Manual transmission car owners must read: Maintenance tips to extend the life of the clutch slave cylinder

2025.07.23

2025.07.23

Industry News

Industry News

Content

Four maintenance tips for the clutch slave cylinder

- Tip 1: Regularly check and replace the hydraulic oil

Why is it important?

The clutch slave cylinder relies on hydraulic oil (usually DOT4 brake fluid) to transmit pressure. Aging or contamination of the oil will cause corrosion of the seal ring, piston jamming, and eventually cause oil leakage or clutch failure.

How to operate?

Inspection cycle: every 2 years or 40,000 kilometers (whichever comes first).

Replacement steps:

Drain the old oil and clean the reservoir.

Add new oil to the standard line to avoid mixing with air.

Oil status: If the color turns black or turbid, replace it immediately!

- Tip 2: Be alert to signs of oil leakage and deal with it in time

Common oil leakage locations:

Slave cylinder seal (oil leaks near the transmission housing).

Hydraulic line interface (oil stains spread along the line).

Emergency treatment:

When oil leakage is found, add hydraulic oil immediately and repair it as soon as possible to avoid air entering the system and causing clutch failure.

Self-check method: Open the engine compartment every month and observe whether there are oil stains on the slave cylinder and pipeline.

Serious consequences: If the oil leakage is not handled in time, it may cause the clutch to fail completely, endangering driving safety.

- Tip 3: Regularly remove air from the hydraulic system

Symptoms:

The clutch pedal becomes soft and the stroke becomes longer.

There is a "clicking" sound or difficulty in shifting gears when shifting gears.

Exhaust steps (two people are required):

Prepare a transparent hose and a container, and connect the exhaust valve of the slave cylinder.

One person repeatedly steps on the clutch pedal, and the other person loosens and tightens the exhaust valve until the oil flows out without bubbles.

Fill the oil to the standard line to ensure that there is no air in the system.

Note: If it is still abnormal after exhausting, it may be that the internal part of the slave cylinder is damaged and requires professional maintenance.

- Tip 4: Avoid long-term "half-clutch" driving

Burden of the slave cylinder:

Frequent half-clutch (such as stepping on the clutch and waiting in a traffic jam) will cause the slave cylinder to be continuously pressurized and accelerate the aging of the seal ring.

Correct operation:

Start on a slope: Use the handbrake to assist and reduce the half-clutch time.

Waiting for a red light: put the car in neutral instead of keeping the clutch pressed for a long time.

Summary: Core maintenance tips

- Change oil regularly - prevent corrosion and maintain pressure.

- Check for oil leaks - detect early and save maintenance.

- Remove air - ensure the efficiency of the hydraulic system.

- Reduce semi-linkage - reduce seal wear.

Abnormal situation handling:

