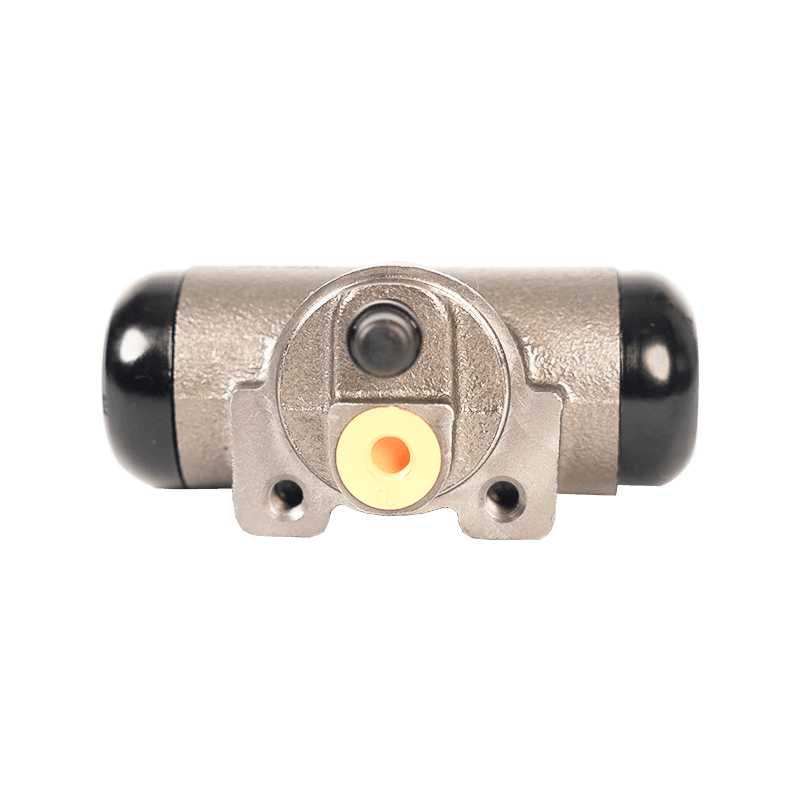

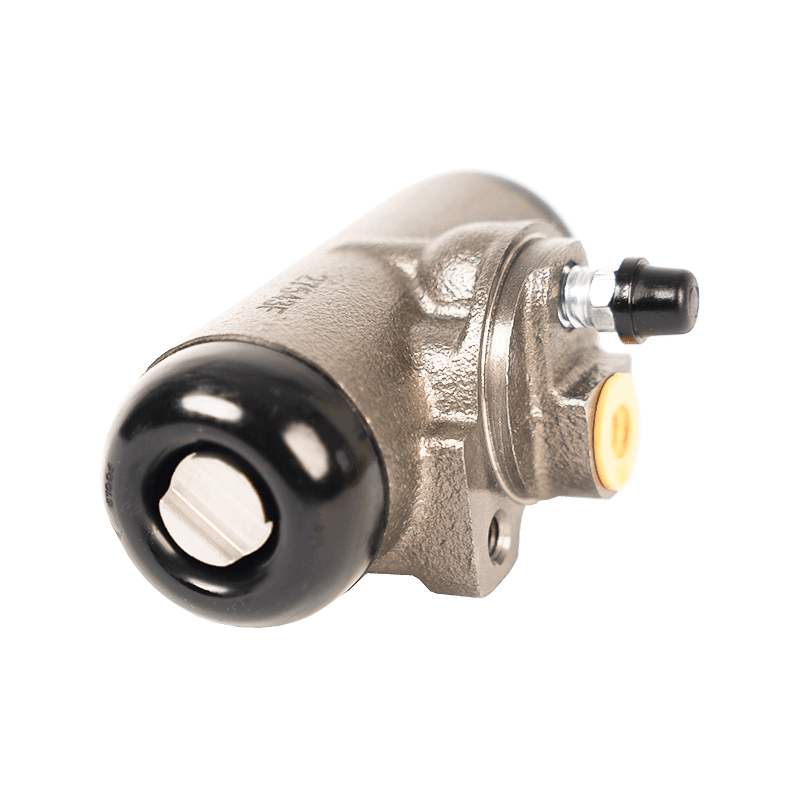

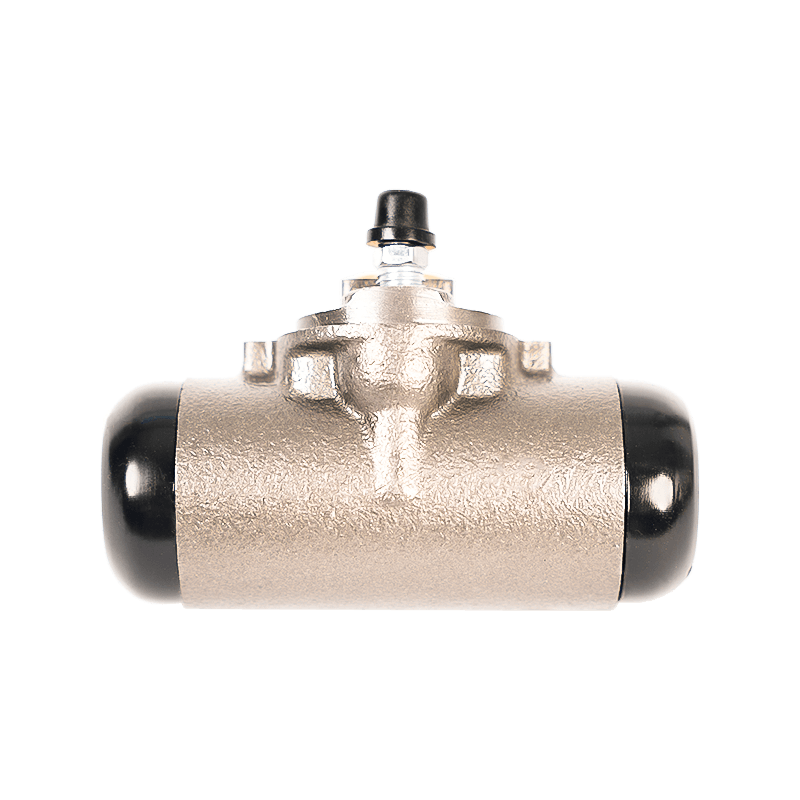

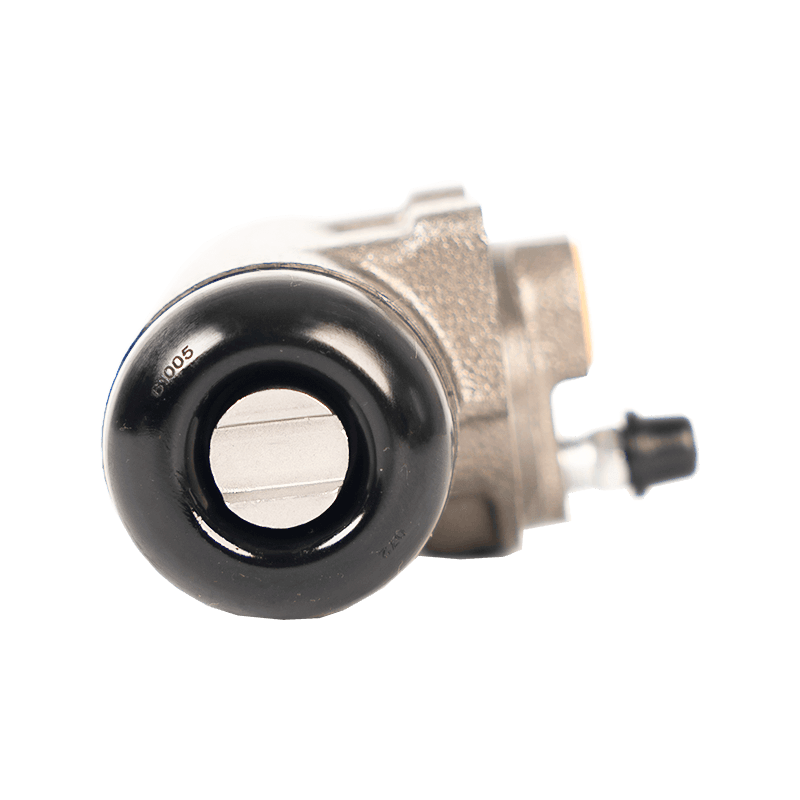

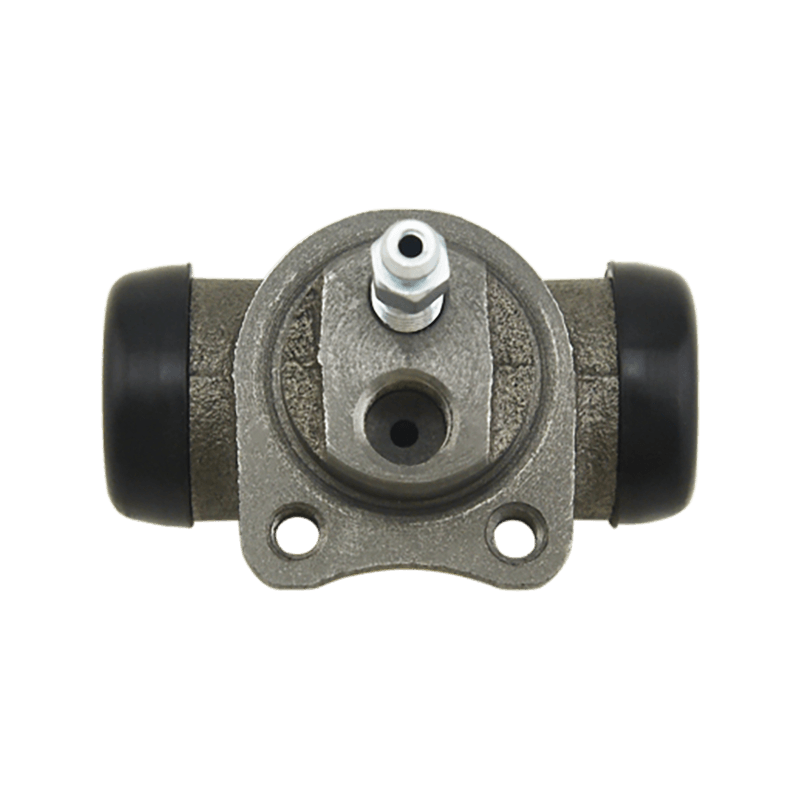

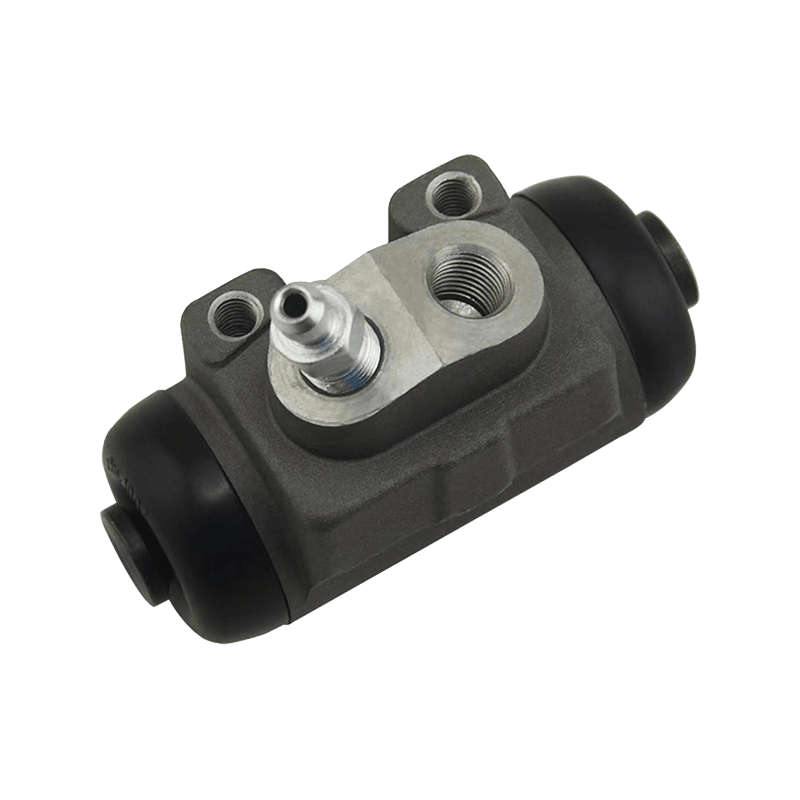

25832113 Brake Wheel Cylinder for Chevrolet

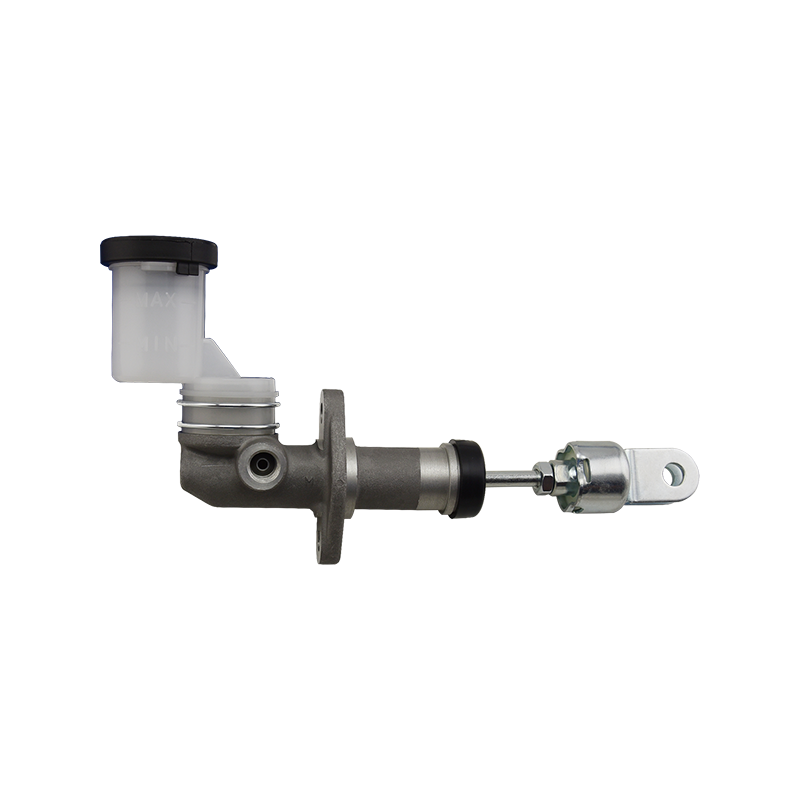

It is usually mounted on the axle, near the wheel that is to be equipped for braking. Air pressure is fed through an inlet port. The air pushes against the diaphragm and the push rod. The push rod is connected by a clevis and pin to a crank arm-type lever called a 'slack adjuster.

|

OE NO |

25832113 |

|

MODEL |

Chevrolet |

Specifications

KEEP IN TOUCH

We have more than 1,000 brake shoes and brake pads for European, American, Russian, Japanese and Korean cars. The associated factories have created a highly experienced manufacturing team that exports thousands of auto part products worldwide. High quality and competitive prices are our targets. Our products have gained the certifications of ISO9001 and TS16949. We have built up a solid reputation with our customers in more than 30 countries.

We are looking forward to having a brighter and more successful business in the near future together with all of our clients all over the world.

-

Why Choose OE Quality Brake Pads? When selecting brake pads, OE QUALITY BRAKE PADS ensure precise fit, optimal braking performance, and long-term dur...

