Why Choose OE Quality Brake Pads? When selecting brake pads, OE QUALITY BRAKE PADS ensure precise fit, optimal braking performance, and long-term durability. Unlike generic pads, OE pads are engineered to meet the origi...

READ MORE

We have more than 1,000 brake shoes and brake pads for European, American, Russian, Japanese and Korean cars. The associated factories have created a highly experienced manufacturing team that exports thousands of auto part products worldwide. High quality and competitive prices are our targets. Our products have gained the certifications of ISO9001 and TS16949. We have built up a solid reputation with our customers in more than 30 countries.

We are looking forward to having a brighter and more successful business in the near future together with all of our clients all over the world.

-

-

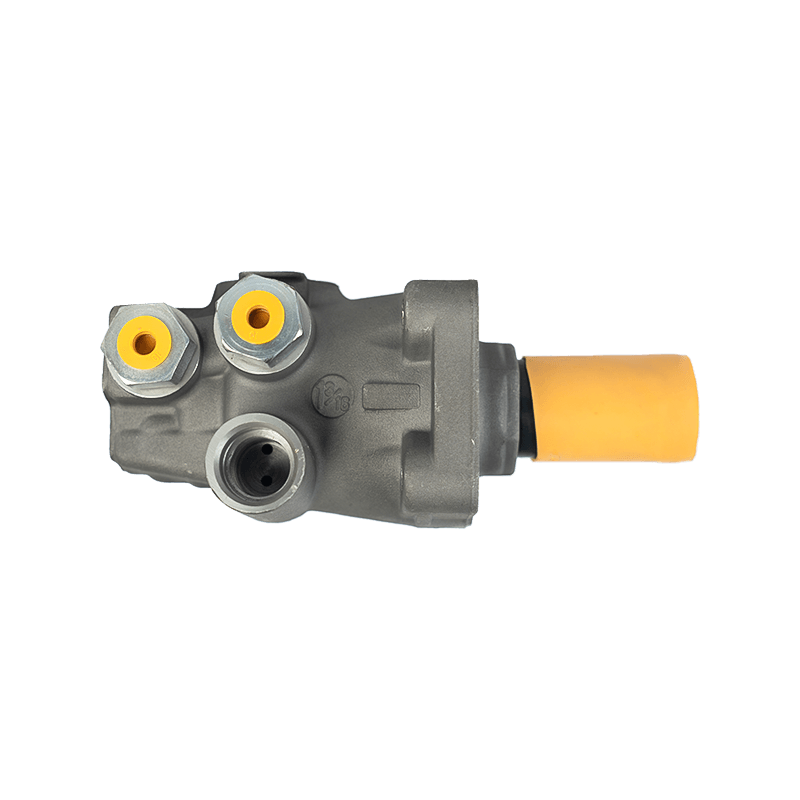

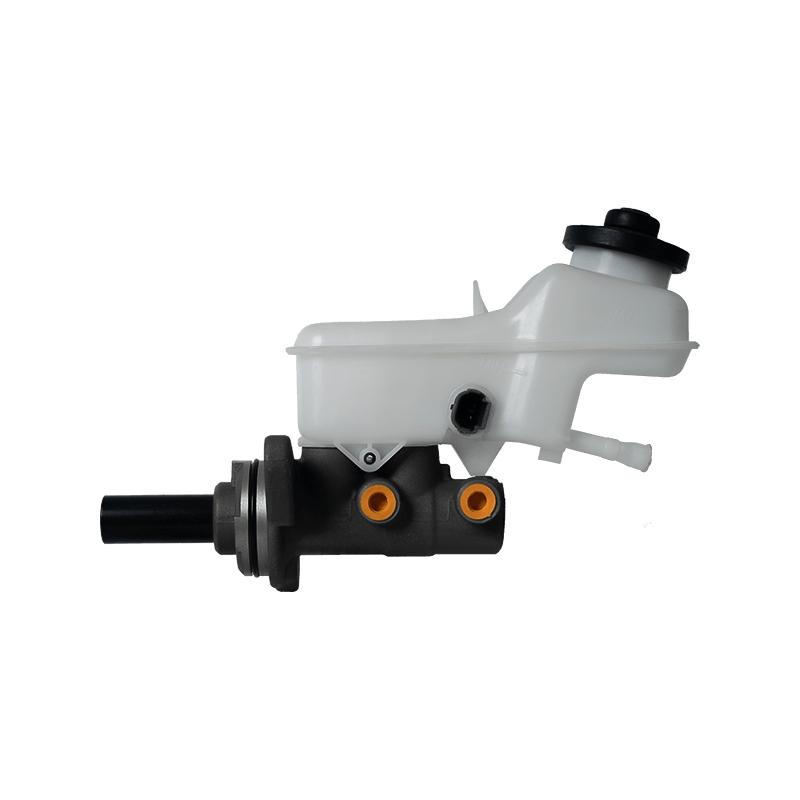

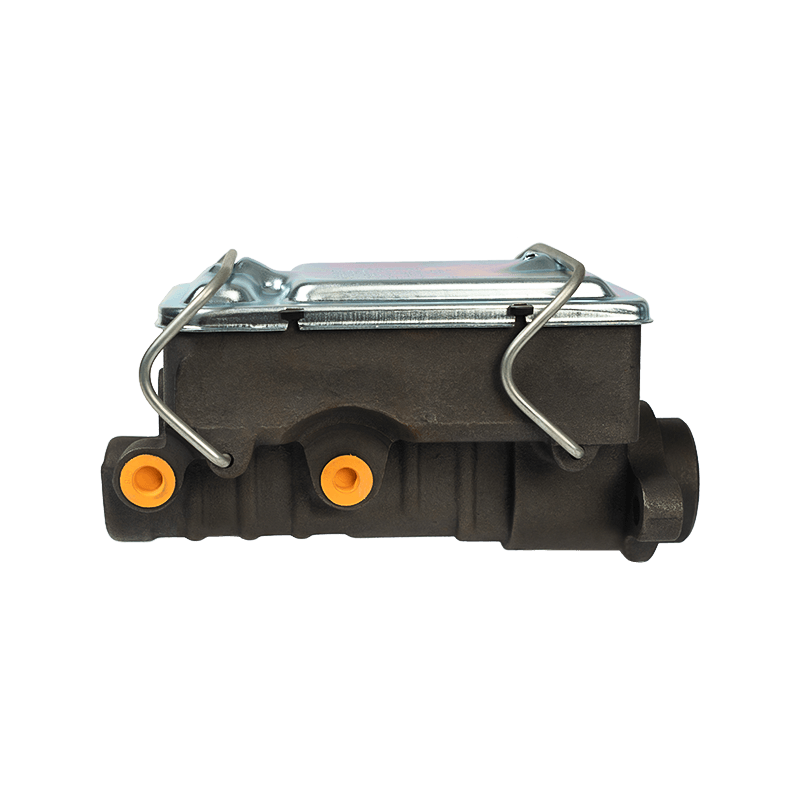

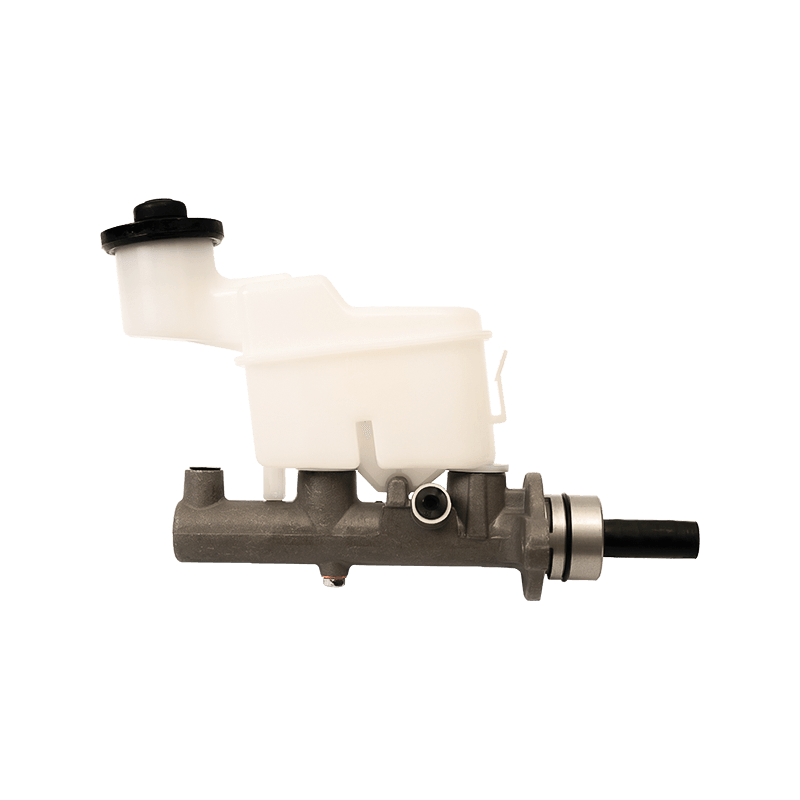

What is a Hydraulic Brake Master Cylinder? The hydraulic brake master cylinder is a critical component in a vehicle's braking system. It converts the force applied to the brake pedal into hydraulic pressure, which is th...

READ MORE -

Why OE Quality Brake Pads Are the Best Choice for Your Car OE (Original Equipment) quality brake pads are specifically designed to match the specifications and performance standards set by the vehicle manufacturer. They...

READ MORE

The brake master cylinder is the core kinetic energy of the automobile hydraulic brake system. Its function is to convert the mechanical force applied by the driver on the brake pedal into hydraulic energy, which is transmitted to the brakes of each wheel through the brake pipe, driving the brake pads to rub against the brake disc (or drum) to achieve