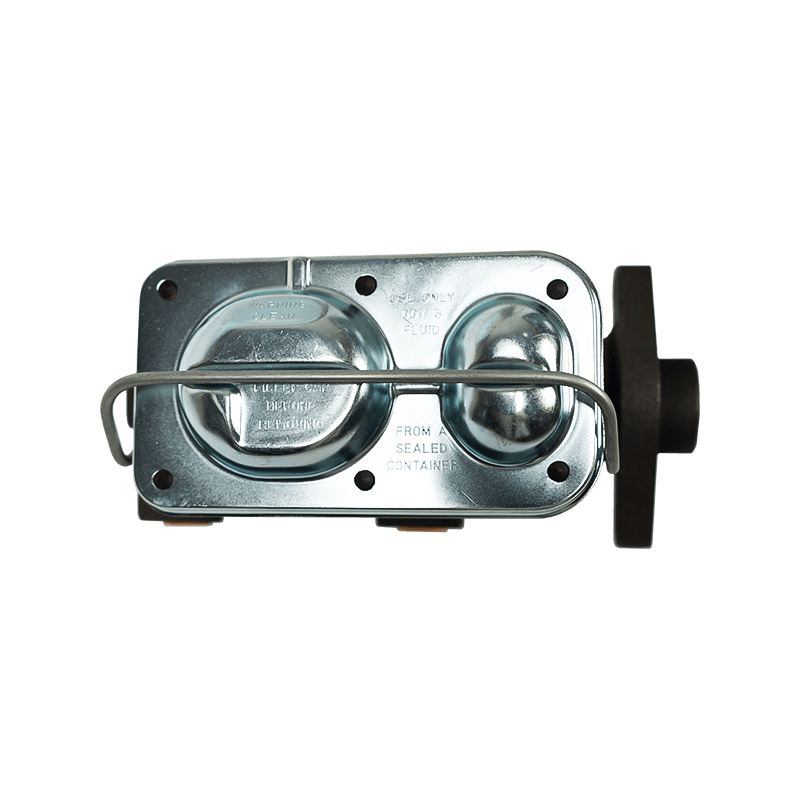

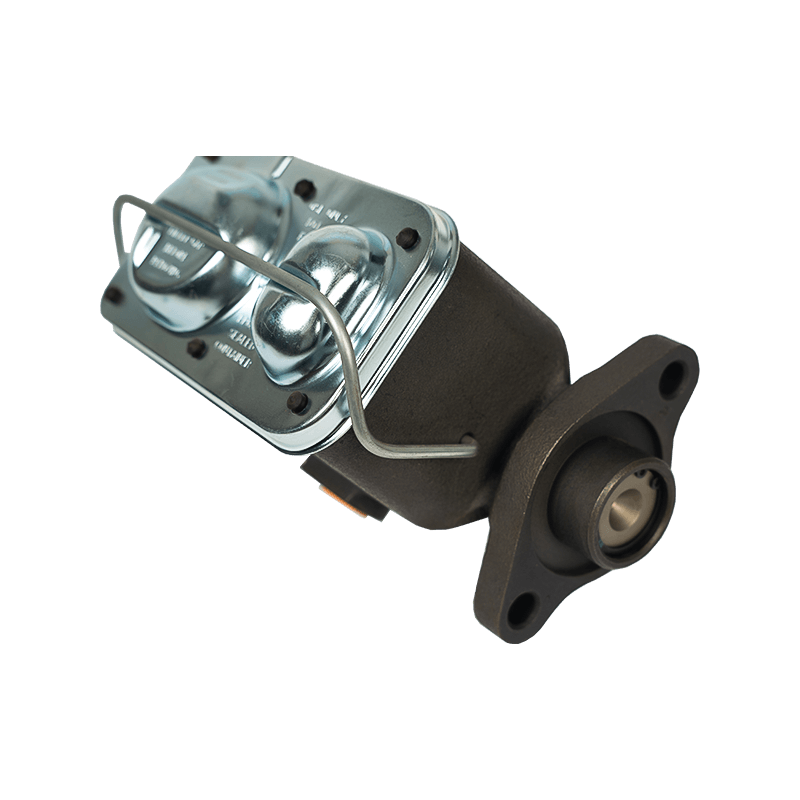

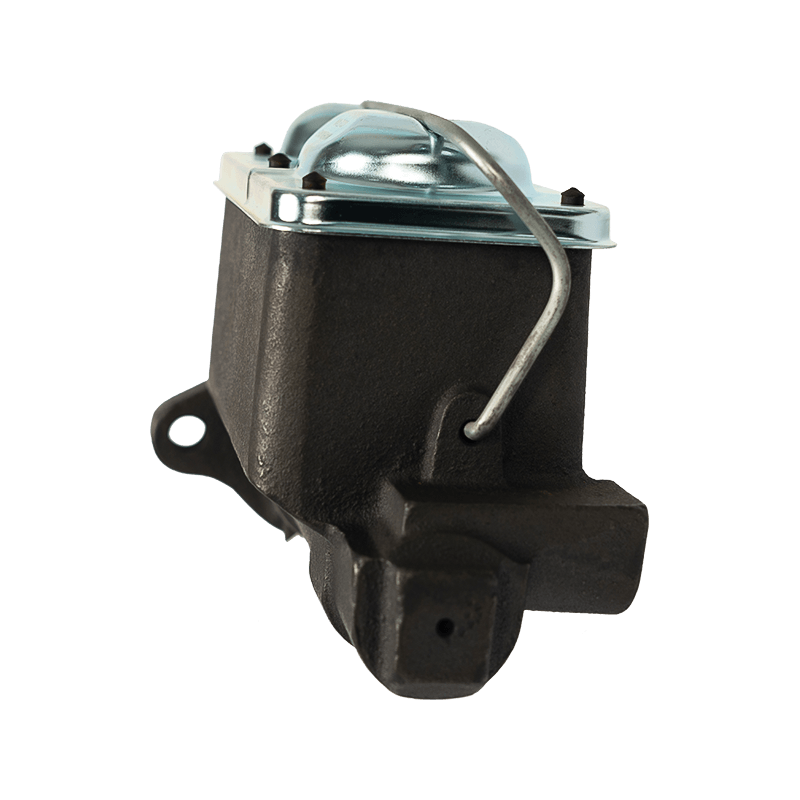

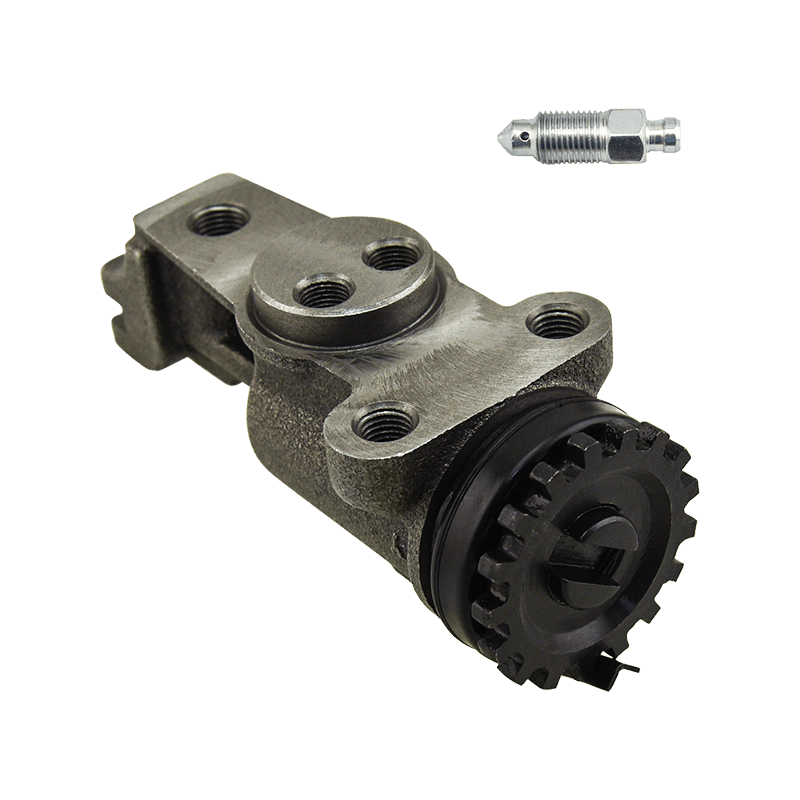

130.62023 Brake Master Cylinder for Chevrolet

|

OE NO |

130.62023 |

|

DESCRIP |

BMC |

|

MODEL |

Chevrolet |

Specifications

KEEP IN TOUCH

We have more than 1,000 brake shoes and brake pads for European, American, Russian, Japanese and Korean cars. The associated factories have created a highly experienced manufacturing team that exports thousands of auto part products worldwide. High quality and competitive prices are our targets. Our products have gained the certifications of ISO9001 and TS16949. We have built up a solid reputation with our customers in more than 30 countries.

We are looking forward to having a brighter and more successful business in the near future together with all of our clients all over the world.

-

Why Choose OE Quality Brake Pads? When selecting brake pads, OE QUALITY BRAKE PADS ensure precise fit, optimal braking performance, and long-term dur...

READ MORE -

What is a Hydraulic Brake Master Cylinder? The hydraulic brake master cylinder is a critical component in a vehicle's braking system. It converts the...

READ MORE -

Why OE Quality Brake Pads Are the Best Choice for Your Car OE (Original Equipment) quality brake pads are specifically designed to match the specific...

READ MORE -

The direct answer: Yes. High-quality brake pads can reduce braking distance by 15%–30%, improve heat resistance, and significantly enhance driving saf...

