How brake pads work: revealing the core components of the braking system

2025.07.03

2025.07.03

Industry News

Industry News

Content

1. How brake pads work?

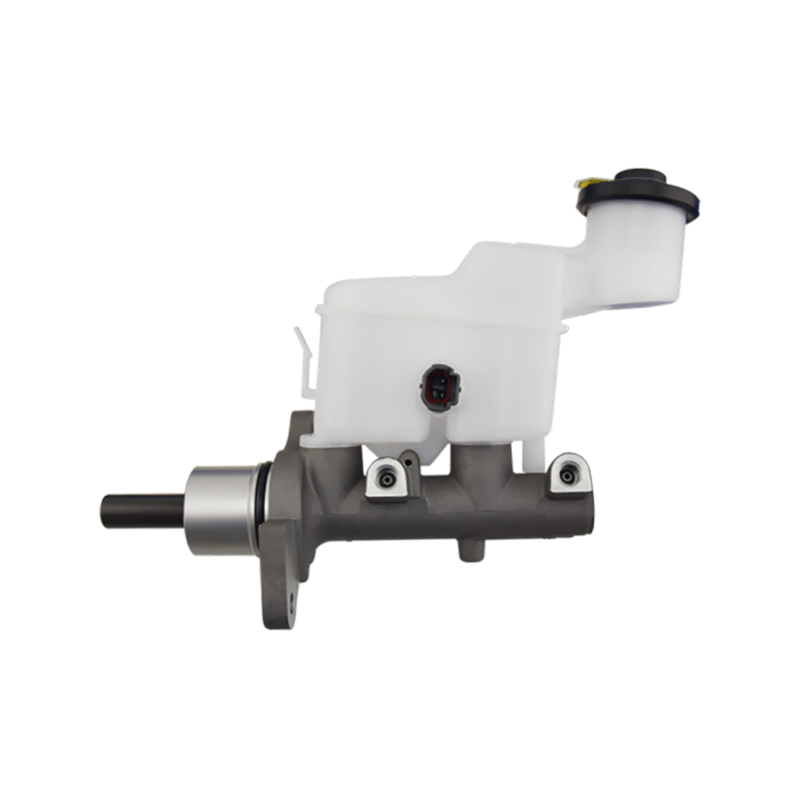

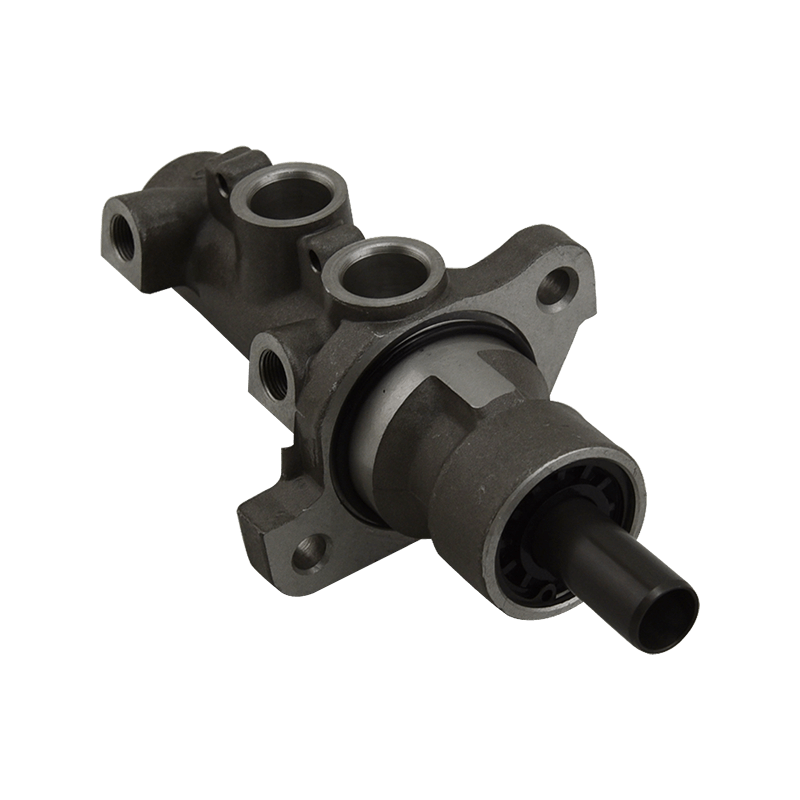

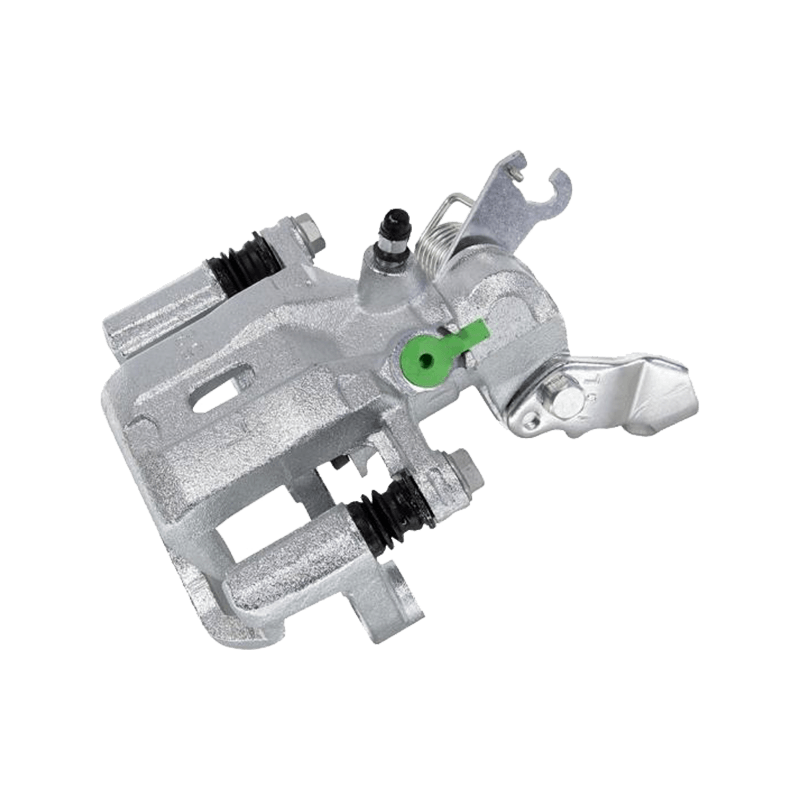

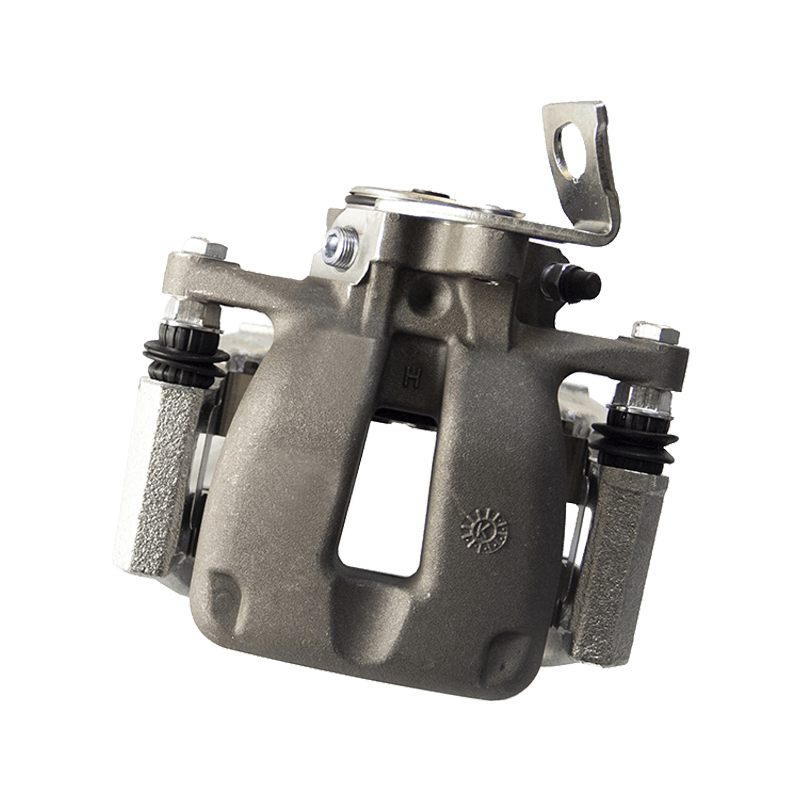

The working principle of brake pads is based on the principle of tribology, which converts kinetic energy into heat energy to achieve vehicle deceleration. When the driver steps on the brake pedal, the hydraulic system transmits pressure to the brake caliper, pushing the brake pads to clamp the brake disc (or brake drum) that rotates synchronously with the wheel, generating huge friction to slow down the vehicle.

Energy conversion process:

Kinetic energy → Friction energy → Heat

During typical braking, the temperature of the brake pad can reach 200-300°C

During intense driving, the temperature may exceed 600°C

2. Structural composition of brake pads

Modern brake pads are usually composed of the following parts:

- Friction material layer (core functional layer):

Accounts for 50-70% of the total thickness

Contains a variety of composite materials

Directly involved in friction braking

- Back plate (metal substrate):

Usually made of steel

Provides structural support

Transmits braking force to the caliper

- Silencer (shock-absorbing layer):

Reduces braking noise

