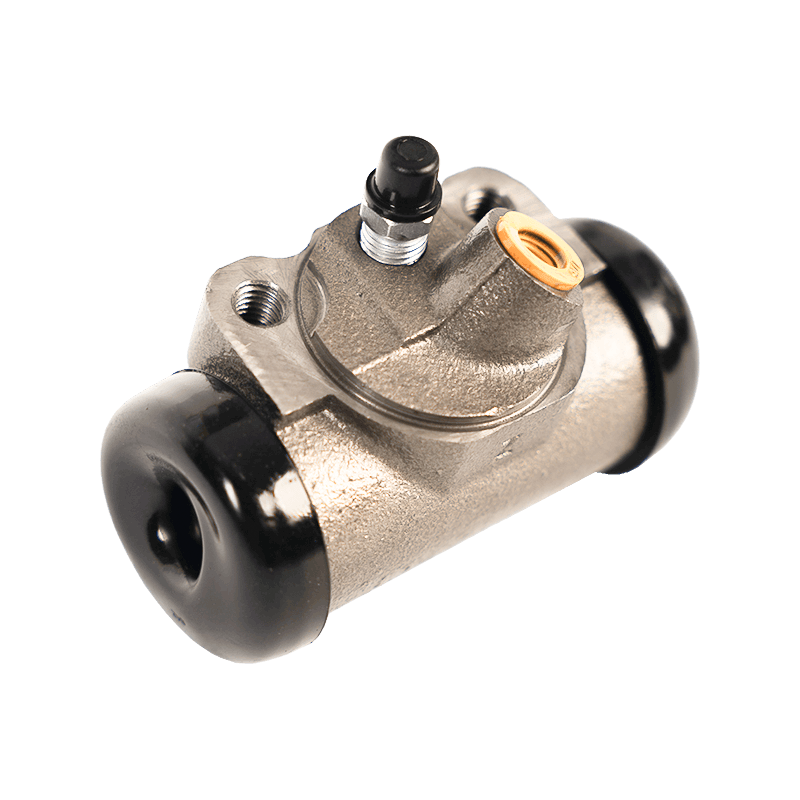

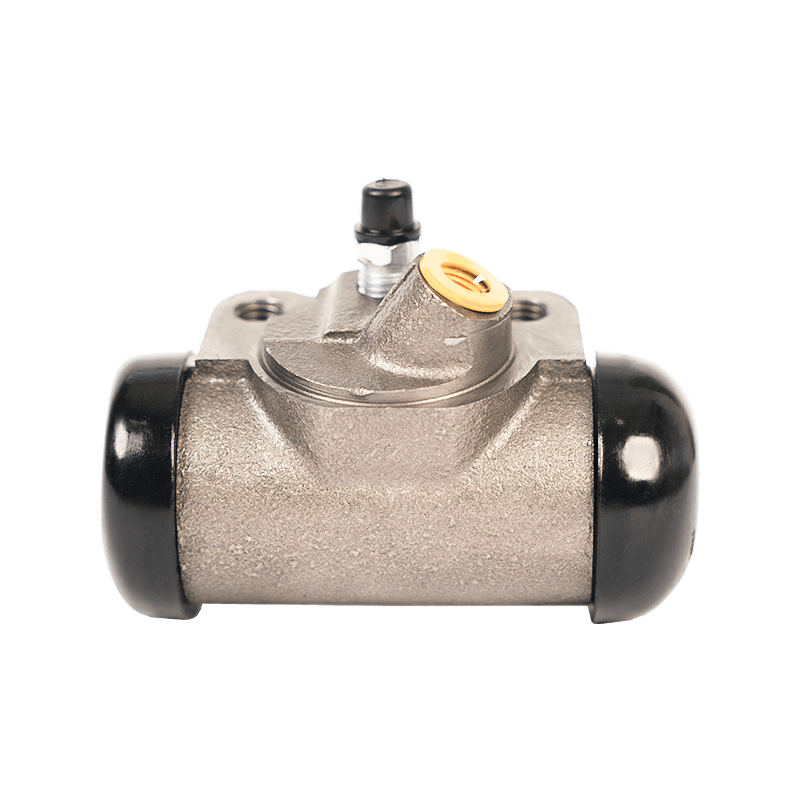

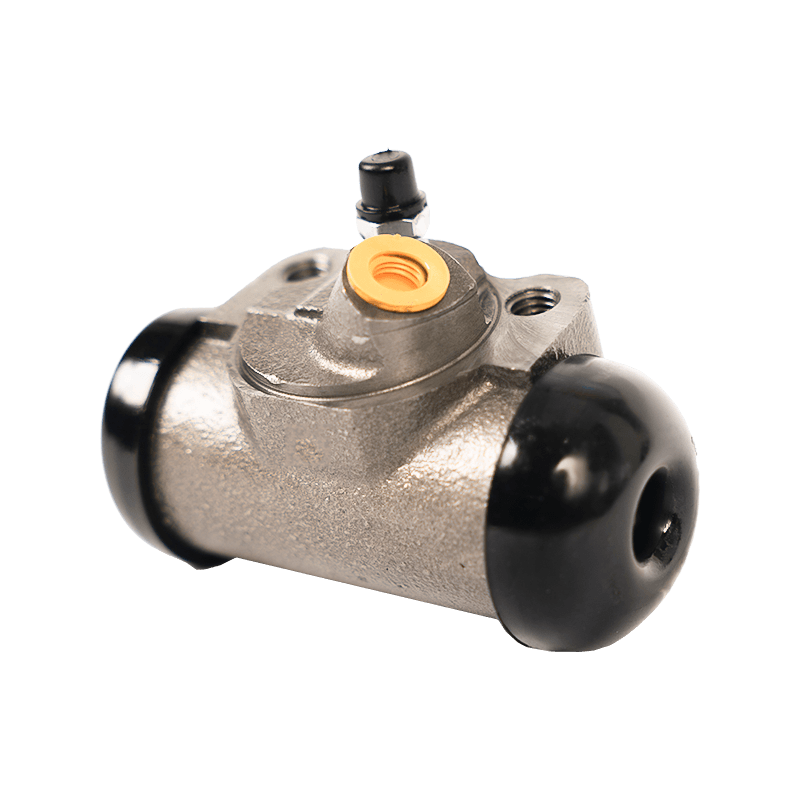

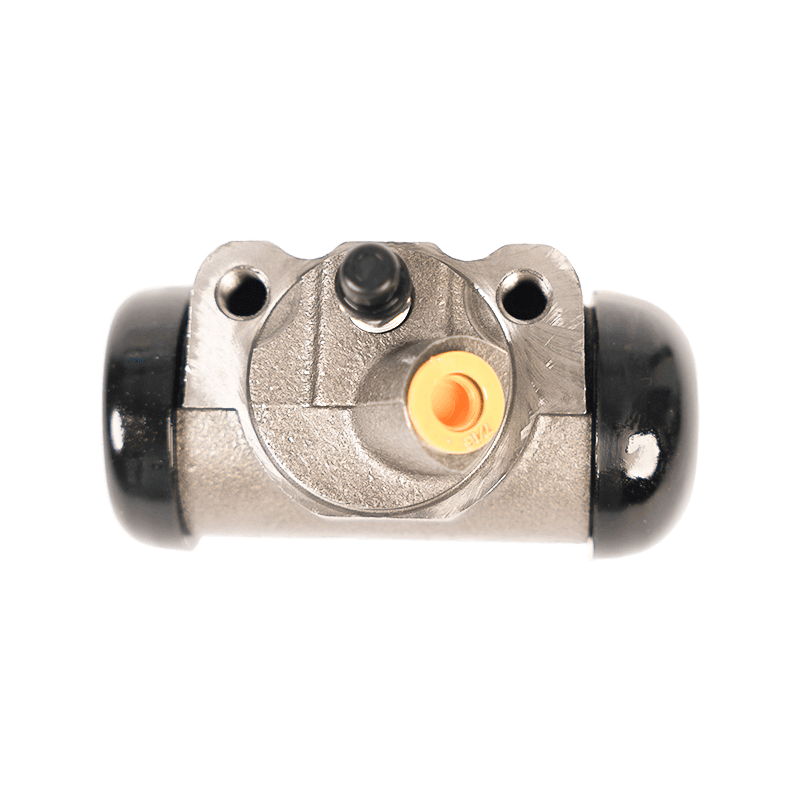

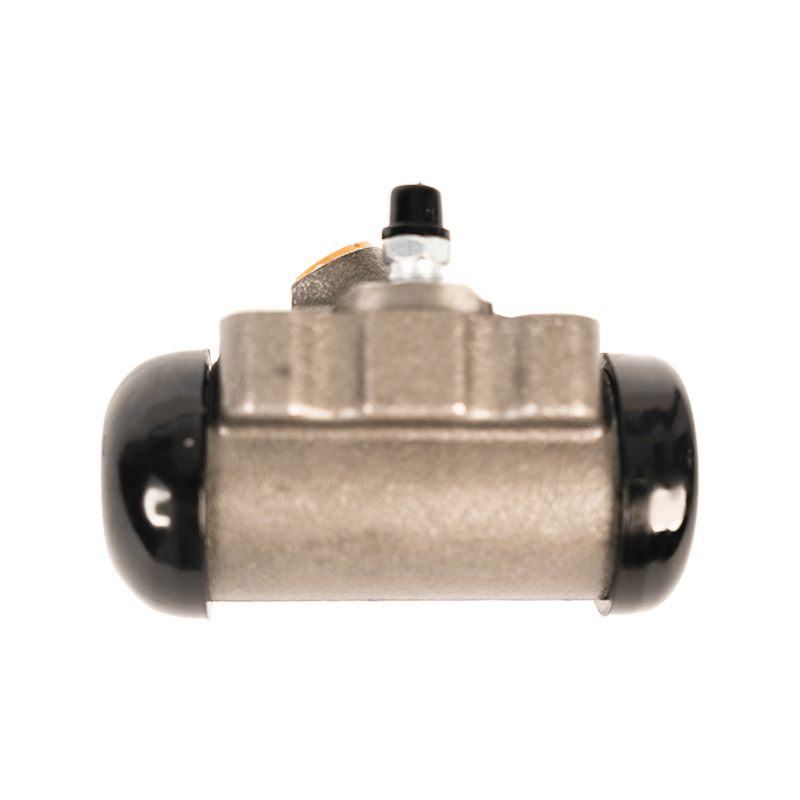

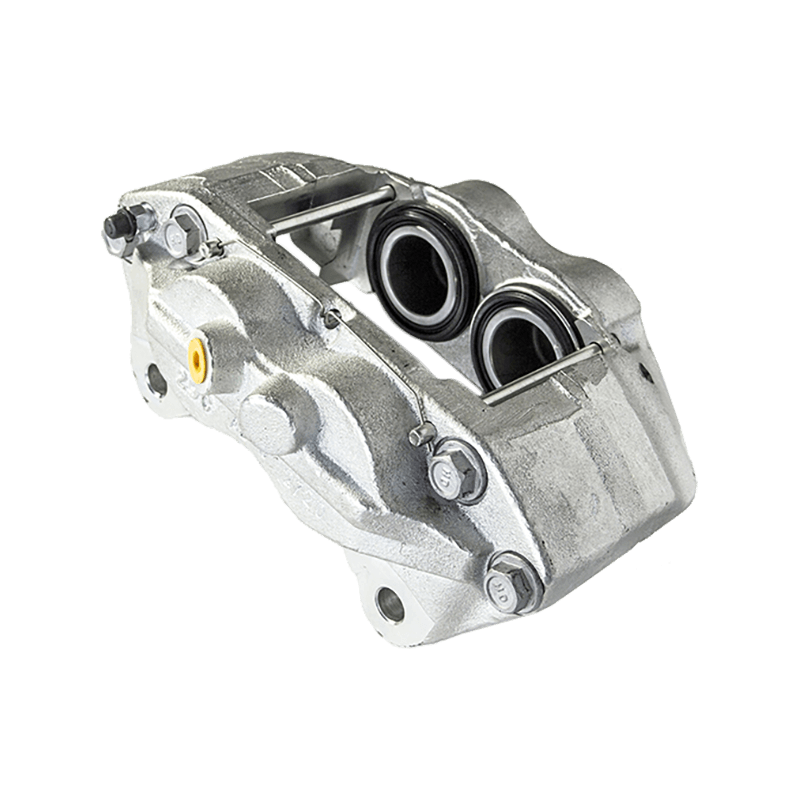

F5UZ2261A Brake Wheel Cylinder for Ford

It is usually mounted on the axle, near the wheel that is to be equipped for braking. Air pressure is fed through an inlet port. The air pushes against the diaphragm and the push rod. The push rod is connected by a clevis and pin to a crank arm-type lever called a 'slack adjuster.

|

OE NO |

F5UZ2261A |

|

MODEL |

Ford |

Specifications

KEEP IN TOUCH

We have more than 1,000 brake shoes and brake pads for European, American, Russian, Japanese and Korean cars. The associated factories have created a highly experienced manufacturing team that exports thousands of auto part products worldwide. High quality and competitive prices are our targets. Our products have gained the certifications of ISO9001 and TS16949. We have built up a solid reputation with our customers in more than 30 countries.

We are looking forward to having a brighter and more successful business in the near future together with all of our clients all over the world.

-

Why Choose OE Quality Brake Pads? When selecting brake pads, OE QUALITY BRAKE PADS ensure precise fit, optimal braking performance, and long-term dur...