|

Fault phenomenon |

Possible cause |

Countermeasures |

|

Clutch pedal does not rebound |

Slave cylinder piston is stuck/air in hydraulic system |

Exhaust or replace slave cylinder |

|

Difficult shifting |

Insufficient hydraulic pressure/oil leakage |

Check oil level and repair leaks |

|

Pedal feels empty |

Slave cylinder seal ring is broken |

Replace slave cylinder immediately |

FAQ about Clutch Slave Cylinder

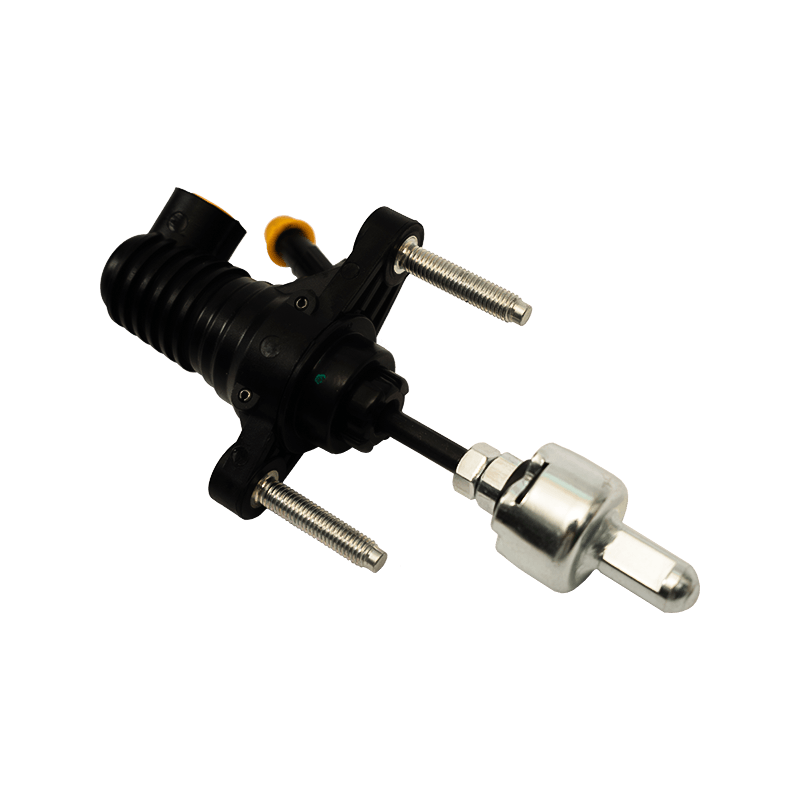

- What is the function of the clutch slave cylinder?

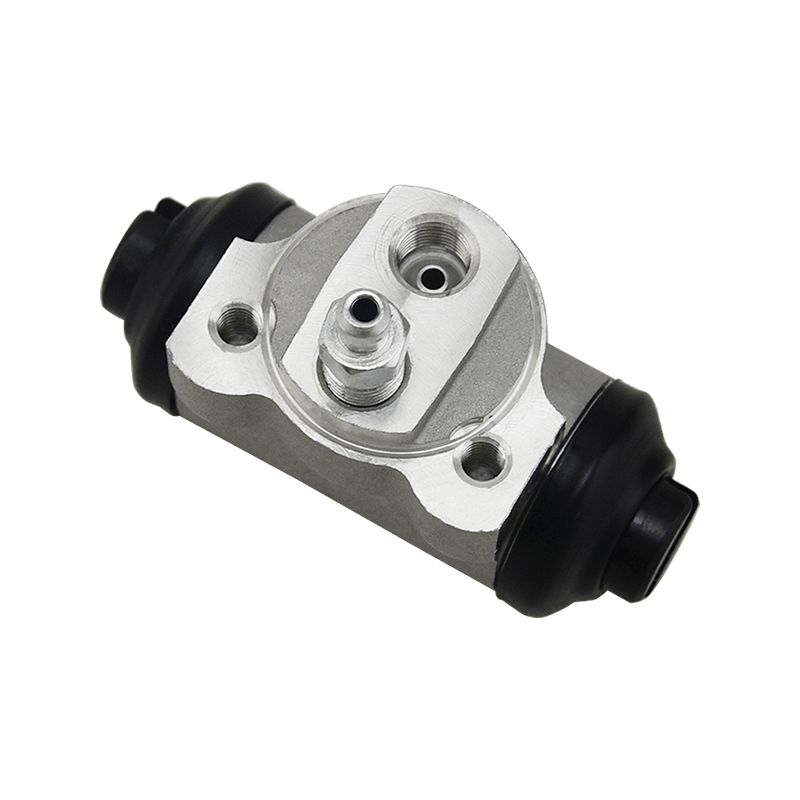

Core function: transfer hydraulic pressure from the master cylinder to the clutch release bearing, push the pressure plate to separate the friction plate and the flywheel, and realize power interruption when shifting or stopping.

Workflow: when the pedal is pressed, the master cylinder is pressurized → the hydraulic oil pushes the slave cylinder piston → the release bearing moves forward → the clutch is separated; when the pedal is released, the hydraulic pressure returns and the clutch is engaged.

- What are the common manifestations of slave cylinder damage?

Difficult shifting: incomplete separation, gear collision when shifting (due to insufficient hydraulic pressure or piston jamming).

Pedal abnormality:

The pedal becomes heavier (seal ring aging or hydraulic leakage).

The pedal does not rebound (piston stuck or air enters the hydraulic system).

Oil leakage: oil seepage at the seal of the slave cylinder or the pipeline interface (immediate maintenance is required to avoid hydraulic failure).

- How to determine whether the slave cylinder needs to be replaced?

Inspection steps:

Observe whether the hydraulic oil is below the standard line or turbid.

Pedal test: If the stroke becomes longer or weak, there may be leakage in the slave cylinder.

Check if the seal is damaged (oil leakage or obvious oil stains).

