Why Choose OE Quality Brake Pads? When selecting brake pads, OE QUALITY BRAKE PADS ensure precise fit, optimal braking performance, and long-term durability. Unlike generic pads, OE pads are engineered to meet the origi...

READ MORE

We have more than 1,000 brake shoes and brake pads for European, American, Russian, Japanese and Korean cars. The associated factories have created a highly experienced manufacturing team that exports thousands of auto part products worldwide. High quality and competitive prices are our targets. Our products have gained the certifications of ISO9001 and TS16949. We have built up a solid reputation with our customers in more than 30 countries.

We are looking forward to having a brighter and more successful business in the near future together with all of our clients all over the world.

-

-

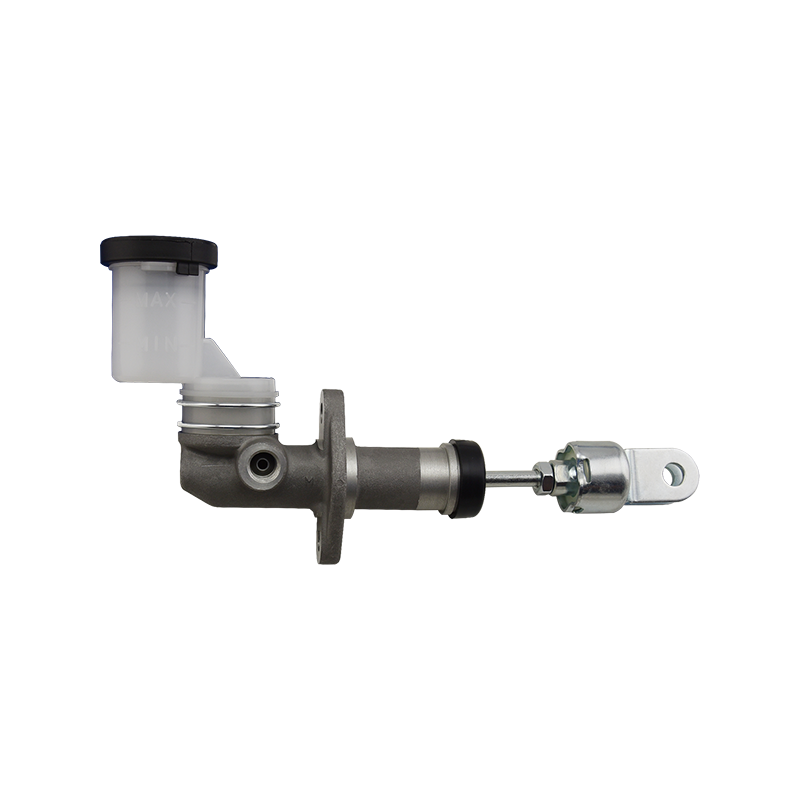

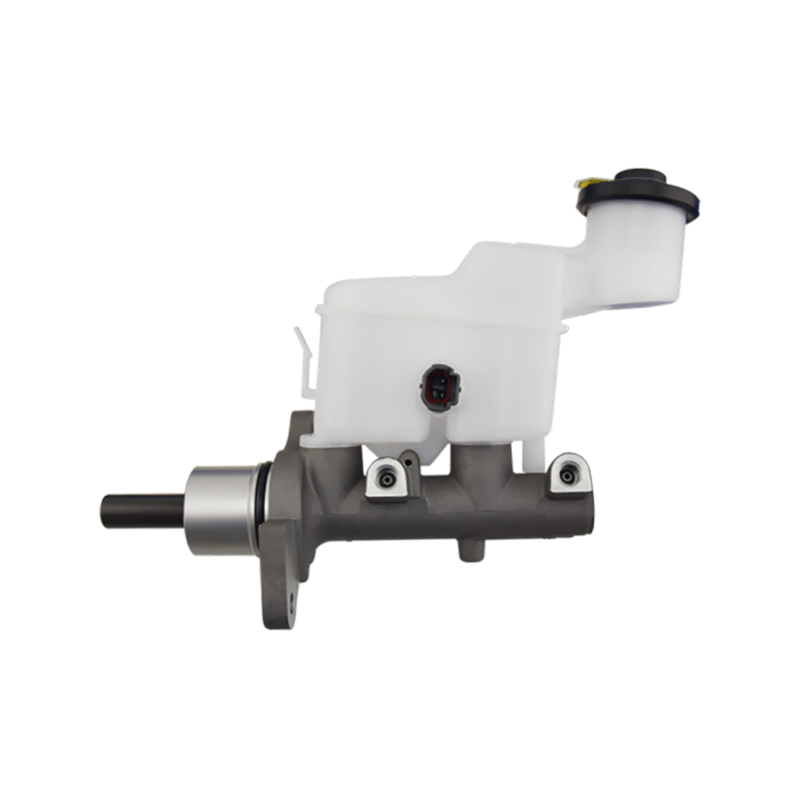

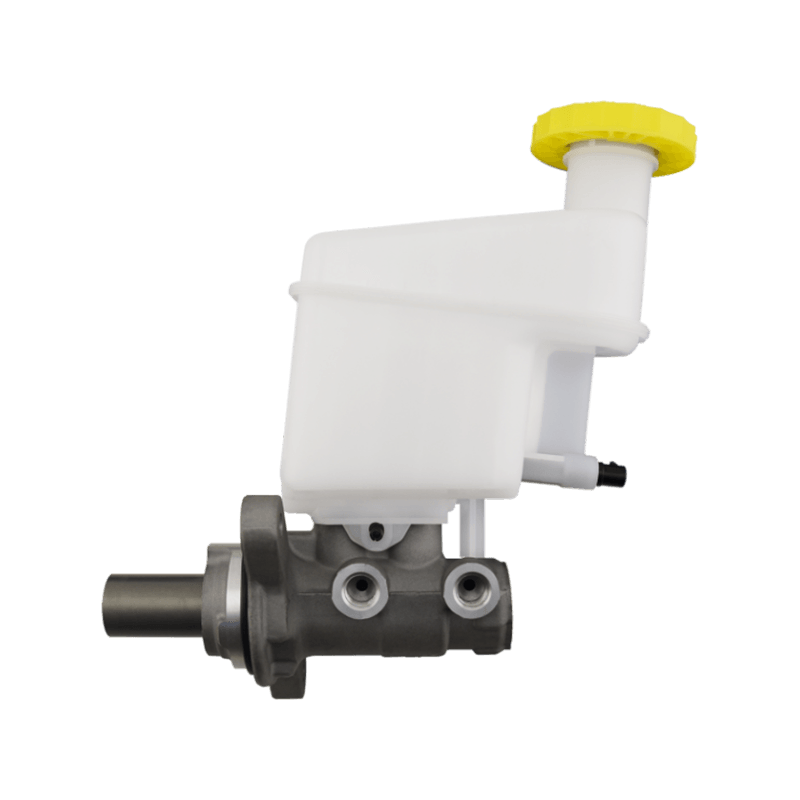

What is a Hydraulic Brake Master Cylinder? The hydraulic brake master cylinder is a critical component in a vehicle's braking system. It converts the force applied to the brake pedal into hydraulic pressure, which is th...

READ MORE -

Why OE Quality Brake Pads Are the Best Choice for Your Car OE (Original Equipment) quality brake pads are specifically designed to match the specifications and performance standards set by the vehicle manufacturer. They...

READ MORE

The automobile brake system is one of the technologies to ensure the safe driving of vehicles. It mainly converts the vehicle's kinetic energy into heat energy through friction to achieve deceleration, parking and stability control. Modern automobile brake products combine precision mechanical structures with intelligent electronic technologies, covering diversified solutions from traditional hydraulic brakes to cutting-edge wire control brakes. The automobile brake system converts the vehicle's kinetic energy into heat energy through friction devices (such as brake discs and friction pads, brake drums and shoes), allowing the moving car to decelerate or stop in an emergency as needed.