READ MORE

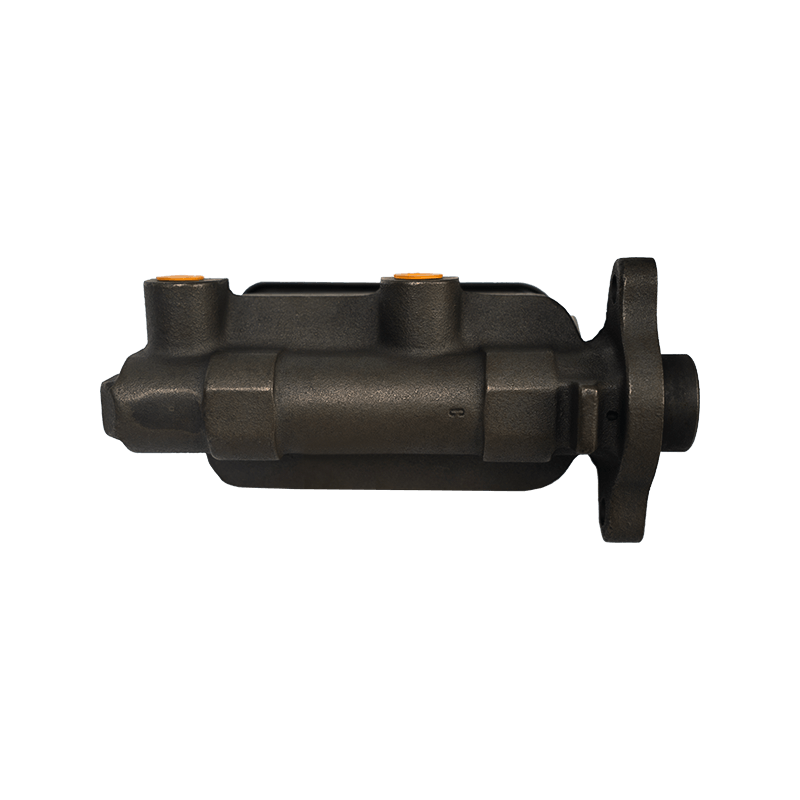

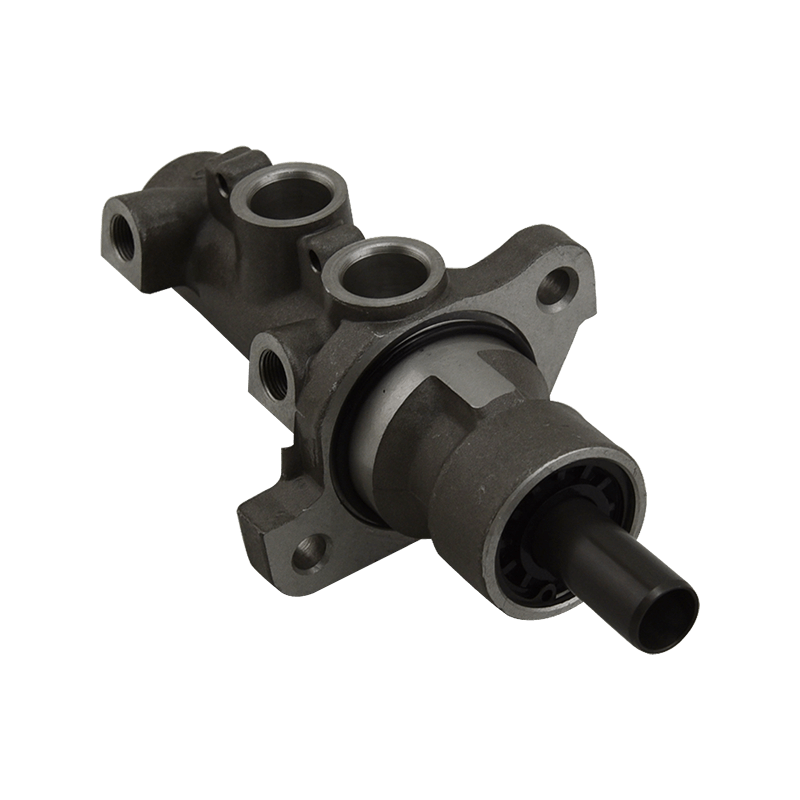

130.62023 Brake Master Cylinder For Chevrolet adopts cast iron casting process, the master cylinder diameter is 28.575mm (1.125 inches), and it can withstand 32MPa hydraulic pressure. The master cylinder adopts a dual-chamber series structure design, equipped with a compensation hole and a fast filling valve to ensure the stable flow of brake fluid under continuous braking conditions. Its friction coefficient is stable in the range of 0.38-0.42, which is especially optimized for the front wheel disc brake system.