Replacement standard: When the above fault occurs and cannot be solved by exhausting/replenishing oil, it needs to be replaced as a whole (the service life of aftermarket parts is only 10,000-30,000 kilometers, and the original parts can reach 60,000-100,000 kilometers)

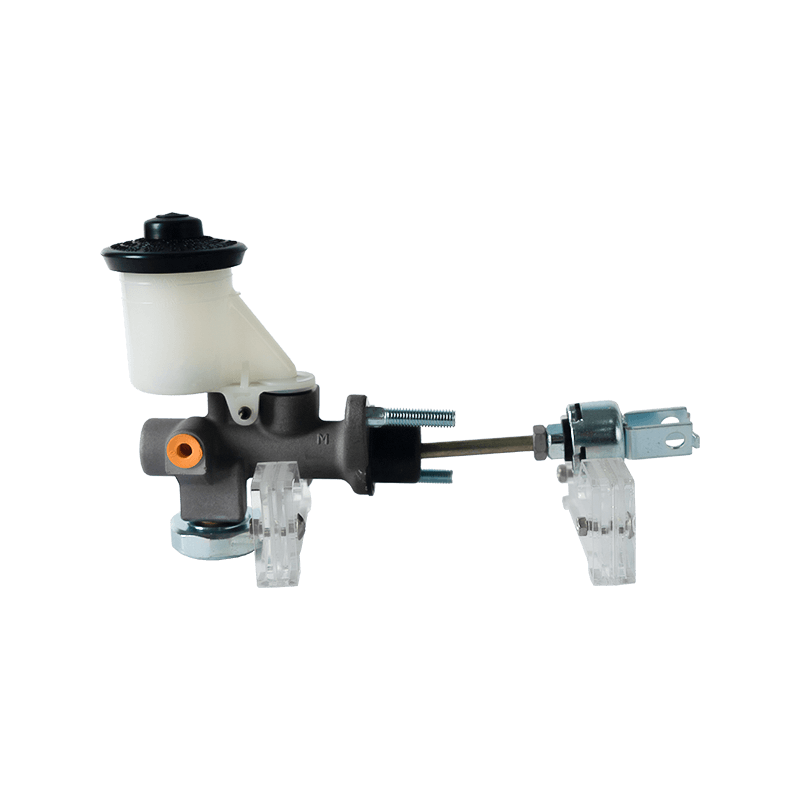

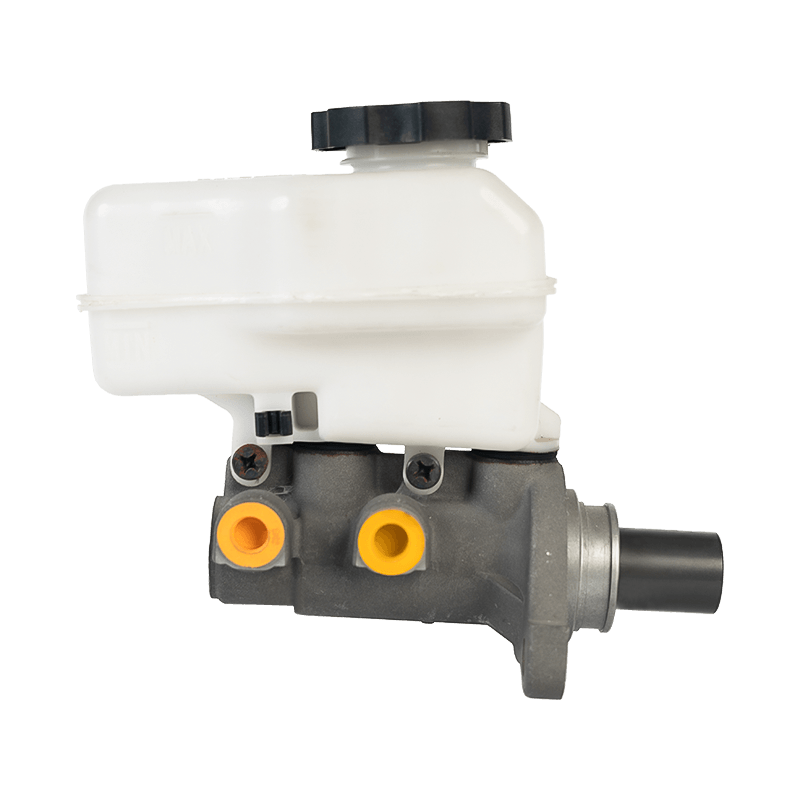

- How to distinguish between the slave cylinder and the master cylinder?

