0446526320 Car brake pads for Toyota

|

OE NO |

0446526320 0446526160 0446526370 AY040TY025 V9118A060 |

|

MODEL |

Toyota |

Specifications

KEEP IN TOUCH

We have more than 1,000 brake shoes and brake pads for European, American, Russian, Japanese and Korean cars. The associated factories have created a highly experienced manufacturing team that exports thousands of auto part products worldwide. High quality and competitive prices are our targets. Our products have gained the certifications of ISO9001 and TS16949. We have built up a solid reputation with our customers in more than 30 countries.

We are looking forward to having a brighter and more successful business in the near future together with all of our clients all over the world.

-

The automobile brake system is one of the most critical safety components in any vehicle. It controls speed, enables smooth stopping, and prevents acc...

READ MORE -

When you're driving, you probably don’t think much about your brake system—until you need it. The brake system in your car is one of the most importan...

READ MORE -

Many customers often have these questions: "Are your brake pads wear-resistant?" "Will they make noise at high speeds?" "How long will they last? Will...

READ MORE -

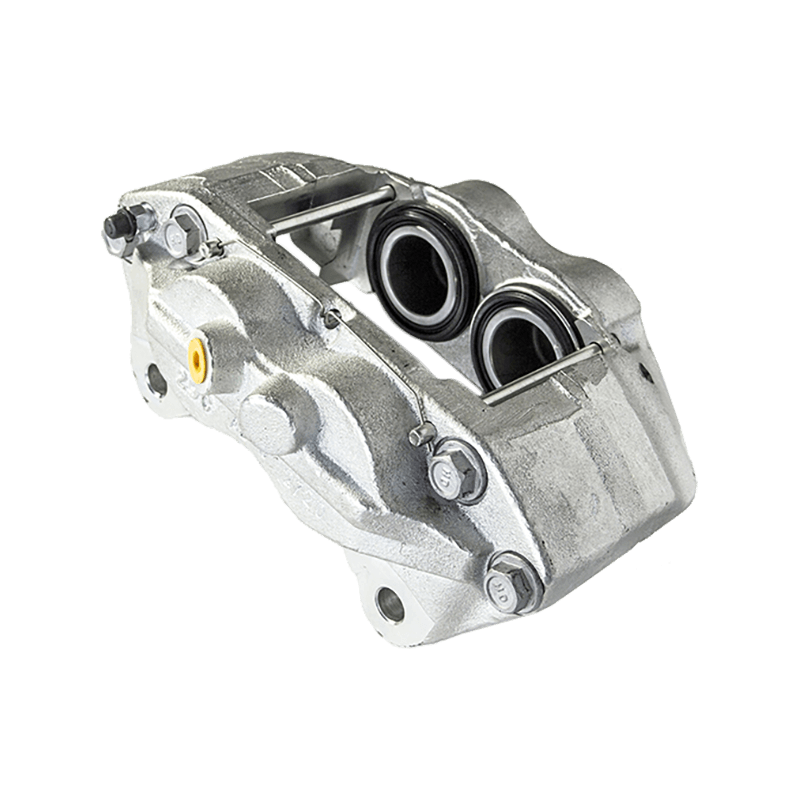

In everyday driving, many car owners encounter strange noises when braking, such as "squeaking," "clicking," or "grinding" sounds. The brake caliper i...

