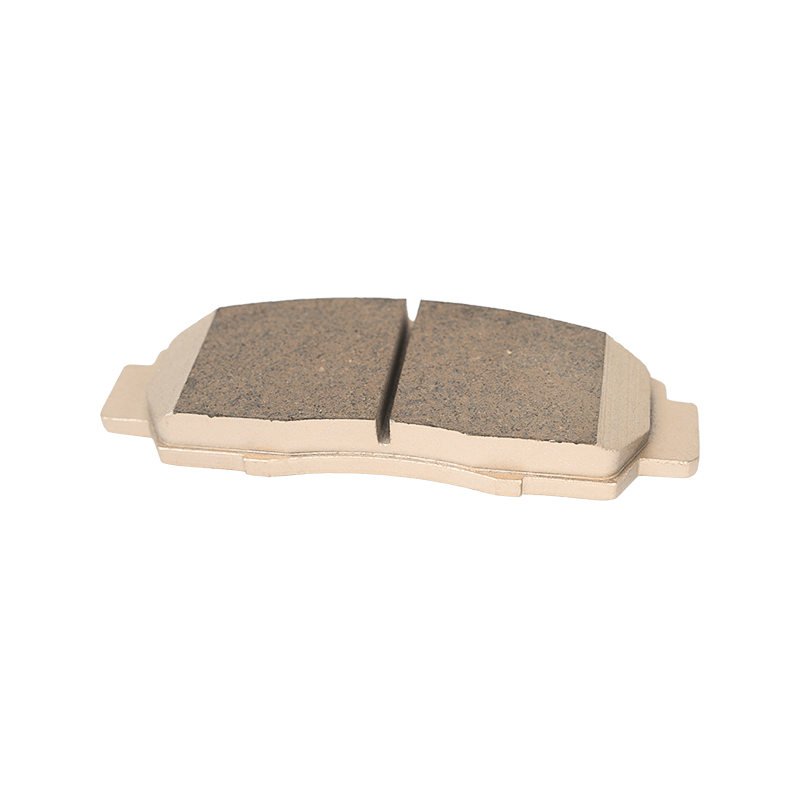

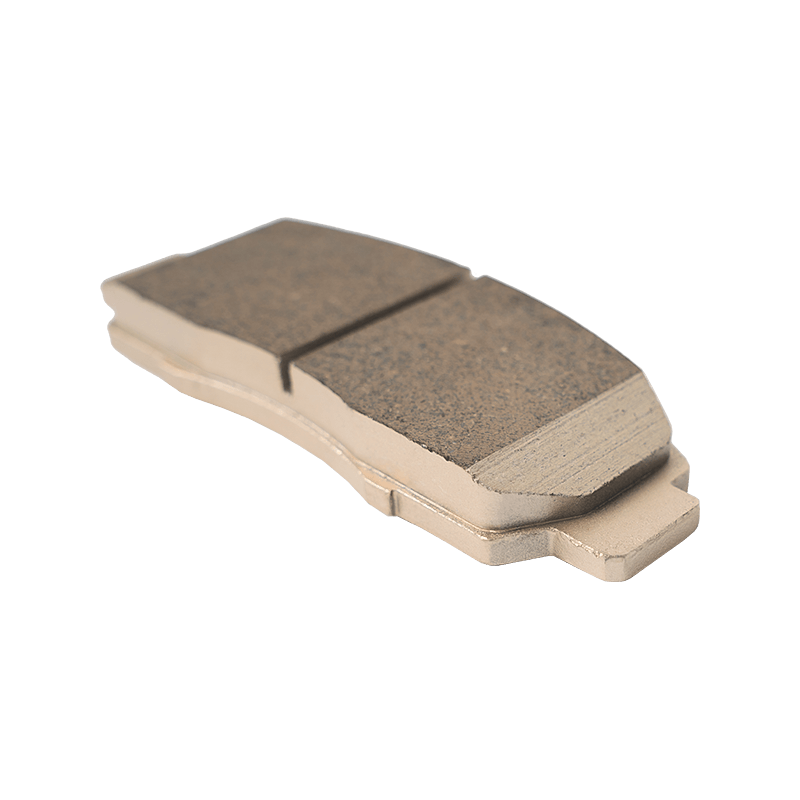

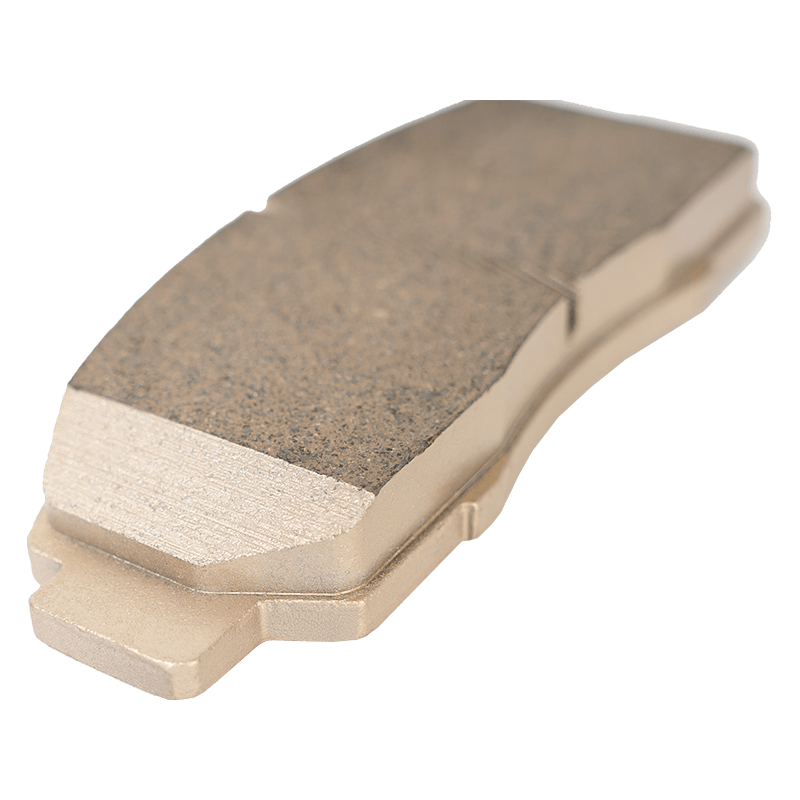

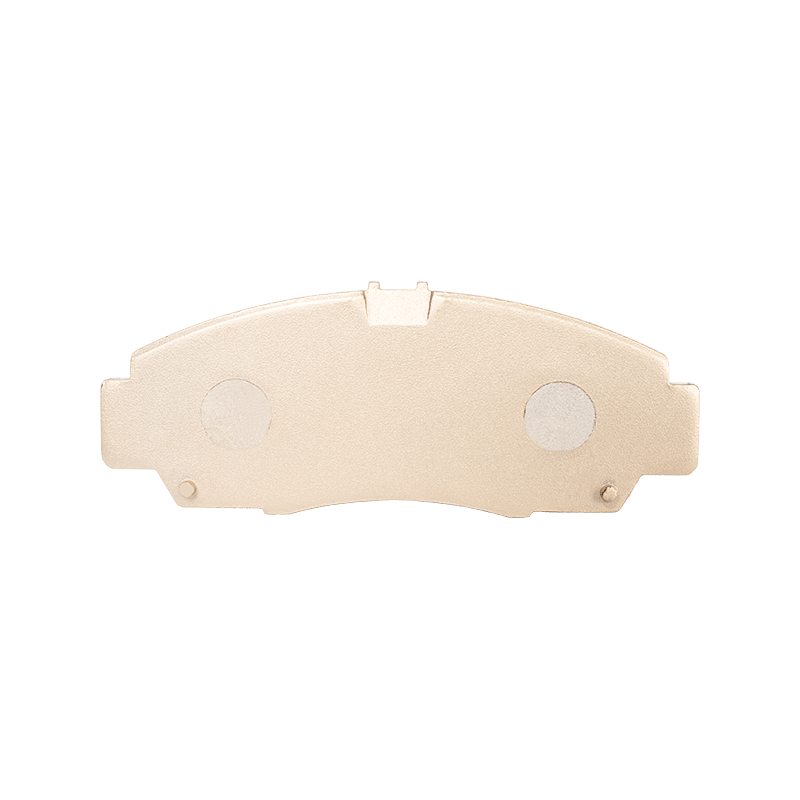

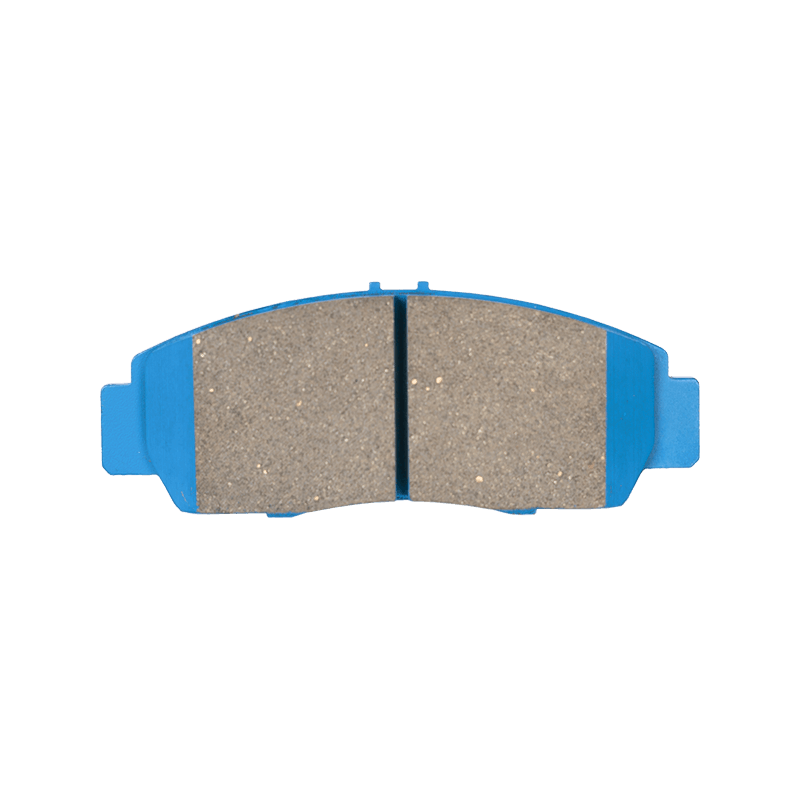

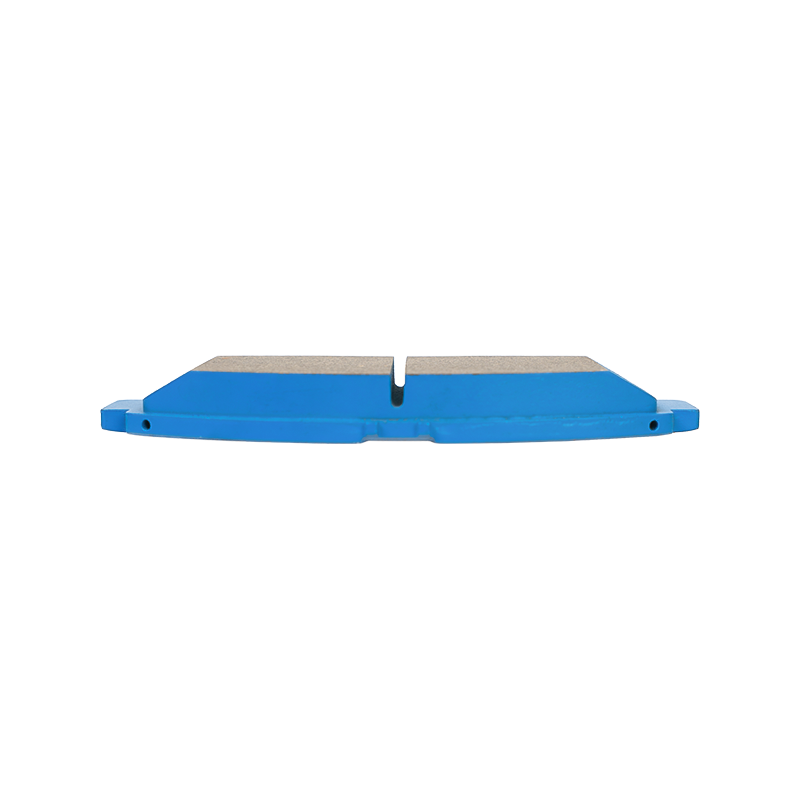

45022-57A-N00 High Quality Car Disc Brake Pads for Honda

|

OE NO |

45022-57A-N00 06450S6EE50 45022-SJF-J00 45022SNBE00 |

|

MODEL |

Honda |

Specifications

KEEP IN TOUCH

We have more than 1,000 brake shoes and brake pads for European, American, Russian, Japanese and Korean cars. The associated factories have created a highly experienced manufacturing team that exports thousands of auto part products worldwide. High quality and competitive prices are our targets. Our products have gained the certifications of ISO9001 and TS16949. We have built up a solid reputation with our customers in more than 30 countries.

We are looking forward to having a brighter and more successful business in the near future together with all of our clients all over the world.

-

The automobile brake system is one of the most critical safety components in any vehicle. It controls speed, enables smooth stopping, and prevents acc...

READ MORE -

When you're driving, you probably don’t think much about your brake system—until you need it. The brake system in your car is one of the most importan...

READ MORE -

Many customers often have these questions: "Are your brake pads wear-resistant?" "Will they make noise at high speeds?" "How long will they last? Will...

READ MORE -

In everyday driving, many car owners encounter strange noises when braking, such as "squeaking," "clicking," or "grinding" sounds. The brake caliper i...

