What is the role of the clutch master cylinder? In what specific aspects is it reflected?

2025.05.12

2025.05.12

Industry News

Industry News

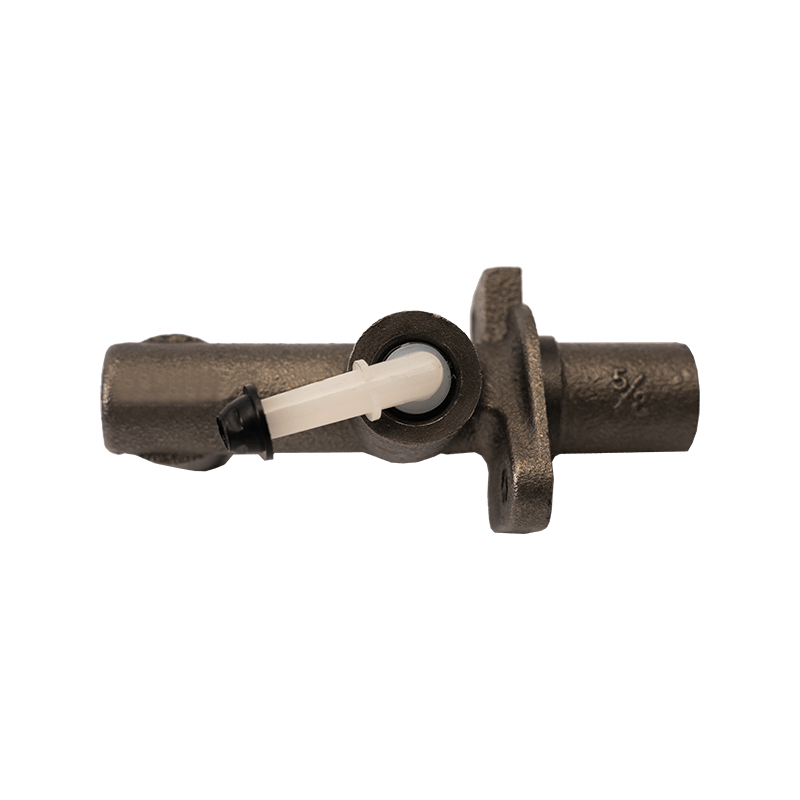

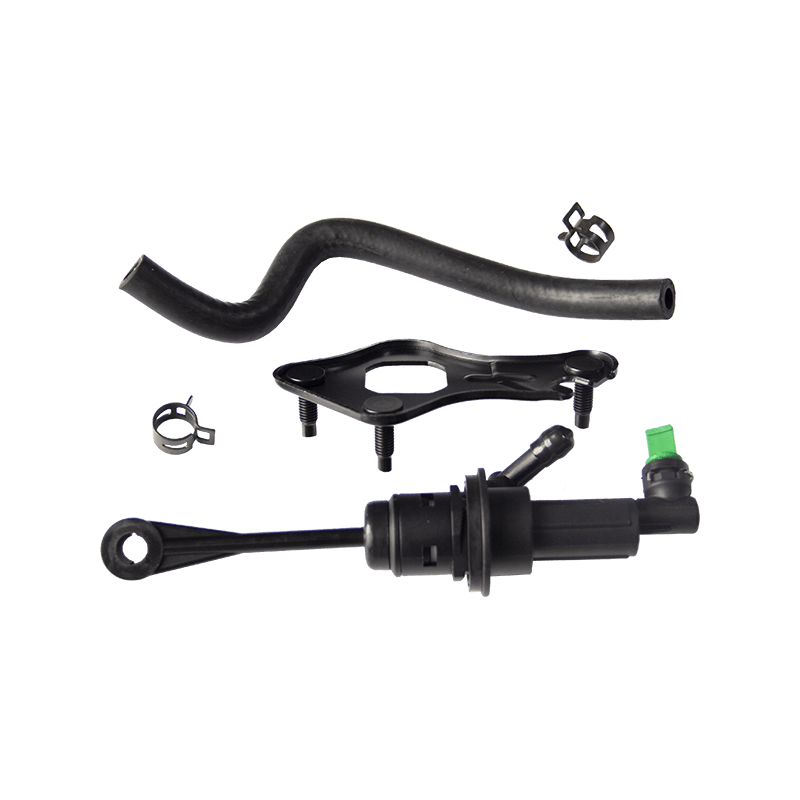

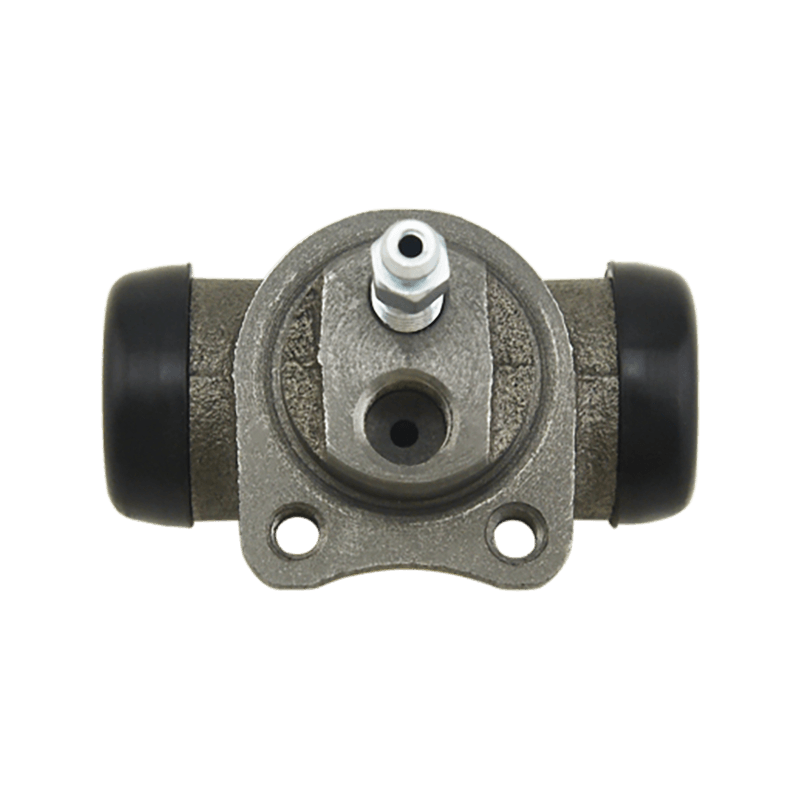

The clutch master cylinder converts the driver's pedaling action into a hydraulic signal through the hydraulic principle. When the pedal is pressed, the piston in the master cylinder moves to compress the brake fluid, generating hydraulic pressure, which is transmitted to the clutch through the oil pipe, driving the release bearing to push the pressure plate to separate the clutch plate from the flywheel. When the pedal is released, the spring pushes the piston to reset, the hydraulic pressure is released, and the clutch is reengaged. This hydraulic transmission mechanism is more efficient and more labor-saving than a pure mechanical structure, especially suitable for heavy vehicles or scenes where frequent gear shifting is required.

The precise control of the master cylinder ensures the smoothness of the clutch engagement process. By adjusting the pedal stroke, the driver can gradually transfer power to avoid engine stalling due to sudden load, while reducing the sense of frustration when starting. When the vehicle brakes in an emergency, the hydraulic system of the clutch master cylinder can quickly disengage the clutch, interrupt the connection between the engine and the transmission system, and prevent damage to mechanical components.

Regularly checking the brake fluid level and sealing can prevent problems such as heavy pedals and hydraulic failure caused by oil aging or leakage. If there is an abnormal pedal free travel or oil bubbles, it is necessary to adjust the push rod length or perform exhaust operation in time.

Search

Search

Eng

Eng

English

English Español

Español Português

Português