READ MORE

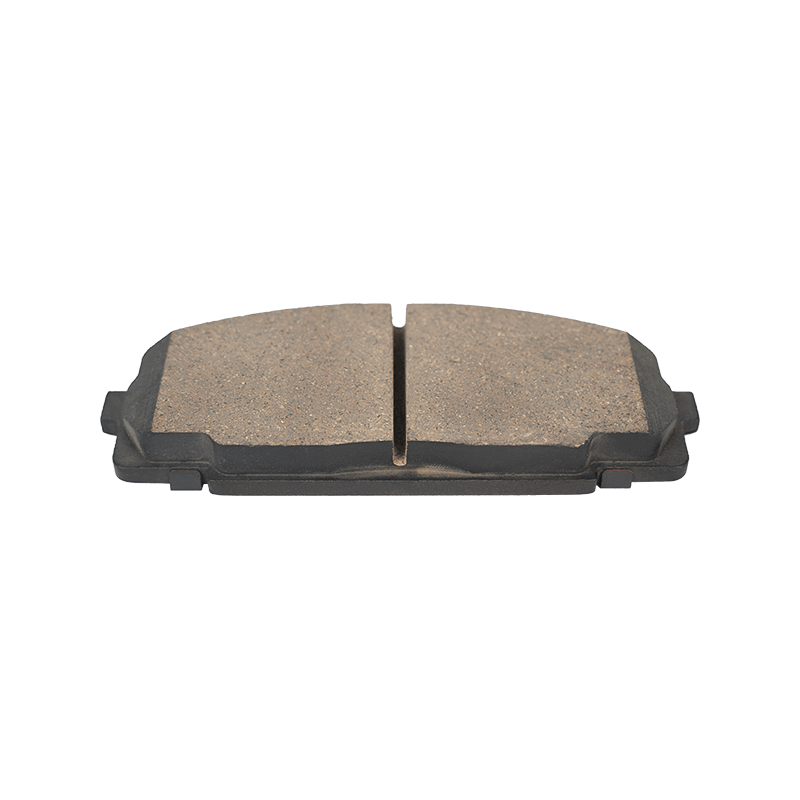

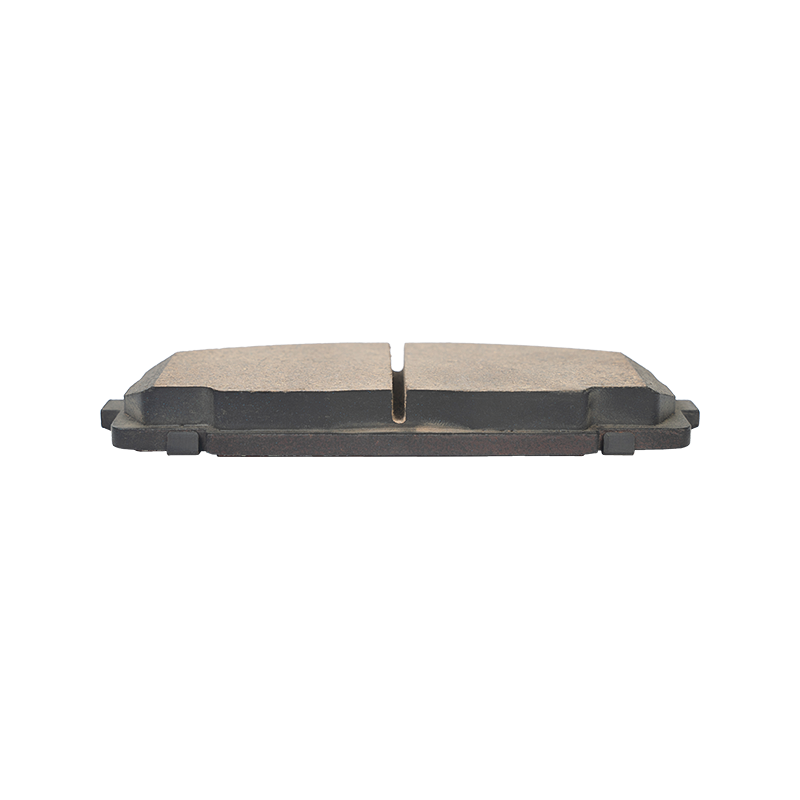

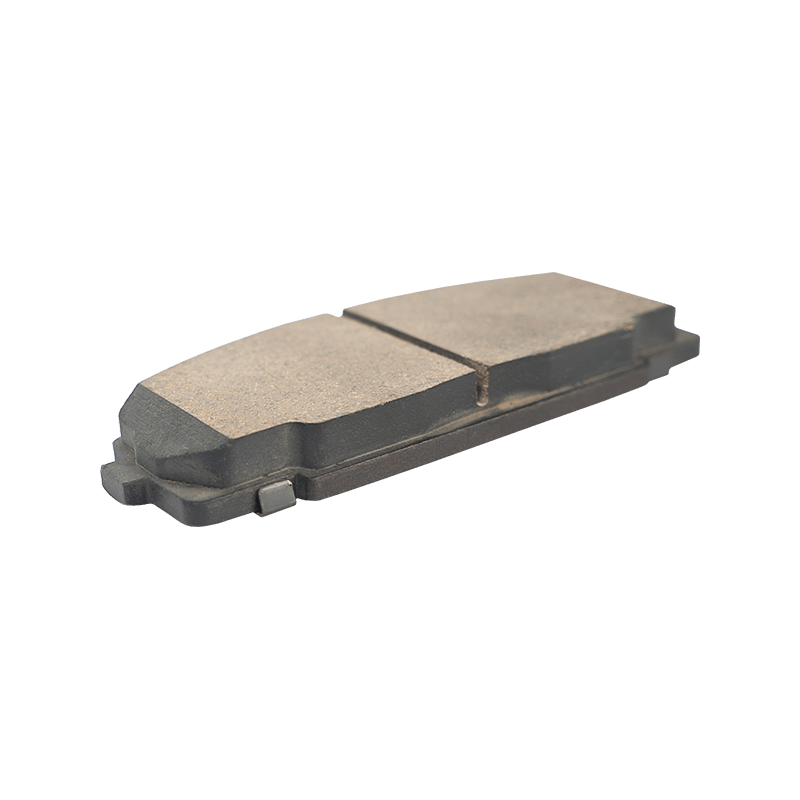

The ultra-high-performance disc brake pads of model 0446526320 are made of semi-metallic composite materials. With its precision craftsmanship and innovative product design, it has become the first choice for car owners who pursue safety and durability. Its core structure uses high-density steel plates as the base, and the surface is covered with an anti-rust coating tested by the SMT-4 furnace temperature tracker to ensure that the metal matrix can still maintain stable performance in a humid environment. The friction material layer combines metal fibers and ceramic particles with a special ratio, and achieves porosity consistency through automatic mold pressure control technology. It not only inherits the high friction coefficient characteristics of traditional semi-metallic materials, but also effectively solves the problems of braking noise and dust.

The brake pad performs well in thermal management. The friction block is embedded with a layered heat dissipation structure. The carbonized surface layer formed by the ablation process can quickly diffuse the high temperature generated during braking to avoid thermal decay. Laboratory data shows that after ten consecutive 100-0km/h emergency braking tests, the friction coefficient fluctuation is less than 5%. This stability is particularly important in the frequent start-stop scenarios of commercial vehicles, especially under high-load conditions of urban logistics transportation, and can still maintain a linear braking feel.

To meet different driving needs, we use precision stamping technology to precisely control the size to 145.4mm×56.9mm×15.5mm, which can be seamlessly replaced with original parts. The specially designed anti-noise pads are made of glass fiber composite materials and combined with blue silicate coating (COTEC technology), so that the new brake pads can be run-in within 200 kilometers after installation, which shortens the running-in mileage by 30% compared with traditional products.

Search

Search

Eng

Eng

English

English Español

Español Português

Português