READ MORE

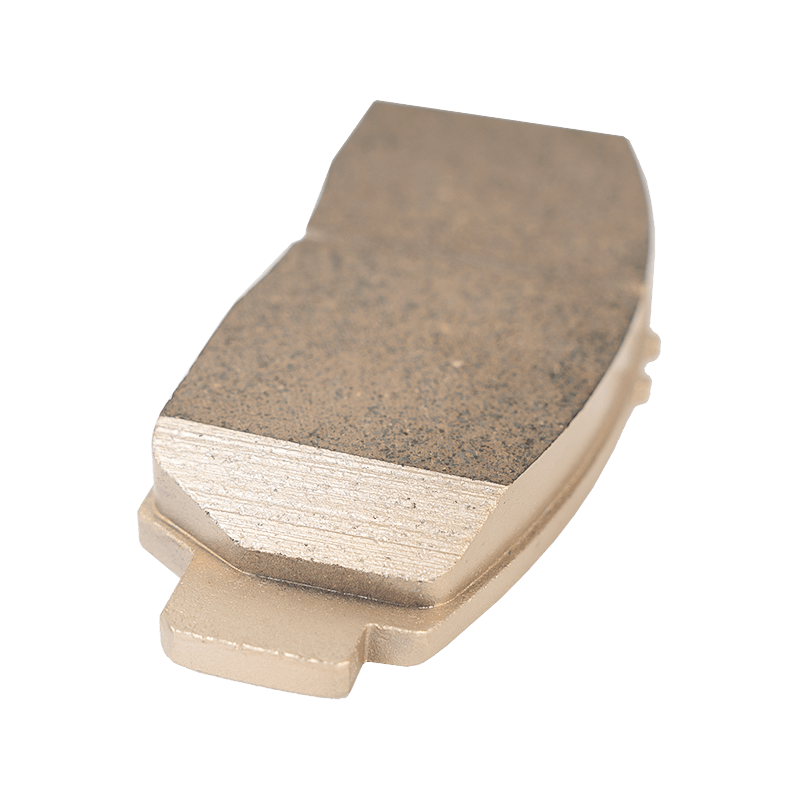

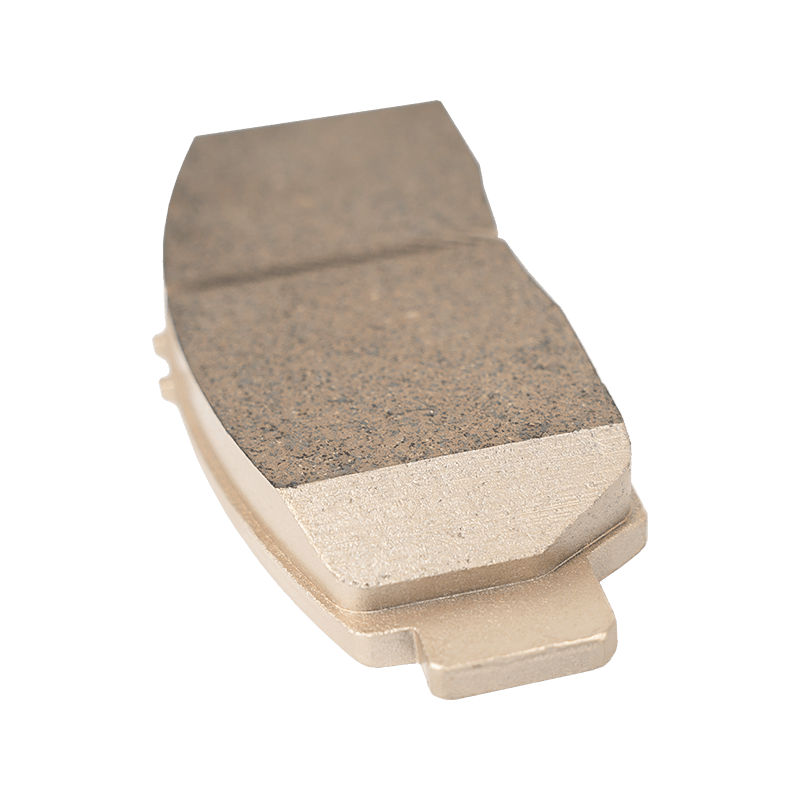

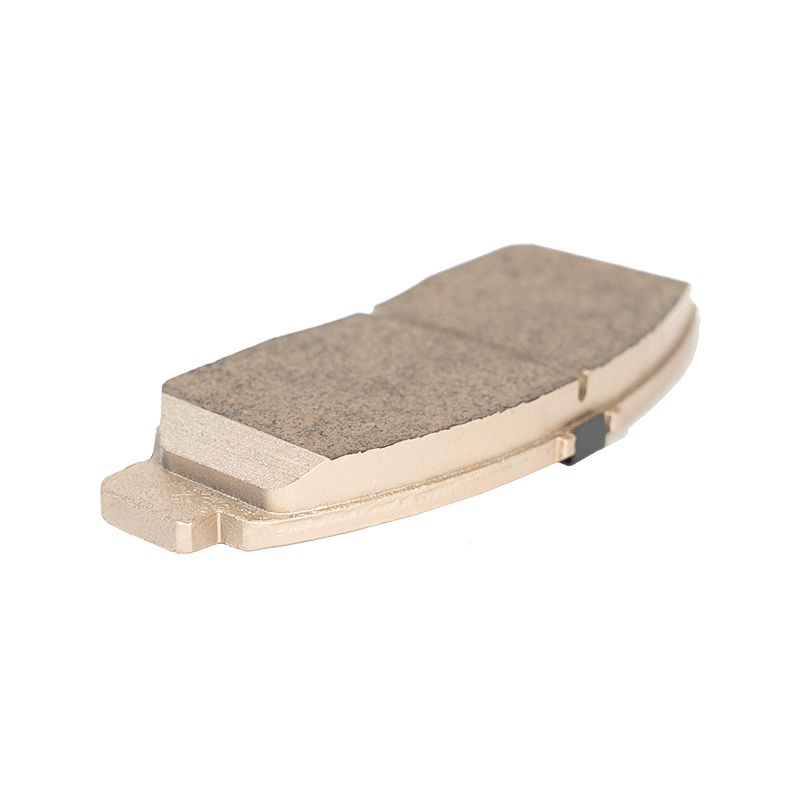

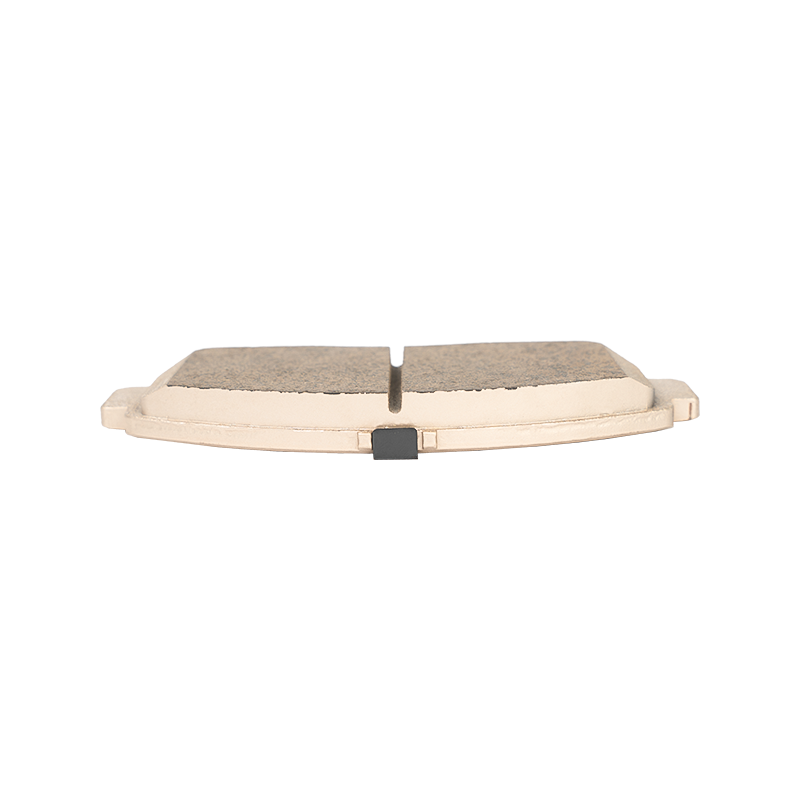

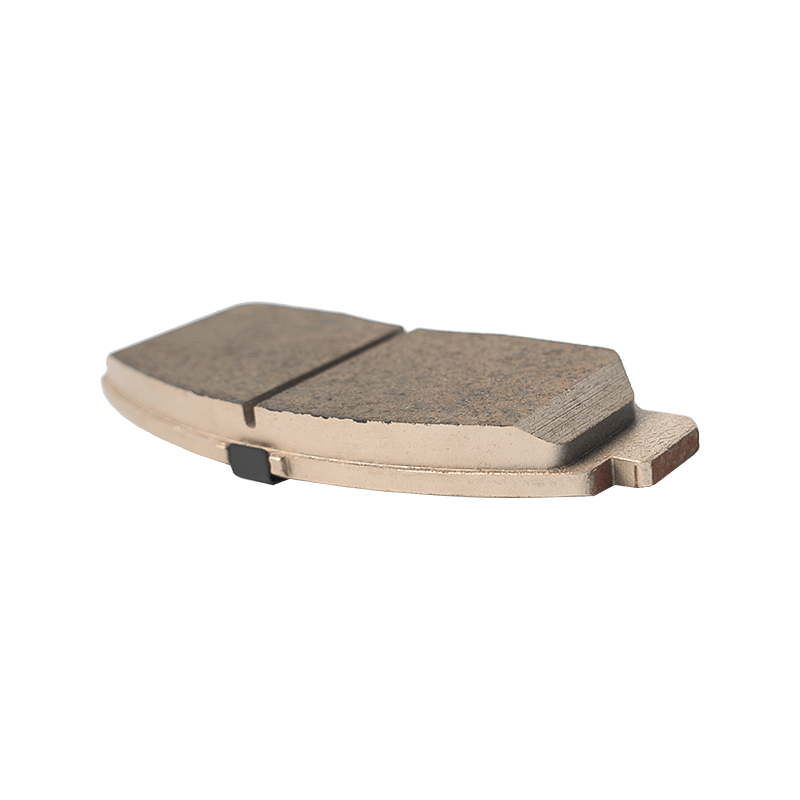

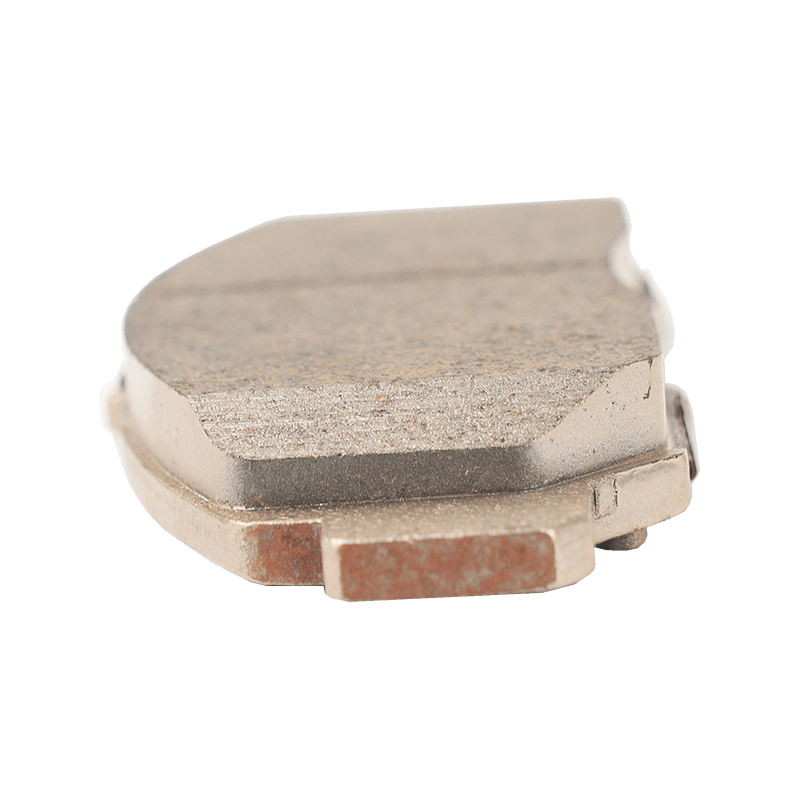

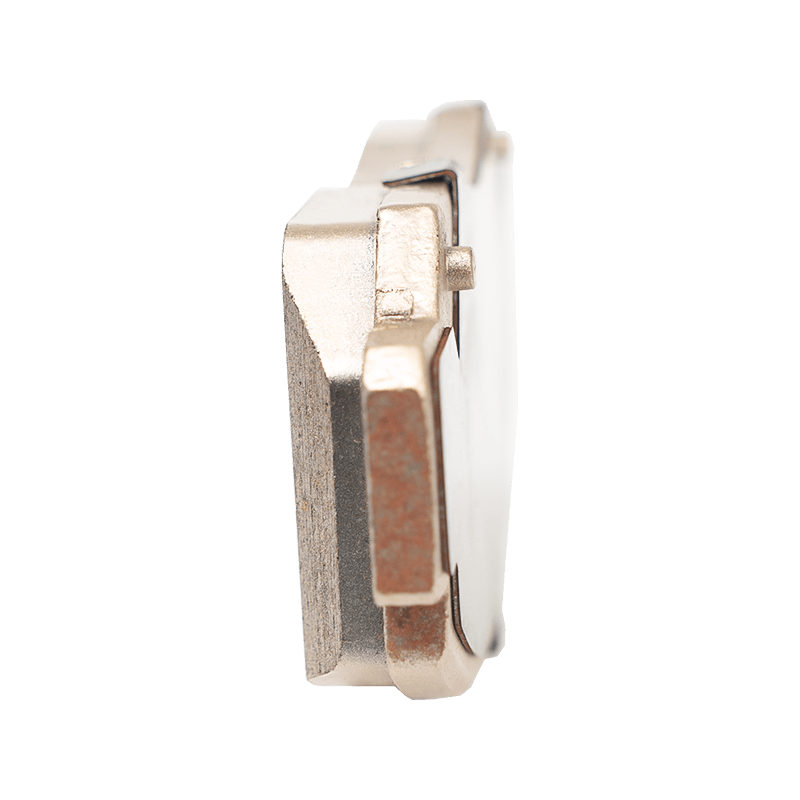

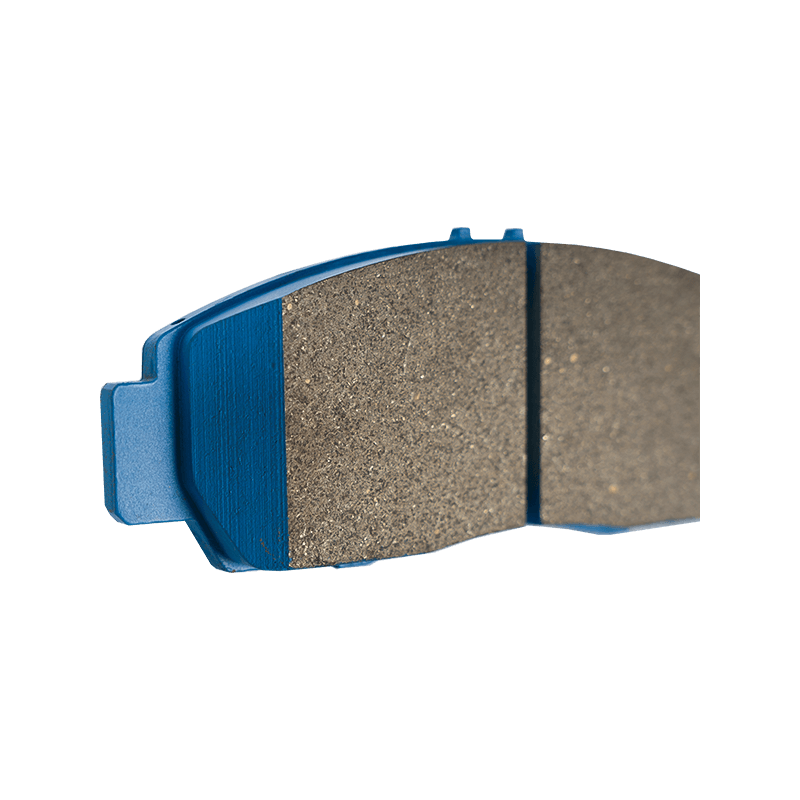

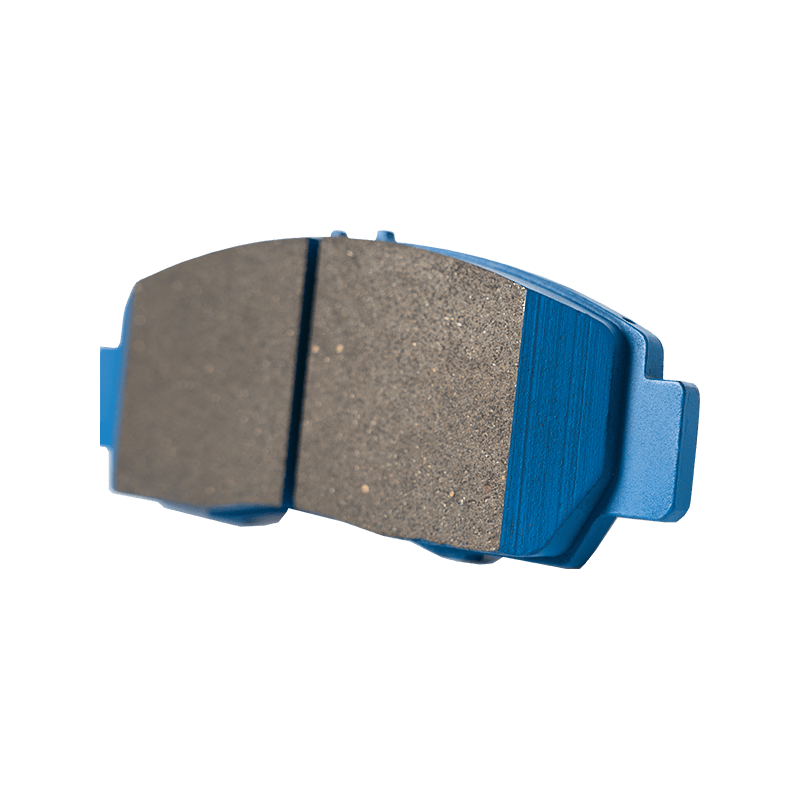

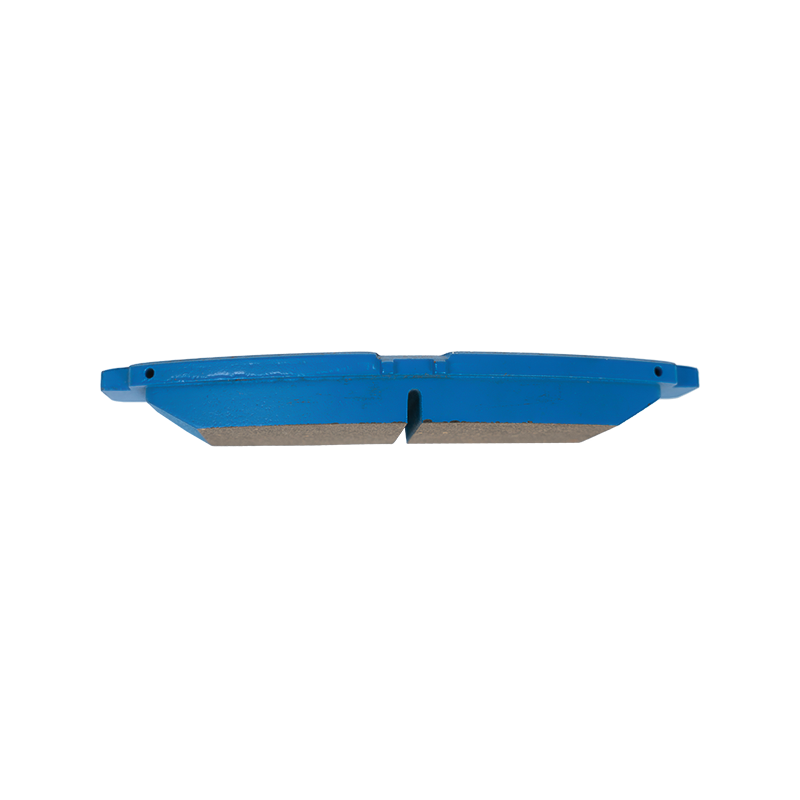

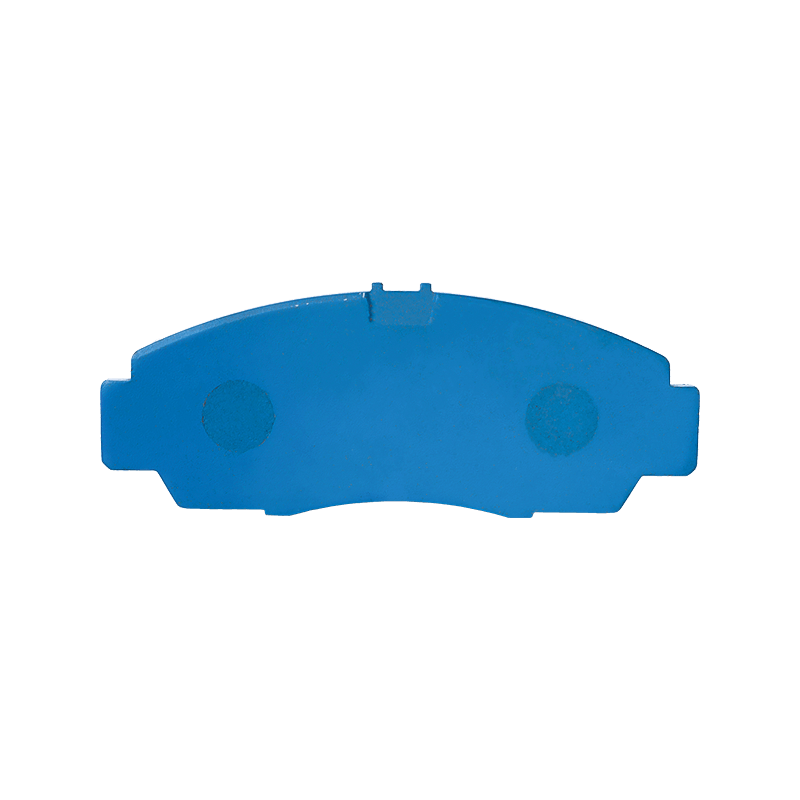