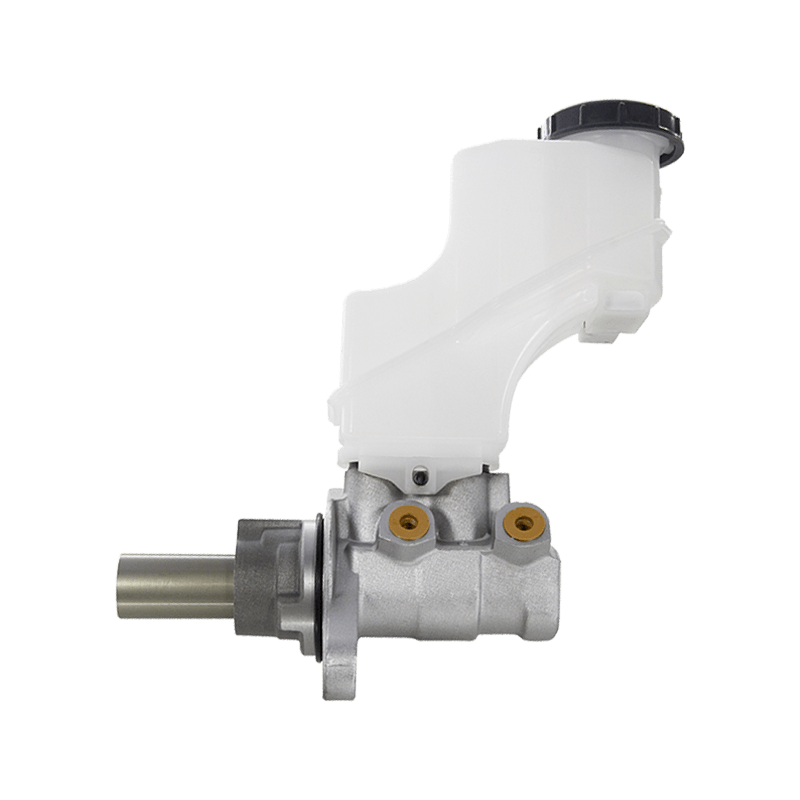

In terms of engineering design, the 130.62023 master cylinder adopts the original aluminum casting process, and the piston sealing system is equipped with high-temperature resistant fluororubber material, with an operating temperature range of -40℃ to 180℃. Its brake fluid storage tank capacity is 350ml, equipped with an integrated float switch, which can monitor the liquid level status in real time. In response to the maintenance needs of classic models, the threaded interface specifications adopt a 1/2"-20 inverted design for the front left port and a 9/16"-18 inverted structure for the rear port to ensure seamless connection with the original vehicle brake line.

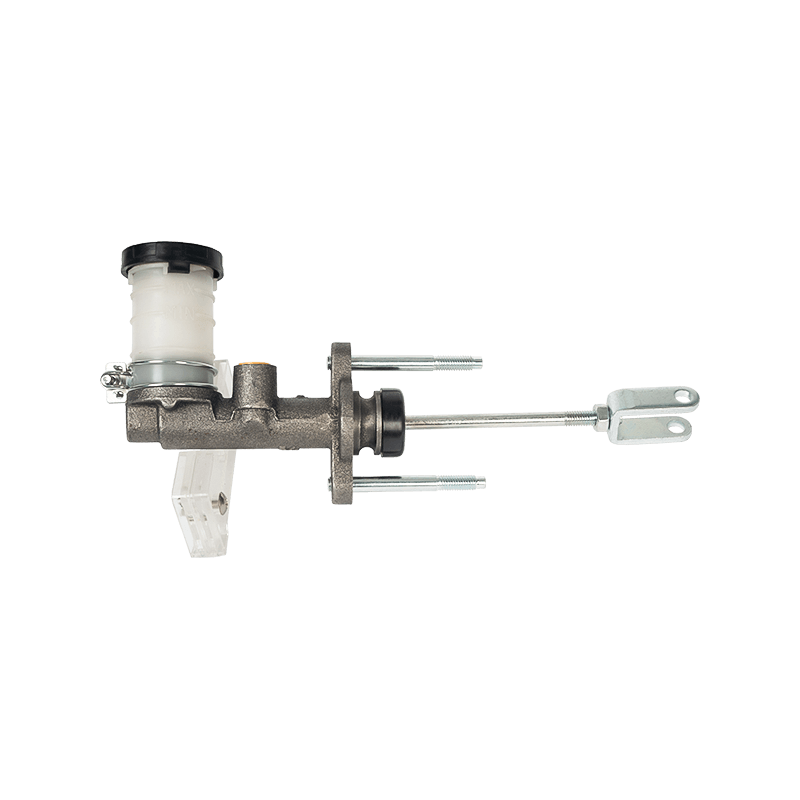

During maintenance practice, it is recommended to check the working condition of the master cylinder every 80,000 kilometers or after 5 years of use. If the scratch depth on the inner wall of the master cylinder exceeds 0.1mm or the elastic loss of the sealing ring exceeds 30%, the assembly needs to be replaced directly. During installation, pay attention to the torque value of the oil pipe interface (18-22N·m for the front port and 20-24N·m for the rear port), and use the two-stage pressure emptying method to completely remove system bubbles.

Search

Search

Eng

Eng

English

English Español

Español Português

Português