Structural differences:

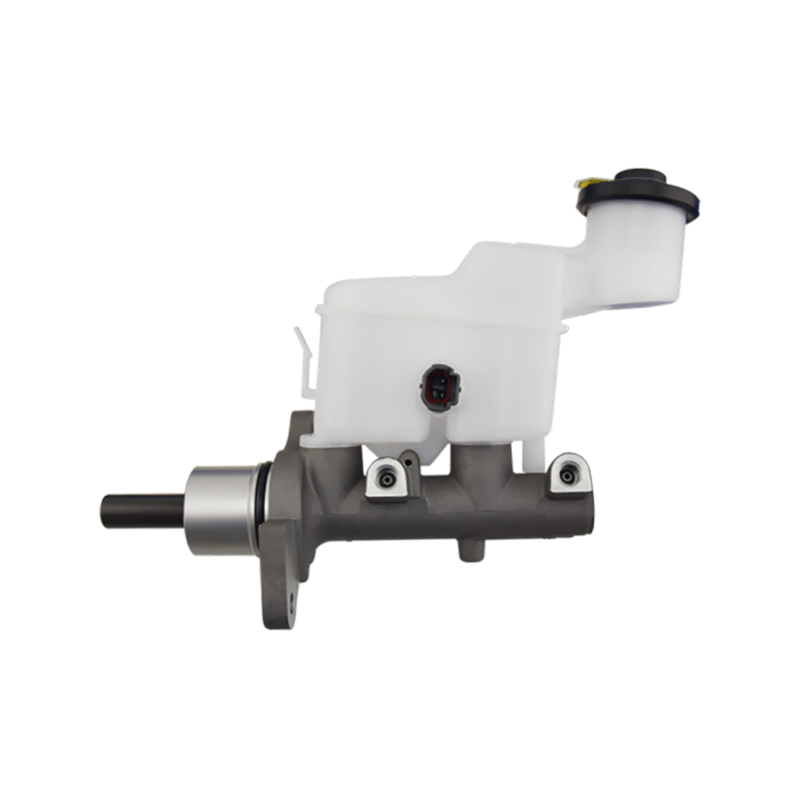

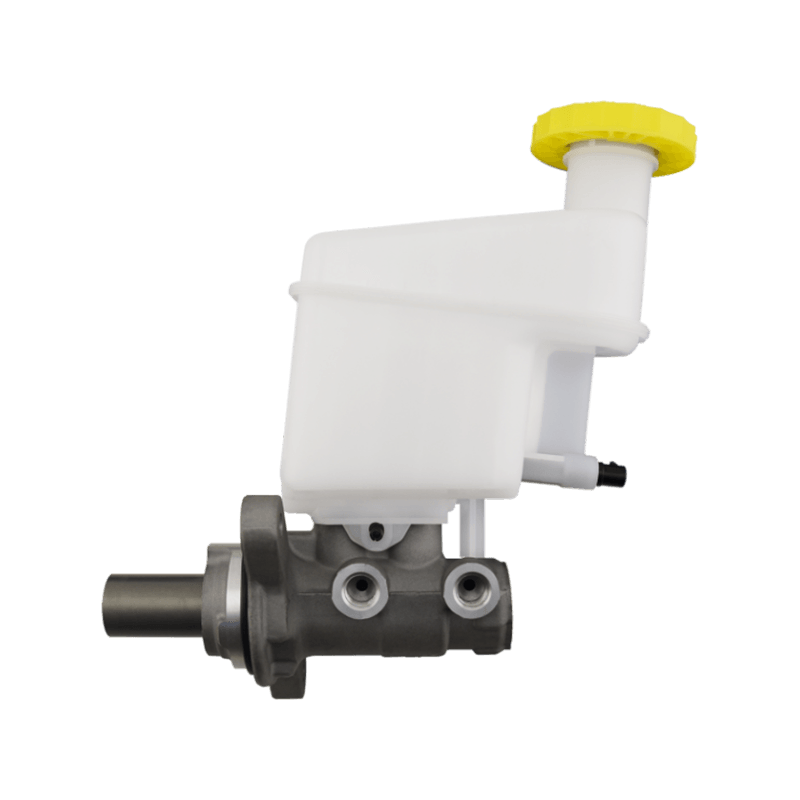

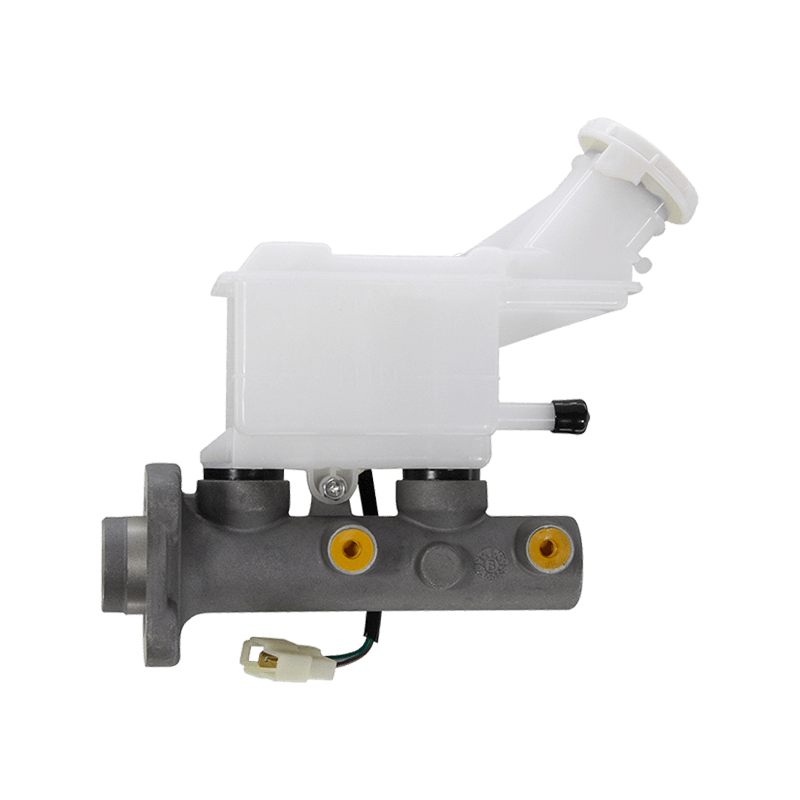

The master cylinder is connected to the pedal and has inlet/outlet oil pipes; the slave cylinder is only connected to the release bearing with a single pipe.

Fault differentiation:

Master cylinder failure is often manifested as no resistance to the pedal; slave cylinder failure is often accompanied by oil leakage or difficulty in shifting.