45022-57A-N00 High-quality Automotive Disc Brake Pad is a high-quality automotive disc brake pad designed for a variety of Honda models. It is made of advanced ceramic composite materials and has excellent braking performance and durability. This product is suitable for Honda and other models, perfectly adapting to the original brake system, providing a smooth braking experience consistent with the original. Its ceramic material effectively reduces braking noise and dust, while maintaining a stable friction coefficient (0.38-0.40) in high temperature environments, ensuring reliability and safety during emergency braking.

Manufacturers optimize the production process through forward molding technology to make the brake pad density more uniform and the resin content lower, thereby reducing thermal decay and extending the service life. In addition, the product supports customized services to meet the environmental protection and safety standards of different markets.

The brake pad presses the brake pad against the brake disc through the brake caliper, and uses the friction between the friction material and the brake disc to convert the vehicle's kinetic energy into heat energy to achieve braking. Ceramic materials have high hardness and no metal components, low wear rate during friction, less dust generated and no heavy metals, reducing wheel hub pollution and environmental burden. Brake pads are usually composed of a metal base plate (support layer), a thermal insulation layer (to prevent heat transfer to the brake fluid) and a friction layer (ceramic composite material). The thermal insulation layer prevents high temperatures from affecting the hydraulic system, avoiding the risk of brake fluid boiling and air lock.

Search

Search

Eng

Eng

English

English Español

Español Português

Português