Specifications

KEEP IN TOUCH

We have more than 1,000 brake shoes and brake pads for European, American, Russian, Japanese and Korean cars. The associated factories have created a highly experienced manufacturing team that exports thousands of auto part products worldwide. High quality and competitive prices are our targets. Our products have gained the certifications of ISO9001 and TS16949. We have built up a solid reputation with our customers in more than 30 countries.

We are looking forward to having a brighter and more successful business in the near future together with all of our clients all over the world.

-

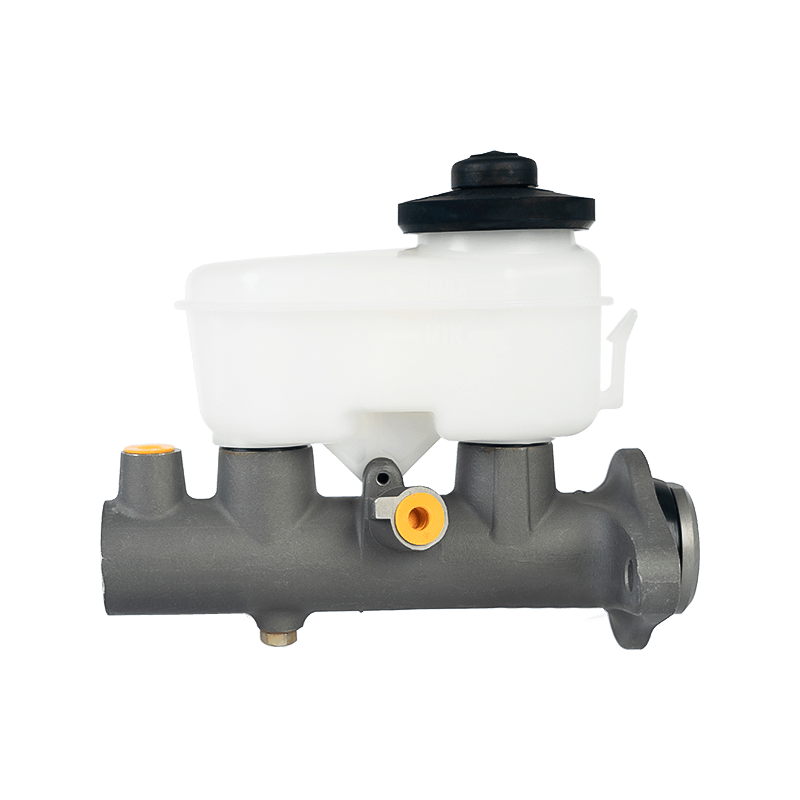

What is a Hydraulic Brake Master Cylinder? The hydraulic brake master cylinder is a critical component in a vehicle's braking system. It converts the...

READ MORE -

Why OE Quality Brake Pads Are the Best Choice for Your Car OE (Original Equipment) quality brake pads are specifically designed to match the specific...

READ MORE -

The direct answer: Yes. High-quality brake pads can reduce braking distance by 15%–30%, improve heat resistance, and significantly enhance driving saf...

READ MORE -

The automobile brake system is one of the most critical safety components in any vehicle. It controls speed, enables smooth stopping, and prevents acc...

READ MORE

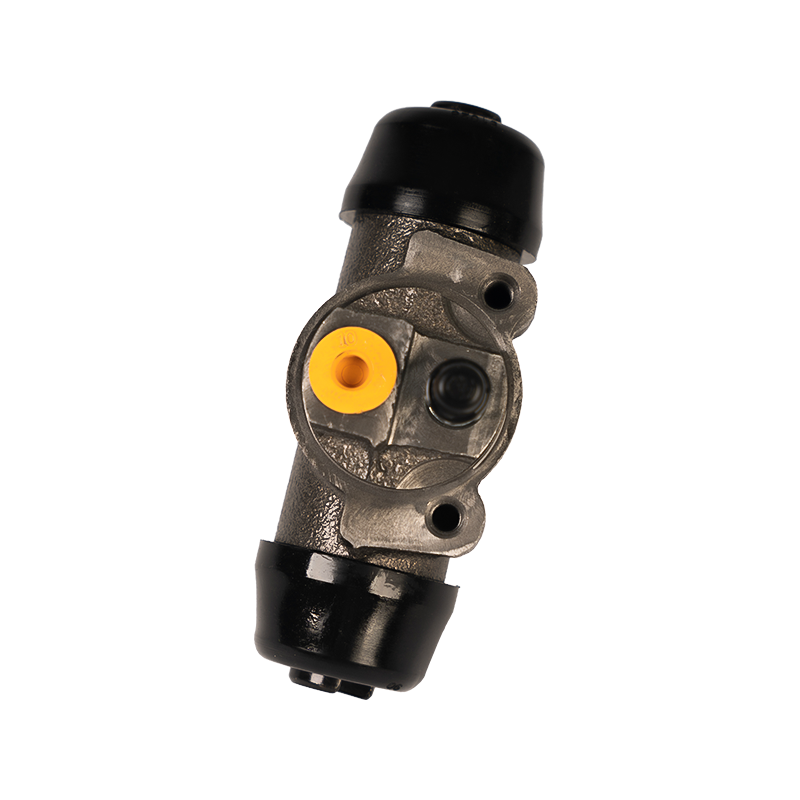

The Toyota 47550-26110 brake wheel cylinder has become the preferred accessory for many generations of Toyota classic models due to its wide adaptability and reliability. The cylinder is made of metal and strictly follows Toyota's original technical standards. The piston movement accuracy and hydraulic transmission efficiency are ensured through precision machining. Its core function is to convert the hydraulic pressure generated by the master brake cylinder into mechanical thrust, drive the brake pads to contact the brake drum or disc, and achieve vehicle deceleration and parking.

As an original equipment component for Toyota and other models, the 47550-26110 wheel cylinder demonstrates excellent compatibility. Its structural design takes into account durability and convenience. The piston sealing system is made of high-temperature resistant rubber material, which effectively resists the high temperature and oil erosion caused by frequent braking, and extends the replacement cycle of seals.

In actual applications, the cylinder is optimized for rear wheel brake systems, especially for pickup trucks and commercial vehicles carrying heavy objects. Its internal guide pin is hardened and combined with the dust cover design, it can reduce the increase in sliding resistance caused by the intrusion of mud and sand, and reduce the risk of brake drag.

Search

Search

Eng

Eng

English

English Español

Español Português

Português