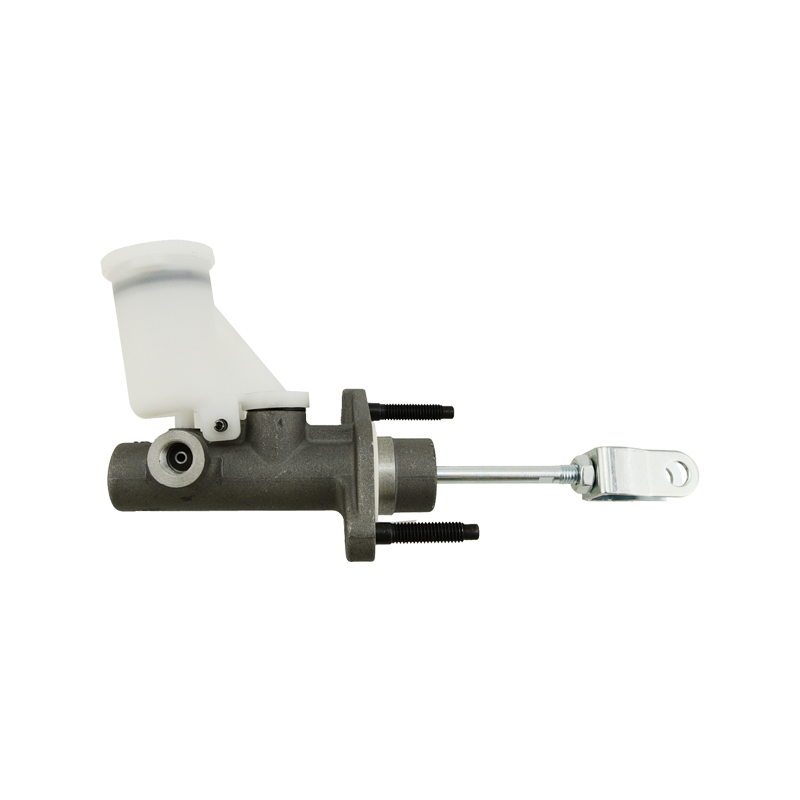

- Precautions for replacing the slave cylinder

Installation points:

Clean the contact surface of the gearbox to avoid impurities causing poor sealing.

Tighten the bolts according to the torque (over-tightening will easily deform, and over-loosening will leak oil).

After replacement, exhaust and test the pedal stroke (free stroke is usually 10-15mm).

Search

Search

Eng

Eng

English

English Español

Español Português

Português