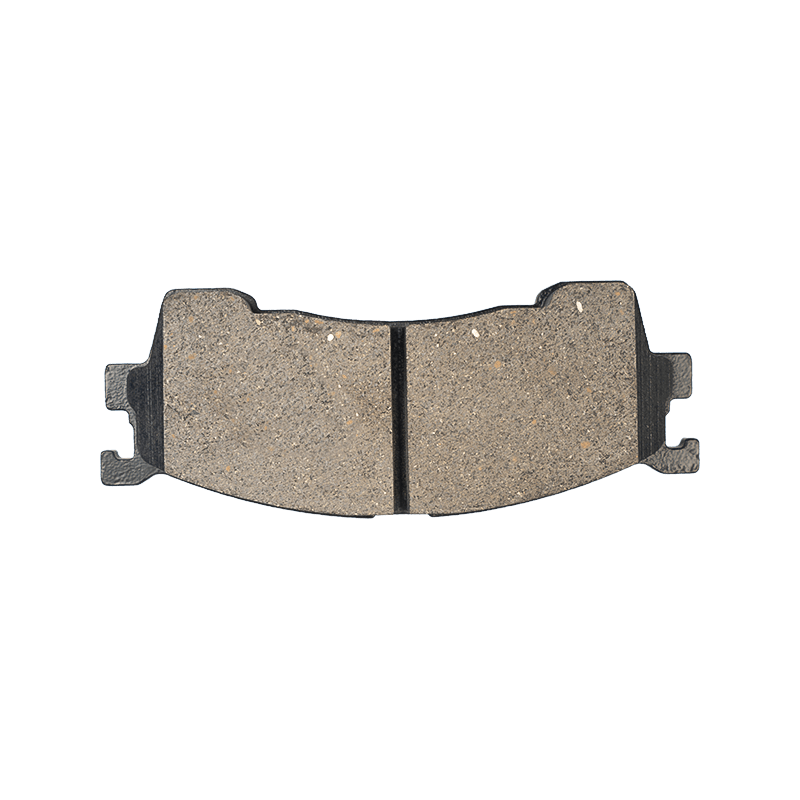

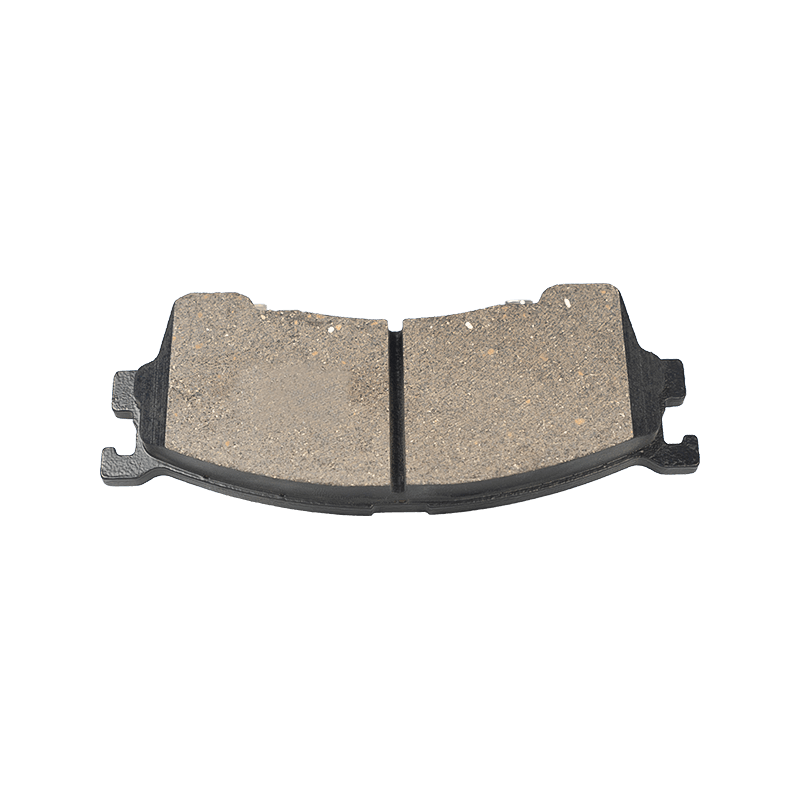

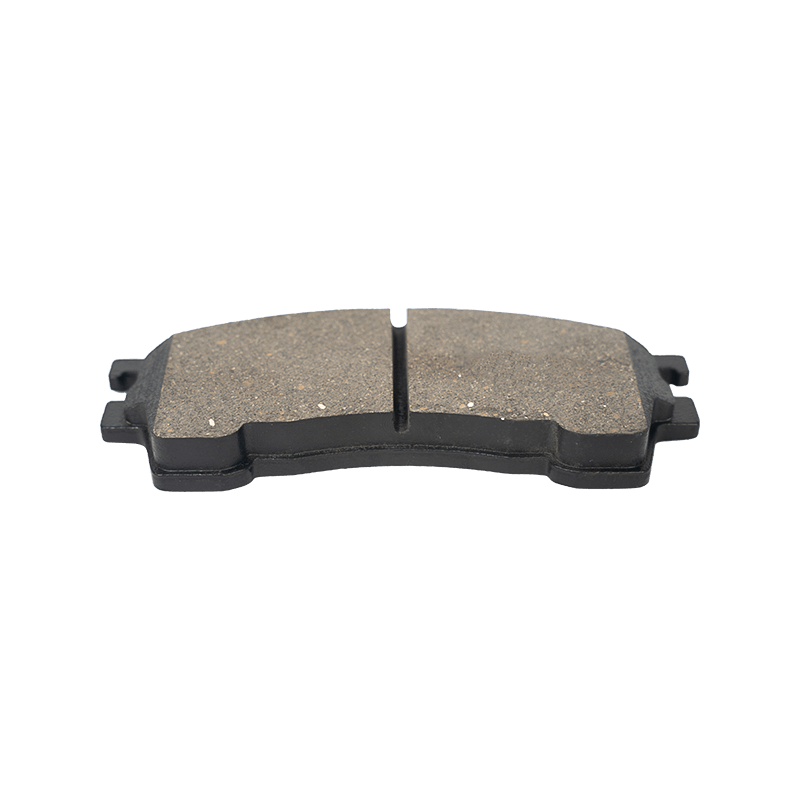

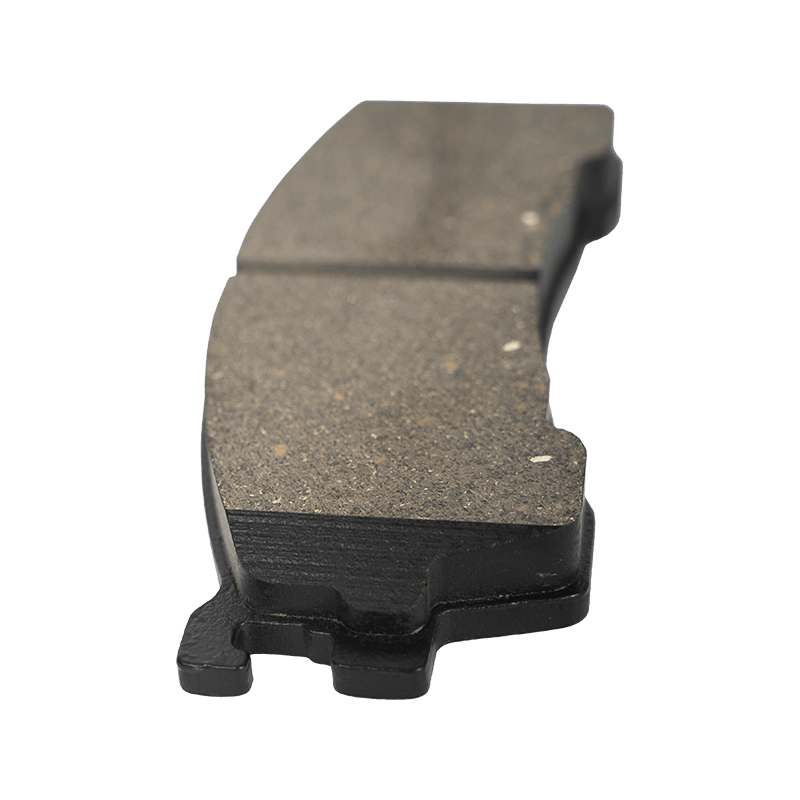

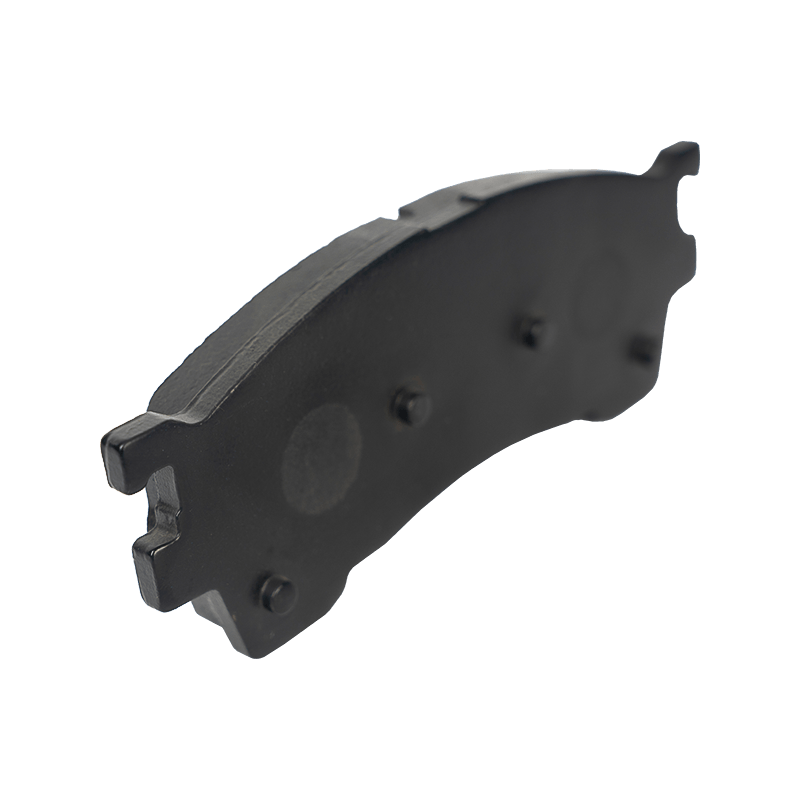

1U0J-33-28Z Car Disc Brake Pad for Mazda

|

OE NO |

1U0J-33-28Z BLYM-33-23Z C1Y0-33-28Z CBY0-33-23Z |

|

MODEL |

Mazda |

Specifications

KEEP IN TOUCH

We have more than 1,000 brake shoes and brake pads for European, American, Russian, Japanese and Korean cars. The associated factories have created a highly experienced manufacturing team that exports thousands of auto part products worldwide. High quality and competitive prices are our targets. Our products have gained the certifications of ISO9001 and TS16949. We have built up a solid reputation with our customers in more than 30 countries.

We are looking forward to having a brighter and more successful business in the near future together with all of our clients all over the world.

-

The automobile brake system is one of the most critical safety components in any vehicle. It controls speed, enables smooth stopping, and prevents acc...

READ MORE -

When you're driving, you probably don’t think much about your brake system—until you need it. The brake system in your car is one of the most importan...

READ MORE -

Many customers often have these questions: "Are your brake pads wear-resistant?" "Will they make noise at high speeds?" "How long will they last? Will...

READ MORE -

In everyday driving, many car owners encounter strange noises when braking, such as "squeaking," "clicking," or "grinding" sounds. The brake caliper i...