deceleration or parking. As the core of the braking system, the master cylinder ensures stable output and rapid response of braking force through precise structural design. Its core structure includes components such as cylinder body, piston, sealing ring and return spring. The cylinder body is usually cast from aluminum alloy, with an oil channel inside; the piston compresses the brake fluid to generate pressure when the pedal is stepped on, and the sealing ring prevents liquid leakage; the return spring pushes the piston to reset after the pedal is released, releasing the hydraulic pressure to release the braking state.

When the driver steps on the pedal, the push rod pushes the master cylinder piston forward, closes the fluid filling hole and compresses the brake fluid in the front cavity, and the hydraulic pressure enters the brake pipe through the oil outlet, and finally drives the wheel cylinder piston to generate braking force. Nowadays, vehicles generally adopt a dual-chamber master cylinder design, which improves safety through independent front and rear hydraulic circuits-if one side of the circuit fails, the other circuit can still maintain more than 50% of the braking force, effectively avoiding complete brake failure.

At the maintenance level, the reliability of the master cylinder depends on regular inspection and maintenance. Aging of the seal ring can lead to hydraulic leakage, which manifests as a longer pedal stroke or reduced braking force; piston jamming may cause brake drag or abnormal pedal rebound. During maintenance, special tools must be used to reset the slave cylinder piston and completely remove the air in the hydraulic line to ensure the purity of the brake fluid to avoid air blockage.

Search

Search

Eng

Eng

English

English Español

Español Português

Português