READ MORE -

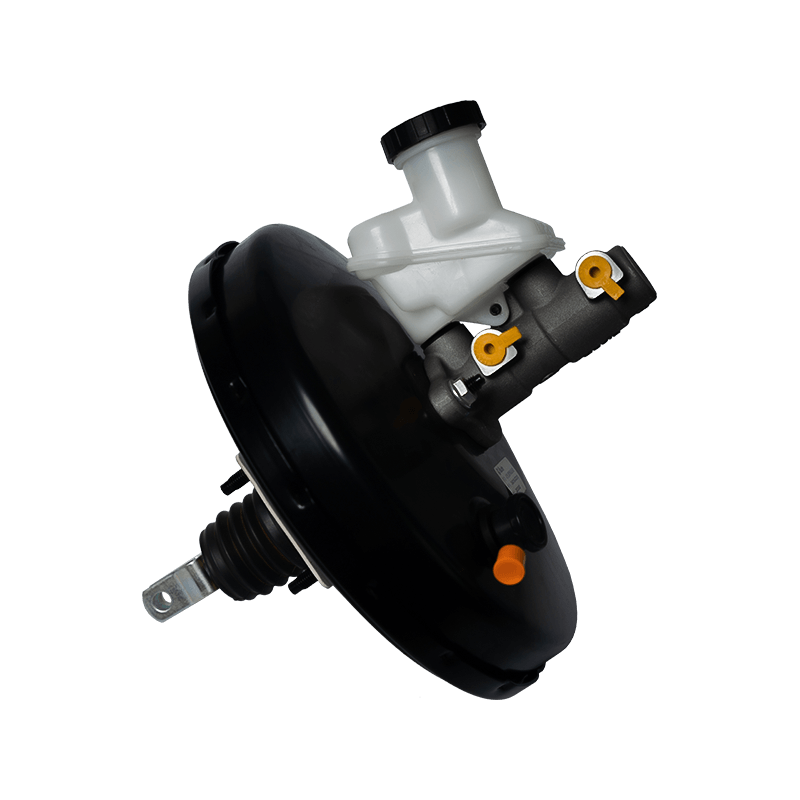

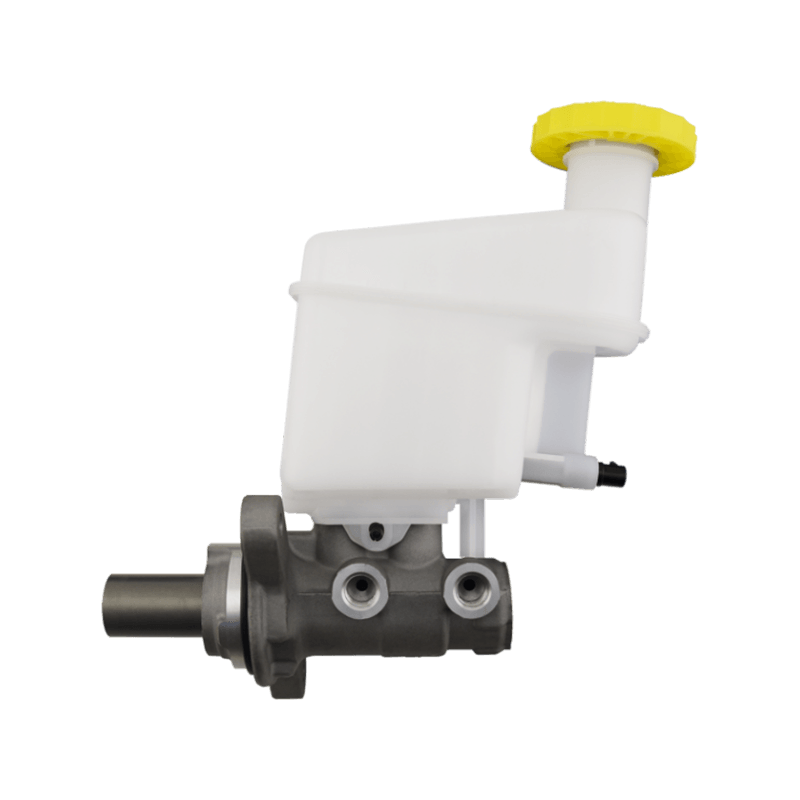

What is a Hydraulic Brake Master Cylinder? The hydraulic brake master cylinder is a critical component in a vehicle's braking system. It converts the...

READ MORE -

Why OE Quality Brake Pads Are the Best Choice for Your Car OE (Original Equipment) quality brake pads are specifically designed to match the specific...

READ MORE -

The direct answer: Yes. High-quality brake pads can reduce braking distance by 15%–30%, improve heat resistance, and significantly enhance driving saf...

READ MORE

Chevrolet 25832113 brake wheel cylinder follows the modularization and reliability principles of modern automobile brake systems. As the core actuator of the drum brake, the wheel cylinder converts the hydraulic pressure of the brake master cylinder into mechanical force through hydraulic transmission, driving the brake shoe to fit the brake drum, thereby realizing the vehicle deceleration or parking function. It adopts a double-piston structure inside, and the cylinder body is cast from cast iron or aluminum alloy. Through precision machining, the matching tolerance between the piston and the cylinder wall is controlled within ±0.01mm. This design not only improves the sealing performance, but also can adapt to the heat expansion generated by high-frequency braking.

In terms of manufacturing process, the production of 25832113 wheel cylinder strictly follows the ISO/TS 16949 quality management system. From raw material selection to finished product testing, it is necessary to go through several key processes: the casting blank needs to be inspected for internal defects by X-ray flaw detection; the inner wall of the cylinder after CNC machine processing needs to reach a surface roughness of Ra0.8μm; ultrasonic cleaning technology is used to remove metal debris during assembly, and rubber seals are installed with special lubricants. Each assembled slave cylinder must pass air tightness tests and dynamic durability tests to ensure its stability under high-load conditions.

In actual applications, the maintenance of the slave cylinder needs to focus on the piston activity and seal aging. When the brake shoe wear exceeds 3mm, it is recommended to simultaneously check whether the slave cylinder piston returns smoothly to avoid piston jamming due to excessive wear. To ensure optimal performance, it is recommended to perform deep maintenance on the slave cylinder every 60,000 kilometers or when the brake pads are replaced twice - including cleaning the carbon deposits on the piston surface, replacing the dust cover and lubricating the guide pin.

Search

Search

Eng

Eng

English

English Español

Español Português

Português