READ MORE

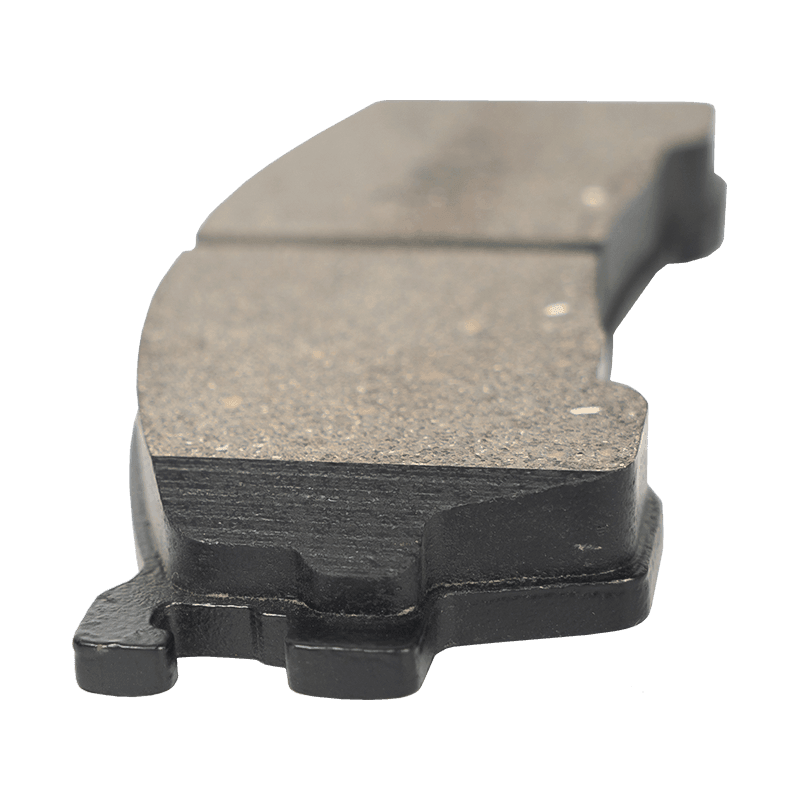

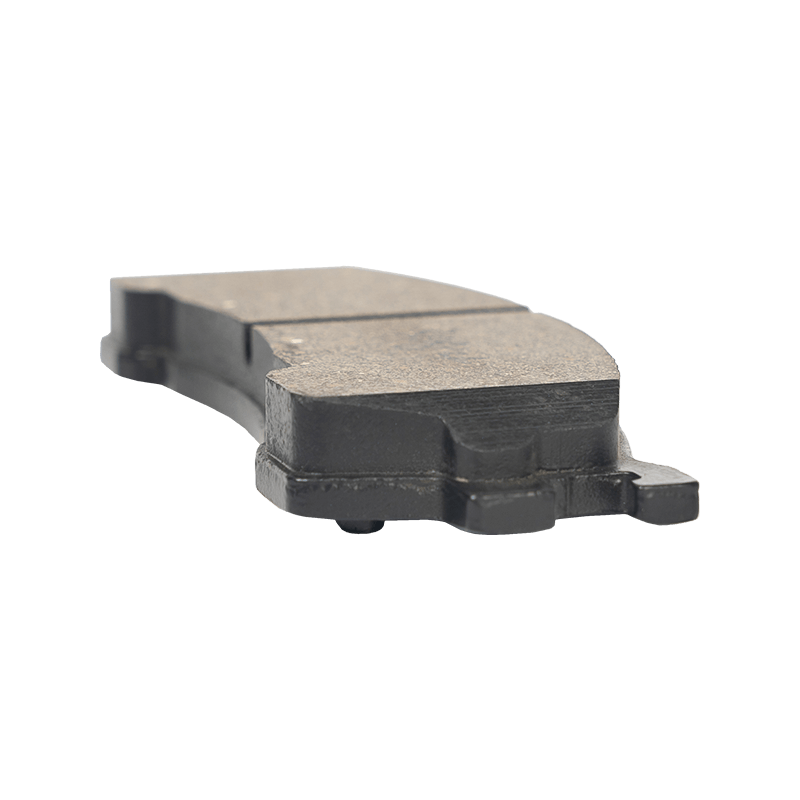

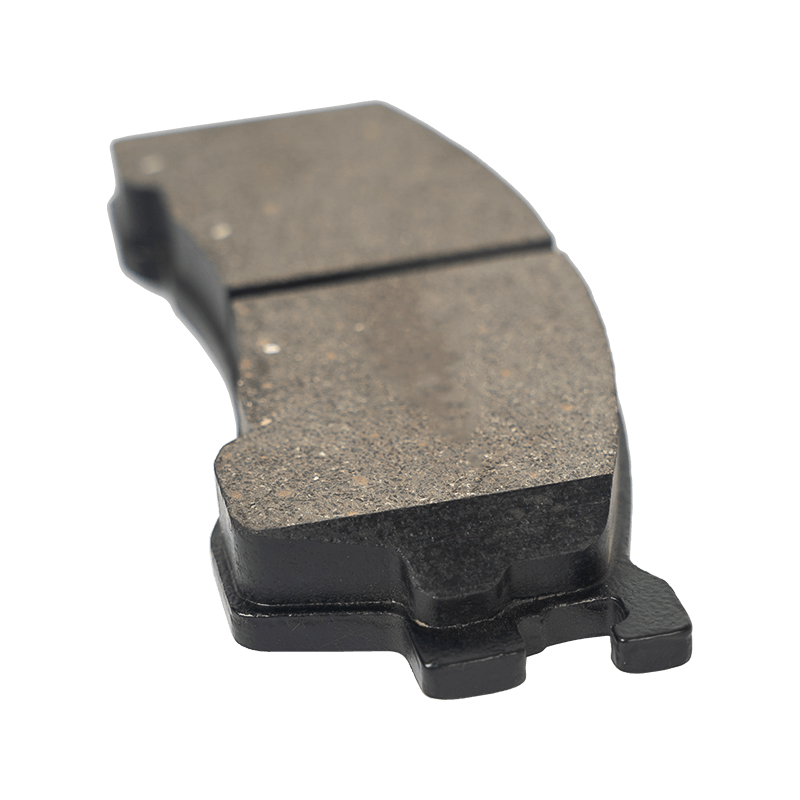

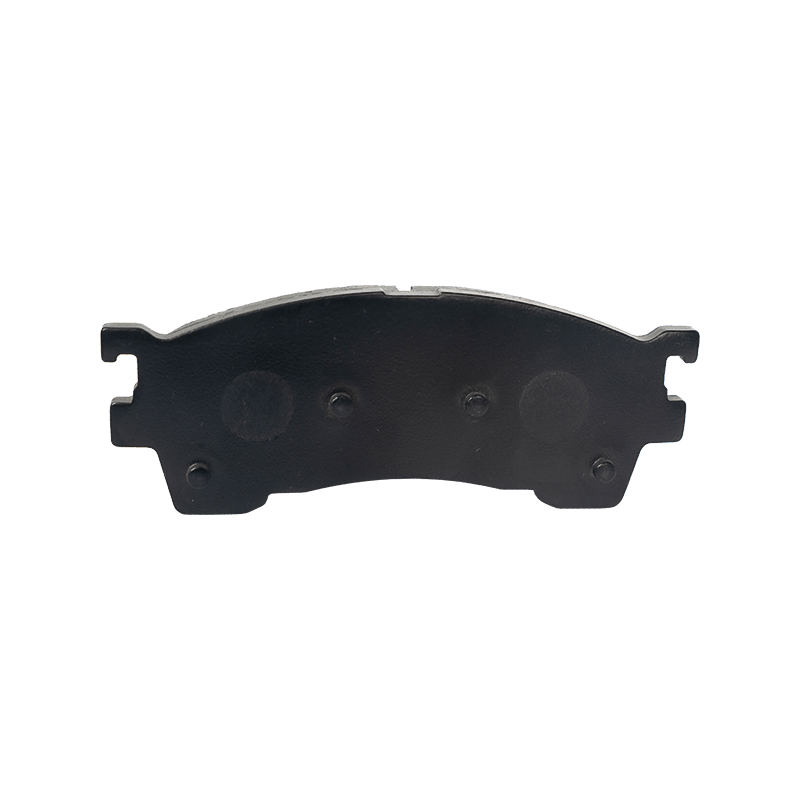

In the automobile braking system, 1U0J-33-28Z disc brake pads, as one of the safety components, have become one of the representatives of vehicle braking technology with their efficient braking performance and reliability. Disc brake pads push the brake pads to contact the high-speed rotating brake disc through the piston in the brake caliper, converting the vehicle's kinetic energy into heat energy to achieve deceleration or parking. In this process, the precise response of the hydraulic system and the high temperature resistance of the material jointly ensure the stability of the braking force.

The material design of 1U0J-33-28Z brake pads reflects the continuous upgrading and innovation of products. Its friction layer usually uses composite ceramic or carbon fiber materials, combined with phenolic resin, mineral fiber and graphite, which not only ensures a high friction coefficient, but also reduces the risk of thermal decay. From a structural point of view, the back plate of 1U0J-33-28Z brake pads is usually made of high-strength alloy steel and formed by precision stamping process to ensure the matching accuracy with the brake caliper. The brake pads and the back plate are fixed by riveting or bonding process, combined with the design of anti-noise sheet, which effectively suppresses high-frequency vibration and noise during braking. In addition, its friction surface is often designed with slotted or drilled structures to further improve drainage and heat dissipation efficiency, and avoid the reduction of braking force due to water accumulation or mud. This feature is particularly critical in rainy seasons or dusty environments.

In terms of manufacturing technology, 1U0J-33-28Z uses hot pressing and gradient curing technology. After the raw materials are evenly proportioned by a mixer, they are molded under high temperature and high pressure, and then multi-stage heat treatment is used to eliminate internal stress and enhance the density and durability of the material. This process not only improves the wear resistance of the brake pad, but also extends its life by about 30% compared to traditional products, reducing the user's maintenance cost. Its fast response characteristics meet the needs of intelligent driving systems for high-frequency braking, while the lightweight design (15% lighter than similar products) helps reduce the energy consumption of the entire vehicle, which is in line with the energy-saving trend of new energy vehicles.

Search

Search

Eng

Eng

English

English Español

Español Português

Português