Why Choose OE Quality Brake Pads? When selecting brake pads, OE QUALITY BRAKE PADS ensure precise fit, optimal braking performance, and long-term durability. Unlike generic pads, OE pads are engineered to meet the origi...

READ MORE

We have more than 1,000 brake shoes and brake pads for European, American, Russian, Japanese and Korean cars. The associated factories have created a highly experienced manufacturing team that exports thousands of auto part products worldwide. High quality and competitive prices are our targets. Our products have gained the certifications of ISO9001 and TS16949. We have built up a solid reputation with our customers in more than 30 countries.

We are looking forward to having a brighter and more successful business in the near future together with all of our clients all over the world.

-

-

What is a Hydraulic Brake Master Cylinder? The hydraulic brake master cylinder is a critical component in a vehicle's braking system. It converts the force applied to the brake pedal into hydraulic pressure, which is th...

READ MORE -

Why OE Quality Brake Pads Are the Best Choice for Your Car OE (Original Equipment) quality brake pads are specifically designed to match the specifications and performance standards set by the vehicle manufacturer. They...

READ MORE

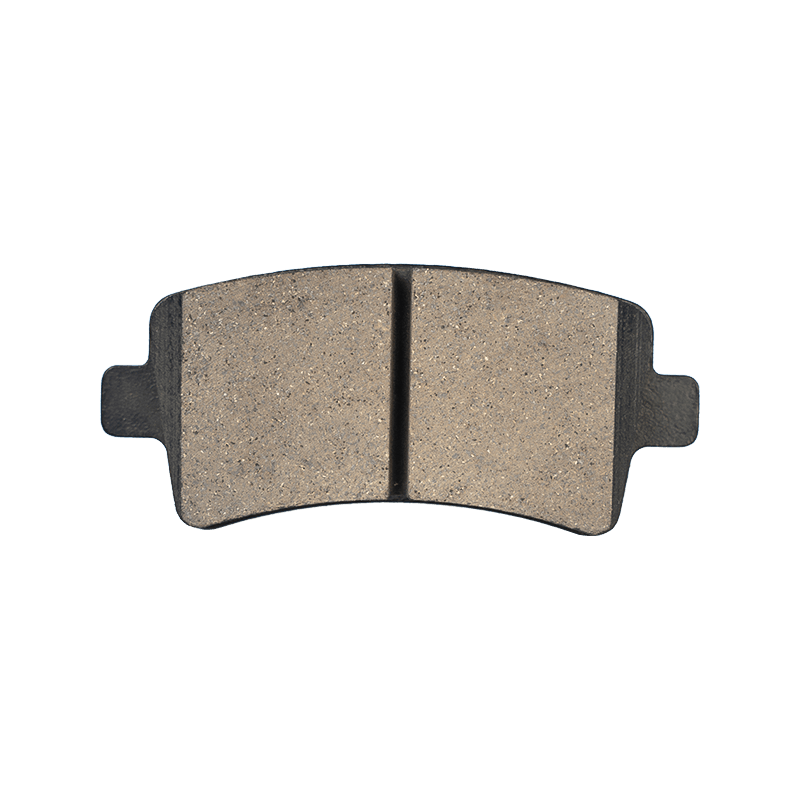

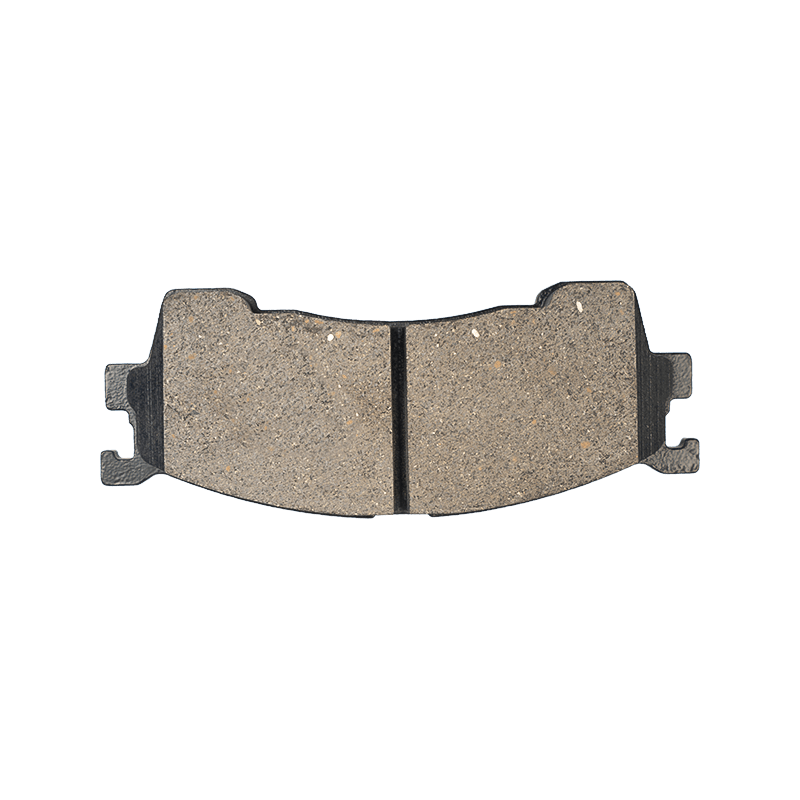

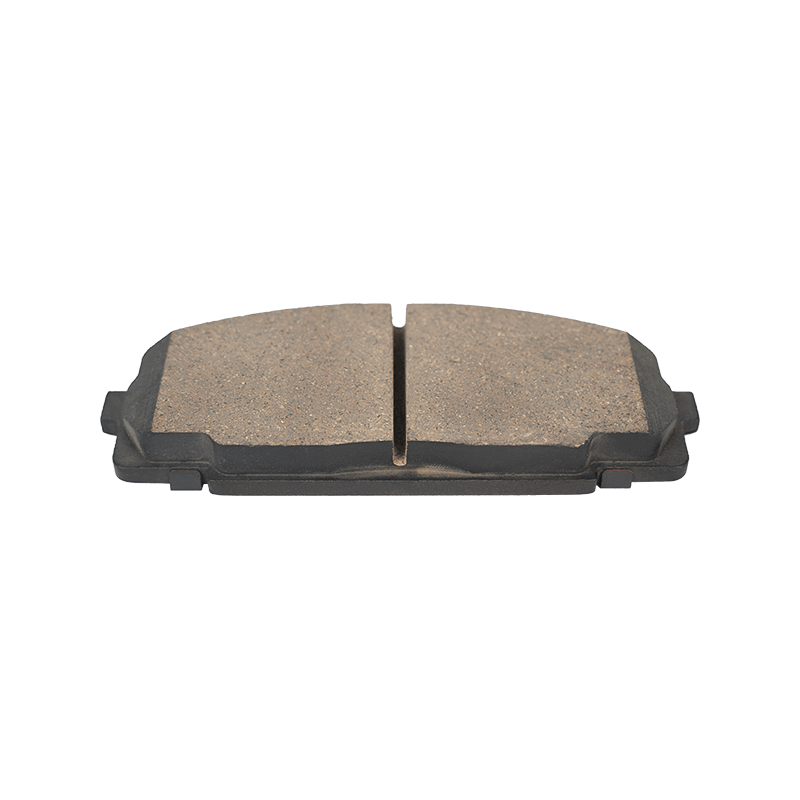

Brake pad is the core safety component of the automobile braking system, and its performance determines the braking efficiency and driving safety of the vehicle. As the key medium for converting vehicle kinetic energy into thermal energy, it is a safety guarantee between the driver and the road.

The working principle of brake pad is based on friction mechanics. It converts vehicle kinetic energy into thermal energy by clamping the rotating brake disc or brake drum to generate friction. In this process, the performance of friction material is crucial. Brake pads are usually composed of steel plates, thermal insulation layers and friction blocks, among which friction materials have evolved from asbestos, semi-metal to ceramic composite materials. Asbestos materials have been eliminated due to poor safety performance. Semi-metal formulas are still widely used in economical vehicles due to their high friction coefficient and low cost, but their noise and wear problems always exist; ceramic brake pads have achieved breakthroughs in high temperature stability, quietness and wear resistance through the composite of carbon fiber and ceramic fiber, becoming the first choice for high-end models.

In actual use, brake pads require scientific maintenance. Under normal driving conditions, the front brake pads need to be tested for thickness every 30,000-50,000 kilometers and the rear brake pads every 40,000-60,000 kilometers. When the thickness of the friction material is less than 3 mm, it must be replaced. When replacing, a special tool must be used to reset the piston of the slave cylinder to avoid damaging the hydraulic system; after installation, a 200-kilometer run-in is required to ensure that the friction material and the brake disc are fully fitted.

Search

Search

Eng

Eng

English

English Español

Español Português

Português