Specifications

KEEP IN TOUCH

We have more than 1,000 brake shoes and brake pads for European, American, Russian, Japanese and Korean cars. The associated factories have created a highly experienced manufacturing team that exports thousands of auto part products worldwide. High quality and competitive prices are our targets. Our products have gained the certifications of ISO9001 and TS16949. We have built up a solid reputation with our customers in more than 30 countries.

We are looking forward to having a brighter and more successful business in the near future together with all of our clients all over the world.

-

The automobile brake system is one of the most critical safety components in any vehicle. It controls speed, enables smooth stopping, and prevents acc...

READ MORE -

When you're driving, you probably don’t think much about your brake system—until you need it. The brake system in your car is one of the most importan...

READ MORE -

Many customers often have these questions: "Are your brake pads wear-resistant?" "Will they make noise at high speeds?" "How long will they last? Will...

READ MORE -

In everyday driving, many car owners encounter strange noises when braking, such as "squeaking," "clicking," or "grinding" sounds. The brake caliper i...

READ MORE

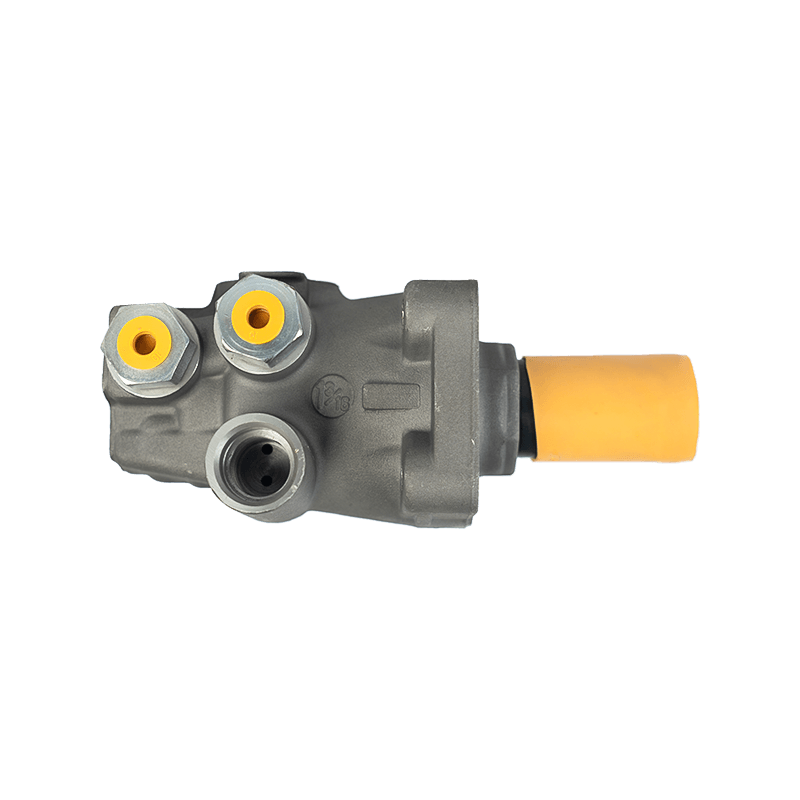

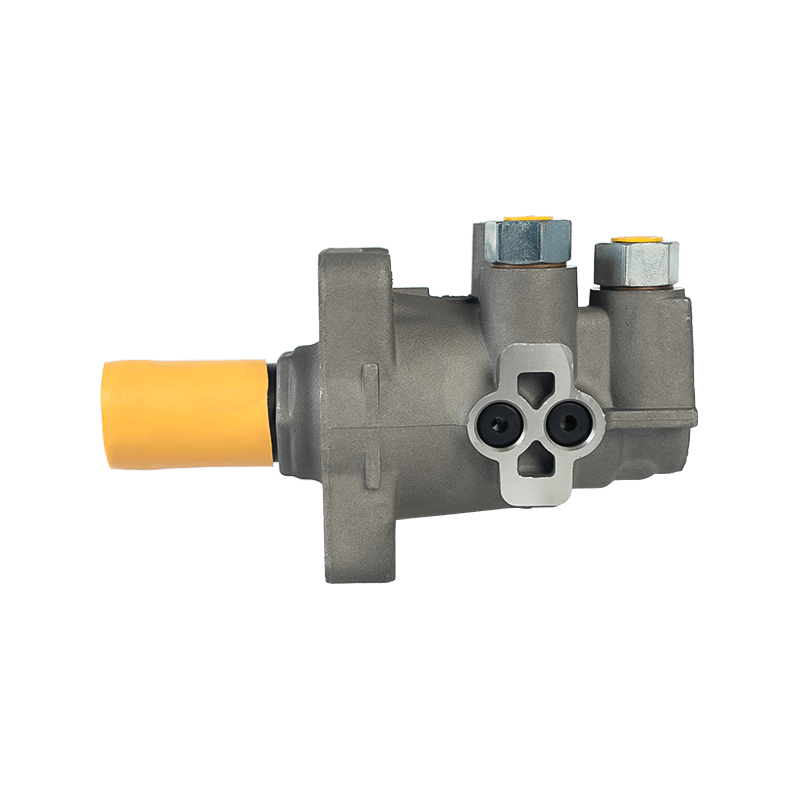

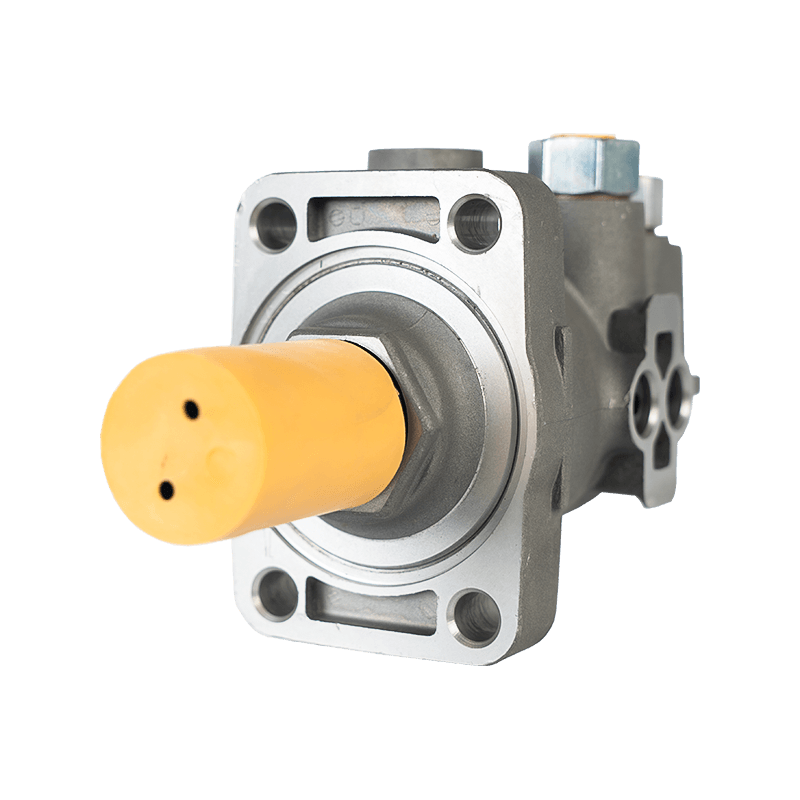

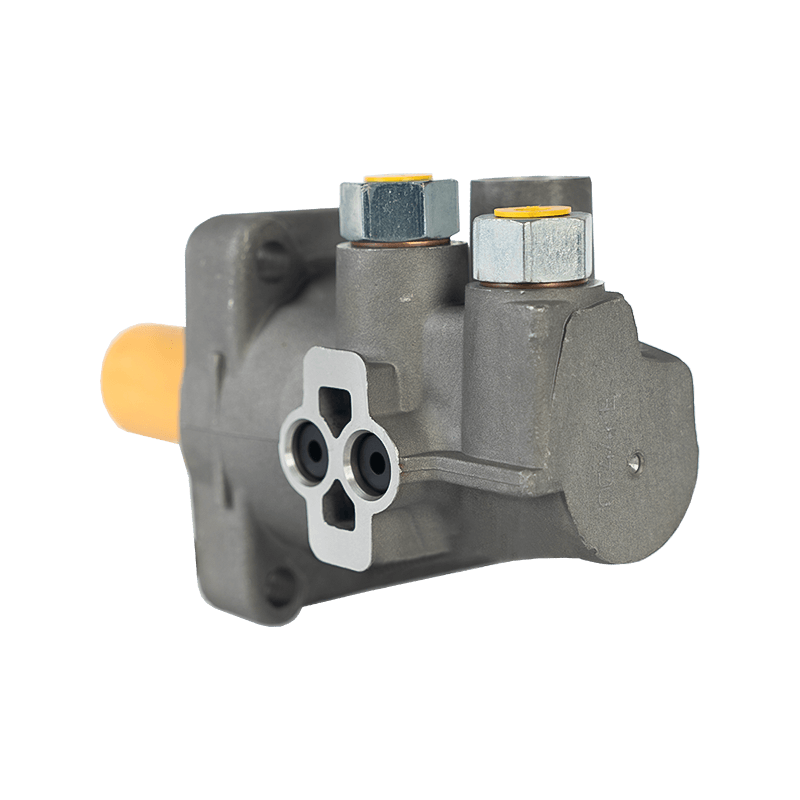

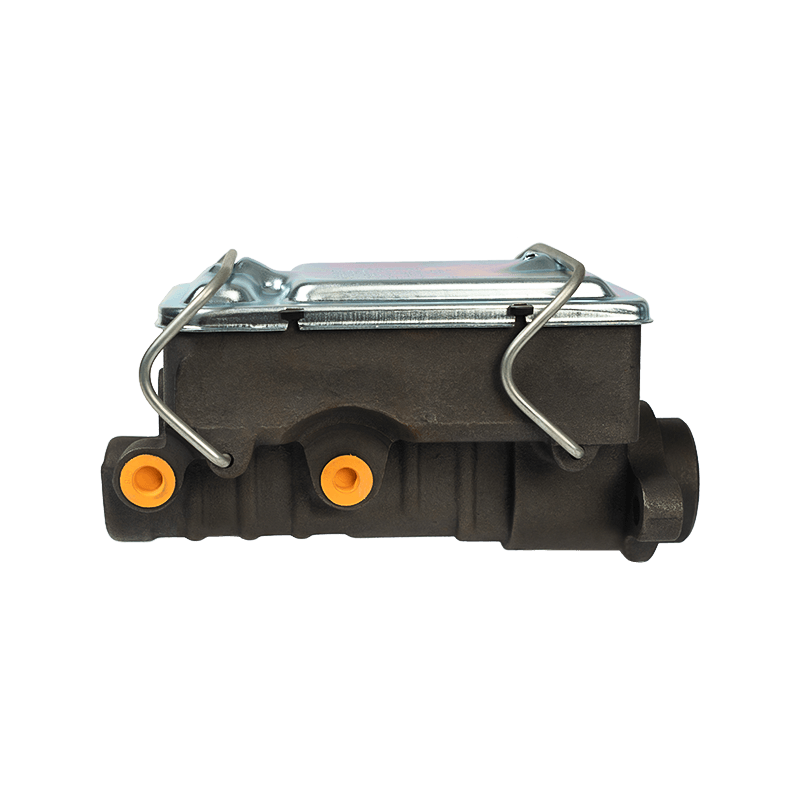

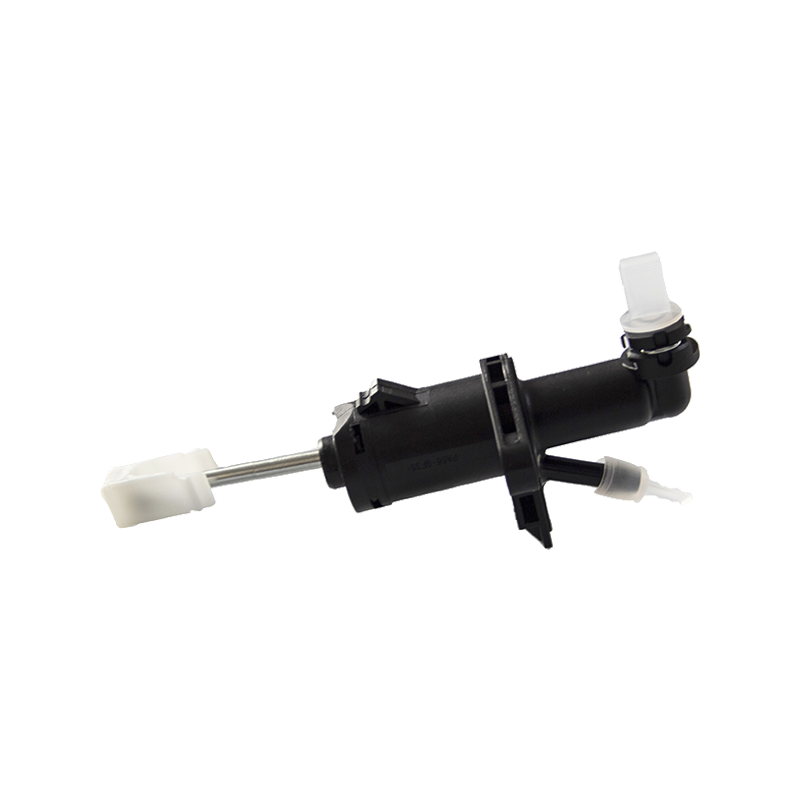

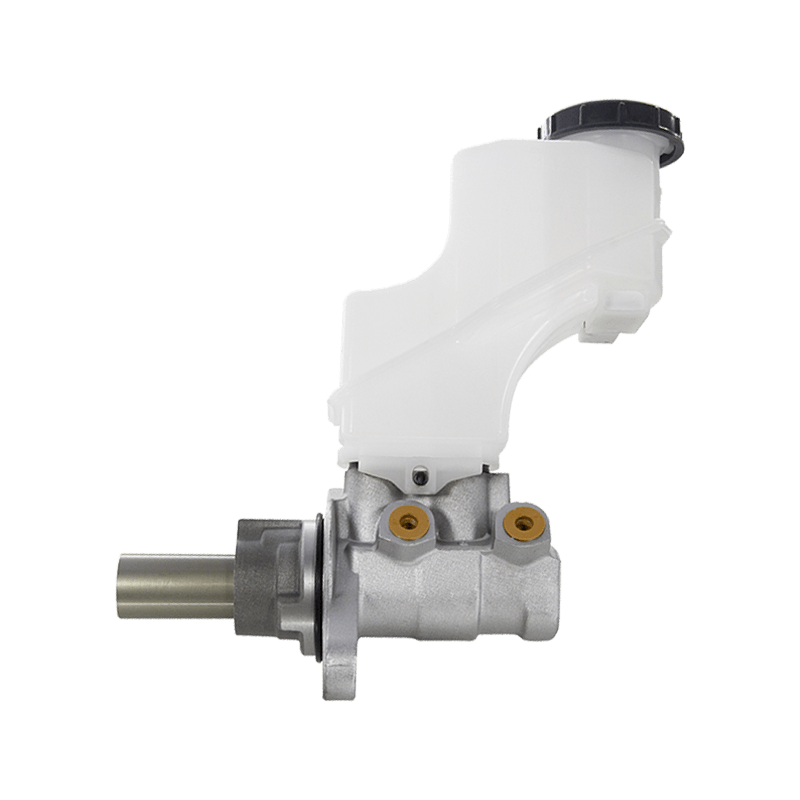