The brake system can achieve deceleration, parking and dynamic stability control. Early mechanical brake systems relied on direct human pressure, with weak braking force and low reliability. It was not until the introduction of hydraulic technology in the early 20th century that a qualitative leap was achieved. The hydraulic system transmits pressure through brake fluid, so that the force is evenly distributed on the wheel brakes, greatly improving the braking efficiency. Drum brakes have become mainstream due to their simple structure and strong braking force, but their closed design makes heat dissipation difficult and easily causes "thermal decay". To solve this problem, disc brakes gradually became popular in the 1970s. Their open structure optimizes heat dissipation through the flat contact between the brake disc and the friction plate, which is particularly suitable for high-speed driving conditions. Modern high-performance models use ventilated discs and ceramic composite materials, which can withstand temperatures of more than 800°C.

When the vehicle is running, the automobile braking system monitors the wheel status in real time through the wheel speed sensor, and dynamically adjusts the braking force during emergency braking to prevent the wheel from locking and causing side slip. The parking brake system (handbrake or electronic parking EPB) locks the rear wheel brakes through a mechanical cable or motor to prevent the vehicle from sliding on a slope or at rest. Some models use an integrated caliper design to integrate the parking function into the disc brake, achieving dual protection of hydraulic braking and mechanical locking. On long downhill sections, the braking system offsets the acceleration of gravity through continuous friction to prevent the main brake from overheating and failure. Commercial vehicles are often equipped with auxiliary braking devices (such as eddy current retarders) to share the braking load.

Search

Search

Eng

Eng

English

English Español

Español Português

Português