READ MORE -

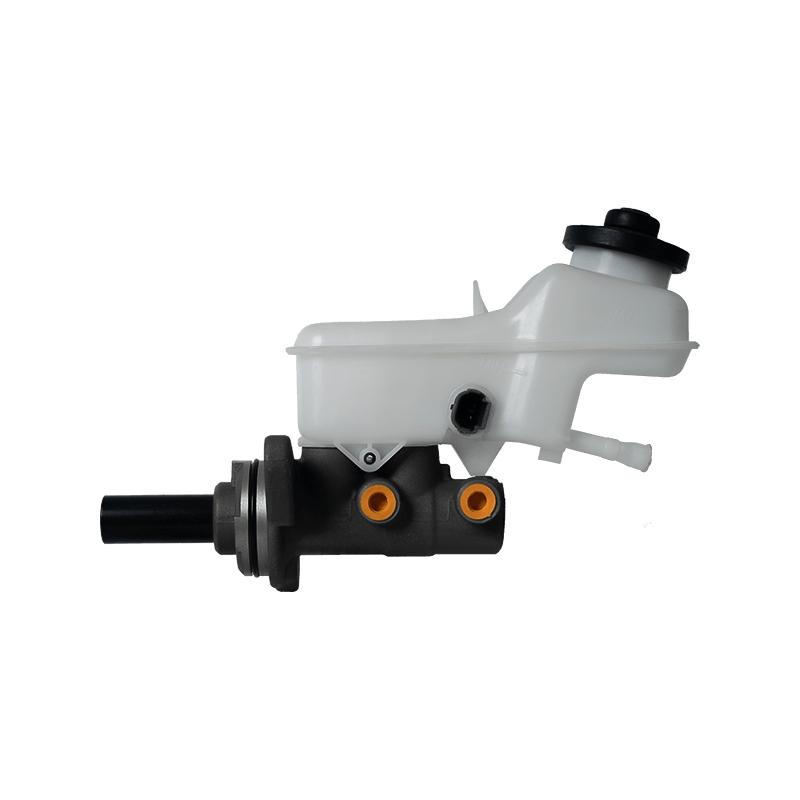

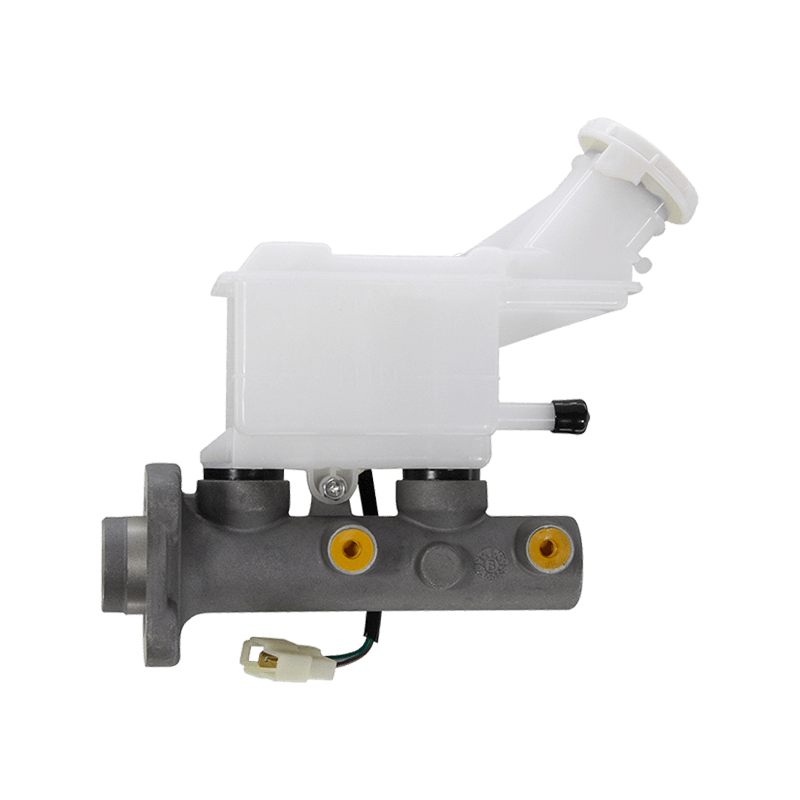

What is a Hydraulic Brake Master Cylinder? The hydraulic brake master cylinder is a critical component in a vehicle's braking system. It converts the...

READ MORE -

Why OE Quality Brake Pads Are the Best Choice for Your Car OE (Original Equipment) quality brake pads are specifically designed to match the specific...

READ MORE -

The direct answer: Yes. High-quality brake pads can reduce braking distance by 15%–30%, improve heat resistance, and significantly enhance driving saf...

READ MORE

Ford's special F5UZ2261A brake cylinder is a hydraulic brake core component designed for Ford's various SUVs and high-performance models. The cylinder adopts an integrated casting process, and the cylinder body is made of high-strength aluminum alloy, which not only reduces the unsprung mass but also improves the heat dissipation efficiency. As the core execution unit of the disc brake system, its working principle is similar to that of the Ford electric rear brake cylinder. It drives the piston to squeeze the brake pad through the hydraulic changes in the cylinder to achieve precise transmission of braking force. At the same time, the built-in dust cover and guide pin self-lubricating system can withstand the high temperature and dust erosion caused by frequent braking.

From the manufacturing standard, F5UZ2261A strictly follows Ford's Q1 supplier management system, and the production process covers four major links: precision casting, CNC machining, ultrasonic cleaning and dynamic testing. The inner wall of the cylinder adopts mirror polishing technology, and the surface roughness is controlled within Ra0.4μm. Combined with the double-layer sealing structure of the fluororubber sealing ring, it can maintain stable sealing in an environment of -40℃ to 180℃.

The wheel cylinder uses VIN code intelligent matching technology and is compatible with 2018-2023 Ford Explorer 2.3T/3.0T models, Edge ST-Line and many other models. During installation, special attention should be paid to the anti-twist protection of the brake oil pipe interface. After removing the old wheel cylinder, the oil line port should be immediately blocked, and the fixing bolts should be tightened with a torque wrench with a standard torque of 28-32Nm. The F5UZ2261A wheel cylinder has been structurally strengthened to meet the heavy-load characteristics of American cars. Its piston diameter reaches 45mm, which is about 15% larger than the basic model. It can shorten the braking distance by 8%-12% when combined with ventilated brake discs.

Search

Search

Eng

Eng

English

English Español

Español Português

Português