Improve vibration characteristics

Some high-end products use special composite materials

- Wear indicator:

Mechanical or electronic

Reminds of replacement time

Usually triggers an alarm when 2-3mm is left

3. Comparison of characteristics of different types of brake pads

|

Type |

Main ingredients |

Advantages |

Disadvantages |

Applicable models |

|

Semi-metallic |

30-65% metal fiber |

Strong braking force, high temperature resistance |

Noisy, fast wear |

Ordinary family car |

|

Ceramic |

Ceramic fiber, filler |

Low noise, low dust |

High cost, poor cold effect |

High-end models |

|

Organic (NAO) |

Organic fiber, resin |

Comfortable and quiet |

Poor high temperature resistance |

Urban commuter car |

|

Carbon ceramic |

Carbon fiber, ceramic |

Ultimate performance |

Expensive |

Supercar/racing car |

4. Usage and maintenance recommendations

Notes during the running-in period:

New brake pads require 300-500 kilometers of running-in

Avoid sudden braking

Gradually establish the best friction surface

Replacement timing judgment:

Replacement is recommended if the thickness is <3mm

Abnormal noise prompt

Significant increase in braking distance

Daily inspection points:

Visually check the wear every month

Pay attention to changes in brake fluid level

Pay attention to changes in brake pedal feel

Search

Search

Eng

Eng

English

English Español

Español Português

Português