How to determine whether brake pads need to be replaced?

2025.10.11

2025.10.11

Industry News

Industry News

Content

1. Core Replacement Standard

New Thickness: The friction material portion of a new brake pad is typically approximately 1.5 cm (15 mm) thick.

Recommended Replacement Thickness: When the brake pad thickness (referring to the friction material portion only) is approximately 3-5 mm, as observed through the gap between the wheel hub or by removing the tire, it's time to prepare for replacement.

Required Replacement Thickness: When the thickness is 2-3 mm or less, it's considered wear limit and must be replaced immediately; failure to do so can be extremely dangerous.

How to Check: Many car models have openings in the wheel hub that allow for direct inspection. If this isn't visible, the most accurate method is to have a mechanic remove the wheel and inspect it during maintenance.

2. Important Reference Signs

Audible Warning: Sharp Metal Grinding Sound

If you hear a continuous, high-pitched "squeaking" sound when lightly applying the brakes, this is usually the sound of the brake pad's wear warning plate (a small metal plate) rubbing directly against the brake disc. This is a designed warning; upon hearing this sound, check the pad's thickness immediately.

Tactile Warning: Change in Brake Feel

Softer, Longer Brake Travel: You feel like you need to apply more force to achieve the same braking effect as before.

Loss of Braking Force: You feel a noticeable "failure to stop," requiring you to apply more force to the pedal.

Brake Pull: When you apply the brakes, the vehicle pulls left or right, indicating uneven brake pad wear on the left and right wheels.

Pedal or Steering Wheel Vibration: This vibration you feel when you apply the brakes may indicate damage to the brake discs due to pad wear.

Dashboard Warning Light

Many modern vehicles are equipped with brake pad wear sensors. When wear reaches its limit, a dedicated brake warning light (usually a circle with a dotted line in parentheses) will illuminate on the dashboard, or a text message will appear.

3. Commonly Overlooked "Invisible Killers"

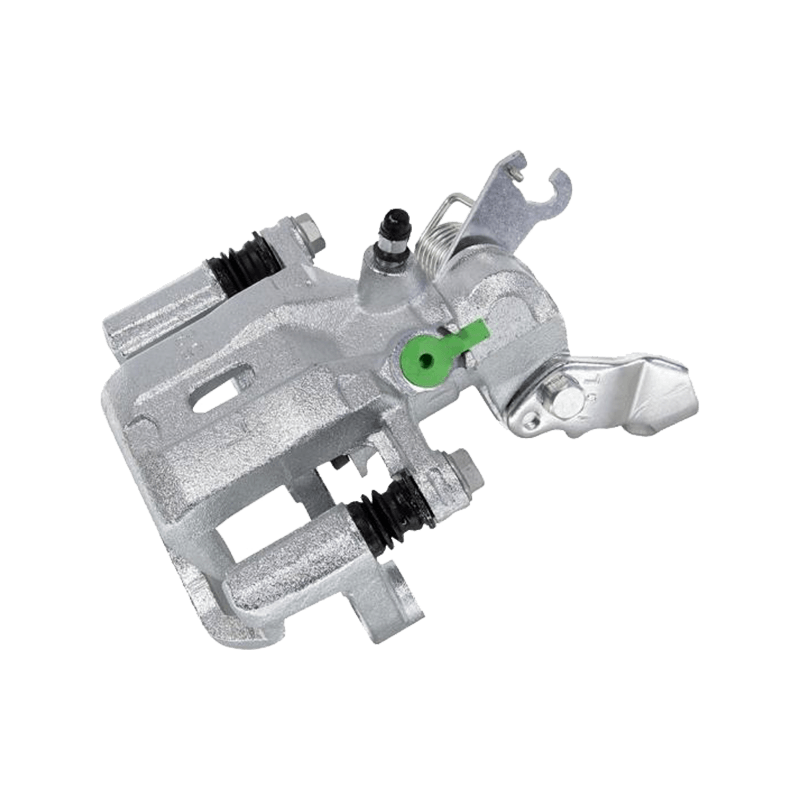

Uneven Wear on the Inside and Outside of the Brake Pads: This often occurs when the guide pin on one side of the floating caliper rusts, leaving 6 mm on the outside and 2 mm on the inside.

Rear Drum Brake Pads: Because they are hidden inside the brake drum, they are often forgotten. Once worn through, the rivets will scratch the drum wall, instantly doubling the repair cost.

Poor-quality brake pads: The friction material is adulterated, resulting in severe powder loss, and the pads can wear from 10 mm to 4 mm in just 5,000 kilometers.

Long-term parking: In humid areas, the brake pads and discs can rust, causing a "crackling" sound when starting the car. This can cause a piece of material to break off, causing the thickness to drop dramatically.

4. Brake Pad Precautions

Defensive Driving:

Core Principle: Always observe the road ahead and make informed decisions. Maintain a safe distance as much as possible and slow down by releasing the accelerator and leveraging engine power, rather than slamming on the brakes at the last minute.

Effect: Reducing unnecessary braking directly reduces brake pad wear and operating temperatures. This is the most effective way to extend brake pad life.

Avoid sudden and heavy braking:

During sudden braking, the brake pads rub against the brake disc at maximum force, generating extremely high temperatures, accelerating wear and even causing "thermal decay" (a decrease in friction coefficient at high temperatures) or hard spots on the pad surface.

Use a low gear on long downhill sections:

On winding mountain roads or long downhill sections, never hold the brakes down for extended periods. This can cause the brake system to overheat, accelerate wear, and, in severe cases, lead to brake failure.

The correct approach: Switch to manual mode or S/L gear, using the engine's braking force to control speed, and apply the brakes intermittently as a secondary measure.

Search

Search

Eng

Eng

English

English Español

Español Português

Português