4720737060 Brake Master Cylinder For Toyota is a core hydraulic brake component designed for commercial vehicles. As an original equipment component for Toyota DYNA, Coaster and other models, it plays a key role in pressure conversion and distribution in the brake system. The master cylinder adopts high-strength aluminum alloy casting technology, and the master cylinder diameter design meets the heavy-load requirements of commercial vehicles and can withstand 32MPa hydraulic pressure.

On the technical level, the master cylinder uses a dual-chamber series structure, equipped with a fast filling valve and compensation hole system to ensure hydraulic stability under extreme braking conditions. Its piston sealing system is made of high-temperature resistant fluororubber material, with a temperature range of -40℃ to 180℃, a stable friction coefficient of 0.38-0.42, and a hydraulic pressure fluctuation range of less than 0.5MPa after 15 consecutive emergency braking. The master cylinder is compatible with multiple generations of DYNA chassis, and its OE number is fully interoperable with 4720737060. It has passed IATF 16949 and ISO9001 certifications, and can match third-party replacement parts such as TRW BWN153 and AISIN MCT-033.

As the cornerstone of commercial vehicle braking safety, the master cylinder has passed the JIS D2601 environmental test: the hydraulic response delay is less than 0.15 seconds under extreme cold conditions of -40℃, and the performance attenuation rate is less than 5% after 50 consecutive brakings in high desert temperatures. Standard use can shorten the braking distance of the DYNA 400 model by more than 2.5 meters per 100 kilometers, and reduce the abnormal wear rate of the brake pads by 40%.

Search

Search

Eng

Eng

English

English Español

Español Português

Português